Table of Contents

Advertisement

Quick Links

Please read and comply with

these original instructions prior

to the initial operation of your appliance and

store them for later use or subsequent own-

ers.

Contents

Device elements . . . . . . . . . . . EN

Safety instructions. . . . . . . . . . EN

Proper use . . . . . . . . . . . . . . . EN

Safety Devices . . . . . . . . . . . . EN

Environmental protection . . . . EN

Before Startup. . . . . . . . . . . . . EN

Start up . . . . . . . . . . . . . . . . . . EN

Operation . . . . . . . . . . . . . . . . EN

Transport. . . . . . . . . . . . . . . . . EN

Storage . . . . . . . . . . . . . . . . . . EN

Care and maintenance . . . . . . EN

Troubleshooting . . . . . . . . . . . EN

Warranty . . . . . . . . . . . . . . . . . EN

EU Declaration of Conformity . EN

Technical specifications . . . . . EN

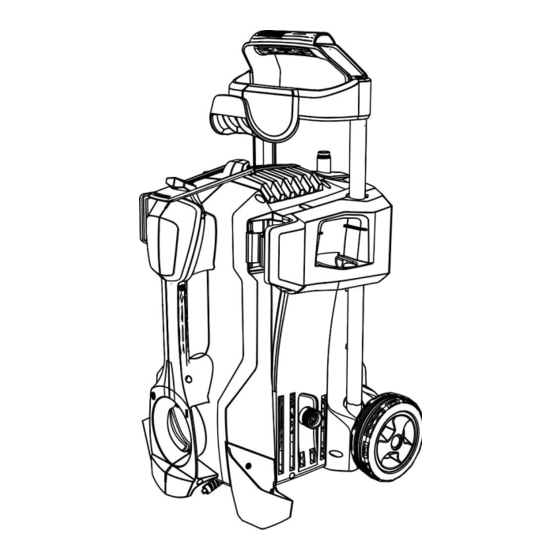

Device elements

Please unfold the front picture side

1 Union joint

2 Nozzle

3 Spray lance EASY!Lock

4 Trigger gun EASY!Force

5 Safety catch

6 Trigger

7 Safety lever

8 High pressure hose EASY!Lock

9 Push handle, top (extended)

10 Push handle, bottom (slid in)

11 Holder for storage of a nozzle with

screw connection or a surface cleaner**

12 Nozzle rack for triple nozzle**

13 Recessed grip

14 Nameplate

15 Skid

16 High-pressure connection EASY!Lock

17 Wheel

18 Nozzle rack for rotor nozzle (rotor noz-

zle is only included in the scope of de-

livery with model HD...Plus)

19 Spray lance holder with clamping, for

transportation

20 Sieve

21 Water connection

22 Quiver for spray lance

23 Power switch

24 Cable clamp

25 Carrying handle

26 Spray lance holder without clamping

1

27 Rubber band

1

28 Storage compartment for hoses

2

** not included in the scope of delivery

2

Colour coding

2

- The operating elements for the cleaning

3

process are yellow.

3

Safety instructions

4

5

- Before first start-up it is definitely nec-

5

essary to read the operating instruc-

5

tions and safety indications Nr. 5.951-

6

949.0!

6

- Please follow the national rules and

6

regulations for fluid spray jets of the re-

7

spective country.

8

- Please follow the national rules and

regulations for accident prevention of

the respective country. Fluid spray jets

must be tested regularly and the results

of these tests must be documented in

writing.

- The appliance/accessories must not be

modified.

DANGER

Pointer to immediate danger, which leads

to severe injuries or death.

WARNING

Pointer to a possibly dangerous situation,

which can lead to severe injuries or death.

CAUTION

Pointer to a possibly dangerous situation,

which can lead to minor injuries.

ATTENTION

Pointer to a possibly dangerous situation,

which can lead to property damage.

- 1

EN

Hazard levels

13

Advertisement

Table of Contents

Summary of Contents for Kärcher HD 4/9 P

-

Page 1: Table Of Contents

Please read and comply with 20 Sieve these original instructions prior 21 Water connection to the initial operation of your appliance and 22 Quiver for spray lance store them for later use or subsequent own- 23 Power switch ers. 24 Cable clamp 25 Carrying handle Contents 26 Spray lance holder without clamping... -

Page 2: Proper Use

Iron < 0,5 mg/l Symbols on the machine Manganese < 0,05 mg/l High-pressure jets can be dan- Copper < 2 mg/l gerous if improperly used. The jet Active chloride < 0,3 mg/l may not be directed at persons, free of bad odours animals, live electrical equipment or at the * Maximum total 2000 μS/cm appliance itself. -

Page 3: Before Startup

an adequate cross section (see "Tech- Before Startup nical data") und fully uncoil it from the Attaching the Accessories cable drum. For connection values, see type plate/tech- Note: The EASY!Lock system joins com- nical data. ponents with a quick-fasten thread solidly ... -

Page 4: Operation

Operation Turn off the appliance Shut off water supply. DANGER Open the hand spray gun. Risk of explosion! Switch on the pump with the power Do not spray flammable liquids. switch and allow to run for about 5-10 If the appliance is used in hazardous areas seconds. -

Page 5: Transport

– Only lift the appliance using the carrying Transport handle. CAUTION – Do not use stop chains. Risk of injury and damage! Observe the – Protect the lifting device from inadvert- weight of the appliance when you transport it. ent load release. ATTENTION –... -

Page 6: Troubleshooting

Check appliance (pump) for leaks. Pressure does not build up in the 3 drops per minute are permitted and appliance can come out from the lower side of the Check the nozzle size, install correct appliance. Call Customer Service if nozzle. - Page 7 EN 62233: 2008 EN 61000–3–2: 2014 EN 61000–3–3: 2013 EN 50581 Applied conformity evaluation method 2000/14/EC: Appendix V Sound power level dB(A) HD 4/9 P Measured: Guaranteed: 85 HD 5/11 P Measured: Guaranteed: 89 The signatories act on behalf of and with the authority of the company management.

-

Page 8: Technical Specifications

Technical specifications Type HD 4/9 P HD 4/9 P HD 5/11 P Main Supply Voltage Current type Connected load Protection (slow, char. C) Type of protection IPX5 Extension cable, max. 30 m (Protection class 1) Water connection Max. feed temperature °C... - Page 9 Type HD 5/11 P HD 5/11 P HD 5/11 P Main Supply Voltage 230...240 Current type Connected load Protection (slow, char. C) Type of protection IPX5 Extension cable, max. 30 m (Protection class 1) Water connection Max. feed temperature °C Min.

Need help?

Do you have a question about the HD 4/9 P and is the answer not in the manual?

Questions and answers