Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for MAXIMATOR MPLV2

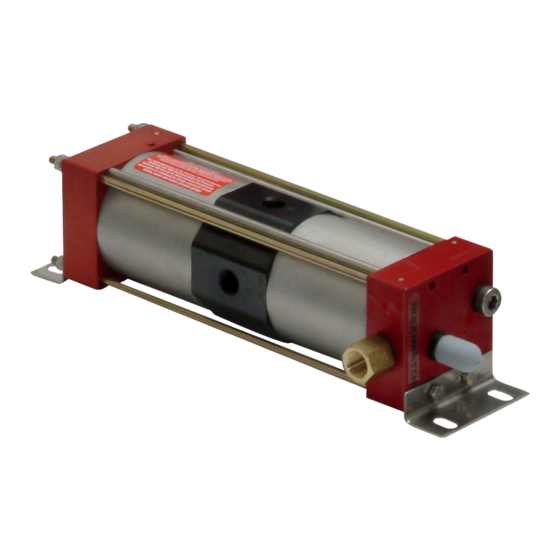

- Page 1 Air Amplifier MPLV2, SPLV2, GPLV2 Installation and operating manual...

- Page 2 Internet: www.maximator.de Warranty and liability: As a general rule, the “General Terms and Conditions” of Maximator GmbH shall apply. These terms and conditions are available at http://www.maximator.de. Warranty and liability claims shall not be accepted if they can be attributed to one or more of the causes mentioned in this manual or explicitly stipulated below: –...

-

Page 3: Table Of Contents

Contents Contents ..........General information . - Page 4 Contents ........... Installation .

- Page 5 Contents ........... . . Removal .

-

Page 6: General Information

The drive fluid and compressed fluid are fed from the same supply line and are therefore identical in terms of pressure and fluid. These instructions apply to air amplifier models MPLV2/SPLV2/GPLV2 (in the sec- tions below referred to as “compressor“) and with a serial number of above 23000001. -

Page 7: Rating Plate

General information Rating plate The rating plate is located on the pneumatic cylinder of the compressor and con- tains the following information: Max. permitted operating pres- Serial number sure Gear ratio Air amplifier 10 Manufacturer contact informa- Type (specifications from the or- tion der code) 11 Label according to applied guide-... -

Page 8: Explanation Of Symbols

General information Explanation of symbols DANGER This combination of symbol and signal word indicates a hazardous situation which - if not avoided - may lead to severe injuries or death. WARNING This combination of symbol and signal word indicates a potentially hazardous sit- uation which - if not avoided - may lead to severe injuries or death. -

Page 9: List Of Abbreviations And Formula Signs Used

General information List of abbreviations and formula signs used Abbreviation Description Gas inlet Fig. Figure ATEX EU explosion prevention directive Gas outlet Exhaust port Central European Time Drive air inlet Personal protective equipment Tab. Table Spool valve air supply Control air port Pilot valve air supply Tab. -

Page 10: Safety And Protection Measures

Safety and protection measures Safety and protection measures The following sections stipulate the residual risks associated with the product, even when used as intended. In order to reduce the risk of personal injuries and material damage, and to prevent hazardous situations, you must observe the safety information listed in this section and the warnings in all other sections of this manual. -

Page 11: Non Obvious Hazards

Safety and protection measures During assessment, check the following leak points: leak point leak type leak source Comment silencer normal operating air cylinder permanent leak of leakage operating fluids air cylinders/caps unexpected defective air cylin- ders, caps or seals on these compo- nents screw fittings unexpected... -

Page 12: Residual Risks

Safety and protection measures Residual risks 2.5.1 Start-up and shut down There is no command device for safe shut-down (E-stop). This can lead to severe injuries or death. Assess the risk for the equipment in the risk assessment. 2.5.2 Unexpected restart When restoring the pneumatic energy supply or in case of changes made to the operating parameters, the compressor may start accidentally. -

Page 13: Product Description

Product description Product description Design and function Structure (MPLV 2/SPLV 2/GPLV 2) schematic diagram xPLV2 without con- schematic diagram xPLV2 with control trol air Tab. 3-1 schematic diagram drive chamber 1 A Gas inlet to the air amplifier drive chamber 2 B Gas outlet from the air amplifier compression chamber 1 Drive air inlet... -

Page 14: Intended Use

Other fluids and other connections, in order to use different pressures on the drive side and the high-pressure side, must be approved individually by Maximator. If the air amplifier bears an ATEX label and comes with a declaration of conformi- ty, it is designated for use in corresponding potentially explosive areas. -

Page 15: Technical Specifications

Product description Gas inlet "A" Input of operating fluid. Gas outlet "B" Output of operating fluid. Exhaust port "E" Output of expanding drive fluid. Control air connection “X“ (SPLV2 and GPLV2 only) Port for control air. The compressor will only operate if the control air connection is pressurised. - Page 16 Product description Drive or operating fluids (based on ISO 8573-1) Specification Value Unit Drive pressure p , min. Drive pressure p , max. Operating fluid Compressed air or nitrogen Operating fluid temperature, min. °C Operating fluid temperature, max. °C Max. compressed air purity class of oil (Class mg/m³...

