Summary of Contents for Microcyber MS0110

- Page 1 MS0110 HART Piezoresistance Silicon Pressure Module set User Manual Microcyber Corporation...

- Page 2 Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the information in this publication is reviewed regularly and any necessary corrections are included in subsequent editions. Microcyber Corporation 2015 The technical data may change at any time.

-

Page 3: Table Of Contents

Table of Contents Section 1 Overview ............................1 Section 2 Instruction of piezoresistance Silicon pressure module set ............. 2 Dimension ................................2 Hardware interface ............................2 Failure warning and configuration protection dial switch ................2 Bus Power Interface ............................3 Sensor Wiring .............................. - Page 4 Table of Figures Figure 1 Pressure module set dimension ......................2 Figure 2 Hardware interface instruction ......................... 2 Figure 3 Schematic diagram of silicon pressure module set ................3 Figure 4 Sensor power supply mode dial switch selection ................. 4 Figure 5 System connection schematic diagram ....................

-

Page 5: Overview

Section 1 Overview HART piezoresistance silicon pressure module set MS0110, using the fieldbus technology, is a new generation of smart temperature module and it is an indispensable field device for process control. It can be widely used in the petroleum, chemicals, electricity, and metallurgical industries, etc. -

Page 6: Instruction Of Piezoresistance Silicon Pressure Module Set

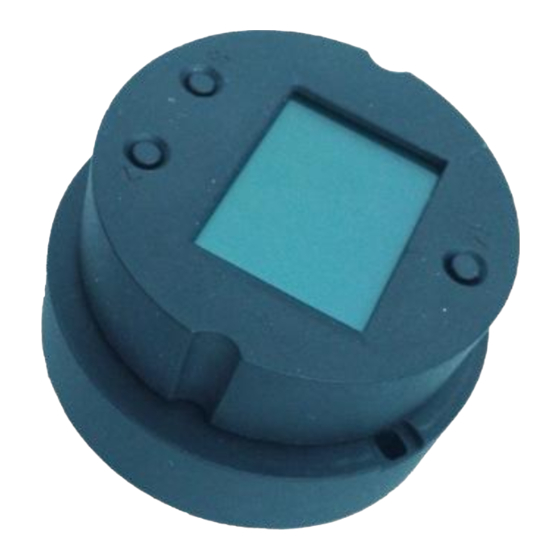

Section 2 Instruction of piezoresistance Silicon pressure module set 2.1 Dimension Φ Figure 1 Pressure module set dimension 2.2 Hardware interface The whole hardware interface of HART piezoresistance silicon pressure module set is showed as figure 2: c i l... -

Page 7: Bus Power Interface

2.4 Bus Power Interface MS0110 HART piezoresistance silicon pressure module set power and bus share the same a pair of cable and it is called bus cable. The specific fieldbus cable recommended by IEC61158-2 is suggested. -

Page 8: System Connection

HART silicon pressure module set supports constant voltage and constant current pressure sensor. The connection for the two drive mode is as showed as figure 3. If pressure sensor internal doesn’t have temperature measurement diode, silicon pressure module set will take A/D internal temperature sensor for temperature compensation by default. -

Page 9: Working Principle

Section 3 Working principle The principle of pressure measurement for Silicon pressure module set is based on silicon pressure sensor, using advanced microcontroller and sensor digitization measuring technique, high accuracy algorithm to ensure pressure signal’s high precision measurement. The communication interface of intelligent instrument uses advanced HART technology. - Page 10 It also take charge of LCD module, intuitively show pressure module set’s current state and tested pressure value.

-

Page 11: Pressure Board Set Setting

Section 4 Pressure board set setting 4.1 Topology Connection The connection modes of smart transmitter with HART piezoresistance silicon pressure module set can be divided into 4~20mA compatible mode and networking mode. 4~20mA Compatible Mode(refer to figure 8)... -

Page 12: Function Configuration

3) Under short address format, it supports at ost 15 equipment networking. 4.2 Function Configuration HART piezoresistance silicon pressure module set supports Microcyber’s HartMPT Configuration Software for configuration debugging. Following is an example for HartMPT Configuration Software, including functions below: 1) Basic information configuration: configure the basic information of device online, including tag, address, date, assemble number and so on;... -

Page 13: Configuration Information Setting

Figure 10 Basic Information After information modification, click the “Apply” button to download it into device. 1) The address selection range is 0~15; 2) Information can be input 32 characters at most; 3) The maximum length of the description is 16 defined characters;... -

Page 14: Current Calibration

Figure 11 Configuration Information Damp: range 0~32s Unit: PV unit modification affects variables related to unit, such as the upper or lower limit for the range or for the sensor. When you modify the unit, you can’t modify upper or lower limit for the primary variable range, instead, you should modify them separately. - Page 15 2) Set device rolling address as 0, please refer to basic info configuration. If rolling address is 0 already, this step can be skipped. 3) Enter current calibration option TAB. 4) Select “current value” as 4mA, when the ammeter is stable, input the value in ammeter to “adjustment value”, and then click “Apply”.

-

Page 16: Variable Monitoring

Figure 12 Current Calibration Note: Calibration current and fixed current output functions are only in the moment when the polling address is 0. It will be at absolute digital communication mode at other polling addresses, the failure info is “Command Execution Failure”. -

Page 17: Special Commands

4.2.6 Special Commands The user is able to configure LCD type, small signal cut parameter, and is able to operate data restore and save via special command optional tab. Shown in Figure 14: Figure 14 Special commands... -

Page 18: Adjustment In The Field

Section 5 Adjustment in the Field 5.1 LCD and Button Instruction HART piezoresistance silicon pressure module set has lattice LCD and local button adjustment function, and the user can do parameter adjustment in local for HART piezoresistance silicon pressure module set. -

Page 19: List Function Items

5.3 List Function Items Here is the introduction for HART piezoresistance silicon pressure module set’s local button operations. With field adjustment, the user shall adjust PV unit, PV upper limit, PV lower limit, LCD display type etc. The supported functions are shown as following... -

Page 20: Figure 15 Function Switch

Figure 15 Function Switch... -

Page 21: Description For Special Symbols

5.4 Description for Special Symbols Display Description PV mark SV mark Square root mark larger or equal to range upper limit mark Smaller or equal to range lower limit mark Write protection mark Alarm mark Communication mark... -

Page 22: Maintenance

Section 6 Maintenance Phenomenon Solution Pressure Module Connection Check the bus cable connection Check bus power polarity Check bus cable shield, whether it is single point earthing or not Bus Power Bus power should in the range 10.5~32V for the pressure module, and bus noise and ripple should fulfill: 1) peak-to-peak value noise 16mV, 7~39kHz;... -

Page 23: Technical Specifications

Section 7 Technical Specifications 7.1 Basic Parameters Content Index Bus Connection (4~20)mA + HART (11.9~42)VDC Bus Power (11.9~30)VDC (Intrinsically Safety) (0~1500)Ω (Normal) Load Resistive (230~550)Ω (With HART) Input Signal Metal capacitance sensor Display COG128x64 Working Temperature (-20~70)℃ Storage Temperature (-40~85)℃... - Page 24 Microcyber Corporation Add: 17-8 Wensu Street, Hunnan New District, Shenyang, China 110179 Tel: 86-24-31217278 Fax: 86-24-31217293 E-mail: guo.ruibing@microcyber.cn Website: www.microcyber-fieldbus.com...

Need help?

Do you have a question about the MS0110 and is the answer not in the manual?

Questions and answers