Summary of Contents for Bermar BRC10

- Page 1 User Guide Inverter BRC10 Variable Speed A.C. drive for induction motors Part Number: 0478-0725-05 Issue: 05...

- Page 2 Compliance Information Manufacturer's EU Authorized Representative: BER-MAR SRL, Via C. Bassi, 28/A, 40015 S.Vincenzo di Galliera, Bologna, Italy. Tel +39 051 812120, info@bermar.it Original instructions With reference to the UK Supply of Machinery (Safety) Regulations 2008 and the EU Machinery Directive 2006/42/EC, the English version of this Manual constitutes the original instructions.

-

Page 3: Table Of Contents

11.11 Motor overload protection .........113 Control connections ..........30 Communication connections .......33 Getting started ........35 Understanding the display ........35 Using the keypad ..........36 Understanding the menu structure ......38 Saving parameters ..........38 Restoring parameter defaults ......38 Drive security ............38 Inverter BRC10 User Guide... -

Page 4: Safety Information

Hazards If a plug and socket are used to connect the PDS / BDM to the supply, This User Guide applies to the Inverter BRC10 which are Basic Drive the plug should conform to IEC60309. Modules (BDM) and auxiliary equipment. All safety information within A hazard may exist where the drive is incorporated into a product which this guide must be observed. -

Page 5: Adjusting Parameters

1.20 Hazardous materials RoHS, REACH WEEE etc. details are available at www.drive-setup.com/ environment Inverter BRC10 User Guide... -

Page 6: Product Information

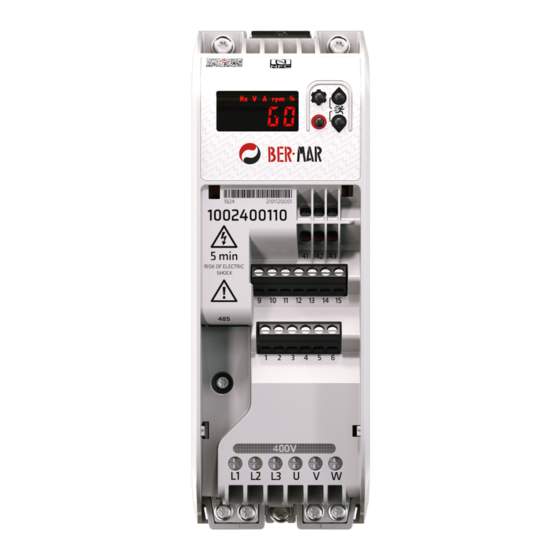

Introduction Inverter BRC10 is a general-purpose drive that delivers maximum machine performance of induction motors for a range of applications. The voltage and power rating of the drive should be chosen to suit the mains supply and the induction motor to be controlled. -

Page 7: Rating Information

The date code is provided in a four digit format. The first two digits indicate the year and the remaining two digits indicate the week number (within the year). Example: A date code of 2110 would correspond to week 10 of year 2021. Inverter BRC10 User Guide... -

Page 8: Drive Ratings

The drive will initiate an error if the drive output current exceeds the over-current threshold, which could occur in the event of a short circuit of the motor output cables. The over-current threshold is the maximum current the drive can measure. Inverter BRC10 User Guide... -

Page 9: Drive Features

Items supplied with the drive Table 2-3 Items supplied with the drive Description Further Details 2 x 8 mm M4 (Phillips/Slotted) These screws should be used to attach the ground cable as covered in section 4.1.3 Ground connections. Inverter BRC10 User Guide... -

Page 10: Mechanical Installation

Openings for cables etc. must be sealed with materials meeting the 5VB requirement, or else have a baffle above. See Figure 3-2 for acceptable ÷ baffle construction. The distance below the drive where this applies to the enclosure wall = Distance from the cabinet wall to the drive 0.0875. Inverter BRC10 User Guide... -

Page 11: Drive Dimensions And Mounting

Figure 3-3 below shows the overall dimensions of the drive. The mounting location marked is only found on BRC1003 drive. Figure 3-3 Overall dimensions Table 3-1 Overall dimensions Weight Model Number BRC1001 6.14 2.70 5.12 1.54 BRC1002 7.56 2.70 5.20 1.76 BRC1003 7.56 3.54 5.20 Inverter BRC10 User Guide... - Page 12 1.81 5.99 2.70 1.34 0.19 1.34 BRC1002 1.81 7.36 2.70 1.34 0.19 2.17 BRC1003 1.81 7.36 3.54 1.77 0.19 NOTE The EMC backplate screw is located slightly off centre on the frame size 3 drive (BRC1003). Inverter BRC10 User Guide...

