Summary of Contents for Taber 710

-

Page 1: Operating Instructions

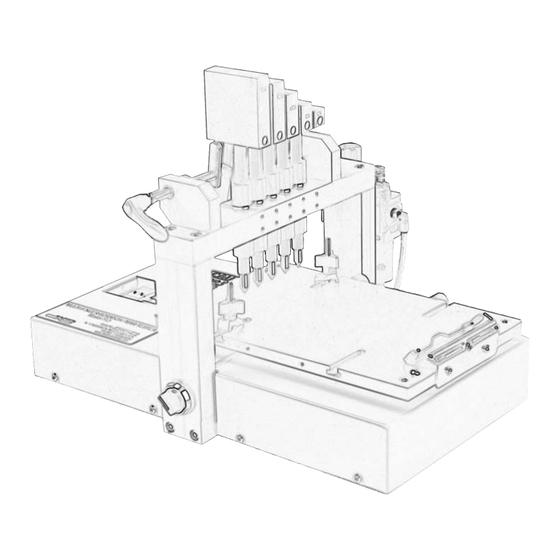

Multi-Finger Scratch/Mar Tester Model 710 Operating Instructions INDUSTRIES 9001:2000 CERTIFIED... -

Page 2: Warranty

• Operating Instructions implied warranty of merchantability, or fitness for any particular purpose. Taber Industries reserves the right to make changes without notice at any time in colors, material, specifications, and models, and to dis- continue models. CLAIMS FOR SHORTAGES We use extreme care in selection, checking, and packing to eliminate the possibility of error. -

Page 3: Product Description

If a shaft DOES NOT support rests are incorporated to allow one or slide easily through the bearings, see MAINTE- more fingers to be moved to an upright, rest posi- NANCE - Spline Shaft Finger Adjustment. 710 Operating Instructions ver 1.1... -

Page 4: Specimen Size

Prior to testing, it is recommended that all sam- ples be preconditioned in a controlled atmos- phere (such as 23 ±2° C and 50 ±5% relative humidity) for not less than 24 hours. Samples should be tested under the same conditions. 710 Operating Instructions ver 1.1... -

Page 5: Calculation Of Results

Report the tip diameter, stylus loading level, and Rating Number for each line on the surface of the sample. SUGGESTION: A lightbooth with North Sky Daylight (D65) has been recommend as a lighting source for automotive specifications. 710 Operating Instructions ver 1.1... -

Page 6: Maintenance

MAINTENANCE For comparable and reproducible tests, it is rec- ommended the operations be performed under Taber recommends annual factory calibration at conditions covered by an established test proce- which time the unit will be thoroughly checked. dure. The following factors are known to affect... - Page 7 WARNING, DO NOT OVER detergent. TIGHTEN SET SCREW. Spline shaft will no e. Before returning to service, ensure that all longer move freely through bearings. seals have been reinstalled or replaced. 710 Operating Instructions ver 1.1...

-

Page 8: Factory Service

• It should not be used in environments, which are very hot or humid. • Do not use abrasive or corrosive substances to clean. • It should not be dropped or shaken vigorously. 710 Operating Instructions ver 1.1... -

Page 9: Consumables / Accessories

Oversized 'EZY' Specimen Hold-Down Clamp (each) 132399 Specimen Platform Protective Guard, Replacement 132451 3/32" Hex Wrench, Replacement 130808 ® TABER Industries 455 Bryant Street North Tonawanda, New York 14120 Toll-Free: 800.333.5300 Phone: 716.694.4000 Fax: 716.694.1450 E-mail: sales@taberindustries.com WebSite: www.TaberIndustries.com www.OrderTaber.com 710 Operating Instructions ver 1.1... - Page 10 NOTES:...

Need help?

Do you have a question about the 710 and is the answer not in the manual?

Questions and answers