Table of Contents

Advertisement

Quick Links

SERVICE MANUAL

Sec. 1: Main Section

I Specifications

I Preparation for Servicing

I Adjustment Procedures

I Schematic Diagrams

I CBA's

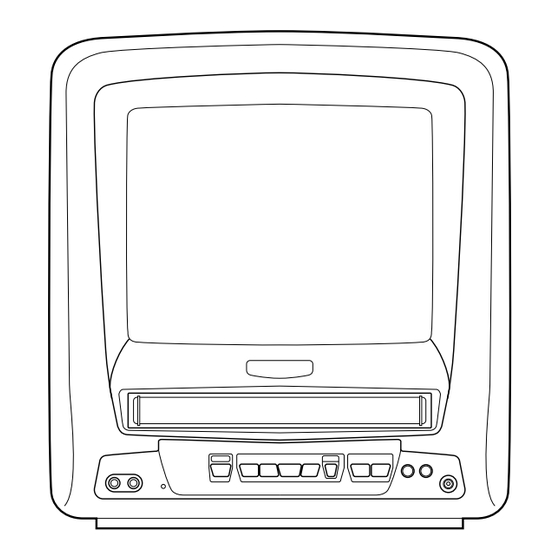

9" COLOR TV/VCR COMBINATION

Sec. 2: Deck Mechanism Section

I Standard Maintenance

I Alignment for Mechanism

I Disassembly/Assembly of Mechanism

SC309D/6309CD

Sec. 3: Exploded views

and Parts List Section

I Exploded views

I Parts List

Advertisement

Table of Contents

Summary of Contents for Sylvania SC309D

- Page 1 I Standard Maintenance and Parts List Section I Specifications I Alignment for Mechanism I Preparation for Servicing I Exploded views I Disassembly/Assembly of Mechanism I Parts List I Adjustment Procedures I Schematic Diagrams I CBA’s 9" COLOR TV/VCR COMBINATION SC309D/6309CD...

- Page 2 IMPORTANT SAFETY NOTICE Proper service and repair is important to the safe, reliable operation of all Funai Equipment. The service procedures recommended by Funai and described in this service manual are effective methods of performing service operations. Some of these service special tools should be used when and as recommended.

-

Page 3: Table Of Contents

MAIN SECTION 9" COLOR TV/VCR COMBINATION SC309D/6309CD Sec. 1: Main Section I Specifications I Preparation for Servicing I Adjustment Procedures I Schematic Diagrams I CBA’s TABLE OF CONTENTS Specifications ................1-1-1 Important Safety Precautions. -

Page 4: Specifications

SPECIFICATIONS *ˆ M ode---------SP mode unless otherwise specified *Test input terminal <Except Tuner>-------------Video input (1Vp-p) Audio input (-10dB) <Tuner>-----------------------Ant. input (80dBµV) Video: 87.5% Audio: 25kHz dev (1kHz Sin) <DEFLECTION> Description Condition Unit Nominal Limit 1. Over Scan — ±5 2. Linearity Horizontal —... - Page 5 <AUDIO> All items are measured across 8Ω resistor at speaker output terminal. Description Condition Unit Nominal Limit 1. Audio Output Power (Max.) (R/P) 2. Audio S/N (W/LPF) (R/P) 3. Audio Distortion (W/LPF) (R/P) 4. Audio Freq. Response 200Hz (R/P) -2.0 -2.0±5.0 (-10dB Ref.

-

Page 6: Important Safety Precautions

IMPORTANT SAFETY PRECAUTIONS Prior to shipment from the factory, our products are strictly inspected for recognized product safety and electrical codes of the countries in which they are to be sold. However, in order to maintain such compliance, it is equally important to implement the following precautions when a set is being serviced. - Page 7 ing is performed that involves B+, horizontal de- earth ground. If a voltage reading in excess of 1.0V flection or high voltage. Correct operation of the is obtained, remove and reinsert the AC power X-radiation protection circuits also must be recon- plug in the opposite polarity and again measure firmed each time they are serviced.

- Page 8 Precautions during Servicing H. When a power cord has been replaced, check that 5~6 kg of force in any direction will not loosen it. A. Parts identified by the ( # ) symbol are critical for I. Also check areas surrounding repaired locations. safety.

- Page 9 Safety Check after Servicing Examine the area surrounding the repaired location for damage or deterioration. Observe that screws, Chassis or Secondary Conductor parts and wires have been returned to original posi- tions. Afterwards, perform the following tests and con- Primary Circuit Terminals firm the specified values in order to verify compliance with safety standards.

-

Page 10: Standard Notes For Servicing

STANDARD NOTES FOR SERVICING Circuit Board Indications How to Read the Values of the Rect- angular Type Chip Components 1. The output pin of the 3 pin Regulator ICs is indi- cated as shown: Example: (a) Resistor Top View Bottom View Input = 473 = 47 [kΩ] (Top View) - Page 11 Notes: 2. The Flat Pack-IC on the CBA is affixed with glue, so be careful not to break or damage the foil of a. Do not attempt to lift the component off the board each pin or solder lands under the IC when remov- until the component is completely disconnected ing it.