-

Page 13: Enclosure Dimensions

filter and drive input short as possible. External controller Table 3-4 Drive clearances Drive Clearances BRC1001S00025 All other drives 100 mm (3.94 in) 45 mm (1.77 in) 0 mm (0 in) Inverter BRC10 User Guide... - Page 14 P0 is the air pressure at sea level • PI is the air pressure at the installation Typically, a factor of 1.2 to 1.3 can be used. This will allow for any pressure drops in dirty air-filters. Inverter BRC10 User Guide...

-

Page 15: Drive Fan Operation

Ensure all screw terminals remain tight Crimp terminals Ensure all crimp terminals remain tight – check for any discoloration which could indicate overheating Cables Check all cables for signs of damage Ground connections Must be inspected and tested at appropriate intervals Inverter BRC10 User Guide... -

Page 16: Electrical Installation

Single phase supply connections Figure 4-1 Single phase power connections Op onal EMC Filter Op onal Line Reactor Fuses / Live Neutral Supply Ground For dual-rated drives, single phase connections should be made to L1 and L2. Inverter BRC10 User Guide... - Page 17 Two copper conductors of the same cross-sectional area as the input phase conductor. If the drive is connected via a plug/socket conforming to IEC60309 then a single protective earthing conductor of at least 2.5 mm as part of a multi- conductor cable with adequate strain relief is permitted. Inverter BRC10 User Guide...

-

Page 18: Terminal Torque Settings

To ensure that the motor and cable are protected against overload, the drive must be programmed with the correct motor rated current. A fuse or other protection must be included in all live connections to the A.C. supply. Inverter BRC10 User Guide... - Page 19 The maximum motor cable lengths specified in section 4.3.1 Cable lengths. are for cables that are shielded and contain four cores. Typical capacitance for this type of cable is 130 pF/m (i.e. from one core to all others and the shield connected together). Inverter BRC10 User Guide...

-

Page 20: Fuse And Mcb Selection

When protected by fuses or circuit breakers with maximum ratings as specified in Table 4-5, this product is suitable for use on a circuit capable of delivering not more than 5,000 RMS symmetrical amperes, 480 V maximum (up to the rated voltage of the drive module). Inverter BRC10 User Guide... -

Page 21: Supply Requirements

For all drive ratings, 2 % line reactors permit drives to be used with a supply unbalance of up to 3.5 % negative phase sequence (equivalent to 5 % voltage imbalance between phases). Higher values may be used if necessary but may result in a loss of drive output (reduced torque at high speed) because of the voltage drop. Inverter BRC10 User Guide... - Page 22 NOTE Inverter-rated or inverter duty motors have a reinforced insulation system designed for the fast-rising pulsed output voltage (PWM) generated by variable frequency drives. Inverter BRC10 User Guide...

- Page 23 Switching of an output contactor should only occur when the output of the drive is disabled. Opening or closing of the contactor with the drive enabled will lead to: 1. Output Over Current error (E003) 2. High levels of radio frequency noise emission (disturbance to nearby equipment) 3. Increased contactor wear and tear Inverter BRC10 User Guide...

-

Page 24: Ground Leakage

If an external EMC filter is used with an ELCB / RCD, a delay of at least 50 ms should be incorporated to ensure spurious trips are not seen. The leakage current is likely to exceed the trip level if all of the phases are not energized simultaneously. Inverter BRC10 User Guide... -

Page 25: Electromagnetic Compatibility (Emc)

(bottom-centre). If it is not possible to use this screw, then the motor cable screen should be bonded to the cable management bracket accessory, or if necessary connected using a short pig-tail to the drive ground connections. Figure 4-6 EMC backplate screw Inverter BRC10 User Guide... - Page 26 (supplied with accessory) into holes with a phillips or 3 mm (1/8 in) slotted screwdriver. The screws should be tightened with a maximum torque of 1.5 Nm (13.27 lb in). Figure 4-8 Grounding the motor cable shield Inverter BRC10 User Guide...

