Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Alfa level LKH-5

- Page 1 Instruction Manual LKH Centrifugal Pump ESE00698-EN13 2009-12 Original manual...

-

Page 3: Table Of Contents

7.3. LKH-70 - 90 Sanitary Version ..............7.4. LKH-5 Centrifugal Pump Single, Flushed and Double Mechanical Shaft Seal ....7.5. LKH-10 Centrifugal Pump Single, Flushed and Double Mechanical Shaft Seal .... 7.6. LKH-15 Centrifugal Pump Single, Flushed and Double Mechanical Shaft Seal .... - Page 4 Table of contents The information herein is correct at the time of issue but may be subject to change without prior notice 7.19. LKH-90 Centrifugal Pump Single, Flushed and Double Mechanical Shaft Seal .... 7.20. LKH-70, LKH-75, LKH-80, LKH-85 and LKH-90 Centrifugal Pump, Shaft Seal ...

-

Page 5: Ec Declaration Of Conformity

1 EC Declaration of Conformity The designated company Alfa Laval Company Name Albuen 31, DK-6000 Kolding, Denmark Address +45 79 32 22 00 Phone No. hereby declare that Pump Denomination Type Year is in conformity with the following directives with amendments: - Low Voltage Directive 2006/95/EC - EMC Directive 2004/108/EC - Machinery Directive 2006/42/EC... -

Page 6: Safety

2 Safety Unsafe practices and other important information are emphasized in this manual. Warnings are emphasized by means of special signs. Always read the manual before using the pump! 2.1 Important information WARNING Indicates that special procedures must be followed to avoid severe personal injury. CAUTION Indicates that special procedures must be followed to avoid damage to the pump. -

Page 7: Safety Precautions

2 Safety All warnings in the manual are summarized on this page. Pay special attention to the instructions below so that severe personal injury and/or damage to the pump are avoided. 2.3 Safety precautions Installation: Always read the technical data thoroughly. (See chapter 6 Technical data) Always use a lifting crane when handling the pump. -

Page 8: Installation

3 Installation The instruction manual is part of the delivery. Study the instructions carefully. The large pump sizes are very heavy. Alfa Laval therefore recommends the use of a lifting crane when handling the pump. 3.1 Unpacking/Delivery Step 1 Check the delivery for: 1. -

Page 9: Installation

3 Installation Study the instructions carefully and pay special attention to the warnings! Always check the pump before operation. - See pre-use check in section 3.3 Pre-use check - Pump without/with impeller screw. The large pump sizes are very heavy. Alfa Laval therefore recommends the use of a lifting crane when handling the pump. 3.2 Installation Step 1 Always have the pump electrically connected by... -

Page 10: Pre-Use Check - Pump Without/With Impeller Screw

3 Installation Study the instructions carefully and pay special attention to the warnings! LKH-5 to -60 is without impeller screw as standard but can be supplied with one. Check the direction of rotation of the impeller before operation. - See the indication label on the pump. -

Page 11: Operation

4 Operation Study the instructions carefully and pay special attention to the warnings! The pump is fitted with a warning label indicating correct throttling 4.1 Operation/Control Step 1 Always read the technical data thoroughly. See chapter 6 Technical data CAUTION Alfa Laval cannot be held responsible for incorrect operation/control. - Page 12 4 Operation Study the instructions carefully and pay special attention to the warnings! The pump is fitted with a warning label indicating correct throttling Step 5 Correct! Flushed shaft seal: 1. Connect the inlet of the flushing liquid correctly. R 1/8” (BSP) 2.

