Summary of Contents for Salvatore Robuschi RDV

- Page 1 Use and Maintenance Manual TRANSLATION OF THE ORIGINAL INSTRUCTIONS MACHINERY PARTLY COMPLETED MACHINERY MODEL • RDV - RGV - RBV - RCV - RNV - REV VERSION • VERTICAL PUMP EDITION • 01/2023...

- Page 2 Salvatore Robuschi & C. S.r.l./Representative’s verification. Salvatore Robuschi & C. S.r.l. is in no way responsible for any consequences as a result of incorrect operations carried out by the user.

-

Page 3: Table Of Contents

RECEIPT, HANDLING AND STORAGE .............EN-19 4.1. PACKAGING .................................EN-19 4.1.1. REMOVAL OF PACKAGING AND HANDLING ...........................EN-19 4.2. CHECKING ON RECEIPT ..........................EN-19 4.3. TRANSPORT AND HANDLING ........................EN-19 4.3.1. TRANSPORTATION OPERATIONS..............................EN-19 4.4. STORAGE ................................EN-25 RDV - RGV - RCV EN-3 VERTICAL PUMP RBV - RNV - REV... - Page 4 LINES OF LUBRICATION FEEDING ......................EN-35 7.5. ROTATION DIRECTION TEST ........................EN-35 7.6. COUPLING ASSEMBLY ..........................EN-35 7.7. PUMP START ..............................EN-36 7.7.1. CHECKS AFTER START-UP ................................EN-36 7.8. STOP ..................................EN-36 7.9. EXTENDED STOPS............................EN-37 RDV - RGV - RCV VERTICAL PUMP EN-4 RBV - RNV - REV...

- Page 5 13. APPENDIX A – AUXILIARY CONNECTIONS AND SEAL FLUSHING ....................EN-49 13.1. SEAL EXECUTION IDENTIFICATION ....................... EN-49 13.2. NAME ..................................EN-49 13.3. AUXILIARY CONNECTIONS AND BUSHES/SEAL FLUSHING ............. EN-50 RDV - RGV - RCV EN-5 VERTICAL PUMP RBV - RNV - REV...

- Page 6 15.1.3. CONNECTION TO A MOTOR PART OF OPERATING PUMPS CERTIFIED FOR OPERATION IN AREAS SUBJECT TO ATEX DIRECTIVE 2014/34/EU ..........................EN-54 15.1.4. ANALYSIS OF RISKS RELATED TO COUPLING WITH A MOTOR PART ..............EN-54 15.2. DECLARATION OF INCORPORATION ....................EN-54 RDV - RGV - RCV VERTICAL PUMP EN-6 RBV - RNV - REV...

-

Page 7: Identification

IT IS STRICTLY PROHIBITED to remove the CE identification plate and/or replace it with other plates. Should the plate be damaged, detached or removed for accidental reasons, the customer must inform the Manufacturer. RDV - RGV - RCV EN-7 VERTICAL PUMP... -

Page 8: Pump Identification Code

1.3. PUMP IDENTIFICATION CODE There is an identification code on every pump. RDV 80 20 A 4 B30 C 250 1 / A Below is the diagram of the coding applied: POS. DESCRIPTION PUMP MODEL • RDV – Vertical Pump – Closed Impeller •... - Page 9 AISI 316L AISI 316L ON DEMAND WEAR PLATE (A) ONLY FOR RD-RB TYPE (B) ONLY FOR RG-RE TYPE RELEASE • If applicable, specify the pump release (ie: A-B-C) RDV - RGV - RCV EN-9 VERTICAL PUMP RBV - RNV - REV...

-

Page 10: Group Partition

50-25 65-12 65-16 65-20 65-25 65-31 80-16 80-20(S) 80-25 80-31 80-40 100-20 100-25 100-31 100-40 125-25 125-31 125-40 150-31 150-35 150-40 200-35 250-35 * RB=2/3 ; RE=3 RDV - RGV - RCV VERTICAL PUMP EN-10 RBV - RNV - REV... -

Page 11: General Information

For pumps compliant with directive 2014/34/EU (ATEX), an addendum is provided together with this manual, which is to be considered an integral part of the manual itself. Salvatore Robuschi & C. S.r.l. shall not be held liable for improper use of the pump and/or damages resulting from operations not indicated in the technical documents. -

Page 12: Directives Of Reference

DIRECTIVES OF REFERENCE To certify the conformity of the pump with the provisions of the Directive, Salvatore Robuschi & C. S.r.l., before placing it on the market, has assessed the risks in order to verify compliance with the essential health and safety requirements provided by Directive 2006/42/EC as well as the tests and checks provided by the applied standards of reference. -