-

Page 17: Dimensions And Weight

Product description Operation with compressed air Maximator air amplifiers generally do not need a compressed air oiler as they are treated with lubricant during installation. However, after the first time an oiler is used, the drive fluid should always be oiled, since the oil washes the lubricant out. -

Page 18: Service Life

Product description Given the following conditions, based on the calculated strokes at stall pressure , it is possible to obtain a rough estimate of the leakage volume: – The strokes n calculated at stall pressure and with gas outlet (B) shut off re- sult from the leakage from the high pressure seal only. -

Page 19: Transport, Packaging And Storage

Transport, packaging and storage Transport, packaging and storage Dimensions and weight The dimensions and weight of the product are indicated in the general drawing. Delivery Scope of delivery Designation Quantity Air amplifier Installation and operating manual including Decla- ration of Incorporation and EU Declaration of Con- formity General drawing Tab. -

Page 20: Installation

Installation Installation Prerequisites for installation Observe the manual and general drawing of the product. In addition, the following conditions must be met: – The product must be free of damage. – The product must be easily accessible from all sides. –... -

Page 21: Installation Of Connecting Lines

Installation Installation of connecting lines The air amplifier is delivered without any connection screw fittings or connecting lines. For this purpose, observe the specifications in section “Connections” and on the general drawing. To prevent malfunctions, the cross-sections of the con- necting lines must be designed for the corresponding volume flows. - Page 22 Installation The following section explains how to commission the air amplifier: Check all connections for proper installation. Check all connecting lines for mechanical damage. Slowly open the shared supply line to drive air inlet P and gas inlet A. – The operating fluid flows in, and the air amplifier automatically starts pumping.

-

Page 23: Operation

Operation Operation Prerequisites for operation Observe the manual and general drawing of the product. In addition, the following conditions must be met: – The product must be free of damage. – The product must be securely attached. – The product is not subject to any vibrations greater than those typically oc- curring in high-pressure systems. -

Page 24: Maintenance

The individual maintenance activ- ities are described in the following section. Maximator recommends the intervals listed below. These intervals are calculated based on 1,300,000 strokes/year. The required maintenance intervals depend on the system and application. The intervals must be adjusted based on the given conditions of use. -

Page 25: Maintenance Work

Risk of injury due to inappropriate spare parts! Making repairs using inappropriate spare parts can lead to accidents resulting in severe injuries or death. ► Only use spare parts that comply with Maximator specifications. WARNING Risk of injury when handling lubricants! Handling lubricants can lead to accidents resulting in severe or fatal injuries. -

Page 26: System Inspection

Maintenance 7.2.1 System inspection The following section explains how to check the air amplifier for proper function: Description Qualifications Operating the system Type of mainte- Check nance Interval weekly – Safety goggles – Hearing protection Shut off the fluid outlet and adjust p to a value that is standard for the sys- tem. -

Page 27: Leak-Testing The Connections

Maintenance 7.2.2 Leak-testing the connections The following section explains how to check the connections for leaks: Description Qualifications Operating the system Type of mainte- Check nance Interval weekly Prerequisites – The air amplifier is easy to access. – All connections are pressurised. Tools –... -

Page 28: Clean Air Amplifier

Maintenance 7.2.4 Clean air amplifier The following section explains how to clean the air amplifier: Description Qualifications Clean air amplifier Type of mainte- Cleaning nance Interval quarterly Prerequisites – The air amplifier is easy to access. – The air amplifier is depressurised. Tools –... -

Page 29: Leak Detection

Maintenance 7.2.6 Leak detection The following section explains how to check the aforementioned air amplifiers for leakage: Description Qualifications Repair and service the air amplifier Type of mainte- Check nance Interval semi-annually Prerequisites The air amplifier is easy to access. Tools –... -

Page 30: Repair Air Amplifier

7.2.6 - Leak test If the compressor has passed all tests, the repair is complete. Maximator devices can be sent in for repairs to your local Maximator representa- tive. All the necessary details are available on the Maximator website http:// www.maximator.de... -