-

Page 13: Fault Finding

4 Operation Pay attention to possible faults. Study the instructions carefully. 4.2 Fault finding NOTE! Study the maintenance instructions carefully before replacing worn parts. - See section 5.1 General maintenance Remedy Problem Cause/result Overloaded motor - Pumping of viscous liquids - Larger motor or smaller impeller - Pumping of liquids with high density - Low outlet pressure (counter pressure) - Higher counter pressure (throttling) -

Page 14: Recommended Cleaning

4 Operation The pump is designed for cleaning in place (CIP). CIP = Cleaning In Place. Study the instructions carefully and pay special attention to the warnings! NaOH = Caustic Soda. = Nitric acid. 4.3 Recommended cleaning Step 1 Caustic danger! Always handle lye and acid with great care. -

Page 15: Maintenance

5 Maintenance Maintain the pump carefully. Study the instructions carefully and pay special attention to the warnings! Always keep spare shaft seals and rubber seals in stock. See separate motor instructions. Check the pump for smooth operation after service. 5.1 General maintenance Step 1 Always read the technical data thoroughly. - Page 16 5 Maintenance Maintain the pump carefully. Study the instructions carefully and pay special attention to the warnings! Always keep spare shaft seals and rubber seals in stock. See separate motor instructions. Check the pump for smooth operation after service. Shaft seal Rubber seals Motor bearings Preventive maintenance...

-

Page 17: Dismantling Of Pump/Shaft Seals

: Relates to the shaft seal. 5.2 Dismantling of pump/shaft seals Step 1 A. LKH-5: Remove screws (56), spring washers (56a), clamps (55+55a) and pump casing (29). B. LKH-10 to 90: Unscrew cap nuts (24) and remove washers (24a) and pump casing (29). - Page 18 5 Maintenance Study the instructions carefully. The items refer to the parts list and service kits section. Handle scrap correctly. : Relates to the shaft seal. Step 6 Use the tool 1. Remove the stationary seal ring (11). supplied 2. Remove the O-ring (12) from back plate (25). Left hand thread! TD 200-462...

-

Page 19: Assembly Of Pump/Single Shaft Seal

5 Maintenance Study the instructions carefully. The items refer to the parts list and service kits section. Handle scrap correctly. : Relates to the shaft seal. 5.3 Assembly of pump/single shaft seal Step 1 1. Remove spring (13). NOTE! Make sure that O-ring (15) has max. clearance from the sealing surface. - Page 20 B. LKH-10 to-90: Fit pump casing (29), washers (24a) and cap nuts (24). 2. Adjust pump casing to the right position. A. LKH-5: Tighten nuts (20) for back plate (25) and tighten screws (56). B. LKH-10 to -90: Tighten nuts (20) for back plate (25) and...

-

Page 21: Assembly Of Pump/Flushed Shaft Seal

Step 1 Use ø63 mm tube! Flushed shaft seal : LKH-5 to -60 use ø63mm tube LKH-70 to -90 press in lip seal by hand 1. Fit lip seal (43) in seal housing (40). 2. Lubricate O-ring (44) and slide onto the seal housing (40). - Page 22 (56a) and screws (56). B. LKH-10 to-90: Fit pump casing (29). 2. Tighten nuts (20) for back plate (25). A. LKH-5: Tighten nuts (20) for back plate (25) and tighten screws (56). B. LKH-10 to -90: Fit washers (24a) and cap nuts (24) and tighten, according to torque values in chapter 6.3...

-

Page 23: Assembly Of Pump/Double Mechanical Shaft Seal

5 Maintenance Study the instructions carefully. The items refer to the parts list and service kits section. Lubricate the rubber seals before fitting them. : Relates to the shaft seal. 5.5 Assembly of pump/double mechanical shaft seal Step 1 1. Fit O-rings (15) in rotating seal rings (14). 2. - Page 24 Step 10 1. Fit pump casing (29). 2. Tighten nuts (20) for back plate (25). A. LKH-5: Fit clamps (55+55a), spring washers (56a) and screws (56) and tighten. B. LKH-10 to -90: Fit washers (24a) and cap nuts (24) and tighten, according to torque values in chapter 6.3 Addendum.

-

Page 25: Adjustment Of Shaft (Lkh-5)

2. Fit back plate (25), washers (21) and nuts (20) and tighten. S S tep 5 LKH-5 = 0.5 mm (0.02 inch) 1. Fit impeller (27) on stub shaft (7). 2. Ensure that the clearance between the impeller and back plate (25) is correct: 0.5 mm (0.02 inch) for LKH-5. - Page 26 5 Maintenance Study the instructions carefully. The items refer to the parts list and service kits section. Lubricate the rubber seals before fitting them. : Relates to the shaft seal. Step 6 Tighten screws (4) evenly to 18 Nm (13 lbf-ft).

