Summary of Contents for VERDER Carbolite Gero MTF 10/25/130

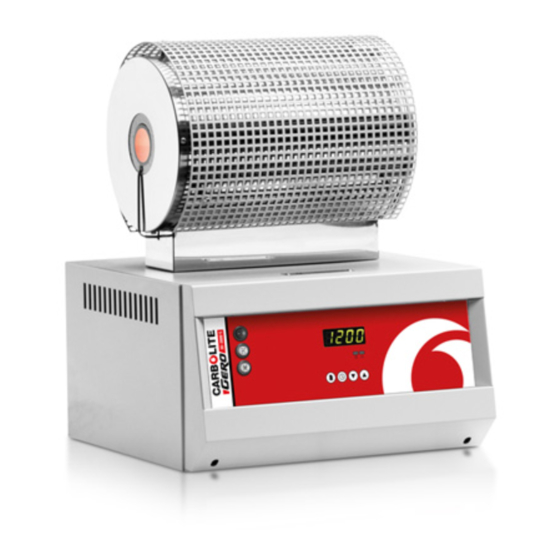

- Page 1 Installation, Operation and Maintenance Instructions 1000°C Small Tube Furnace - MTF Model: 130mm No Controller MTF 10/25/130 + No Controller MEN-MTF1025-005_NOCTRL 08-01-2018...

-

Page 2: Table Of Contents

Contents This manual is for guidance on the use of the Carbolite Gero product specified on the front cover. This manual should be read thoroughly before unpacking and using the furnace or oven. The model details and serial number are shown on the back of this manual. - Page 3 7.0 Wiring Diagrams WA-11-30 WA-11-31 8.0 Fuses and Power Settings Fuses Power Settings 9.0 Specifications Environment...

-

Page 4: Symbols And Warnings

1.0 Symbols and Warnings 1.0 Symbols and Warnings Switches and Lights Instrument switch: when the instrument switch is operated the temperature control circuit is energised. Heat light: the adjacent light glows or flashes to indicate that power is being supplied to the elements. Heat switch: the switch disconnects power to the heating elements;... - Page 5 1.0 Symbols and Warnings Caution – Double Pole/Neutral Fusing...

-

Page 6: Installation

2.0 Installation 2.0 Installation Unpacking and Handling When unpacking or moving the product always lift it by its base or by both ends of the main body. Never lift it by its work tube or the surrounding insulation. Use two or more people to carry the product and control box. -

Page 7: Electrical Connections

2.0 Installation Horizontal models: if heavy fittings are to be clamped to the end of an extended work tube they can increase the bending stress at the centre of the tube. Support such fittings in such a way that expansion of the tube is allowed. If a metal work tube is being used in the furnace, ensure that it is earthed. - Page 8 2.0 Installation Products with a factory fitted supply cable are designed to be wired directly to an isolator or fitted with a line plug. Products without a factory fitted supply cable: require a permanent connection to a fused and isolated supply should be made to the internal terminals after temporary removal of the product's electrical access panel.

-

Page 9: Operation

3.0 Operation 3.0 Operation Operating Cycle This product is fitted with an instrument switch which cuts off power to the control circuit. Connect the product to the electrical supply. There is also a heater switch which can be used to disconnect power to the elements. Operate the instrument switch to activate the temperature controller. -

Page 10: Operator Safety

3.0 Operation Operator Safety The ceramic materials used in the product manufacture become electrically conductive to some extent at high temperatures. DO NOT use any conductive tools within the product without isolating it. If a metal work tube is used, it must be earthed (grounded). Switch off the heater switch whenever loading or unloading the product. -

Page 11: Running At Low Temperatures

3.0 Operation 3.6 Running at Low Temperatures The power limit may be adjusted to a low level in order to achieve better control when operating the product at a low temperature. Before changing the power limit, record the default settings for possible future use. Refer to section 0.1 for default power limit. If the product fails to reach the desired temperature, refer to sections 3.0 and 1.0. -