- Page 12 Hot Air Blower Iron Wire Soldering Iron Fig. S-1-1 To Solid Mounting Point Fig. S-1-5 Hot-air Flat Pack-IC Desoldering Machine Example : Masking Flat Pack-IC Tape Tweezers Fig. S-1-2 Pin 1 of the Flat Pack-IC is indicated by a " "...

- Page 13 Instructions for Handling Semiconductors Electrostatic breakdown of the semiconductors may occur due to a potential difference caused by electro- static charge during unpacking or repair work. Ground for Human Body Be sure to wear a grounding band (1MΩ) that is prop- erly grounded to remove any static electricity that may be charged on the body.

-

Page 14: Preparation For Servicing

PREPARATION FOR SERVICING How to Enter the Service Mode Adjustment Mode No need to use. Caution: 1 Purity check mode: Shows Red, 1. Optical sensors system are used for Tape Start and Green, Blue or White cyclically on the End Sensor on this equipment. Read this page screen each time the “7”... -

Page 15: Operating Controls And Functions

OPERATING CONTROLS AND FUNCTIONS - TV/VCR FRONT PANEL - POWER STOP/EJECT PLAY F.FWD REC/OTR OLUME CHANNEL VIDEO AUDIO EARPHONE 6 7 8 12 13 POWER button– Press to turn TV/VCR on and off. - REMOTE CONTROL - Press to activate timer recording. STOP button–... - Page 16 - REAR VIEW - Press for manual recording. Press to choose the desired REC button– SPEED button– recording speed:SP/SLP. Activates One Touch Recording. OTR button– (only on the TV/VCR) Press to cancel a set- T-PROG. CLEAR button– ting of timer program. VOLUME buttons–...

-

Page 17: Cabinet Disassembly Instructions

CABINET DISASSEMBLY INSTRUCTIONS 1. Disassembly Flowchart (1): Order of steps in Procedure. When reassembling, follow the steps in reverse order.These numbers are also used as the identification (location) No. of This flowchart indicates the disassembly steps for the parts in Figures. cabinet parts, and the CBA in order to gain access to item(s) to be serviced. - Page 18 [1] REAR CABINET Fig. 1 [1] REAR CABINET Fig. 2 1-6-2 T4404DC...

- Page 19 [4] TRAY CHASSIS UNIT [3] POWER SUPPLY CBA UNIT [6] DECK UNIT [5] POWER SUPPLY [7] MAIN [2] VCR CHASSIS UNIT Fig. 3 1-6-3 T4404DC...

- Page 20 ANODE CAP. CRT CBA [8] CRT Fig. 4 1-6-4 T4404DC...

- Page 21 CRT CBA CL502A ANODE CL501A CN505 SCREEN FOCUS TO SPEAKER MAIN CBA CL502B CN801 CL403 CL601 TO DEGAUSS COIL CL401 WH1951A CL402 CN602 DC POWER SUPPLY CBA CN571 CL501B CL201 CYLINDER CAPSTAN ASSEMBLY MOTOR AC HEAD FE HEAD DECK UNIT ASSEMBLY Fig.

-

Page 22: Electrical Adjustment Instructions

ELECTRICAL ADJUSTMENT INSTRUCTIONS General Note: How to Set up the Service mode: "CBA" is abbreviation for "Circuit Board Service Mode: Assembly." 1. Use the service remote control unit. NOTE: 2. Turn the power on. Electrical adjustments are required after replacing 3. - Page 23 1b. DC 117V (+B) Adjustment 3. C-Trap Adjustment (DC Power) Purpose: To get minimum leakage of the color signal carrier. Purpose: To obtain correct operation. Symptom of Misadjustment: If C-Trap Adjustment is Symptom of Misadjustment: The picture is dark and incorrect, stripes will appear on the screen.

- Page 24 4. Y DL Time/Y SW LPF Adjustment 5. V. Size Adjustment Purpose: To get minimum leakage of the color signal Purpose: To obtain correct vertical height of screen carrier. image. Symptom of Misadjustment: If Y DL Time Adjust- Symptom of Misadjustment: If V. Size is incorrect, ment is incorrect, stripes will appear on the screen.

- Page 25 7. H. Shift Adjustment Notes: Screen Control FBT --- HV/DC Power Supply Purpose: To obtain correct horizontal position and F.B.T= Fly Back Transformer size of screen image. Use the Remote Control Unit Symptom of Misadjustment: Horizontal position and 1. Degauss the CRT and allow CRT to operate for 20 size of screen image may not be properly displayed.

- Page 26 9. Sub-Brightness Adjustment 10. Focus Adjustment Purpose: To get proper brightness. Purpose: Set the optimum Focus. Symptom of Misadjustment: If Sub-Brightness is Symptom of Misadjustment: If Focus Adjustment is incorrect, proper brightness cannot be obtained by incorrect, blurred images are shown on the display. adjusting the Brightness Control.