- Page 27 The motor cable shields should be bonded to the back-plate using uninsulated metal cable-clamps which should be positioned as close as possible to the terminal block. Keep the length of power conductors to a minimum and ensure that all sensitive equipment and circuits are at least 0.3 m (12 in) away from the terminal block. Inverter BRC10 User Guide...

- Page 28 Figure 4-12. If a digital port experiences a severe surge its protective alarm may operate A.7 (I/O Overload). Figure 4-12 Surge suppression for digital and unipolar inputs and outputs Signal from plant Signal to drive 30V zener diode e.g. 2 x BZW50-15 Inverter BRC10 User Guide...

- Page 29 Internal EMC filter The Inverter BRC10 is available with C1 and C3 internal filters. It is recommended that the internal EMC filter be kept in place unless there is a specific reason for disconnecting it. The internal EMC filter reduces radio-frequency emission into the line power supply. The filter may need to be ❶...

-

Page 30: Control Connections

The control connections shown above and the 485 port can be PELV rated when connected within a PELV circuit. The terminals are not PELV rated if the relay is connected to a circuit exceeding Overvoltage Category II. WARNING Inverter BRC10 User Guide... - Page 31 PWM Output 1 kHz maximum current Resolution 0.02 % Common to all output types T3, T5, T10 0 V Common Voltage Range 0 V to +24 V Common connection for all external devices Sample rate 4 ms Inverter BRC10 User Guide...

- Page 32 -8 V to +30 V relative to 0V range Impedance 6.8 kΩ Voltage Range 0 V to +24 V Sample rate 4 ms As a Frequency Input Maximum 100 kHz Frequency < 5 V Low Level > 15 V High Level Inverter BRC10 User Guide...

-

Page 33: Communication Connections

RJ45 pin 2 connection (RX TX) to +5 V and the other resistor from the RJ45 pin 7 connection (/RX /TX) to 0 V. These resistors should be in the range 450 to 650 Ohms and fitted in or as close as possible to the master controller. Inverter BRC10 User Guide... - Page 34 The EIA-232 to EIA-485 adapter automatically detects the end of the message frame and disables the transmitters. • Manual hardware control. The EIA-232 to EIA-485 adapter uses the 'TX Enable' output from the drive to enable or disable the transmitters. Inverter BRC10 User Guide...

-

Page 35: Getting Started

Understanding the display The Inverter BRC10 display is used to show drive status, parameter numbers, parameter values and to indicate units of the currently displayed parameter or to indicate that the drive is running. See Figure 5-1 for more information. -

Page 36: Using The Keypad

Information Using the keypad The Inverter BRC10 has four keys as can be seen in Table 5-2 below. Table 5-2 Key functions Setting button - Used to navigate through the drive parameter settings and rotate displayed parameters when the drive is running. - Page 37 Figure 5-2 Menu structure Indicates the key should be pressed and held to enact the desired movement. This time varies for different operations to allow for the best usability but 1 second is the standard time for most operations. Inverter BRC10 User Guide...

-

Page 38: Understanding The Menu Structure

Table 5-1. The PIN set in Security PIN (P4.02) will then have to entered one digit at a time, pressing the settings button to confirm each digit before the parameter value can be edited or viewed. Inverter BRC10 User Guide... -

Page 39: Running The Motor

Remove the Run Forward (T13) or Run Reverse (T14) signal to stop the motor by following the selected deceleration Stopping rate. If the Enable signal (T12) is removed while the motor is running, the drive output is immediately disabled, and the motor will coast to a stop. Inverter BRC10 User Guide... -

Page 40: Controlling The Motor Speed

Controlling the motor speed In the Inverter BRC10, up to four references can be configured at one time and the user can switch between these references using digital inputs or by selecting a specific reference in Frequency Reference 1 to 4 Switch (P2.20). The references are configured in the parameters Frequency Reference 1 Selector (P2.21) to Frequency Reference 4 Selector (P2.24) with the reference inputs shown in Table 6-1. - Page 41 6 Analog output (P2.18) +24 V Output Preset Frequency 4 Reference 4 (P2.19) Ref Select 1 (DIO 1) DI 2 DI 3 DI 4 Ref Select 0 (DI 5) Current input and presets (P0.05 = 3) Inverter BRC10 User Guide...

- Page 42 Run and Stop commands. See section 6.3 Running, stopping and controlling motor direction. No changes are made to the I/O for this setting. Up/Down Reference 1 Percentage (P1.18) Not Configured Reference 2 Not Configured Reference 3 Not Configured Reference 4 Inverter BRC10 User Guide...

