Table of Contents

Advertisement

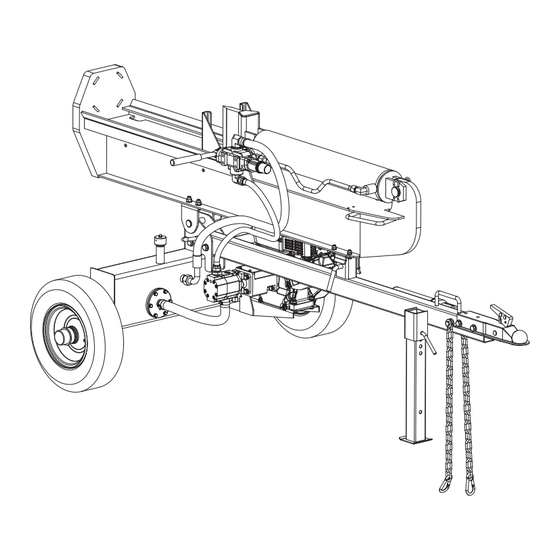

Gas Log Splitter

Operator's Manual

MODEL NUMBER

H6028FB

H6028FBO

H6033FB

H6033FBO

H6038FB

H6038FBO

SERIAL NUMBER

PURCHASE DATE

Both model number and serial

number may be found on the main

label. You should record both of them

in a safe place for future use.

READ AND UNDERSTAND THE ENTIRE MANUAL BEFORE OPERATING MACHINE

H6028BR

H6028BRO

H6033BR

H6033BRO

H6038BR

H6038BRO

FOR YOUR SAFETY

Save This Manual for Future Reference

GO FULL BOAR

TM

Advertisement

Table of Contents

Need help?

Do you have a question about the H6028FB and is the answer not in the manual?

Questions and answers