- Page 27 14. Convergence Adjustment The following 2 adjustments normally are not attempted in the field. They should be done Purpose: To obtain proper convergence of red, green only when replacing the CRT then adjust as a and blue beams. preparation. Symptom of Misadjustment: If Convergence Adjust- 13.

- Page 28 1. Set the unit to the AUX Mode which is located before CH2 then input a Dot or crosshatch pattern. 2. Loosen the Ring Lock and align red with blue dots or Crosshatch at the center of the screen by rotat- ing (RB) C.P.

-

Page 29: Block Diagrams

BLOCK DIAGRAMS Servo/System Control Block Diagram IC201 (SERVO/SYSTEM CONTROL) SW201 SW204,SW206 (DECK ASSEMBLY KEY 0 SWITCH MAIN CBA SW205,SW207 SW210 AL+5V KEY 1 SWITCH D203 RS201 S-LED REMOTE P-ON-H REMOTE P-ON-H FROM/TO POWER SENSOR P-DOWN SUPPLY BLOCK P-DOWN AC HEAD ASSEMBLY TP201 CL402 CTL AMP-OUT... - Page 30 Video Block Diagram REC VIDEO SIGNAL PB VIDEO SIGNAL MODE: SP/REC MAIN CBA TP301 Q401 V-OUT BUFFER IC401 VIDEO/AUDIO SIGNAL PROCESS Q402 CCD 1H TO CHROMA/ VIDEO BUFFER DELAY TUNER BLOCK CHARA LUMINANCE DOC YNR Y/C COMB SIGNAL PROCESS V-AGC TU-VIDEO TUNER FROM/TO CHROMA/...

- Page 31 Audio Block Diagram PB-AUDIO SIGNAL REC-AUDIO SIGNAL Mode : SP/REC MAIN CBA IC301(VIDEO/AUDIO SIGNAL PROCESS) IC801 (AMP) OUTPUT FROM JK801 TU-AUDIO CHROMA/TUNER EARPHONE JACK MUTE BLOCK FROM/TO TUNER SERIAL SERVO/SYSTEM AUDIO CONTROL BLOCK LINE CL802 CN801 SPEAKER SP801 JK702 SP-MUTE SPEAKER A-IN SP-GND...

- Page 32 Chroma/Tuner Block Diagram REC-AUDIO SIGNAL REC VIDEO SIGNAL PB VIDEO SIGNAL Mode : SP/REC MAIN CBA IC100 (IF SIGNAL PROCESS) SF001 CF031 TU001 VIDEO 4.5MHz TU VIDEO TO VIDEO BLOCK FILTER TRAP CF032 4.5MHz TU AUDIO TO AUDIO BLOCK FILTER VCO F/B EXT-L FROM...

- Page 33 CRT/H.V. Block Diagram REC VIDEO SIGNAL PB VIDEO SIGNAL Mode : SP/REC IC551 (V-DEFLECTION CONTROL) L551 DEFLECTION-YOKE WF13 THERMAL PROTECTION DRIVE Q572 H.DRIVE PUMP DRIVE WF12 Q571 T572 CN571 H.OUTPUT FROM POWER SUPPLY BLOCK DEF+B FOCUS VR T571 F.B.T. ANODE FOCUS SCREEN ANODE...

- Page 34 Power Supply Block Diagram CAUTION ! Fixed voltage ( or Auto voltage selectable ) power supply circuit is used in this unit. If Main Fuse (F601) is blown, check to see that all components in the power supply NOTE : CAUTION: FOR CONTINUED PROTECTION AGAINST RISK OF FIRE, circuit are not defective before you connect the AC plug to the AC power supply.

- Page 35 DC Power Supply Block Diagram Fixed voltage power supply circuit is used in this unit. CAUTION: FOR CONTINUED PROTECTION AGAINST RISK OF FIRE, If Main Fuse (F1951) is blown, check to see that all components in the power supply REPLACE ONLY WITH SAME TYPE 8 A, 125V FUSE. circuit are not defective before you connect the DC plug to the DC power supply.

-

Page 36: Mechanical Trouble Indicator

MECHANICAL TROUBLE INDICATOR 1, Each Malfunction Indication POWER SAFETY 1) POWER SAFETY 2 If the MONITOR is turned ON right after the Mechani- If P-SAFETY 2 port becomes continuously 2.5V or cal Malfunction occurs or POWER SAFETY/X-RAY is less for 120 msec. (4 times 40 msec. interval) when turned ON, display the following character to show P-ON-H port is ON, the unit shall be assumed to be Malfunction after the EJECT display. - Page 37 Mechanical Malfunction determination 4) Countermeasure for CASSETTE LOADING Mal- function 1) REEL Malfunction detection a) CASSETTE IN operating Malfunction Countermeasure for REEL and CAPSTAN motor If LD-SW does not go to SB position after a lapse of rotation malfunction (Except CASSETTE LOAD- 5 sec.

