Summary of Contents for Caravaggi Bio 150

- Page 1 USE AND MAINTENANCE INSTRUCTION MANUAL Bio 150 BEFORE USING THE MACHINE , READ THE INSTRUCTION MANUAL...

- Page 2 1. HOW TO USE AND KEEP THE INSTRUCTION MANUAL This instruction manual is aimed at the user of the machine , the owner , the maintenance cleaning operator and the repair technician and must always be avaiable for consultation. The instruction manual shows the user for which the machine was designed and the machine’s technical characteristics .

-

Page 3: Identification Of Main Parts

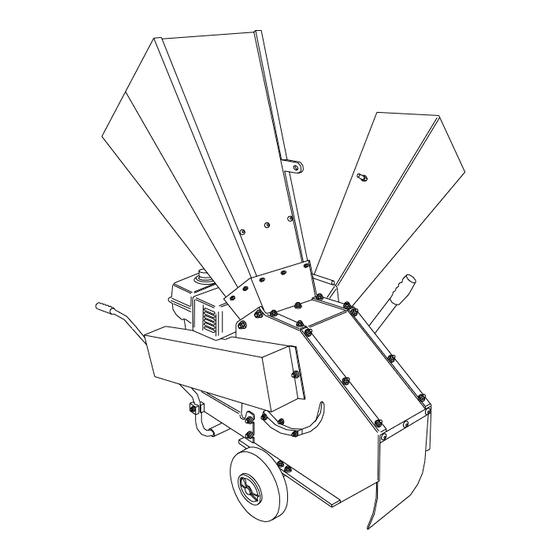

2. IDENTIFICATION OF MAIN PARTS 1. Hopper with guards 2. Chaff cutter hopper 3. Petrol engine-electric motor 4. Handles for transport 5. Outlet 6. Chassis 3 point 7. Power take-off for MTC 8. Power take-off for a tractor Fig. 1 Fig. -

Page 4: Correct Use Of The Machine

The operator must be aware of all the instructions given in the instruction manual . 4. UNPACKING AND PREPARATION The Bio 150 bio-shredder is delivered partially dismantled. It ca be arranged on pallets to facilitate handling and transport before installation, depending on the versions. - Page 5 Kg. 150 Fig. 3 Fig. 4 Fig. 5 Fig. 6 Fig. 7...

-

Page 6: Technical Characteristics

5. TECHNICAL CHARACTERISTICS The EC identification plate is clearly visible on the Bio 150 bio- chopper ( fig. 8 ) . In all communications with the manufacturer state the serial number on the identification plate . MACCHINE INDUSTRIALI 25037 PONTOGLIO (BS) - VIA M. ADAMELLO, 20 TELEF. -

Page 7: Safety Norms

6. SAFETY NORMS Training The machine must not be used by under 16’s and persons who have not learnt the user instructions . The operator is responsible for third parties present in the work area . Keep children and domestic animals at distance when the bio-chopper is in operation . - Page 8 If the blades undergo heavy shock and function in an anomalous manner , stop the engine , remove the spark plug hood and request expert advice . Caution ! The fuel is highly flammable : Keep fuel only in the containers made avaiable for this purpose ; ...

- Page 9 7. START - UP Caution ! Before starting up the engine / motor check that the bio- chopper is on a stable surface and that there are no animals or unauthorised persons in the work zone . Read the engine / motor manufacturer’s instruction book carefully . Check that there is oil and fuel in the tank .

- Page 10 Functioning Having correctly prepared the bio-chopper you can now proceed to working the material to be chopped . Upper hopper Load trimming and foliage into the upper loading hopper , taking account of avaiable power in function of the model you possess ( fig. 11 ) .

-

Page 11: Maintenance

/ motor and in any case ensure that there is no possibility of the machine functioning . Suitable gloves are obligatory for all maintenance operations . To facilitate transportation of the Bio 150 bio-chopper its overall size can be reduced by folding the side hopper inwards as follow : ... - Page 12 8.1 Blade replacement Unscrew the retaining screws and remove the upper hopper . Insert the keys in the two apertures ( fig. 14 ) and remove the blade. Proceed with sharpening the blade or , in the case of replacement , request an original spare part from the manufacturer and reassemble following the instructions in reverse order .