- Page 43 5 0 V 6 Analog output Not Configured Reference 2 +24 V Output Not Configured Reference 3 DIO 1 DI 2 DI 3 Not Configured Reference 4 DI 4 Frequency input (DI 5) Frequency input (P0.05 = 7) Inverter BRC10 User Guide...

- Page 44 PID Feed Forward 0-10 V Input (AI1) Not Configured Reference 2 PID Feedback 4-20 mA Input (AI2) 5 0 V Not Configured Reference 3 6 Analog output PID with Feed Forward (P0.05 = 9) Not Configured Reference 4 Inverter BRC10 User Guide...

-

Page 45: Running, Stopping And Controlling Motor Direction

If both Run Forward and Run Reverse signals are active at the same time, the drive will decelerate to 0 Hz (STOP) until one signal is removed. +24 V Output DIO 1 Enable (DI 2) Run forward (DI 3) Run reverse (DI 4) DI 5 Enable and RF/RR Signals (P6.13 = 1) Inverter BRC10 User Guide... - Page 46 +24 V Output DIO 1 Run Permit (DI 2) Run (DI 3) Reverse (DI 4) DI 5 Run + F/R 3 Wire Control (P6.13 = 4) Inverter BRC10 User Guide...

- Page 47 +24 V Output DIO 1 DI 2 Run (DI 3) Reverse (DI 4) DI 5 Run + F/R 2 Wire Control (P6.13 = 7) Inverter BRC10 User Guide...

- Page 48 Hold the UP & DOWN buttons together to run the motor at Jog Frequency (P2.13). This can be used to provide a quick spin test once the motor rating data has been set in the drive. Inverter BRC10 User Guide...

-

Page 49: Connecting Motor Thermistors

= The resistance of the thermistor when the error should occur. • Set Threshold Detector Function Select (P5.17) to External Error (14) • For an NTC thermistor, or a thermistor where the resistance decreases as the temperature increases, set Threshold Detector Output Invert (P5.16) to 1. Inverter BRC10 User Guide... -

Page 50: Drive Parameters

Run + Jog (3 Wire) (5), P0.10 Run/Stop Configuration Enable + Run Forward + Run Reverse (1) P6.13 Run Forward + Run Reverse (2 Wire) (6), Run + Reverse (2 Wire) (7), Keypad (8), Keypad With Enable (9), Keypad Jog (10) Inverter BRC10 User Guide... -

Page 51: Single Line Parameter Descriptions

Dependent on parameter saved P1.29 Error 0 to 255 P1.30 Error History 1 0 to 255 P1.31 Error History 2 0 to 255 P1.32 Error History 3 0 to 255 P1.33 Drive Diagnostic 0 to 17 Inverter BRC10 User Guide... - Page 52 None (0) P2.25 Skip Frequency 0.0 to Maximum Frequency Reference (P2.02) Hz 0.0 Hz P2.26 Skip Frequency Band 0.0 to 25.0 Hz 0.5 Hz P2.27 Fire Mode Reference ± Maximum Frequency Limit (P2.02) Hz 0.0 Hz Inverter BRC10 User Guide...

- Page 53 Binary Control Word 0 to 65535 (Binary 16 bit) P4.19 Save Parameters Off (0) or On (1) Off (0) P4.20 Near Field Communication (NFC) Disabled (0), Read Only (1), Read & Write (2) Read & Write (2) Inverter BRC10 User Guide...

- Page 54 Ref Switch Bit 0 (10), Ref Switch Bit 1 (11), Ramp Select (12), PID Enable (13), External Error (14), Drive Reset (15), Run (16), Reverse (17), Jog Forward (18), Jog Reverse (19), Fire Mode (20) P5.18 PID Negative Limit Enable Off (0) or On (1) Off (0) Inverter BRC10 User Guide...

- Page 55 T15 Frequency Input Percentage at P6.30 ±100.00 % 0.00 % Minimum Input P6.31 T15 Frequency Input Maximum Input 0.00 to 100.00 % 100.00 % T15 Frequency Input Percentage at P6.32 ±100.00 % 100.00 % Maximum Input Inverter BRC10 User Guide...

