Summary of Contents for Alfa level CSI LKH-112

- Page 1 Instruction Manual LKH Multi-Stage Pump 3003-0004 100002859-EN7 2020-08 Original manual...

- Page 2 CONTACT CSI FOR MORE INFORMATION | CSIDESIGNS.COM | SALES@CSIDESIGNS.COM | 417.831.1411...

-

Page 3: Table Of Contents

Table of contents The information herein is correct at the time of issue but may be subject to change without prior notice 1. EC Declaration of Conformity ............... 2. Safety ....................2.1. Important information ................2.2. Warning signs ..................2.3. Safety precautions ................3. -

Page 4: Ec Declaration Of Conformity

1 EC Declaration of Conformity Revision of Declaration of Conformity 2009-12-29 The Designated Company Alfa Laval Kolding A/S Company Name Albuen 31, DK-6000 Kolding, Denmark Address +45 79 32 22 00 Phone No. hereby declare that Pump Designation LKH-112, LKH-112/P, LKH-113, LKH-113/P, LKH-114, LKH-114/P, LKH-122/P, LKH-123/P, LKH-124/P Type From serial number 10.000 to 1.000.000 is in conformity with the following directive with amendments:... -

Page 5: Safety

2 Safety Unsafe practices and other important information are emphasized in this manual. Warnings are emphasized by means of special signs. A A l l w w a a y y s s r r e e a a d d t t h h e e m m a a n n u u a a l l b b e e f f o o r r e e u u s s i i n n g g t t h h e e p p u u m m p p ! ! 2.1 Important information W W A A R R N N I I N N G G Indicates that special procedures must be followed to avoid serious personal injury. -

Page 6: Safety Precautions

2 Safety All warnings in the manual are summarized on this page. Pay special attention to the instructions below so that severe personal injury and/or damage to the pump are avoided. 2.3 Safety precautions I I n n s s t t a a l l l l a a t t i i o o n n : : A A l l w w a a y y s s read the technical data thoroughly. -

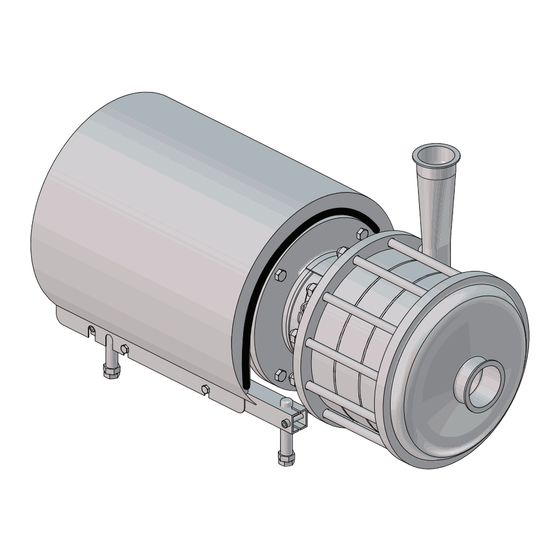

Page 7: Installation

3 Installation The LKH-110 and -120P pump is highly efficient and econominal centrifugal pump, which meets the requirements of sanitary and gently product treatment and chemical resistance. LKH-110 and the LKH-120P is avaliable in the following sizes, LKH-112, -113, -114 and LKH122/P, -123/P, -124/P. The instruction manual is part of the delivery. Study the instructions carefully. The large pump sizes are very heavy. -

Page 8: Installation/Pre-Use Check

3 Installation Study the instructions carefully and pay special attention to the warnings! The direction of rotation of the impeller can be checked by observing the direction of rotation of the motor fan. - See the indication label on the pump. 3.2 Installation/Pre-use Check S S t t e e p p 1 1 A A l l w w a a y y s s read the technical data thoroughly. - Page 9 3 Installation Study the instructions carefully and pay special attention to the warnings! The direction of rotation of the impeller can be checked by observing the direction of rotation of the motor fan. - See the indication label on the pump. S S t t e e p p 4 4 Remember seal rings! 1.