-

Page 38: Power Supply Trouble Shooting Guide

Power Supply Trouble Shooting Guide It is highly recommended that a variable isolation Voltage approx. 5Vp-p transformer which can monitor current be used. (Alternatively a variable AC source which monitors current will do). Read directions below before power is added! T=Approx. - Page 39 Repair method #2 Check the primary rectifying diodes (D603-D606) as possible problems. Remove the above mentioned parts and check them. Perform check according to the step 1 and 2 of repair method #1 and check for defects following parts, then if necessary replace with factory originals.

-

Page 40: Schematic Diagrams / Cba's And Test Points

SCHEMATIC DIAGRAMS / CBA’S AND TEST POINTS Standard Notes Note: 1. Do not use the part number shown on these draw- Warning ings for ordering. The correct part number is shown in the parts list, and may be slightly different or Many electrical and mechanical parts in this chassis amended since these drawings were prepared. - Page 41 LIST OF CAUTION, NOTES, AND SYMBOLS USED IN THE SCHEMATIC DIAGRAMS ON THE FOLLOWING PAGES: 1. CAUTION: FOR CONTINUED PROTECTION AGAINST RISK OF FIRE, REPLACE ONLY WITH SAME TYPE_A,_V FUSE. ATTENTION: UTILISER UN FUSIBLE DE RECHANGE DE MÊME TYPE DE_A,_V. 2.

- Page 42 Main 1/5 Schematic Diagram MAIN 1/5 Ref No. Position IC201 IC202 TRANSISTORS Q205 Q206 CONNECTOR CL201 TEST POINTS J274 TP201 1-9-3 1-9-4 T4400SCM1...

- Page 43 Main 2/5 Schematic Diagram REC Video Signal PB Video Signal PB Audio Signal REC Audio Signal MAIN 2/5 Ref No. Position IC401 IC801 TRANSISTORS Q401 Q402 Q871 Q872 Q873 Q874 Q875 CONNECTOR CL401 CL402 CL403 CN801 TEST POINTS TP301 TP401 TP402 T4400SCM2 1-9-5...

- Page 44 Main 3/5 Schematic Diagram PB Video Signal REC Video Signal PB Audio Signal REC Audio Signal MAIN 3/5 Ref No. Position IC100 IC301 TRANSISTOR Q301 TEST POINT J271 TP302 1-9-7 1-9-8 T4400SCM3...

- Page 45 Main 4/5 Schematic Diagram VOLTAGE CHART (Power off mode) MAIN 4/5 CAUTION ! CAUTION: FOR CONTINUED PROTECTION AGAINST RISK Ref No. Position Ref No. Position Ref. No. Fixed voltage ( or Auto voltage selectable ) power supply circuit is used in this unit. OF FIRE, REPLACE ONLY WITH SAME TYPE 4A, 125V FUSE.

- Page 46 Main 5/5 & CRT Schematic Diagram MAIN 5/5 Ref No. Position Ref No. Position TRANSISTORS CC-2 IC551 Q511 CC-2 TRANSISTORS Q521 Q571 AA-2 Q531 CC-2 CONNECTORS Q572 BB-3 Q591 CL501A BB-2 CONNECTORS CL502A CN505 DD-2 CL501B BB-3 BB-2 CL502B CN571 PB Video Signal REC Video Signal 1-9-11...

- Page 47 DC Power Supply Schematic Diagram DC POWER SUPPLY Ref No. Position IC1951 CAUTION ! Fixed voltage power supply circuit is used in this unit. TRANSISTORS CAUTION: FOR CONTINUED PROTECTION AGAINST RISK If Main Fuse (F1951) is blown, check to see that all components in the power supply circuit OF FIRE, REPLACE ONLY WITH SAME TYPE 8A, 125V FUSE.

- Page 48 Main CBA Top View Sensor CBA Top View CAUTION: FOR CONTINUED PROTECTION AGAINST RISK CAUTION ! OF FIRE, REPLACE ONLY WITH AME TYPE 4A, 125V FUSE. Fixed voltage ( or Auto voltage selectable ) power supply circuit is used in this unit. ATTENTION: UTILISER UN FUSIBLE DE RECHANGE DE If Main Fuse (F601) is blown, check to see that all components in the power supply circuit BHB300F01014-A...

- Page 49 Main CBA Bottom View CAUTION ! BECAUSE A HOT CHASSIS GROUND IS PRESENT IN THE POWER CAUTION: FOR CONTINUED PROTECTION AGAINST RISK Fixed voltage ( or Auto voltage selectable ) power supply circuit is used in this unit. OF FIRE, REPLACE ONLY WITH SAME TYPE 4A, 125V FUSE. SUPPLY CIRCUIT, AN ISOLATION TRANSFORMER MUST BE USED.

- Page 50 DC Power Supply CBA Top View CAUTION ! Fixed voltage power supply circuit is used in this unit. CAUTION: FOR CONTINUED PROTECTION AGAINST RISK If Main Fuse (F1951) is blown, check to see that all components in the power supply circuit OF FIRE, REPLACE ONLY WITH SAME TYPE 8A, 125V FUSE.