-

Page 56: Parameter Descriptions

The drive is injecting D.C. braking current into the motor Error The drive in an error state, check the error log for more information Under Voltage The drive is in the under-voltage state Initialising The drive systems are initialising Inverter BRC10 User Guide... - Page 57 Bit 6 At Speed ± 1 Hz Indicates the Ramp Output (P1.14) is within 1 Hz of the Ramp Input. Bit 7 At Zero ± 2 Hz Indicates the Ramp Output (P1.14) is within 2 Hz of 0 Hz. Inverter BRC10 User Guide...

- Page 58 These values can be used for speed control by selecting an appropriate configuration in Frequency Reference Configuration (P2.03) or by selecting the function in Frequency Reference 1 Selector (P2.21) to Frequency Reference 4 Selector (P2.24). When selected for speed control, 100 % is the Maximum Frequency Limit (P2.02). Inverter BRC10 User Guide...

- Page 59 If Thermal Protection Action (P3.21) is set to Error, the error will occur when this parameter = 100 %. An alarm is indicated if this percentage is > 95 % and cleared when < 75 %, see Alarm Indicators (P1.09). Inverter BRC10 User Guide...

- Page 60 Error History 2 P1.32 Error History 3 Range: 0 to 255 Default: Displays the most recent error (including an active error). Previous errors are listed with Error History 1 being more recent than Error History 3. Inverter BRC10 User Guide...

- Page 61 Drive has stopped because the current loop has been lost on one of the analog inputs, see Alarm Indicators Current Loop Loss (P1.09). The drive is not running because it is currently in Supply Loss, Injecting D.C., Error, Under Voltage or it is still Drive State initialising, see Drive State (P1.05). Inverter BRC10 User Guide...

- Page 62 This is used for scaling the range of percentage inputs. Default for 50 Hz regions = 50.0 Hz Default for 60 Hz regions = 60.0 Hz. Output Frequency (P1.01) can be higher than this limit due to motor slip compensation. NOTE Inverter BRC10 User Guide...

- Page 63 T15 Digital Input 5 Type (P6.05) T11 Digital Input 1 Function Select (P6.16) T15 Digital Input 5 Function Select (P6.20) “-” indicates that the configuration will not change the setting of the parameter from the current value. Inverter BRC10 User Guide...

- Page 64 Distance Stop Example: Figure 7-3 Distance Stop Frequency (Hz) Frequency (Hz) P2.02 P2.02 x 0.5 Time (s) 2 x T T = Deceleration Rate 1 (P2.07) Distance (5) is the point that the ‘Run’ signal is removed. Inverter BRC10 User Guide...

- Page 65 Acceleration Rate 1 (P2.06) and Deceleration Rate 1 (P2.07) are used by the ramp system. Acceleration Rate 1 (P2.06) and Deceleration Rate 1 (P2.07) are used by the ramp system. Acceleration Rate 2 (P2.08) and Deceleration Rate 2 (P2.09) are used by the ramp system. Inverter BRC10 User Guide...

- Page 66 The rate of change of Up/Down Percentage (P1.18) is defined by this parameter which is the number of seconds to change from 0 % to 100 %. This rate is applied when holding the Up or Down buttons and the terminal control. Single presses will change the value by 0.1 %. Inverter BRC10 User Guide...

- Page 67 0 to 9 Default: 6 (T2 Analog 1 %) P2.22 Frequency Reference 2 Selector Range: 0 to 9 Default: 7 (T4 Analog 2 %) P2.23 Frequency Reference 3 Selector Range: 0 to 9 Default: 0 (None) Inverter BRC10 User Guide...

- Page 68 Figure 7-6 Percent to Frequency scaling If this parameter is set to 0 (None), the drive will run at the Minimum Frequency Limit (P2.01). NOTE The value of these parameters can be set by Frequency Reference Configuration (P2.03). NOTE Inverter BRC10 User Guide...

- Page 69 Skip Frequency Band (P2.26) defines the range either side of the value set here over which references are rejected in either direction. Figure 7-7 Skip Frequency set up P2.26 Skip Frequency Band Range: 0.0 to 25.0 Hz Default: 0.5 Hz Defines the range either side of the skip reference to be skipped. See Skip Frequency (P2.25). Inverter BRC10 User Guide...

- Page 70 It is recommended that the drive parameters should be protected from un-authorized changes by using Security PIN (P4.02) to reduce the risk. The parameters listed may also be changed via serial communications so adequate precautions should be taken if this functionality is utilized. Inverter BRC10 User Guide...

