Table of Contents

Summary of Contents for Lissmac LWSE 1200

- Page 1 CONSTRUCTION TECHNOLOGY OPERATING MANUAL CONTROL UNIT HF Motors LWSE 1200 LISSMAC Maschinenbau GmbH Lanzstrasse 4 D-88410 Bad Wurzach Telefon +49 (0) 7564 / 307-0 Telefax +49 (0) 7564 / 307-500 lissmac@lissmac.com www.lissmac.com 1/50...

- Page 2 Page 2...

-

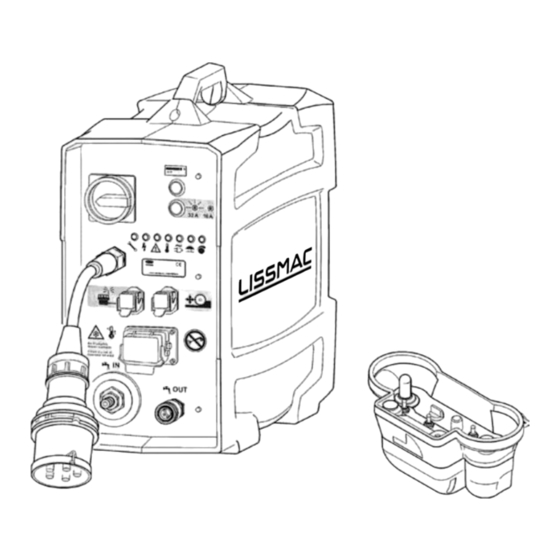

Page 3: In Case Of Emergency

If the EMERGENCY STOP is activated on the radio remote controller, the LED warning light flashes rapidly. In an emergency the sawing machine can be also switched off using the main switch on the control unit. LWSE 1200 EMERGENCY STOP Page 3... - Page 4 Description Main components control unit LWSE 1200 Main components control unit 1 Operating hours counter Water connection / water outlet 2 Main switch Main motor connection 3 Feed motor connection Name plate 4 Remote controller connection 10 Indicator lights 5 Mains connector...

-

Page 5: Remote Controller

Remote controller The remote controller can be replaced by an accumulator or a battery operated radio remote controller. Additionally the remote controller can be operated using a cable. Radio remote control The transmitter and receiver are a pair of matched units. They cannot be used with other devices. Operating modes Rechargeable battery operation: The interchangeable rechargeable battery is inserted in the base of the casing. - Page 6 Accessories Remote control The battery charger is exclusively for recharging the interchangeable rechargeable battery. The battery holder and the cable insert must not be inserted. Accessories 1 2x Interchangeable rechargeable batteries 2 Rechargeable battery charger Rechargeable battery charger with 10-30 VDC connection 3 Remote control cable 4 Battery holder 5 Key...

- Page 7 9 The control unit is isolated from the power supply 9 Connectors/plugs are clean 9 Cables are undamaged LWSE 1200 Making the mains connection and water supply 9 The power supply is earthed and fitted with a residual current operated protective device (FI Typ B;...

-

Page 8: Operation

13 Mains system selection button 7 On / Off Main motor The control unit can also be used for wire sawing with suitable LISSMAC system components. Wire sawing: Change the control unit wire sawing mode by selecting the wire saw symbol with the rotary switch (9) (diameter selector switch). -

Page 9: Starting The Control Unit

9 The sawing machine is connected to the control unit. (see «Operating instructions - Sawing machine ) 9 The remote control EMERGENCY STOP has been deactivated. LWSE 1200 Starting the control unit X Move the controls shown below on the remote controller to the 0 position. - Page 10 4.2.1 Remote control frequency change Remote control frequency change The remote control systems are equipped with a frequency generator for frequency selection. If the systems malfunction or the radio link is interrupted (another transmitter, range, empty battery), the systems immediately go into EMERGENCY OFF mode. New frequency search: You can select the next frequency by switching the start switch on the remote control off and back on.

-

Page 11: Tool Soft Start

X Turn the main motor (8) potentiometer slowly to 100% power. Select tool settings After the control unit has been started correctly the tool settings can be selected. LWSE 1200 Selecting the tool settings Proceed as follows: X Set the diameter selector switch to the desired tool and turn the main motor potentiometer from 0 to 100%. -

Page 12: Power Control

Power control The main motor and the feed motor power are controlled via the potentiometers. LWSE 1200 Power control Feed motor potentiometer (6) Main motor potentiometer (8) Adjusting the feed The feed movements are selected with the joystick. LWSE 1200 Adjusting the feed During the cutting process the feed speed is automatically assisted by a feed facility. -

Page 13: Switching Off The Control Unit

4.7.1 Manually adjusting the feed speed 9 Control unit has been initialized X Select the required feed speed via the feed potentiometer (6). 4.7.2 Feed stop So that the joystick does not have to be held in position during the travel feed motion the travel feed can be locked. - Page 14 4.10 Deactivating EMERGENCY STOP If the EMERGENCY STOP is activated on the radio remote controller, the radio and battery light (8) flash. LWSE 1200 Deactivating EMERGENCY STOP The following controls must be moved the 0 position: Feed potentiometer (6). Feed joy stick (10).

- Page 15 Responding to displays LWSE 1200 Symbols on the control unit / remote controller Symbols on the control unit Symbols on the remote controller 1 Service Radio and battery remote control Cooling water 2 Fault within the control unit 3 Control unit external fault...

- Page 16 Power and error displays on the control unit Symbol Response Possible cause Action Carried out only by LISSMAC or an Lights up red After the first 100 operating hours, then after every 200 op- authorised representative erating hours. Lights up red Fault: The control unit will not start.

- Page 17 Power and error displays on the remote controller Symbol Response Possible cause Action Flashes red Rechargeable battery voltage X Recharge rechargeable battery. too low Flashes rapidly No radio connection X Switch on the control unit. green The EMERGENCY STOP has been X Defective receiver.

-

Page 18: Servicing And Maintenance

X Clean with damp cloth no high pressure cleaner unit Service X To be performed by LISSMAC or First service after 100 operating hours an authorized worjshop. Further services after every further 200 operating hours Cleaning using high pressure cleaning equipment is not permitted. - Page 19 X Refer to fault indicator. Main motor is not running • Main motor potentiometer is in 0-po- X Contact LISSMAC customer service. X Do not start control unit, see Chapter 4.2 sition • Defective main motor On / Off switch...

- Page 20 Insufficient water pressure X Make sure that the water pressure is at least 2 bar. Water filter is blocked X Remove filter and clean X Contact LISSMAC customer service. Switch for the radio remote controller X Contact LISSMAC customer service. defective Uncontrolled water leak •...

-

Page 21: Technical Data

Technical data Dimensions in inch Technical data Parameter Value Type Frequency converter Weight Control unit incl. remote 48.5 lbs controller Remote controller separate 4.4 lbs Protection class IP 65 (4.4 X NEMA rating) Connection values 460 to 480 VAC / 60 Hz Power consumption 16 to 32 A (400 V/ 50 Hz) Power... -

Page 22: Spare Parts

Spare parts Page 22... -

Page 23: Translation Of The Original Declaration Of Conformity

LISSMAC Maschinenbau GmbH Lanzstrasse 4 D-88410 Bad Wurzach Machine description: The control unit LWSE 1200 may only be used with LISSMAC Diamond cutting systems. LWSE 1200 Electric power supply 380 to 420 VAC / 50 Hz / 60 Hz 8 kW at 16 A / 400 V...

Need help?

Do you have a question about the LWSE 1200 and is the answer not in the manual?

Questions and answers