Advertisement

Quick Links

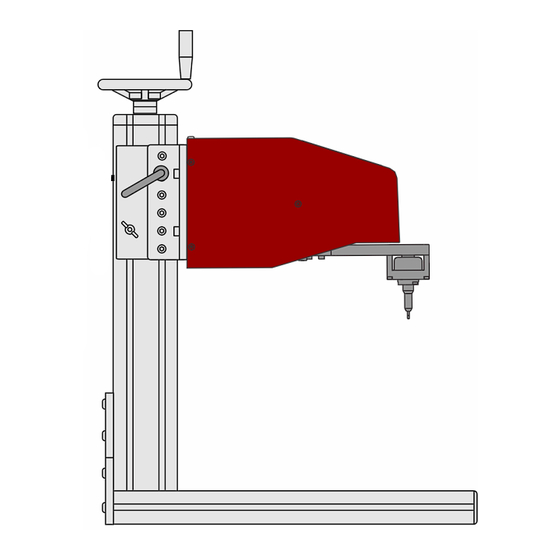

BenchMark320/BM470 Marking System – General Arrangement

SYSTEM OVERVIEW

The Telesis

BenchMark

®

®

permanently prints messages into materials such as

steel, aluminum, and plastic. An electric solenoid

accelerates a hardened pin to indent dot matrix

characters into the item being marked. Character

shape, size, density, and location are determined by

the user through the marking system software.

Marking Head. The BenchMark 320 marking head

is an electromechanical marker. A thermoformed

cover houses the internal, mechanical components

that position the pin cartridge and fire the marking

pin. A spring returns the pin to its idle position

within the cartridge. The marking head moves the

pin cartridge through X- and Y-axis motions to

reach the correct position for each dot of the

characters to be marked. The system software

controls pin extension to mark the message.

The marker's two stepper-motor drives rapidly and

accurately position the pin at coordinate-defined

locations in the marking window within 0.032 mm

(0.00125 inch). The marker accommodates the

rigorous dynamics of impacting, rebounding, and

rapid positioning of the marking pin through a

system of rigid rails and ball bearing saddles, timing

belts, and direct-drive, toothed pulleys.

34753A

Disclaimer: Printed or downloaded copies of this document are considered to be uncontrolled. Documentation is subject to change without

notice.

320 marking system

© 2020 Telesis Technologies, Inc. – All Rights Reserved

BenchMark 320/BM470 Marking System

The pin design permits high-quality, consistent

marks on irregular, slightly curved surfaces. It also

accommodates applications where marking surfaces

cannot be positioned at a consistent distance from

the marker.

The unique design of the BenchMark 320 provides

liberal access for securing and positioning parts for

printing. Using a gantry arm and a programmable

Park position, you can tuck the impact pin out of the

way when the marker finishes printing. Parts can be

easily secured and removed in front of the marking

head.

Marker Cable. The marker cable connects the

marker to the BM470 controller. The cable is 4 m

(13 feet) and is prewired to the marking head.

Pin Cartridge. The pin cartridge is machined from

engineered plastic materials and offers long life with

little maintenance. Screws attach the pin cartridge

to the marking head for easy removal, cleaning, and

pin replacement.

Marking Pins. The 25XLE-series marking pins are

made of tungsten carbide and are available in 30°

and 45° cone angles.

Controller. The BM470 controller allows full

operational control of the marking head. It contains

an integrated keyboard with an LCD display and

provides a text-only operator interface. The back

panel provides an electrical interface for connecting

optional remote I/O sources. Refer to BM470

Controller Specifications for details.

1 of 10

Advertisement

Summary of Contents for Telesis BenchMark 320

- Page 1 An electric solenoid the marker. accelerates a hardened pin to indent dot matrix The unique design of the BenchMark 320 provides characters into the item being marked. Character liberal access for securing and positioning parts for shape, size, density, and location are determined by printing.

-

Page 2: System Options

The (0.5 inch) into the back plate. Refer to the tool stand comes with two 8 mm T-nuts to aid in BenchMark 320 Marking Head Dimensions securing the parts for marking. drawing for details. - Page 3 Dimensions...... see the BenchMark 320 Marking Head Dimensions drawing Marking Depth Weight The BenchMark 320 can obtain a marking depth of Marker ....... 5.84 kg (12.865 lb) .127 mm (.005 inch) in mild steel (Rb53) using a Marker & Cable ... 6.39 kg (14.055 lb) 25XLE carbide pin with a 45°...

- Page 4 BenchMark 320/BM470 Marking System BenchMark 320 Marking Head Dimensions 4 of 10 34753A...

- Page 5 BenchMark 320/BM470 Marking System BM470 CONTROLLER Environmental Considerations The following environmental considerations must be Specifications taken into account when installing the BM470 controller. The BM470 controller specifications are subject to change without notice. Contaminants. The vented and fan-cooled controller is rated NEMA 1 (I. P. 30). In Compliance ....

- Page 6 BenchMark 320/BM470 Marking System BM470 Controller Dimensions 6 of 10 34753A...

-

Page 7: Bm470+ Enhanced Communications Software

Marker Port. The Marker port connects the Non-printable objects can be defined to specify BenchMark 320 marking head to the BM470 commands for the marker to execute (for example, controller. It supplies the marking head with Go To, Print, and Stop). - Page 8 BenchMark 320/BM470 Marking System Host Communications The BM470+ Enhanced Communications software allows you to configure the RS-232 parameters for the Comm port. The serial interface is most often used to connect a host computer, a data terminal, or a barcode scanner.

- Page 9 BenchMark 320/BM470 Marking System Extended Protocol. This protocol selection includes error checking and transmission acknowledgment. It should be used in applications where serial communication is a vital part of the marking operation. All communications are carried out in a parent/child relationship with the host being the parent. Only the host can initiate communications.

- Page 10 BenchMark 320/BM470 Marking System TRADEMARKS Telesis and BenchMark are registered trademarks of Telesis Technologies, Inc. in the United States. 10 of 10 34753A...

Need help?

Do you have a question about the BenchMark 320 and is the answer not in the manual?

Questions and answers