- Page 71 480 V 460 V 60 Hz P3.04 Motor Rated Power Factor Range: 0.00 to 1.00 Default: Rating Dependent Motor Rated Power Factor is the rated power factor of the machine, cos φ (taken from the motor nameplate). Inverter BRC10 User Guide...

- Page 72 For Square V to F, only the starting boost is adjustable and the voltage output follows a square law from this point until the voltage reaches Motor Rated Voltage (P3.03) at Motor Rated Frequency (P3.15). At frequencies above this the motor voltage is constant. Inverter BRC10 User Guide...

- Page 73 Defines the time during which D.C. current is injected into the motor during timed injection stopping modes. See Stopping Mode Selector (P2.04). Excessive braking time when the motor speed is low can cause motor overheating due to reduced motor self-ventilation. Inverter BRC10 User Guide...

- Page 74 The disadvantages of setting this parameter are increased acoustic noise from the motor and a reduction in the thermal capability of the drive at low output frequencies. Inverter BRC10 User Guide...

- Page 75 Increasing the value may be required if Standard Ramp (1) or Ramp + Motor Loss (2) are being used in Deceleration Ramp Type (P2.11) with a high inertia load, or if Supply Loss Action (P4.08) > 0, as the increased gain will help the control of the D.C. link voltage during these operations. Inverter BRC10 User Guide...

- Page 76 8 data bits, 1 stop bit, even parity bit 8.1OP 8 data bits, 1 stop bit, odd parity bit The drive always uses MODBUS RTU and is always a slave. All parameters can be accessed as 16-bit registers. Inverter BRC10 User Guide...

- Page 77 If the supply voltage returns during a Ramp Stop or before the drive has shut down, the run signal needs to be removed and reapplied before the drive will run again. P4.09 Parameter 1 Save on Error Selector Range: 0 to 25 Default: 14 (Ramp Output) P4.10 Parameter 2 Save on Error Selector Range: 0 to 25 Default: 6 (Output Current) Inverter BRC10 User Guide...

- Page 78 Set to 255 to clear the error history. Set to 100 to reset the drive. Setting to 0 will not result in an error. Errors related to the EEPROM and non-resettable errors cannot be initiated via this parameter. Inverter BRC10 User Guide...

- Page 79 The drive's NFC features are fully enabled NOTE If a security PIN is set in Security PIN (P4.02) this will apply to the App and parameters will not be able to be changed unless the PIN is provided. Inverter BRC10 User Guide...

- Page 80 Menu 5 - PID controller The Inverter BRC10 has a dedicated PI (Proportional-Integral) control loop that is suitable for use in applications requiring basic closed-loop control of a system or process. The output of the PID Controller, PID Output Percentage (P1.19), can be used to control the speed of the motor when selected as a reference in Frequency Reference 1 Selector (P2.21) or in another reference selector parameter.

- Page 81 PID Fixed Reference Setpoint 1 P5.02 PID Fixed Reference Setpoint 2 Range: -100.00 to 100.00 % Default: 0.00 % Used where a setpoint for the controller is fixed and does not change, or could be updated via serial comms. Inverter BRC10 User Guide...

- Page 82 If PID Error (P1.21) = 10 % and a proportional gain of 1.000, then the proportional term is a value of 10 %. A higher value will reduce response time. However, if the value is set too high it may introduce oscillation in the system. Inverter BRC10 User Guide...

- Page 83 Enabling the PID is dependent on two conditions, the value set in this parameter and any digital input function that has been configured to PID Hardware Enable (13). Bit 0 in PID Status Indicators (P1.20) indicates whether the PID is enabled or not. the value of this parameter can be set by Frequency Reference Configuration (P2.03). NOTE Inverter BRC10 User Guide...

- Page 84 No change of state Threshold Input ≥ Upper Threshold Lower Threshold = Threshold Detector Level (P5.13) - (Threshold Detector Hysteresis (P5.14) / 2) Upper Threshold = Threshold Detector Level (P5.13) + (Threshold Detector Hysteresis (P5.14) / 2) Inverter BRC10 User Guide...

- Page 85 P5.16 Threshold Detector Output Invert Range: 0 to 1 Default: Set to 1 to invert the logic level from the Threshold Detector. The Threshold Detector output is shown in bit 2 of PID Status Indicators (P1.20). Inverter BRC10 User Guide...