-

Page 27: Adjustment Of Shaft (Lkh-10 To -90)

5 Maintenance Study the instructions carefully. The items refer to the parts list and service kits section. Lubricate the rubber seals before fitting them. : Relates to the shaft seal. 5.7 Adjustment of shaft (LKH-10 to -90) Step 1 1. Loosen screws (6). 2. - Page 28 5 Maintenance Study the instructions carefully. The items refer to the parts list and service kits section. Lubricate the rubber seals before fitting them. : Relates to the shaft seal. Step 6 Counterhold with a screwdriver 1. Remove impeller (27), back plate (25) and drive ring (52). 2.

-

Page 29: Cleaning Procedure

5 Maintenance 5.8 Cleaning Procedure Cleaning Procedure for Soiled Impeller Screw Tapped Hole: 1. Remove stub shaft (7) per section 4 of Service manual. 2. Submerge and soak Stub Shaft for 5 minutes in COP tank with 2% caustic wash 3. -

Page 30: Technical Data

Normally atmospheric (max. 1 bar) (max. 14.5 psi ) Water consumption (flushed seal) 0.25 - 0.5 l/min. (0.07-0.13 gl ) Max. water pressure LKH-5 to -60 (DMS) Normally atmospheric (max. 5 bar) (max. 72.5 psi ) Max. water pressure LKH-70 to -90 (DMS) Normally atmospheric (max. -

Page 31: Relubrication Intervals

The table is for 100°C internal bearing temperature.an increase in temperature of 15°C (ambient or internal in bearings), will reduce the greasing interval and bearing lifetime by 50%. Lubrication interval for vertically mounted pumps is half the value stated in the table. Frame Motor LKH-5 - 90 LKHP-10 - 60 LKH-122/P power size... -

Page 32: Addendum

Always use below torques if no other values are stated. This can be a matter of personal safety. Tightening torgue Size lbf-ft 14.8 29.5 49.0 81.0 Section 2 Noise Pump Type Sound pressure level (dBA) LKH-5 LKH-10 LKH-15 LKH-20 LKH-25 LKH-35 LKH-40 LKH-45 LKH-50 LKH-60 LKH-70 LKH-75... -

Page 33: Parts List And Service Kits

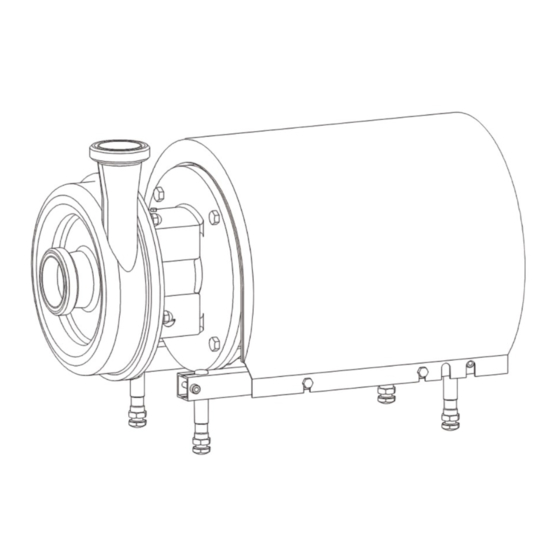

7 Parts list and Service Kits The drawing shows LKH pump, sanitary version. The items refer to the parts lists in the following sections 7.4 LKH-5 Centrifugal Pump Single, Flushed and Double Mechanical Shaft Seal 7.1 LKH-5 Sanitary Version Impeller screw... -

Page 34: Lkh-10, -15, -20, -25, -35, -40, -50, -60 Sanitary Version

7 Parts list and Service Kits The drawing shows LKH pump, sanitary version. The items refer to the parts lists in the following sections 7.5 LKH-10 Centrifugal Pump Single, Flushed and Double Mechanical Shaft Seal to 7.13 LKH-60 Centrifugal Pump Single, Flushed and Double Mechanical Shaft Seal 7.2 LKH-10, -15, -20, -25, -35, -40, -50, -60 Sanitary Version Impeller screw Only used for 0.75, 1.1 and 3 kW... -

