Table of Contents

Advertisement

Quick Links

PRODUCT MANUAL

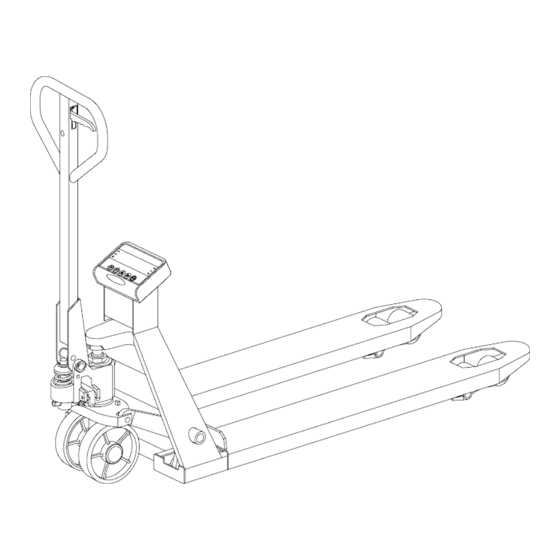

4500-lb Pallet Jack Scale Truck

Model:TMG-PJ45S

Please read the product manual completely before assembly

Check against the parts list to make sure all parts are received

Wear proper safety goggles or other protective gears while in assembly

Missing parts or questions on assembly?

Please call: 1-877-761-2819 or email: cs@tmgindustrial.com

Do not return the product to dealer, they are not equipped to handle your requests

WWW.TMGINDUSTRIAL.COM

Toll Free:1-877-761-2819

Advertisement

Table of Contents

Summary of Contents for TMG TMG-PJ45S

- Page 1 PRODUCT MANUAL 4500-lb Pallet Jack Scale Truck Model:TMG-PJ45S Please read the product manual completely before assembly Check against the parts list to make sure all parts are received Wear proper safety goggles or other protective gears while in assembly Missing parts or questions on assembly? Please call: 1-877-761-2819 or email: cs@tmgindustrial.com...

-

Page 2: Table Of Contents

CONTENT 1. Instruction manual....................3 1.1 Range of application...................3 1.2 Operational order..................3 1.3 Safety precautions..................3 2. Product Description....................4 2.1 Brief Introduction..................4 2.2 Technical data.....................4 2.3 Diagram of Assembly..................5 3. Operating instruction...................7 3.1Test run......................7 3.2 Adjustment of control handle knob.............8 3.3Safety shutdown...................8 4. -

Page 3: Instruction Manual

1. Instruction manual 1.1 Range of application Please use and maintain the scale pallet truck according to this instruction manual. Operations that are not listed in this manual may cause harm to the operator or the scale pallet truck, and may cause property damage. Please read the name plate before use, and make sure that the load isn’t overweight. -

Page 4: Product Description

It has advantages of smaller size, easy moving, convenient lifting/lowering, flexible steering, and accurate measurement. 2.2 Technical data Technical data of scale pallet truck (hardware): Item/Model Unit TMG-PJ45S Rated Load 4500 Overall Length L Overall Height H 47-1/4 Fork Length A... -

Page 5: Diagram Of Assembly

Indicator Clearance G 2-1/2 Height to Top of Indicator E 26-1/2 Overall Width W Fork Width F 6-1/4 Diameter of Carrying Wheel 2-3/4 Diameter of Steering Wheel D Weight Input voltage AC100~240V(+10%, -15%)- 50~60HZ 2.3 Diagram of Assembly Scale pallet truck is composed of fork assembly, frame assembly, display assembly, pump assembly, and control handle assembly. - Page 6 C. Press the handle to the lowest position, and remove the limit shaft. D. Thread the chain through the hole in the fixed shaft. E. Insert the screw into the lever plate. F. Knock the pin into the hole in the fixed shaft. 2) Installation of display Fix the supporting structure on the frame with screws.