- Page 86 P5.18 PID Negative Limit Enable Range: 0 to 1 Default: 0 (Off) Setting this parameter to On (1) allows PID Percentage (P1.19) to be negative which will allow the motor to rotate in the reverse direction. Inverter BRC10 User Guide...

- Page 87 1 kHz output frequency. The value of this parameter can be set by Frequency Reference Configuration (P2.03). NOTE Inverter BRC10 User Guide...

- Page 88 If a scale set here causes the output to exceed 100 %, the output value is limited to 10 V or 20 mA. Inverter BRC10 User Guide...

- Page 89 Negative Logic inputs (sourcing inputs) to suit NPN type sensors. When analog inputs are used as digital inputs, they do not source or sink current and the logic is not affected when this parameter is set. This parameter has no effect on the digital output or analog inputs. Inverter BRC10 User Guide...

- Page 90 0 to 20 Default: 1 (Hardware Enable) P6.18 T13 Digital Input 3 Function Select Range: 0 to 20 Default: 2 (Run Forward) P6.19 T14 Digital Input 4 Function Select Range: 0 to 20 Default: 3 (Run Reverse) Inverter BRC10 User Guide...

- Page 91 0.00 to 100.00 % Default: 0.00 % P6.22 T2 Analog Input 1 Percentage at Minimum Input Range: -100.00 to 100.00 % Default: 0.00 % P6.23 T2 Analog Input 1 Maximum Input Range: 0.00 to 100.00 % Default: 100.00 % Inverter BRC10 User Guide...

- Page 92 0.00 to 100.00 % Default: 0.00 % P6.30 T15 Frequency Input Percentage at Minimum Input Range: -100.00 to 100.00 % Default: 0.00 % P6.31 T15 Frequency Input Maximum Input Range: 0.00 to 100.00 % Default: 100.00 % Inverter BRC10 User Guide...

- Page 93 Information P6.32 T15 Frequency Input Percentage at Maximum Input Range: -100.00 to 100.00 % Default: 100.00 % These scaling parameters apply to T15 Frequency Input. See the description below T2 Analog Input 1 Minimum Input (P6.21). Inverter BRC10 User Guide...

-

Page 94: Communications

MODBUS RTU, a serial communications protocol that allows a controller to request and send data between connected devices. The number of drives that can be connected on the same network work depends on the capacity of the network. Each BRC10 has a 1.125 unit load so if the network can support a unit load of 30, 26 drives can be connected. - Page 95 BRC10 parameters are all 16-bits and each parameter value is stored in a single MODBUS registers. The MODBUS protocol specification defines registers as 16-bit signed integers. To access the correct drive parameter, the client must reference the correct MODBUS register, the MODBUS RTU...

- Page 96 15 =Enable Control Word Register data (P4.18 LSB) Register data (P4.18 LSB) bit 5 = Run bit 0 = Software Enable CRC LSB CRC LSB See details in section 8.1.5 CRC CRC MSB CRC MSB Inverter BRC10 User Guide...

- Page 97 5 = Run Register data (P1.05 LSB) bit 0 = Software Enable CRC LSB CRC LSB See details in section 8.1.5 CRC CRC MSB CRC MSB *For the interpretation of the response message see Table 8-4. Inverter BRC10 User Guide...

- Page 98 CRC based on all bytes in the frame and ensure this matches the CRC of the message. The CRC for the Inverter BRC10 uses the standard CRC-16 polynomial x16 + x15 + x2 + 1. The 16-bit CRC is appended to the message and transmitted LSB first.

-

Page 99: Controlling The Motor With Modbus

Set to 1 to enable the binary control word Table 8-13 Run forward with MODBUS Frame (0x) Server Bit 15 = 1 Function Description node Set P4.18 Bit 1 = 1 code 06 address Bit 0 = 1 Inverter BRC10 User Guide... - Page 100 Set P4.18 code 06 Bit 0 = 1 address Table 8-16 Disable control word to prevent watchdog error (E030) with MODBUS Frame (0x) Server Function Description node Set P4.18 All bits = 0 code 06 address Inverter BRC10 User Guide...