Page 13: Safety Rules

SAFETY RULES CAUTION! Failure to comply with the information in this manual may cause the pump to malfunction and cause problems for which Salvatore Robuschi & C. S.r.l. is not responsible. 3.1. PERSONAL PROTECTIVE EQUIPMENT When operating near the line for assembly and maintenance and/or adjustment operations strictly respect the main accident-prevention rules. -

Page 14: Residual Risks

CAUTION! Failure to comply with the information in this manual may cause the pump to malfunction and cause problems for which Salvatore Robuschi & C. S.r.l. is not responsible. CAUTION! It is forbidden to use the pump without its safety devices/shields. -

Page 15: Safety Requirements

Check the conformity of the performance with the order confirmation using the installed pressure gauges (or other instruments). • In the event of excessive vibrations or noise, switch off the pump and check the cause before operating on the system. RDV - RGV - RCV EN-15 VERTICAL PUMP RBV - RNV - REV... -

Page 16: Noise

< 74 100-31 < 82 < 76 125-31 < 82 < 76 100-40 < 76 125-40 < 76 Table 1 - Vibration and noise values for RD/RG/RN series RDV - RGV - RCV VERTICAL PUMP EN-16 RBV - RNV - REV... - Page 17 < 90 125-31 < 90 150-31 < 94 150-35 < 94 200-35 < 94 250-35 < 94 Table 3 - Vibration and noise values for RC series RDV - RGV - RCV EN-17 VERTICAL PUMP RBV - RNV - REV...

- Page 18 (increase in dB) on the curve and add it to the higher value between pump and motor. Difference in dB between two noise levels to be added Graph 1 - Calculation of the dB increase for two noise sources RDV - RGV - RCV VERTICAL PUMP EN-18...

-

Page 19: Receipt, Handling And Storage

CHECKING ON RECEIPT The material leaves Salvatore Robuschi & C. S.r.l. intact in all its parts and always travels at the risk of the recipient. At machine delivery, the customer is obliged to check that there is no damage caused by transport. - Page 20 Adapt the transport speed according to the flooring and type of load, avoiding sudden manoeuvres. Place the load in the chosen area. RDV - RGV - RCV VERTICAL PUMP EN-20 RBV - RNV - REV...

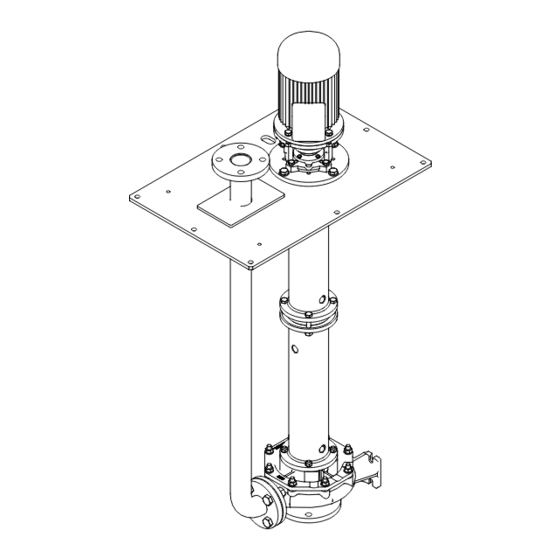

- Page 21 Connect the belts / straps to the component in the appropriate grip points, depending on the type of pump to be moved - see image below. MACHINERY PARTLY COMPLETED MACHINERY RDV - RGV - RCV EN-21 VERTICAL PUMP RBV - RNV - REV...

- Page 22 Make sure that the pump is always properly balanced and in a horizontal position. MACHINERY PARTLY COMPLETED MACHINERY RDV - RGV - RCV VERTICAL PUMP EN-22 RBV - RNV - REV...

- Page 23 After removing the pump from the wooden box, carefully lay it on the ground. MACHINERY PARTLY COMPLETED MACHINERY Hook the belts/chains into the jacking points, as shown in the following pictures. MACHINERY PARTLY COMPLETED MACHINERY RDV - RGV - RCV EN-23 VERTICAL PUMP RBV - RNV - REV...

- Page 24 Fix the belts/chains to the crane or crane system’s hook. MACHINERY PARTLY COMPLETED MACHINERY Lift the pump carefully, to put it into a vertical position. MACHINERY PARTLY COMPLETED MACHINERY Place the pump in the chosen area. RDV - RGV - RCV VERTICAL PUMP EN-24 RBV - RNV - REV...