- Page 51 DC Power Supply CBA Bottom View CAUTION ! Fixed voltage power supply circuit is used in this unit. CAUTION: FOR CONTINUED PROTECTION AGAINST RISK If Main Fuse (F1951) is blown, check to see that all components in the power supply circuit OF FIRE, REPLACE ONLY WITH SAME TYPE 8A, 125V FUSE.

- Page 52 CRT CBA Top View CRT CBA Bottom View CRT CBA Ref No. Position TRANSISTORS Q511 Q521 Q531 CONNECTORS CL501A CL502A CN505 WF15 WF14 WF16 Q521 Q511 Q531 Collector Collector Collector 1-9-23 1-9-24 BT4400F01012-B...

- Page 53 Junction CBA Top View Junction CBA Bottom View BT4400F01022-B 1-9-25 1-9-26...

-

Page 54: Waveforms

WAVEFORMS WAVEFORM NOTES INPUT: NTSC COLOR BAR SIGNAL (WITH 1kHz AUDIO SIGNAL) BRIGHTNESS, COLOR AND TINT CONTROLS: CENTER POSITION CONTRAST CONTROL: APPROX 70% VOLTAGES SHOWN ARE RANGE OF OSCILLOSCOPE SETTING. 5 ms 10 V 5 ms 0.5 V 20 µs 0.5 V 0.5 ms 20 µs... -

Page 55: Wiring Diagrams

WIRING DIAGRAM WIRING DIAGRAM FOR SECTION 2 (DECK MECHANISM) ANODE CN801 CL801 1 SPEAKER SP801 SPEAKER 2 SP-GND CAPSTAN MOTOR CRT CBA FOCUS LOADING CL201 BT4400F01012 MOTOR P-ON+12V P-ON+5V(2) C-FG CN505 CL502A CL502B C-F/R CYLINDER ASSEMBLY 1 GND C-CONT 2 RED FG-GND GREEN 3 GREEN... -

Page 56: System Control Timing Charts

SYSTEM CONTROL TIMING CHARTS Chart 1 EJECT ST-S "OFF" CASS.LOAD LD-FWD 0.2S LD-REV SFT-SW STOP(B) POWER LD-FWD 0.4S LD-FWD 0.2S LD-REV 0.2S LD-FWD 0.5S LD-REV STOP(A) PLAY LD-FWD PLAY LD-FWD RS1(RS2) LD-REV 0.2S LD-FWD FS1(FS2) PLAY PLAY PAUSE STILL PAUSE NOISE CANCEL PAUSE... - Page 57 Chart 2 STOP(A) STOP LD-REV 0.2S LD-FWD 0.2S STOP /EJECT 1.0S LD-FWD 0.5S LD-REV STOP(A) LD-REV 0.2S LD-FWD 0.2S STOP /EJECT LD-REV 1.0S LD-FWD 0.5S LD-REV STOP(A) LD-FWD PAUSE LD-FWD 2.5S Short REV LD-REV 0.2S LD-FWD REC PAUSE REC or PAUSE STOP /EJECT...

-

Page 58: Ic Pin Function Descriptions

IC PIN FUNCTION DESCRIPTIONS IC 201 (TV/VCR Micro Computer) Signal Function Name “H” ≥ 4.5V, “L” ≤ 1.0V Rental Position Control 30 OUT RENTAL Signal Signal Function Name 31 OUT P-ON-H Power On Signal at High LD-SW Loading Switch Input Special Playback Control 32 OUT SPL-PLAY Not Used... - Page 59 Signal Signal Function Function Name Name 64 OUT OSD-R Red Output CTL (+) CTL (+) 65 OUT A-MUTE Audio Mute Output AMPC AMPC Capstan Motor FWD/REV 66 OUT C-F/R CTL AMP Control Signal 97 OUT Control Amp Output Not Used P-ON+5V Power Supply for AMP Not Used...

-

Page 60: Lead Identifications

LEAD IDENTIFICATIONS 2SC5884000RF 2SK2662 TT2138LS-YB11 MID-32A22 2SD400(F) S: Souce E: Emitter D: Drain C: Collector G: Gate B: Base B C E E C B S D G LA78040A AN5522 2SC1627Y-TPE2 BN1F4M-T KRA103M 2SA950(Y,O) KTC3199(GR) 2SC1815-GR(TPE2) KTA1271(Y) 2SC2785(J,H,F) 2SC3331(T,U) 2SC2482 TPE6 2SA1015-GR(TPE2) 2SC2120-(O,Y)(TPE2) 2SC3468(E,D)-AE... - Page 61 DECK MECHANISM SECTION 9" COLOR TV/VCR COMBINATION SC309D/6309CD Sec. 2: Deck Mechanism Section I Standard Maintenance I Alignment for Mechanism I Disassembly/Assembly of Mechanism I Alignment Procedures of Mechanism TABLE OF CONTENTS Standard Maintenance ..............2-1-1 Service Fixtures and Tools.