Page 35: Lkh-70 - 90 Sanitary Version

7 Parts list and Service Kits The drawing shows LKH pump, sanitary version. The items refer to the parts lists in the following sections 7.15 LKH-70 Centrifugal Pump Single, Flushed and Double Mechanical Shaft Seal to 7.19 LKH-90 Centrifugal Pump Single, Flushed and Double Mechanical Shaft Seal 7.3 LKH-70 - 90 Sanitary Version LKH-85 and LKH-90 LKH-75: USA version only, no shroud, US leg set. -

Page 36: Lkh-5 Centrifugal Pump Single, Flushed And Double Mechanical Shaft Seal

7 Parts list and Service Kits The drawing and the parts list include all items. 7.4 LKH-5 Centrifugal Pump Single, Flushed and Double Mechanical Shaft Seal DMSS = Double Mechanical Shaft Seal. FSS = Flushed Shaft Seal Alternatives... - Page 37 7 Parts list and Service Kits The drawing and the parts list include all items. Parts list Service kits Denomination C C /SIC SIC/SIC Pos. Denomination Service kit for single shaft seal Motor Shroud Service kit, EPDM (Std.) ..†...

-

Page 38: Lkh-10 Centrifugal Pump Single, Flushed And Double Mechanical Shaft Seal

7 Parts list and Service Kits The drawing and the parts list include all items. 7.5 LKH-10 Centrifugal Pump Single, Flushed and Double Mechanical Shaft Seal DMSS = Double Mechanical Shaft Seal. FSS = Flushed Shaft Seal Impeller with Inducer Alternatives... - Page 39 7 Parts list and Service Kits The drawing and the parts list include all items. Parts list Service kits Denomination C C /SIC SIC/SIC Pos. Denomination Service kit for single shaft seal Motor Edge list Service kit, EPDM (Std.) ..†...

-

Page 40: Lkh-15 Centrifugal Pump Single, Flushed And Double Mechanical Shaft Seal

7 Parts list and Service Kits The drawing and the parts list include all items. 7.6 LKH-15 Centrifugal Pump Single, Flushed and Double Mechanical Shaft Seal DMSS = Double Mechanical Shaft Seal. FSS = Flushed Shaft Seal Impeller with Inducer Alternatives... - Page 41 7 Parts list and Service Kits The drawing and the parts list include all items. Parts list Service kits Denomination C C /SIC SIC/SIC Pos. Denomination Service kit for single shaft seal Motor Edge list Service kit, EPDM (Std.) ..†...

-

Page 42: Lkh-20 Centrifugal Pump Single, Flushed And Double Mechanical Shaft Seal

7 Parts list and Service Kits The drawing and the parts list include all items. 7.7 LKH-20 Centrifugal Pump Single, Flushed and Double Mechanical Shaft Seal DMSS = Double Mechanical Shaft Seal. FSS = Flushed Shaft Seal Impeller with Inducer Alternatives... - Page 43 7 Parts list and Service Kits The drawing and the parts list include all items. Parts list Service kits Denomination C C /SiC SiC/SiC Pos. Denomination Service kit for single shaft seal Motor Shroud complete Service kit, EPDM (Std.) ..†...

-

Page 44: Lkh-25 Centrifugal Pump Single, Flushed And Double Mechanical Shaft Seal

7 Parts list and Service Kits The drawing and the parts list include all items. 7.8 LKH-25 Centrifugal Pump Single, Flushed and Double Mechanical Shaft Seal DMSS = Double Mechanical Shaft Seal. FSS = Flushed Shaft Seal Impeller with Inducer Alternatives... - Page 45 7 Parts list and Service Kits The drawing and the parts list include all items. Parts list Service kits Denomination C C /SIC SIC/SIC Pos. Denomination Service kit for single shaft seal Motor Shroud complete Service kit, EPDM (Std.) ..†...