-

Page 10: Recycling Information

3 Installation 3.3 Recycling information • • U U n n p p a a c c k k i i n n g g - Packing material consists of wood, plastics, cardboard boxes and in some cases metal straps. - Wood and cardboard boxes can be reused, recycled or used for energy recovery. -

Page 11: Operation

4 Operation Study the instructions carefully and pay special attention to the warnings! 4.1 Operation/Control S S t t e e p p 1 1 A A l l w w a a y y s s read the technical data thoroughly. See technical data on page 32 C C A A U U T T I I O O N N Alfa Laval cannot be held responsible for incorrect operation/control. - Page 12 4 Operation Study the instructions carefully and pay special attention to the warnings! S S t t e e p p 4 4 C C A A U U T T I I O O N N The shaft seal must not run dry. D D o o n n o o t t a a l l l l o o w w t t o o C C A A U U T T I I O O N N...

-

Page 13: Trouble Shooting

4 Operation Pay attention to possible faults. Study the instructions carefully. 4.2 Trouble shooting N N O O T T E E ! ! Study the maintenance instructions carefully before replacing worn parts. - See section 5.1 General maintenance on page 15 R R e e m m e e d d y y P P r r o o b b l l e e m m C C a a u u s s e e / / r r e e s s u u l l t t... -

Page 14: Recommended Cleaning

4 Operation The pump is designed for cleaning in place (CIP). CIP = Cleaning In Place. Study the instructions carefully and pay special attention to the warnings! NaOH = Caustic Soda. = Nitric acid. 4.3 Recommended cleaning S S t t e e p p 1 1 C C a a u u s s t t i i c c d d a a n n g g e e r r ! ! A A l l w w a a y y s s handle lye and acid with great care. -

Page 15: Maintenance

5 Maintenance Maintain the pump carefully. Study the instructions carefully and pay special attention to the warnings! Always keep spare shaft seals and rubber seals in stock. See separate motor instructions. 5.1 General maintenance S S t t e e p p 1 1 A A l l w w a a y y s s read the technical data thoroughly. -

Page 16: Cleaning Procedure

5 Maintenance Maintain the pump carefully. Study the instructions carefully and pay special attention to the warnings! Always keep spare shaft seals and rubber seals in stock. See separate motor instructions. S S h h a a f f t t s s e e a a l l R R u u b b b b e e r r s s e e a a l l s s M M o o t t o o r r b b e e a a r r i i n n g g s s Preventive maintenance... -

Page 17: Dismantling Of Pump/Shaft Seals

5 Maintenance Study the instructions carefully. The items refer to the parts list and service kits section. Handle scrap correctly. : Relates to the shaft seal. 5.3 Dismantling of pump/shaft seals S S t t e e p p 1 1 Remove the cap nuts (29), washer (30), pump cover (49) and O-ring (32). - Page 18 5 Maintenance Study the instructions carefully. The items refer to the parts list and service kits section. Handle scrap correctly. : Relates to the shaft seal. S S t t e e p p 4 4 Counterhold with a screwdriver! Remove impeller screw (47) O-ring (41) and impeller (45).

- Page 19 5 Maintenance Study the instructions carefully. The items refer to the parts list and service kits section. Handle scrap correctly. : Relates to the shaft seal. S S t t e e p p 8 8 Remove space ring (35) and the rotating part of the seal from the impeller.

- Page 20 5 Maintenance Study the instructions carefully. The items refer to the parts list and service kits section. Handle scrap correctly. : Relates to the shaft seal. S S t t e e p p 1 1 2 2 F F l l u u s s h h e e d d s s h h a a f f t t s s e e a a l l : : 1.

-

Page 21: Assembly Of Pump/Assembly Of Shaft Seal - Lkh-110

5 Maintenance Study the instructions carefully. The items refer to the parts list and service kits section. Handle scrap correctly. : Relates to the shaft seal. 5.4 Assembly of Pump/Assembly of Shaft Seal - LKH-110 S S t t e e p p 1 1 10-20 mm 1. - Page 22 5 Maintenance Study the instructions carefully. The items refer to the parts list and service kits section. Handle scrap correctly. : Relates to the shaft seal. S S t t e e p p 4 4 Fit back plate (31), washers (21) and nuts (20). 3003-0036 S S t t e e p p 5 5 1.