- Page 62 STANDARD MAINTENANCE Service Schedule of Components H: Hours : Check I: Change Deck Periodic Service Schedule Ref.No. Part Name 1,000 H 2,000 H 3,000 H 4,000 H Cylinder Assembly Loading Motor Assembly Pulley Assembly B587 Tension Lever Assembly AC Head Assembly B573,B574 Reel (SP)(D2), Reel (TU)(D2) Capstan Motor...

- Page 63 Cleaning Cleaning of Audio Control Head Clean the head with a cotton swab. Cleaning of Video Head Procedure Clean the head with a head cleaning stick or chamois 1.Remove the top cabinet. cloth. 2.Dip the cotton swab in 90% isopropyl alcohol and Procedure clean the audio control head.

- Page 64 SERVICE FIXTURE AND TOOLS J-1-1, J-1-2 Ref. No. Name Part No. Adjustment J-1-1 Alignment Tape FL8A Head Adjustment of Audio Control Head J-1-2 Alignment Tape FL8N Azimuth and X Value Adjustment of Audio Control (2Head only) Head / Adjustment of Envelope Waveform FL8NW (4Head only) Guide Roller Adj.Screwdriver...

- Page 65 MECHANICAL ALIGNMENT PROCEDURES Explanation of alignment for the tape to correctly run B. Method to place the Cassette Holder in the tape- starts on the next page. Refer to the information below loaded position without a cassette tape on this page if a tape gets stuck, for example, in the 1.

- Page 66 1.Tape Interchangeability Alignment Note: To do these alignment procedures, make sure that the Tracking Control Circuit is set to the center position every time a tape is loaded or unloaded. (Refer to page 2-3-4, procedure 1-C, step 2.) Equipment required: Dual Trace Oscilloscope VHS Alignment Tape (FL8N) Guide Roller Adj.

- Page 67 1-A. Preliminary/Final Checking and 3. Check to see that the tape runs without creasing at Alignment of Tape Path Take-up Guide Post [4] or without snaking between Guide Roller [3] and AC Head. (Fig. M3 and M5) Purpose: 4. If creasing or snaking is apparent, adjust the Tilt To make sure that the tape path is well stabilized.

- Page 68 6. Press CH DOWN button on the unit until the CTL 1-D. Azimuth Alignment of Audio/Con- waveform has shifted from its original position (not trol/ Erase Head the position achieved in step 5, but the position of Purpose: CTL waveform in step 4) by approximately -2msec. To correct the Azimuth alignment so that the Audio/ Make sure that the envelope is simply attenuated Control/Erase Head meets tape tracks properly.

- Page 69 DISASSEMBLY/ASSEMBLY PROCEDURES OF DECK MECHANISM Before following the procedures described below, be sure to remove the deck assembly from the cabinet. (Refer to CABINET DISASSEMBLY INSTRUCTIONS on page 1-6-1.) All the following procedures, including those for adjustment and replacement of parts, should be done in Eject mode;...

- Page 70 REMOVAL INSTALLATION STEP START- REMOVE/*UNHOOK/ /LOC. PART ADJUSTMENT Fig. No. UNLOCK/RELEASE/ CONDITION UNPLUG/DESOLDER Loading Arm (TU) (+)Refer to Alignment [32] [33] DM2,DM14 Assembly Sec.Pg.2-4-9 [34] [2],[25] M Brake (TU) Assembly DM1,DM15 *(P-7), Brake Belt [35] [2],[25] M Brake (SP) Assembly DM1,DM15 *(P-8) [36] [35]...

- Page 71 Top View [41] [42] [46] [43] [14] [13] [11] [15] [36] [10] [12] [35] [34] [40] [29] [30] [16] [39] [38] Fig. DM1 Bottom View [20] [33] [32] [24] [26] [27] [25] [23] [28] [22] [21] [31] Fig. DM2 2-4-3 Z12NDA...

- Page 72 (S-1) (S-1) (L-1) (L-3) (L-2) (P-1) Fig. DM5 [46] Fig. DM3 [47] Pin D (L-14) Pin C Pull up Slide Pin A Pin B Slot A (S-2) Slots B Slot A First, while pushing the locking tab as shown at right, slide and pull up the right side on [2] to release Pin A and Pin B from the slots A.

- Page 73 (S-4) (S-5) [14] (S-6) [16] [15] Desolder from bottom (S-3) Lead with White Stripe Belt View for A Fig. DM7 Fig. DM9 Adj. Screw [11] [18] (L-4) (L-5) (P-3) [17] [13] [19] [12] (P-4) [10] (P-2) (S-7) Pin of [12] Pin of [10] Fig.

- Page 74 [22] (C-4) (S-8) (C-1) [23] (L-6) [21] (P-5) [20] Cap Belt (P-5) [28] Fig. DM11 When installing [23], install the spring (P-5) to [28] as shown in the left figure, and then install [23] while Pin on pressing the spring (P-5) to bottom the direction of the arrow in of [23]...