-

Page 46: Lkh-35 Centrifugal Pump Single, Flushed And Double Mechanical Shaft Seal

7 Parts list and Service Kits The drawing and the parts list include all items. 7.9 LKH-35 Centrifugal Pump Single, Flushed and Double Mechanical Shaft Seal DMSS = Double Mechanical Shaft Seal. FSS = Flushed Shaft Seal Impeller with Inducer Alternatives... - Page 47 7 Parts list and Service Kits The drawing and the parts list include all items. Parts list Service kits Denomination C C /SIC SIC/SIC Pos. Denomination Service kit for single shaft seal Motor Service kit, EPDM (Std.) ..†...

-

Page 48: Lkh-40 Centrifugal Pump Single, Flushed And Double Mechanical Shaft Seal

7 Parts list and Service Kits The drawing and the parts list include all items. 7.10 LKH-40 Centrifugal Pump Single, Flushed and Double Mechanical Shaft Seal DMSS = Double Mechanical Shaft Seal. FSS = Flushed Shaft Seal Impeller with Inducer Alternatives... - Page 49 7 Parts list and Service Kits The drawing and the parts list include all items. Parts list Service kits Denomination C C /SIC SIC/SIC Pos. Denomination Service kits for single shaft seal Motor Shroud Service kit, EPDM (Std.) ..†...

-

Page 50: Lkh-45 Centrifugal Pump Single, Flushed And Double Mechanical Shaft Seal

7 Parts list and Service Kits The drawing and the parts list include all items. 7.11 LKH-45 Centrifugal Pump Single, Flushed and Double Mechanical Shaft Seal DMSS = Double Mechanical Shaft Seal. FSS = Flushed Shaft Seal Impeller with Inducer Alternatives... - Page 51 7 Parts list and Service Kits The drawing and the parts list include all items. Parts list Service kits Denomination C C /SIC SIC/SIC Pos. Denomination Service kit for single shaft seal Motor Shroud complete Service kit, EPDM (std) ..†...

-

Page 52: Lkh-50 Centrifugal Pump Single, Flushed And Double Mechanical Shaft Seal

7 Parts list and Service Kits The drawing and the parts list include all items. 7.12 LKH-50 Centrifugal Pump Single, Flushed and Double Mechanical Shaft Seal DMSS = Double Mechanical Shaft Seal. FSS = Flushed Shaft Seal Impeller with Inducer Alternatives... - Page 53 7 Parts list and Service Kits The drawing and the parts list include all items. Parts list Service kits Denomination C C /SIC SIC/SIC Pos. Denomination Service kit for single shaft seal Motor Service kit, EPDM (Std.) ..†...

-

Page 54: Lkh-60 Centrifugal Pump Single, Flushed And Double Mechanical Shaft Seal

7 Parts list and Service Kits The drawing and the parts list include all items. 7.13 LKH-60 Centrifugal Pump Single, Flushed and Double Mechanical Shaft Seal DMSS = Double Mechanical Shaft Seal. FSS = Flushed Shaft Seal Alternatives... - Page 55 7 Parts list and Service Kits The drawing and the parts list include all items. Parts list Service kits Denomination C C /SIC SIC/SIC Pos. Denomination Service kit for single shaft seal Motor Service kit, EPDM (Std.) ..†...

-

Page 56: Lkh 5-60 Centrifugal Pumps, Shaft Seals

7 Parts list and Service Kits The drawing and the parts list include all items. 7.14 LKH 5-60 Centrifugal Pumps, Shaft Seals Single Shaft Seal. TD 200-372_1 Flushed Shaft Seal. TD 200-373_1 Double Mechanical Shaft Seal TD 200-374... - Page 57 7 Parts list and Service Kits The drawing and the parts list include all items. Parts list Pos. Denomination †™ Complete shaft seal — Complete shaft seal {„ Complete shaft seal › Complete shaft seal Complete shaft seal ¨z Complete shaft seal Stationary seal ring O-ring Spring...