-

Page 25: Storage

Close any holes that can connect the inside of the pump with the outside. (Only during storage) • Protect the outside of the pump by waterproof sheets RDV - RGV - RCV EN-25 VERTICAL PUMP RBV - RNV - REV... -

Page 26: Features

Frequency 50 HZ For operation outside the above limits, request an update from Salvatore Robuschi & C. S.r.l. specifying the model and serial number of the pump. Table 5 shows the maximum permissible pressure values in the pump casing (design pressure). -

Page 27: Installation

Level the plate on the supporting surface and fix it with bolts. If required fix some spacers between the plate and the supporting surface to level it. Tighten the bolts fully. RDV - RGV - RCV EN-27 VERTICAL PUMP RBV - RNV - REV... -

Page 28: Pipes

2019 1232 1521 1367 2387 1234 1559 1925 1733 3023 1415 2079 2580 1925 4023 1020 1251 1848 Table 6 - Values of the maximum permissible loads RDV - RGV - RCV VERTICAL PUMP EN-28 RBV - RNV - REV... -

Page 29: Fixing Of Pipes

1.5 times biggher than suction’s DN. Check periodically the solids and/or other parts in the tank do not clog the filter’s holes , affecting pump performances. RDV - RGV - RCV EN-29 VERTICAL PUMP... -

Page 30: Vent

Pressure gauge connections must be placed in a position as not to disturb measurement of valves, filters or other elements causing any pressure drops. RDV - RGV - RCV VERTICAL PUMP EN-30... -

Page 31: Lubrication Systems

Table 10 - Grease lubrication for bearings N.L.G.I. RECOMMENDED GREASE TYPES ESSO – BEACON EP2 MOBIL – MOBILUX EP2 SHELL – ALVANIA EP GREASER Table 11 - Grease types RDV - RGV - RCV EN-31 VERTICAL PUMP RBV - RNV - REV... -

Page 32: Installation Of Protections

5%. • if available, connect the PTCs and any other probes provided. RDV - RGV - RCV VERTICAL PUMP EN-32 RBV - RNV - REV... -

Page 33: Use

CAUTION! The pump must only be used for the purpose intended by Salvatore Robuschi & C. S.r.l. Salvatore Robuschi & C. S.r.l. will not be held responsible for damage caused due to improper use of the pump. 7.1. PRELIMINARY INSPECTIONS The following checks must be performed before commissioning the pump. -

Page 34: Check The Medium Level In The Tank

RD-RG RB-RE SIZE 32-12 32-16 32-20 40-12 40-16 40-20 40-25 50-12 50-16 50-20 50-25 65-12 65-16 65-20 65-25 65-31 80-16 80-20(S) 80-25 80-31 80-40 100-20 100-25 100-31 RDV - RGV - RCV VERTICAL PUMP EN-34 RBV - RNV - REV... -

Page 35: Lines Of Lubrication Feeding

Check the half couplings are fitted without forcing them. Otherwise remove the motor and repeat the operation. In case of problems, get in touch with Salvatore Robuschi & C s.r.l. Technical Dept. Check the distance between the two half-couplings is 3÷ 5 mm Tighten the motor fixing bolts 3÷5 mm... -

Page 36: Pump Start

Close the auxiliary liquid valves (if present). In case of shutdown with temperatures that could freeze the flushing liquid, drain the flushing pipes. For extended stops, see the paragraph "EXTENDED STOPS" RDV - RGV - RCV VERTICAL PUMP EN-36 RBV - RNV - REV... -

Page 37: Extended Stops

If the pump is removed from the system, proceed with the instructions in the "STORAGE" section after having fully cleaned and dried the hydraulics and all the components in contact with the pumped fluid. RDV - RGV - RCV EN-37... -

Page 38: Checks And Maintenance

Use only original or authorised spare parts from Salvatore Robuschi & C. S.r.l. The use of any other non-foreseen or unauthorised spare part absolves Salvatore Robuschi & C. S.r.l. from any liability in case of damage and invalidates the pump warranty. -

Page 39: Periodic Checks

50% in case of long-term use of the pump. The possibility of effectively bearing this increase depends on the pumped liquid features and the running conditions. For higher wear levels it’s recommended to replace the part. RDV - RGV - RCV EN-39 VERTICAL PUMP... - Page 40 (For clearance adjustment see the Assembly and Disassembly manual) GRANDEZZA GIOCO S [mm] 32-12, 32-16, 32-20, 40-12, 40-16, 40-20, 50-12, 50-16 65-16, 80-16, 50-20, 65-20 RDV - RGV - RCV VERTICAL PUMP EN-40 RBV - RNV - REV...