-

Page 7: Operating Instruction

Wire of Sensor Symbol of Socket Black Green White A) Fix the circuit board on the back of display with screws, and then fix the wires of sensor to the circuit board according to the table. B) install the display into the rack, and fix with screws. Please be cautious of the wire harness. -

Page 8: Adjustment Of Control Handle Knob

3.2 Adjustment of control handle knob Lowering Neutral Lifting The control handle switch has three positions. Press down the handle switch to lower position, then pump the handle up and down to lift load. When keeping the switch at the neutral position, the forks will not be able to lift. -

Page 9: Display Area Introduction

4.2 Display area introduction 1. Null point 2. Low power 3. Tare 4. Counting mode 5. Lb6.Kg 4.3 Button Function Introduction Turn on and off button/zero-setting button This button is used for power on and off. It is also used for zero-setting if value is in the range of zero-setting. Tare button/right shift button This button is used for taring except negative value when turn on or over the max. - Page 10 Operation Display Remark 1 Charge Plug in external [CHArGE] Charging power supply [---] Charging, scroll display from right to left [PbtXX] Showing the charging capacity [-End-] End of charge 2 Boot Press and hold [-t 15-] Appearance Model [UEr2.01] Software Version Number for 1 second [17.09.03] Date(year.month.day), set showing with...

-

Page 11: Calibration Introduction

10 Lock Press [Hold] Enter weigh lock mode. times Press Enter lock mode. When weight is stable, the weigh is locked. Press Exit weigh lock mode, and back to weigh mode. Press Enter accumulate function. times Press three [ACC 12] Choose 1 or 2. -

Page 12: Recharging Power

[-------] Range correction Press A few seconds [100.0] Display the loaded weight value, and enter the later weighing mode Note: 1 if zero is constant, only the range correction is made. When [CAL 00] is displayed, press the to skip zero correction, and enter the range correction. (compensation calibration) 2 if only the zero correction is made, please press , when [-LoAd-] is displayed. -

Page 13: Trouble Shooting

5. Trouble shooting Fault Description Reason Method Fork cannot reach the Lacking of hydraulic oil. Add hydraulic oil. wanted height 1.Hydraulic oil is not pure. 1.Change hydraulic oil. 2. Bob up and down the handle to extract 2. Air in the hydraulic oil. the air. -

Page 14: Routine Maintenance And Cleaning

6. Routine Maintenance and Cleaning The daily inspection and maintenance of scale pallet truck can improve the service time of the vehicle. 1) Check whether the pump is dripping. 2) Check whether there are sundries entangled in the wheels or axle. 3) Lubricate the moving parts of the pallet truck once a day. -

Page 15: Exploded Drawings And Parts List

Exploded Drawings and Parts List Main exploded drawings DESCRIPTION Q’TY DESCRIPTION Q’TY Handle assembly Spherical composite washer Pump assembly Fork connection pin Spring washerφ12 Thrust plate pin Swing arm Screw M12X30 Frame assembly Fork Shaft ringφ16 Weighing sensor Pushing rod and load wheel Tapping screw 3X10 assembly Screw M8X35... - Page 16 Structure of Control Handle Assembly DESCRIPTION Q’TY Handlebar Spring pin Handle Limit board Torsional spring Lever Connecting rod Chain lever Handle triangle Pinch roller Roller pin Spring pin Fixed pin Subplate Pump assembly WWW.TMGINDUSTRIAL.COM P16/18 Toll Free:1-877-761-2819...

- Page 17 DESCRIPTION Q’TY DESCRIPTION Q’TY Pump core Compound gasket Φ10 Spring cap Adjusting screw Spring Safety valve spring Scraper seal Steel ball pad Seal ring Gasket Steel ball Firing pin Compound gasket Firing pin seat Screw-plug Compound gasket Volute spring O ring Valve core Firing pin spring Valve body...

- Page 18 Display assembly DESCRIPTION Q’TY Operation panel Upper cover Mainboard of display Tapping screw 3X8 Tapping screw 3X10 Battery holder Pedestal Battery Tapping screw 3.5X10 Sensor connection circuit board Tapping screw 3X6.5 WWW.TMGINDUSTRIAL.COM P18/18 Toll Free:1-877-761-2819...

Need help?

Do you have a question about the TMG-PJ45S and is the answer not in the manual?

Questions and answers