Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Huvema HU 200 BG

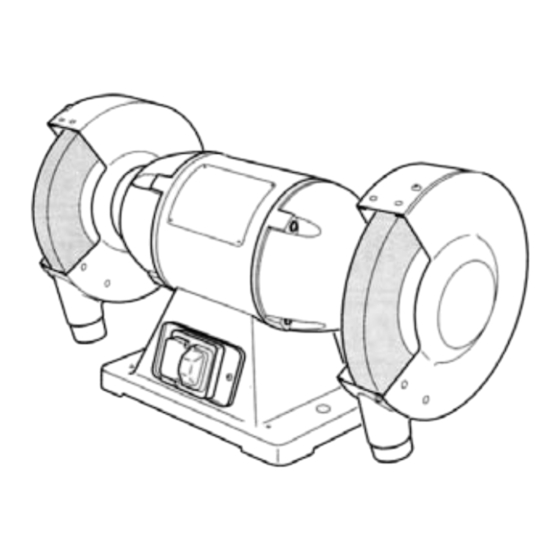

- Page 1 G R I N D I N G M A C H I N E S HU 200 BG - HU 250 BG...

-

Page 2: Table Of Contents

Handling of the machine Environment requirements for installation Electrical (dis)connection and operation Operation Maintenance Electric schemes 14.1 HU 200 BG (230V - 400V) 14.2 HU 250 BG (400V) CHANGES AND T YPING ERRORS RESER VED CHANGES AND T YPING ERRORS RESER VED... -

Page 3: General Safety Rules For All Machines

200 bG - hU 250 bG rindinG machines 1. G eneral safeTy rUles for all machines N.B.: Read the instructions carefully in order to avoid any problems. As with all machinery there are certain hazards involved with operation and use of this machine. Using the machine with respect and caution will considerably lessen the possibility op personal injury. -

Page 4: Additional Safety Rules

Burrs and chips should only be removed using a sweeper or other aid, never with your bare hands! Never leave the machine running unattended. Always wear safety glasse 3. T echnical daTa HU 200 BG HU 250 BG 200 x 25 x 20 mm 250 x 38 x 25,4 mm Grinding stone... -

Page 5: Machine Parts

4. m achine parTs For safety reasons it is recommended that you use a base CHANGES AND T YPING ERRORS RESER VED... -

Page 6: Unpacking And Checking The Machine

5. U npackinG and checkinG The machine 5.1 G rindinG machine 5.2 e yeshield Description Q’ty Eyeshield Screw Eyeshield bracket Washer Hexagonal nut Hexagonal bolt Eyeshield bracket Spring washer Spring washer Screw Support Splash screen CHANGES AND T YPING ERRORS RESER VED CHANGES AND T YPING ERRORS RESER VED... -

Page 7: Tool Rest

5.3 T ool resT Description Q’ty Tool bracket Nexagonal nut Washer 5.4 m oUnTnG The Tool resT Make sure there is a 5 mm gap between the grinding stone and the tool rest. CHANGES AND T YPING ERRORS RESER VED... -

Page 8: Mounting The Eyeshield

5.5 m oUnTinG The eyeshield 5.6 r eplacinG The GrindinG sTone Step 1 Step 2 Step 3 Step 4 CHANGES AND T YPING ERRORS RESER VED CHANGES AND T YPING ERRORS RESER VED... -

Page 9: Adjusting The Protective Covers

Step 5 5.7 a djUsTinG The proTecTive covers Step 1: Loosen screws A to D and Step 2: Gently tap the bracket of the protective cover with remove the side panel a wooden mallet, until the gap between the cover and the grinding stone is about 10 mm. -

Page 10: Balancing The Grinding Stone

5.8 b alancinG The GrindinG sTone CHANGES AND T YPING ERRORS RESER VED CHANGES AND T YPING ERRORS RESER VED... -

Page 11: Parts Drawings And Lists

6. p arTs drawinGs and lisTs # Only HU 250 BG * Only HU 250 BG CHANGES AND T YPING ERRORS RESER VED... - Page 12 * Only HU 250 BG CHANGES AND T YPING ERRORS RESER VED CHANGES AND T YPING ERRORS RESER VED...

-

Page 13: Base - Universal Or With Tray (Both Optional)

7. b Universal or wiTh Tray boTh opTional Always screw the machine onto the base and anchor the base to the floor! CHANGES AND T YPING ERRORS RESER VED... -

Page 14: Dust Collector (Optional)

8. d UsT collecTor opTional CHANGES AND T YPING ERRORS RESER VED CHANGES AND T YPING ERRORS RESER VED... -

Page 15: Handling Of The Machine

9. h andlinG of The machine 10. e nvironmenT reqUiremenTs for insTallaTion 11. e lecTrical connecTion and operaTion 12. o peraTion 13. m ainTenance CHANGES AND T YPING ERRORS RESER VED... -

Page 16: Electric Schemes

14. e lecTric schemes 14.1 hU 200 bG (230v - 400v) (RECOM) 50Hz 230V Limit of 0.75mm equipment 0.75mm 0.3kW/230V 2.0A/2850rpm PE 0.75mm (RECOM) 50Hz 400V 0.75mm Limit of equipment 0.75mm 0.3kW/400V 1.0A/2850rpm PE 0.75mm Indication (type) Description Q’ty Remarks... -

Page 17: 250 Bg (400V)

14.2 hU 250 bG (400v) Item designation Description & Function Technical Data Remark E-STOP 600Vac,10A (single phase) Option (three phase) Magnetic contactor 230Vac,10A(single phase) CE,KJD12 400Vac,10A(three phase) CE,JD2 Overload protector CE,BTH (1 phase) Overload protector 1.4-2.2/1.8 (3 phase) CE,BTH − Plug for Supply 250V,16A (single phase) −... - Page 18 All rights reserved. No part of this booklet may be reproduced in any form, by print, photoprint, microfilm or any other means without written permission from the publisher. © Huberts bv, Kennedylaan 14, Veghel, the Netherlands. Internet: www.huvema.nl CHANGES AND T YPING ERRORS RESER VED CHANGES AND T YPING ERRORS RESER VED...

- Page 19 (in accordance with supplement II A of the Machinery Directive) Industrie & Handelsonderneming Huberts bv, Kennedylaan 14, 5466 AA Veghel, the Netherlands, in the capacity of importer, is to be held responsible for declaring that the Huvema machines: Grinding machines HU 200 BG - HU 250 BG...

Need help?

Do you have a question about the HU 200 BG and is the answer not in the manual?

Questions and answers

Good day. We use your product. The instructions do not contain bearing numbers to replace them. Tell me the bearing numbers. Thank you!

The bearing number for the Huvema HU 200 BG is KGR 6206 2RS.

This answer is automatically generated