- Page 75 (P-6) [25] [31] Refer to the Alignment (C-3) Section, Page 2-4-9. (S-9) [29] [33] [30] (L-11) [32] (L-10) (L-8) (C-2) [27] [28] [24] [26] (L-9) Fig. DM14 [36] Position of Mode Lever when installed Break belt Pin of [35] (P-7) Pin of [31] Pin of [34] [34]...

- Page 76 [42] [41] [43] (L-13) Fig. DM16 (P-9) [44] [45] Slide Fig. DM17 2-4-8 Z12NDA...

- Page 77 ALIGNMENT PROCEDURES OF MECHANISM Alignment 1 The following procedures describe how to align the individual gears and levers that make up the tape Loading Arm (SP) and (TU) Assembly loading/unloading mechanism. Since information about the state of the mechanism is provided to the Install Loading Arm (SP) and (TU) Assembly so System Control Circuit only through the Mode Switch, that their triangle marks point to each other as...

- Page 78 EXPLODED VIEWS AND PARTS LIST SECTION 9" COLOR TV/VCR COMBINATION SC309D/6309CD Sec. 3: Exploded views and Parts List Section I Exploded views I Parts List TABLE OF CONTENTS Cabinet Exploded Views ..............3-1-1 Packing Exploded Views .

- Page 79 EXPLODED VIEWS Cabinet CRT CBA DG1601 TB24 JUNCTION CBA V501 SP801 SENSOR CBA TB26 CLN801 TB20 TB10 A1-5 TB21 DC POWER SUPPLY CBA MAIN CBA TB20 TL18 SENSOR CBA TL14 A1-4 A1-1 A1-3 See Electrical Parts List A1-2 for parts with this mark. 3-1-1 3-1-2 T4404CEX...

- Page 80 Packing TAPE TAPE 3-1-3 T4400PEX...

- Page 81 DECK EXPLODED VIEWS Deck Mechanism View 1 Mark Description Floil G-684G or Multemp MH-D (Blue grease) SLIDUS OIL #150 B494 L1467 L1191 B553 B411 B567 L1053 B410 L1051 Chassis Assembly Top View (Lubricating Point) B501 B560 L1450 L1450 B426 L1466 B121 B126 B492...

- Page 82 Deck Mechanism View 2 Mark Description Floil G-684G or Multemp MH-D (Blue grease) B587 B521 B487 SLIDUS OIL #150 B416 B591 SANKOUL FG84M (Yellow grease) B520 B590 B522 B499 L1406 B148 B508 B573 B592 B574 B558 B564 B557 B414 B565 B525 L1151 B417...

- Page 83 Deck Mechanism View 3 Mark Description Floil G-684G or Multemp MH-D (Blue grease) SLIDUS OIL #150 L1321 B347 L1321 B355 B354 B483 B425 B482 B562 B300 B563 B313 B529 B360 B359 B361 B555 B561 B303 Some Ref. Numbers are not in sequence. B514 3-1-6 Z12NDEX...

- Page 84 CONTROL PLATE T4401UB 0EM301769 NE126UD or A1-3 BRAND PLATE T4300UA:SYMPHONIC 0EM406938 REMOTE CONTROL 512/ERC001/ NE150UD NE150UD A1-3 BRAND PLATE T4401UB:SYLVANIA 0EM408140 DRY BATTERY R6P UM3 or XB0M451GH001 A1-4 CASSETTE DOOR T4300UA 0EM406939 DRY BATTERY R6P(AR)2PX or XB0M451HU002 A1-4 CASSETTE DOOR T4401UB...

- Page 85 ELECTRICAL PARTS LIST PRODUCT SAFETY NOTE: Products marked with a Ref. No. Description Part No. # have special characteristics important to safety. C210 CHIP CERAMIC CAP . F Z 1µF/10V CHD1AZB0F105 Before replacing any of these components, read care- C211 CERAMIC CAP .(AX) F Z 0.01µF/25V CCA1EZTFZ103 fully the product safety notice in this service manual.

- Page 86 Ref. No. Description Part No. Ref. No. Description Part No. C330 CHIP CERAMIC CAP .(MELF) F Z 0.01µF/16V CZM1CZB0F103 C574# ELECTROLYTIC CAP . 4.7µF/250V M or CE2EMASDL4R7 C331 ELECTROLYTIC CAP .(SS.T) 220µF/10V M H7 CA1A221S6028 ELECTROLYTIC CAP . 4.7µF/250V M CE2EMASTL4R7 C336 ELECTROLYTIC CAP .

- Page 87 Ref. No. Description Part No. Ref. No. Description Part No. ELECTROLYTIC CAP . 47µF/35V M CE1GMASTL470 D226 ZENER DIODE MTZJT-776.2B or QDTB0MTZJ6R2 C630 ELECTROLYTIC CAP . 100µF/10V M or CE1AMASDL101 ZENER DIODE DZ-6.2BSBT265 NDTB0DZ6R2BS CARBON RES. 1/4W J 1k Ω or ELECTROLYTIC CAP .