- Page 13 8.3 Breaker bar removal , inversion and replacement Unscrew the retaining screws and remove the upper hopper Remove the side hopper by unscrewing the 3 nuts ( fig. 5 ) . Remove the transmission belt casing as shown in fig. 17 . ...

- Page 14 8.4 Routine maintenance Beginning Before End of of season each job season Check engine oil level Check screws , tightness , casing , hopper , etc . Check belt tension and state of wear ...

-

Page 15: Troubleshooting - Remedies

9. TROUBLESHOOTING - REMEDIES Troubleshooting Remedies The bio-chopper does Check belt tension and condition , blocked not start pulleys , PTO or gears . Check cutters , blade , counter-blade presence of material in the milling chamber . Check state of engine / motor ( consult the instruction manual supplied ) . - Page 16 Seller authorised CARAVAGGI importer . 2. You are required to present the guarantee duly filled in or the bill , if this is not avaiable. 3. The claim will be completed by the Dealer , who will forward it to the Manufacturer .

-

Page 17: Declaration Of Conformity

11. DECLARATION OF CONFORMITY The company Caravaggi , hereby declares under its own responsability , that the machine: BIOSHREDDER Type BIO 150 electric ( E ) , with petrol engine ( B ) , and with P.T.O. ( MTC , PTO ) ,... - Page 18 SPARES BIO 150...

- Page 19 SPARES BIO 150 Pos. Description Q.ty Code Rivet ø 4,9x16 Al 530002000 Upper rubber 010302000 010610000 Washer ø5x15x2 510003005 Angle 010310000 Lower rubber 010410000 Knob M8 F 013710000 Upper hopper 010304100 Chaff cutter hopper 011810000 Washer ø11x22x2 530001800 Self-lock nut M10...

- Page 20 SPARES BIO 150...

- Page 21 SPARES BIO 150 Pos. Description Q.ty Code Thickness element PS ø30x1 012720001 Rotor 010101050 Seeger ring E-15 510012001 Rotor pin 010102000 Key 8x25 530004000 Washer ø16x3 511120020 Blade TR 3 010105001 Spacer H=21 010105000 Spacer H=18 010108001 Sieve pin C...

- Page 22 SPARES BIO 150 B / E...

- Page 23 SPARES BIO 150 B / E Pos. Description Q.ty Code Electric motor 5,5 HP 019200000 Centrifugal clutch 1A 122 (E) 013800028 Retainer washer 014900006 Engine 13 HP 014100001 Engine support 014500001 Engine adjustment plate 014500005 Wheel 014700000 Cotter pin R 5...

- Page 24 SPARES BIO 150 MTC...

- Page 25 SPARES BIO 150 MTC Pos. Description Q.ty Code Seeger ring E-20 510009000 Ball bearing 6204 2 RS 540001000 Support AR 010201000 Gudgeon pin 010202000 Cotter pin R 2,5 530003000 Decal 010920000 Shaft 010203000 Screw TE M8x20 500008008 Washer ø9x18 510005009...

- Page 26 SPARES BIO 150 PTO...

- Page 27 SPARES BIO 150 PTO Pos. Description Q.ty Code Screw TE M6x16 520004506 Washer ø6x18 510000835 Protective hood P.T.O. 520008003 Belt cover casing 014300254 Washer ø11x22 530001800 Screw TE M10x30 500010010 Protective metal sheet 014300256 Gudgeon pin 010202001 Cotter pin R5...

- Page 28 SPARES BIO 150 4 R...

- Page 29 SPARES BIO 150 4 R Pos. Description Q.ty Code Cotter pin R5 530001000 Wheel 3.50-8 014700001 Axle 014300270 Drawbar support 014300269 Screw TE M10x70 500070010 Seeger ring E-20 510009000 Screw TE M8x70 500070008 Self-lock nut M10 520007010 Swivelled bracket 014300271...

- Page 30 CARAVAGGI MACCHINE INDUSTRIALI Via Monte Adamello , 20 25037 Pontoglio ( BS ) - ITALY Tel. +39 030 7470464 - Fax +39 030 7470004 Internet http://www.caravaggi.com Email info@caravaggi.com Rev.1-2008...

Need help?

Do you have a question about the Bio 150 and is the answer not in the manual?

Questions and answers

How tgo unblock Bio 150?