Page 31: Spare Parts And Consumables

Making repairs using inappropriate spare parts can lead to accidents resulting in severe injuries or death. ► Only use spare parts that comply with Maximator specifications. A list of the available spare parts, spare part kits and consumables can be found on the general drawing. -

Page 32: Troubleshooting

Troubleshooting Troubleshooting The following is a list of typical product faults, their causes and the appropriate solutions. If you experience any other specific or unexpected faults, please notify us at ser- vice@maximator.de Drive side Fault Cause of fault Solution The compressor does not Friction of the O-rings on –... -

Page 33: High Pressure Side

Troubleshooting High pressure side Fault Cause of fault Solution The compressor operates Check valve failure Inspect the check valves without delivering the and replace if necessary gas, or it operates errati- cally. It does not reach the calculated operating pressure. Operating fluid escapes The O-ring/seal ring on Replace and lubricate the... -

Page 34: Removal And Disposal

► Use protective gloves and goggles. ► Avoid contact with the skin. ► Observe the safety data sheet of the lubricant accordingly. If the service life has expired: Send the product back to Maximator, postage paid, for proper disposal. 0000000432 - 002 - EN... -

Page 35: Use In Explosion-Prone Zones

Use in explosion-prone zones Use in explosion-prone zones 10.1 General information If the compressors feature an ATEX label and a Declaration of Conformity to 2014/ 34/EU was provided, it will be intended for the use in areas conforming to the ap- plicable device label. -

Page 36: Temperature Class

Use in explosion-prone zones Fig. 10-2 Display of ATEX zones Legend: No zone: Zone 0: Zone 1: Zone 2: 10.2 Temperature class The temperature of the compressor mainly depends on the temperature of the operating fluid. Refer to the following table for the maximum operating fluid tem- perature required in order to attain temperature class T4: Max. -

Page 37: Operation And Maintenance

Use in explosion-prone zones 10.3 Operation and maintenance Static electricity on the product can lead to explosions. This may result in severe or fatal injuries. Never use high-power mechanisms for charge generation on or near the product. The possibility of an explosive atmosphere must be excluded before undertaking any and all work on the product –... -

Page 38: Summary Of Ignition Hazards

Summary of ignition hazards Summary of ignition hazards Ignition hazard Cause Protective measure implemented Source of ignition – Hot surfaces Heating by the operating fluid Temperature class definition and compression – Insulation prohibited – Hot surfaces Friction Operating fluid quality specification –... -

Page 39: Appendix

Appendix Appendix The appendix comprises the following documents: – EU Declaration of Conformity air amplifier MPLV2/SPLV2/GPLV2 – Declaration of Incorporation air amplifier MPLV2/SPLV2/GPLV2 – Description of the basic safety and occupational health and safety require- ments 0000000432 - 002 - EN... - Page 40 Appendix 0000000432 - 002 - EN...

- Page 41 Appendix 0000000432 - 002 - EN...

- Page 42 Appendix Description of the basic safety and occupational health and safety requirements (MRL 2006/42/EC, Appendix I) Basic requirement Applicable Met Comment BASIC SAFETY AND OCCUPA- TIONAL HEALTH AND SAFETY RE- QUIREMENTS GENERAL INFORMATION 1.1.1 Terminology 1.1.2 Safety integration principles 1.1.3 Materials and products 1.1.4 Lighting...

- Page 43 Appendix Basic requirement Applicable Met Comment 1.3.2 Risk of breakage during opera- tion 1.3.3 Risks posed by dropping or eject- ed objects 1.3.4 Risks posed by surfaces, edges Deburring generally re- and corners quired 1.3.5 Risks posed by multiple ma- chines combined 1.3.6 Risks posed by changed usage...

- Page 44 Appendix Basic requirement Applicable Met Comment 1.5.4 Assembly fault Connection labels 1.5.5 Extreme temperatures Machine may heat up or cool down 1.5.6 Fire 1.5.7 Explosion Considered separately 1.5.8 Noise Depending on installa- tion and application 1.5.9 Vibrations Vibrations within the range common for the market 01/05/...

- Page 45 Appendix Basic requirement Applicable Met Comment 1.6.5 Cleaning of machine parts in the The capacity of the in- interior ternal volume in ques- tion is not sufficient to pose a risk to the main- tenance personnel due to residues of the per- missible operating flu- ids when the compressor is at a...

- Page 46 Appendix 0000000432 - 002 - EN...

- Page 47 Appendix 0000000432 - 002 - EN...

- Page 48 Appendix Visit our website at: www.maximator.de 1999.0051 EN 0000000432 - 002 - EN...

Need help?

Do you have a question about the MPLV2 and is the answer not in the manual?

Questions and answers