- Page 88 Ref. No. Description Part No. Ref. No. Description Part No. RECTIFIER DIODE ERB12-06 QDQZ0ERB1206 SWITCHING DIODE 1N4148 NDTZ001N4148 D607# ZENER DIODE MTZJT-7720C or QDTC00MTZJ20 D803 SWITCHING DIODE 1SS133(T-77) or QDTZ001SS133 ZENER DIODE DZ-20BSCT265 NDTC00DZ20BS SWITCHING DIODE 1N4148 NDTZ001N4148 D609 SWITCHING DIODE 1SS133(T-77) or QDTZ001SS133 D961 ZENER DIODE MTZJT-775.6B or...

- Page 89 Ref. No. Description Part No. Ref. No. Description Part No. TRANSISTOR 2SC2785(J) or QQSJ02SC2785 TRANSISTOR KTA1267(GR) or NQS10KTA1267 TRANSISTOR KTC3199(GR) or NQS10KTC3199 TRANSISTOR KTA1266(GR) or NQS40KTA1266 TRANSISTOR KTC3198(GR) or NQS40KTC3198 TRANSISTOR 2SA1015-GR(TPE2) QQS102SA1015 TRANSISTOR 2SC1815-GR(TPE2) QQS102SC1815 Q872 TRANSISTOR 2SC2120-O-TPE2 or QQS002SC2120 Q206 PHOTO TRANSISTOR MID-32A22...

- Page 90 Ref. No. Description Part No. Ref. No. Description Part No. CARBON RES. 1/4W J 1.5k Ω or R216 RCX4JATZ0152 R283 PCB JUMPER D0.6-P5.0 JW5.0T CARBON RES. 1/6W J 1.5k Ω CHIP RES.(1608) 1/10W J 10k Ω RCX6JATZ0152 R291 RRXAJB5Z0103 CARBON RES. 1/4W J 2.2k Ω or CHIP RES.(1608) 1/10W J 22k Ω...

- Page 91 Ref. No. Description Part No. Ref. No. Description Part No. CARBON RES. 1/6W J 470 Ω METAL OXIDE FILM RES. 2W J 0.39 Ω RCX6JATZ0471 RN02R39DP004 CARBON RES. 1/4W J 18k Ω or CARBON RES. 1/4W J 1.2M Ω or R558 RCX4JATZ0183 R604#...

- Page 92 Ref. No. Description Part No. Ref. No. Description Part No. CHIP RES.(1608) 1/10W J 47k Ω CARBON RES. 1/4W J 100 Ω or R644 RRXAJB5Z0473 R874 RCX4JATZ0101 CARBON RES. 1/2W J 82 Ω or CARBON RES. 1/6W J 100 Ω R646 RCX2JZQZ0820 RCX6JATZ0101...

- Page 93 CRT CBA Ref. No. Description Part No. FUSE 4.00A/125V PAGG20CNG402 Ref. No. Description Part No. FH601 FUSE HOLDER MSF-015 XH01Z00LY001 CRT CBA (MMA-B) ------------ FH601# FUSE HOLDER FH-V-03078 XH01Z00DK001 Consists of the following FH602 FUSE HOLDER MSF-015 XH01Z00LY001 CAPACITORS FH602# FUSE HOLDER FH-V-03078 XH01Z00DK001 C501...

- Page 94 Ref. No. Description Part No. Ref. No. Description Part No. CARBON RES. 1/4W J 56k Ω or R532 RCX4JATZ0563 D1930 PCB JUMPER D0.6-P5.0 JW5.0T CARBON RES. 1/6W J 56k Ω RCX6JATZ0563 D1952# DIODE 1ZC18 or QDQZ0001ZC18 CARBON RES. 1/4W J 56k Ω or R533 RCX4JATZ0563 ZENER DIODE RD18F...

- Page 95 Ref. No. Description Part No. Ref. No. Description Part No. CARBON RES. 1/4W J 47 Ω or TRANSISTOR KTC3198(GR) or NQS40KTC3198 R1972 RCX4JATZ0470 CARBON RES. 1/6W J 47 Ω TRANSISTOR 2SC1815-GR(TPE2) QQS102SC1815 RCX6JATZ0470 CARBON RES. 1/4W J 5.6k Ω or RESISTORS R1973 RCX4JATZ0562...

- Page 96 DECK PARTS LIST Ref. No. Description Part No. B521 REV BRAKE SPRING MK12 0VM414222 Ref. No. Description Part No. B522 TG POST ASSEMBLY MK11 0VSA12080 CYLINDER ASSEMBLY MK12 NTSC 2HD N1628CYL B525 LDG BELT MK11 0VM412804 LOADING MOTOR ASSEMBLY MK11 TVCR 0VSA13465 B529 CLEANER ASSEMBLY MK10...

- Page 97 Printed in Japan 2003-04-04 HO...

Need help?

Do you have a question about the SC309D and is the answer not in the manual?

Questions and answers