- Page 23 5 Maintenance Study the instructions carefully. The items refer to the parts list and service kits section. Handle scrap correctly. : Relates to the shaft seal. S S t t e e p p 7 7 1. Remove impeller screw (47) and remove impeller (40,45) and 15 Nm back plate (31).

- Page 24 5 Maintenance Study the instructions carefully. The items refer to the parts list and service kits section. Handle scrap correctly. : Relates to the shaft seal. S S t t e e p p 1 1 1 1 LKH-112: 1. Fit pump casing (42) on back plate (31). 2.

- Page 25 5 Maintenance Study the instructions carefully. The items refer to the parts list and service kits section. Handle scrap correctly. : Relates to the shaft seal. S S t t e e p p 1 1 5 5 1. Fit O-ring (32) and pump cover (49). 2.

- Page 26 5 Maintenance Study the instructions carefully. The items refer to the parts list and service kits section. Handle scrap correctly. : Relates to the shaft seal. S S t t e e p p 1 1 7 7 F F l l u u s s h h e e d d s s h h a a f f t t s s e e a a l l : : Fit the tubes (25) on seal housing (26).

-

Page 27: Assembly Of Pump/Assembly Of Shaft Seal - Lkh-120/P

5 Maintenance Study the instructions carefully. The items refer to the parts list and service kits section. Lubricate the rubber seals before fitting them. : Relates to the shaft seal. 5.5 Assembly of Pump/Assembly of Shaft Seal - LKH-120/P S S t t e e p p 1 1 10-20 mm 1. - Page 28 5 Maintenance Study the instructions carefully. The items refer to the parts list and service kits section. Lubricate the rubber seals before fitting them. : Relates to the shaft seal. S S t t e e p p 4 4 1.

- Page 29 5 Maintenance Study the instructions carefully. The items refer to the parts list and service kits section. Lubricate the rubber seals before fitting them. : Relates to the shaft seal. S S t t e e p p 8 8 1.

- Page 30 5 Maintenance Study the instructions carefully. The items refer to the parts list and service kits section. Lubricate the rubber seals before fitting them. : Relates to the shaft seal. S S t t e e p p 1 1 2 2 Counterhold with a screwdriver! 1.

- Page 31 5 Maintenance Study the instructions carefully. The items refer to the parts list and service kits section. Lubricate the rubber seals before fitting them. : Relates to the shaft seal. S S t t e e p p 1 1 5 5 1.

-

Page 32: Technical Data

6 Technical data It is important to observe the technical data during installation, operation and maintenance. Inform possible personnel about the technical data. 6.1 Technical data The LKH-110 and -120P pump is highly efficient and econominal centrifugal pump, which meets the requirements of sanitary and gently product treatment and chemical resistsnce. -

Page 33: Relubrication Intervals

6 Technical data R R e e l l u u b b r r i i c c a a t t i i o o n n i i n n t t e e r r v v a a l l 5 5 0 0 H H z z ( ( 3 3 0 0 0 0 0 0 r r p p m m ) ) / / R R e e l l u u b b r r i i c c a a t t i i o o n n i i n n t t e e r r v v a a l l 6 6 0 0 H H z z ( ( 3 3 6 6 0 0 0 0 r r p p m m ) ) . (Vendor) quantity in Drive End/quantity in Non Drive End. -

Page 34: Torque Specifications

6 Technical data R R e e l l u u b b r r i i c c a a t t i i o o n n i i n n t t e e r r v v a a l l 5 5 0 0 H H z z ( ( 3 3 0 0 0 0 0 0 r r p p m m ) ) / / R R e e l l u u b b r r i i c c a a t t i i o o n n i i n n t t e e r r v v a a l l 6 6 0 0 H H z z ( ( 3 3 6 6 0 0 0 0 r r p p m m ) ) . (Vendor) quantity in Drive End/quantity in Non Drive End. -

Page 35: Weight (Kg)

