Table of Contents

Advertisement

O W N E R ' S M A N U A L

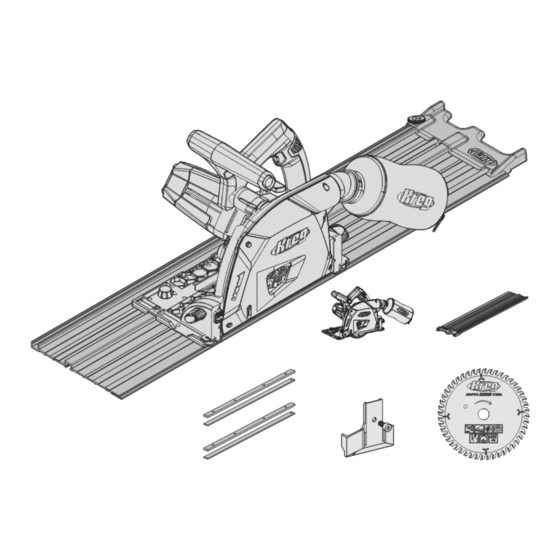

Plunge-Cut Track Saw

Every user must read and follow instructions and safety precautions in this manual.

WARNING

Failure to do so could result in serious injury. Save manual for future reference.

We're here to help.

We want you to have an exceptional project building experience.

If you have questions or need support, please get in touch.

1-800-447-8638 | technicalsupport@kregtool.com

Tell us about your experience.

Your opinion counts. And we're always looking for ways to improve.

Share your feedback so we can keep growing and innovating for you.

www.kregtool.com/feedback

Guide Track Connectors

Items covered in this manual:

Plunge-Cut Track Saw

Saw Splinter Guard

Guide Tracks

Saw Blade

English

2

French

35

Spanish

69

Advertisement

Table of Contents

Need help?

Do you have a question about the ACS3100 and is the answer not in the manual?

Questions and answers