-

Page 58: Lkh-70 Centrifugal Pump Single, Flushed And Double Mechanical Shaft Seal

7 Parts list and Service Kits The drawing and the parts list include all items. 7.15 LKH-70 Centrifugal Pump Single, Flushed and Double Mechanical Shaft Seal DMSS = Double Mechanical Shaft Seal. FSS = Flushed Shaft Seal Legs for motor sizes 55-75 kW... - Page 59 7 Parts list and Service Kits The drawing and the parts list include all items. Parts list Service kits Denomination C C /SIC SIC/SIC Pos. Denomination Service kit for single shaft seal Motor Shroud Service kit, EPDM (Std.) ..†...

-

Page 60: Lkh-75 Centrifugal Pump Single, Flushed And Double Mechanical Shaft Seal

7 Parts list and Service Kits The drawing and the parts list include all items. 7.16 LKH-75 Centrifugal Pump Single, Flushed and Double Mechanical Shaft Seal DMSS = Double Mechanical Shaft Seal. FSS = Flushed Shaft Seal TD 239-013... - Page 61 7 Parts list and Service Kits The drawing and the parts list include all items. Parts list Service kits Denomination C C /SIC SIC/SIC Pos. Denomination Service kit for single shaft seal Motor Compression ring with thread Service kit, EPDM (Std.) ..†...

-

Page 62: Lkh-80 Centrifugal Pump Single, Flushed And Double Mechanical Shaft Seal

7 Parts list and Service Kits The drawing and the parts list include all items. 7.17 LKH-80 Centrifugal Pump Single, Flushed and Double Mechanical Shaft Seal DMSS = Double Mechanical Shaft Seal. FSS = Flushed Shaft Seal Legs for motor sizes 55-75 kW... - Page 63 7 Parts list and Service Kits The drawing and the parts list include all items. Parts list Service kits Denomination C C /SIC SIC/SIC Pos. Denomination Service kit for single shaft seal Motor Shroud Service kit, EPDM....†...

-

Page 64: Lkh-85 Centrifugal Pump Single, Flushed And Double Mechanical Shaft Seal

7 Parts list and Service Kits The drawing and the parts list include all items. 7.18 LKH-85 Centrifugal Pump Single, Flushed and Double Mechanical Shaft Seal DMSS = Double Mechanical Shaft Seal. FSS = Flushed Shaft Seal Legs for motor sizes 55-110 kW... - Page 65 7 Parts list and Service Kits The drawing and the parts list include all items. Parts list Service kits Denomination C C /SIC SIC/SIC Pos. Denomination Service kit for single shaft seal Motor Edge list Service kit, EPDM (Std.) ..†...

- Page 66 7 Parts list and Service Kits The drawing and the parts list include all items. 7.19 LKH-90 Centrifugal Pump Single, Flushed and Double Mechanical Shaft Seal DMSS = Double Mechanical Shaft Seal. FSS = Flushed Shaft Seal Legs for motor sizes 55-75 kW...

- Page 67 7 Parts list and Service Kits The drawing and the parts list include all items. Parts list Service kits Denomination C C /SIC SIC/SIC Pos. Denomination Service kit for single shaft seal Motor Shroud Service kit, EPDM (Std.) ..†...

- Page 68 7 Parts list and Service Kits The drawing and the parts list include all items. 7.20 LKH-70, LKH-75, LKH-80, LKH-85 and LKH-90 Centrifugal Pump, Shaft Seal Single Shaft Seal TD 239-002_1 Flushed Shaft Seal TD 239-003_2 Double Mechanical Shaft Seal TD 239-004_2...

- Page 69 7 Parts list and Service Kits The drawing and the parts list include all items. Parts list Pos. Denomination † Complete shaft seal ™ Complete shaft seal Complete shaft seal — Complete shaft seal Complete shaft seal „ Complete shaft seal Stationary seal ring, SiC.

- Page 70 How to contact Alfa Laval Contact details for all countries are continually updated on our website. Please visit www.alfalaval.com to access the information direct.

Need help?

Do you have a question about the LKH-5 and is the answer not in the manual?

Questions and answers