Page 12: Maintenance

4.0 Maintenance 4.0 Maintenance General Maintenance Preventive rather than reactive maintenance is recommended. The type and frequency depends on the product use; the following are recommended. 4.1.1 Cleaning Soot deposits may form inside the furnace, depending on the process. At appropriate intervals remove these by heating as indicated in the General Operation Notes. -

Page 13: Repairs And Replacements

5.0 Repairs and Replacements 5.0 Repairs and Replacements Safety Warning - Disconnection from Power Supply Immediately switch the product off in the event of unforeseen circumstances (e.g. large amount of smoke). Allow the product to return to room temperature before inspection. Always ensure that the product is disconnected from the electrical supply before repair work is carried out. -

Page 14: Thermocouple Replacement

5.0 Repairs and Replacements Thermocouple Replacement The coverings and guards which must be removed to gain access to the thermocouple depend on the model, its orientation (horizontal or vertical), and possibly other options and fittings. It will usually be necessary to separate the product from its base or stand. On horizontal models one outer end-cap will need to be removed and on vertical models the terminal cover. - Page 15 5.0 Repairs and Replacements If any fuse has failed, it is advisable for an electrician to check the internal circuits. Replace any failed fuses with the correct type. For safety reasons do not fit larger capacity fuses without first consulting Carbolite Gero. The fuses are located at the cable entry point.

-

Page 16: Element Replacement

5.0 Repairs and Replacements Element Replacement See section 5.2 - wearing a face mask is required. The coverings and guards which must be removed to enable replacement of the wound tube element depend on the furnace model, its orientation (horizontal or vertical), and other options and fittings. -

Page 17: Fault Analysis

6.0 Fault Analysis 6.0 Fault Analysis Furnace Does Not Heat Up The HEAT The heating element Check also that the SSR is working light is ON has failed correctly The controller shows a The HEAT The thermocouple has broken or has very high temperature light is OFF a wiring fault... -

Page 18: Product Overheats

6.0 Fault Analysis Product Overheats Product only heats up The controller when the instrument shows a very high The controller is faulty switch is ON temperature The thermocouple may be The controller faulty or may have been shows a low removed out of the heating temperature chamber... -

Page 19: Wiring Diagrams

7.0 Wiring Diagrams 7.0 Wiring Diagrams WA-11-30 Connections below show single phase with indirect safety switch(es). F1, F2, F3 Fuses Filter R1/1, R1/2 Relay Contactor Relay Cables Temperature Controller Blue Control Thermocouple Solid State Relay GR/Y Green + Yellow Safety Switch Grey Heat Lamp Pink... - Page 20 7.0 Wiring Diagrams WA-11-31 Connections below show single phase with safety switches and over-temperature control. F1, F2, F3 Fuses Filter R1/1, R1/2 Relay Contactor Relay Temperature Controller Cables Over-Temperature Controller Blue Over-Temperature Thermocouple Control Thermocouple GR/Y Green + Yellow Solid State Relay Grey Safety Switch Pink...

-

Page 21: Fuses And Power Settings

8.0 Fuses and Power Settings 8.0 Fuses and Power Settings Fuses F1 - F3: Refer to the circuit diagrams. GEC Safeclip of the type shown Fitted if supply cable fitted. Internal (glass type F up to 16 A) Supply Fitted on board to some types 38 mm x 10 mm type F fitted on Fuses of EMC filter. -

Page 22: Specifications

9.0 Specifications 9.0 Specifications Carbolite Gero reserves the right to change the specification without notice. Work Uniform Work Tube Heated Tube Zone Model Temp Power Length Length Weight Bore Length (°C) (kW) (mm) (mm) (kg) (mm) (mm) Tube furnaces with a ceramic work tube wound with resistance wire 1000 10/25/130 note... - Page 23 Notes Service Record Engineer Name Date Record of Work...

- Page 24 The products covered in this manual are only a small part of the wide range of ovens, chamber furnaces and tube furnaces manufactured by Carbolite Gero for laboratory and industrial use. For further details of our standard or custom built products please contact us at the address below, or ask your nearest stockist.

Need help?

Do you have a question about the Carbolite Gero MTF 10/25/130 and is the answer not in the manual?

Questions and answers