-

Page 41: Bearing Bushes

After any maintenance operation, check that the supporting column holes are not clogged (execution A and B) Check periodically and after every maintenance operation the correct level of medium in the column by the level rod (execution E). RDV - RGV - RCV EN-41 VERTICAL PUMP... -

Page 42: Suction Strainer And Filters

INSTRUMENTATION AND AUXILIARY DEVICES Check the efficiency of the instrumentation (pressure gauges, etc.) and of the accessories necessary for the adjustment and proper operation of the pump. RDV - RGV - RCV VERTICAL PUMP EN-42 RBV - RNV - REV... -

Page 43: Disassembly And Reassembly

CAUTION! It is necessary that the disassembly and reassembly are carried out by using suitable equipment and in rooms suitable for ensuring the maximum safety of the operators. RDV - RGV - RCV EN-43 VERTICAL PUMP RBV - RNV - REV... -

Page 44: Preliminary Operations

• In the case of a pump with double seal: remove the liquid remaining inside the seal chamber. RDV - RGV - RCV VERTICAL PUMP EN-44 RBV - RNV - REV... -

Page 45: Instructions For Disassembly And Reassembly Of The Pump

INSTRUCTIONS FOR DISASSEMBLY AND REASSEMBLY OF THE PUMP To disassemble and reassemble the pump, ask Salvatore Robuschi & C. S.r.l. for the dedicated manual, stating the model and serial number. IT IS SPECIFICALLY PROHIBITED to work on the pump without having this manual with you. -

Page 46: Spare Parts

Use only original or authorised spare parts from Salvatore Robuschi & C. S.r.l. The use of any other non-foreseen or unauthorised spare part absolves Salvatore Robuschi & C. S.r.l. from any liability in case of damage and invalidates the pump warranty. -

Page 47: Start Up Spare Parts And Spare Parts Set

545.1 / Bottom bearing bush 545.3 861.3 Coupling elastomers (Set) PUMPS WITH MECHANICAL SEALS Complete Mechanical Seal (Set) 433.2 (if present) Table 14 – Start-up Spare parts set RDV - RGV - RCV EN-47 VERTICAL PUMP RBV - RNV - REV... -

Page 48: Shipping To Supplier

It is also mandatory to indicate the possible presence of residual risks and the appropriate precautions to be taken in carrying out maintenance. Pack the pump properly and correctly. RDV - RGV - RCV VERTICAL PUMP EN-48 RBV - RNV - REV... -

Page 49: End Of Life And Disposal

SEAL EXECUTION IDENTIFICATION To identify the type of seal, see the paragraph "PUMP IDENTIFICATION CODE". The version is the one corresponding to point 6. RDV 80 20 A 4 B30 C 250 1 / A 13.2. NAME ρ = Fluid density [kg/dm3]... -

Page 50: Auxiliary Connections And Bushes/Seal Flushing

Flushing pressure must be: Pf = Pm/3 + 1bar Flushing medium will dissolve into the tank. RDV - RGV - RCV VERTICAL PUMP EN-50 RBV - RNV - REV... - Page 51 Fill the column with clean water + 30% of glycol and check the medium level by the appropriate level rod (and/or sensor). The mechanical seal is lubricated by the process medium and by the medium in the column pump (see the paragraph CHECK OF THE MEDIUM LEVEL IN THE TANK). RDV - RGV - RCV EN-51 VERTICAL PUMP...

- Page 52 Ø THREAD TIGHTENING TORQUE (Nm) M 10 M 12 M 14 M 16 M 18 M 20 M 22 M 24 Table 15 – Screw tightening torques RDV - RGV - RCV VERTICAL PUMP EN-52 RBV - RNV - REV...

- Page 53 CAUTION! Periodically check the degree of wear of the coupling with respect to the criteria recommended by the manufacturer. RDV - RGV - RCV EN-53 VERTICAL PUMP RBV - RNV - REV...

- Page 54 We also undertake to transmit information on the aforementioned machine (s) to the national authorities, should there be any requests, as quickly as possible, by ordinary or electronic mail. Salvatore Robuschi & C. S.r.l. is the sole party liable to compile the technical documentation relevant to the machine, should there be the need.

Need help?

Do you have a question about the RDV and is the answer not in the manual?

Questions and answers