-

Page 101: Diagnostics

Reduce the load on the motor I/O Overload The current demand on the drive 24 V circuit has exceeded 100 mA. Recommended Actions: • Check 24 V output, digital output and 485 port for a current overload condition or potential short Inverter BRC10 User Guide... -

Page 102: Errors

Ramp Output (P1.14) has exceeded the threshold defined by 1.2 x Maximum Frequency Limit (P2.02). Recommended actions: • Check that the motor is not being driven by another part of the system E009 Capacitor Failed The D.C. bus capacitors have failed - Contact the supplier of the drive. Inverter BRC10 User Guide... - Page 103 3 mA. Recommended actions: • Check control wiring is correct • Check control wiring is undamaged • Check T2 Analog Input 1 Type (P6.01) • Check the current signal is present and greater than 3 mA Inverter BRC10 User Guide...

- Page 104 Check motor and drive connections • Check cable integrity E099 Save Blocked A save has been triggered while the App is attempting to communicate with the drive. Recommended actions: • Save parameter settings using Save Parameters (P4.19) Inverter BRC10 User Guide...

- Page 105 Recommended actions: • Restore factory defaults (P4.01) E252 Database Changed A firmware update has been interrupted. The firmware has been changed but the project parameter values have been lost. Recommended actions: • Restore Factory Defaults (P4.01) Inverter BRC10 User Guide...

-

Page 106: Technical Data

200 V Drive (200 to 240 V ±10 %) 1001S00025 0.25 0.33 1001S00037 0.37 1001S00075 0.75 1001D00110 1001D00150 1001D00220 10.6 400 V Drive (380 to 480 V ±10 %) 1002400037 0.37 1002400055 0.55 0.75 1002400075 0.75 1002400110 1002400150 0.55 1002400220 0.55 1003400300 1003400400 Inverter BRC10 User Guide... - Page 107 Information 10.1.2 Altitude Altitude range of the Inverter BRC10 is 0 to 3,000 m (9,900 ft), subject to the following conditions: • 0 m to 1000 m above sea level: no derate required. • 1,000 m to 3,000 m (3,300 ft to 9,900 ft) above sea level: de-rate the maximum output current from the specified figure by 1 % per 100 m (330 ft) above 1,000 m (3,300 ft).

-

Page 108: Power Dissipation

It is therefore recommended that drive are powered up for a minimum of 1 hour after every 2 years of storage. This process allows the drive to be stored for a further 2 years. Inverter BRC10 User Guide... -

Page 109: Emission Compliance

Not a plug-in or movable device, and intended for use in the first environment only when installed by a professional, or in the second environment Intended for use in the second environment, not the first environment Rated at over 1000 V or over 400 A, intended for use in complex systems in the second environment Inverter BRC10 User Guide... -

Page 110: Maximum Cable Lengths

4200-0033 4200-0042 4200-3008 *The alternative Filter does not support footprint mounting of the Inverter BRC10 but does meet the levels specified in Table 10-4. 10.5 Maximum cable lengths Since capacitance in the motor cable causes loading on the output of the drive, ensure the cable length does not exceed 50 m. For motor lengths to comply to a particular EMC standard, such as C1, refer to the cable lengths given in section 10.4 Emission compliance . -

Page 111: Acoustic Noise

Enclosures are intended for indoor use, primarily to provide a degree of protection against limited amounts of falling dirt. Enclosures are intended for indoor use, primarily to provide a degree of protection against dust, falling dirt and dripping non- Type 12 corrosive liquids. Inverter BRC10 User Guide... -

Page 112: Vibration

Frequency range: 5 to 13.2 Hz ± 1.0 mm 13.2 to 100 Hz ± 0.7 g (6.9 ms -2) For more information, please refer to section 12 Vibration Test 1 of the Lloyds Register Test Specification Number 1. Inverter BRC10 User Guide... -

Page 113: Ul Listing Information

All models incorporate internal overload protection for the motor that is adjustable. Refer to section 6 Running the motor. All models are provided with thermal memory retention. The drives are provided with user terminals that can be connected to a motor thermistor. Refer to section 6.4 Connecting motor thermistors. Inverter BRC10 User Guide... - Page 114 Security PIN ............... 35 Jog ................45 Square (Quadratic) V to F ............72 Stopping the motor ............ 39 Switching Frequency ..........73 Keypad ........ 36 Threshold Detector ..........49 Linear (Fixed) V to F ...............72 Up/Down Percentage ......40 Inverter BRC10 User Guide...

- Page 115 0478-0725-05...

Need help?

Do you have a question about the BRC10 and is the answer not in the manual?

Questions and answers