6 Technical data R R e e l l u u b b r r i i c c a a t t i i o o n n i i n n t t e e r r v v a a l l 5 5 0 0 H H z z ( ( 3 3 0 0 0 0 0 0 r r p p m m ) ) / / R R e e l l u u b b r r i i c c a a t t i i o o n n i i n n t t e e r r v v a a l l 6 6 0 0 H H z z ( ( 3 3 6 6 0 0 0 0 r r p p m m ) ) . (Vendor) quantity in Drive End/quantity in Non Drive End. -

Page 36: Noise Emission

6 Technical data R R e e l l u u b b r r i i c c a a t t i i o o n n i i n n t t e e r r v v a a l l 5 5 0 0 H H z z ( ( 3 3 0 0 0 0 0 0 r r p p m m ) ) / / R R e e l l u u b b r r i i c c a a t t i i o o n n i i n n t t e e r r v v a a l l 6 6 0 0 H H z z ( ( 3 3 6 6 0 0 0 0 r r p p m m ) ) . (Vendor) quantity in Drive End/quantity in Non Drive End. -

Page 37: Parts List And Service Kits

7 Parts list and service kits R R e e l l u u b b r r i i c c a a t t i i o o n n i i n n t t e e r r v v a a l l 5 5 0 0 H H z z ( ( 3 3 0 0 0 0 0 0 r r p p m m ) ) / / R R e e l l u u b b r r i i c c a a t t i i o o n n i i n n t t e e r r v v a a l l 6 6 0 0 H H z z ( ( 3 3 6 6 0 0 0 0 r r p p m m ) ) . (Vendor) quantity in Drive End/quantity in Non Drive End. -

Page 38: Lkh Multi-Stage - Wet End

7 Parts list and service kits 7.2 LKH Multi-Stage - Wet end 34 35 36 33/37 38a 38 3003-0075 CONTACT CSI FOR MORE INFORMATION | CSIDESIGNS.COM | SALES@CSIDESIGNS.COM | 417.831.1411... - Page 39 7 Parts list and service kits P P a a r r t t s s l l i i s s t t Pos. Denomination Washer Cap nut Washer Back plate std. blasted O-ring ♦ Impeller back std. blasted O-ring Pump casing O-ring...

-

Page 40: Lkh Multi-Stage - Motor Dependent Parts

7 Parts list and service kits 7.3 LKH Multi-Stage - Motor dependent parts 34 35 36 33/37 38a 38 3003-0075 CONTACT CSI FOR MORE INFORMATION | CSIDESIGNS.COM | SALES@CSIDESIGNS.COM | 417.831.1411... - Page 41 7 Parts list and service kits P P a a r r t t s s l l i i s s t t Pos. Denomination Motor ABB 3000rpm Shroud Edge list Screw Distance sleeve Nut for adaptor Connex pin Compression ring Connex pin Shaft...

-

Page 42: Lkh Multi-Stage - Shaft Seal And Service Kits

7 Parts list and service kits 7.4 LKH Multi-Stage - Shaft seal and Service kits 34 35 36 33/37 38a 38 3003-0075 CONTACT CSI FOR MORE INFORMATION | CSIDESIGNS.COM | SALES@CSIDESIGNS.COM | 417.831.1411... - Page 43 7 Parts list and service kits P P a a r r t t s s l l i i s s t t Pos. Denomination Shaft seal complete ♦ Shaft seal complete O-ring ♦ Sleeve ♦ Screw Tube Seal housing O-ring ♦...

- Page 44 7 Parts list and service kits Parts marked with are included in the service kits. ♦ (900732/1) Recommended Spare Parts: Service kits. Conversion single to flushed shaft seal : Please order Flushed service kit + pos. 23+24+25+26 CONTACT CSI FOR MORE INFORMATION | CSIDESIGNS.COM | SALES@CSIDESIGNS.COM | 417.831.1411...

- Page 45 CONTACT CSI FOR MORE INFORMATION | CSIDESIGNS.COM | SALES@CSIDESIGNS.COM | 417.831.1411...

- Page 46 H H o o w w t t o o c c o o n n t t a a c c t t A A l l f f a a L L a a v v a a l l Contact details for all countries are continually updated on our website.

Need help?

Do you have a question about the CSI LKH-112 and is the answer not in the manual?

Questions and answers