Summary of Contents for Sintratec S1

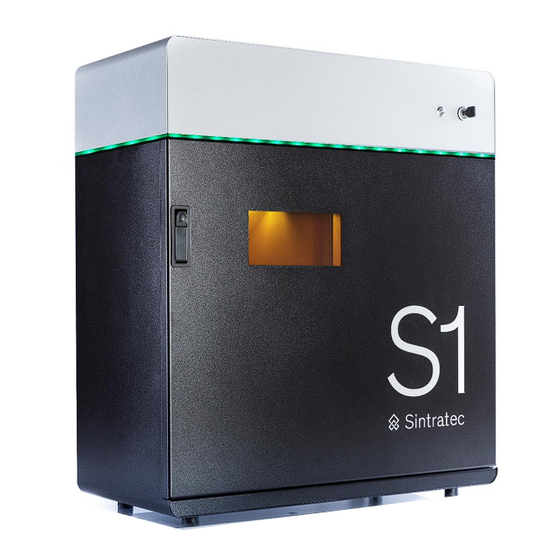

- Page 1 Pos : 2 /Sintratec/Titels eite/Titels eite Si ntr atec S1 @ 3\mod_1463981082828_6556.doc x @ 7874 @ @ 1 Operating Manual Sintratec S1 Laser Sintering System === Ende der Liste für T extmar ke Titelseite ===...

- Page 2 Pos : 4 /Sintratec/Original anl eitung/ORIGIN ALBETR IEBSAN LEITUNG @ 3\mod_1466083441254_6556.doc x @ 9494 @ @ 1 This document is an ORIGINAL OPERATING MANUAL as defined by the EC "Machinery" directive 2006/42/EC. Pos : 5 /Sintratec/Identifi kati on/Dokumentidentifi kation @ 3\mod_1466668600137_6556.doc x @ 9748 @ @ 1...

-

Page 3: Table Of Contents

Table of contents Pos : 8 /Sintratec/Inhalts verzeic hnis/Inhalts verz eic hnis @ 3\mod_1463981096972_6556.doc x @ 7882 @ @ 1 Table of contents CE Declaration of Conformity .................. 6 About this manual ..................... 7 Use and storage ........................7 Contact address of manufacturer ..................7 Support .......................... - Page 4 Table of contents Place of installation, positioning ..................30 Installing the "Sintratec Central" print software ..............31 Electrical connection ......................32 Data connection ........................ 33 6.10 Initial start-up........................34 Operation ........................35 Safety ..........................35 7.1.1 Personal protective equipment ..................35 Operating and auxiliary materials ..................

- Page 5 Table of contents 11.1.1 Personal protective equipment ..................64 11.2 Disposal ..........................64 11.3 Safety ..........................64 11.4 Information on disposal...................... 64 Appendix ........................66 === Ende der Liste für T extmar ke Inhalts verz eichnis === Sintratec S1 BA_S1_en 1.1...

-

Page 6: Ce Declaration Of Conformity

Pos : 11 /Si ntr atec/Ü bersc hriften/1. Ebene/CE- Konfor mitätser kl ärung @ 3\mod_1463981136611_6556.doc x @ 7906 @ 1 @ 1 CE Declaration of Conformity Pos : 12 /Si ntr atec/Kap./CE-Konformi tätser kl ärung/CE- Konfor mitäts erkl ärung S1 @ 3\mod_1466671320680_6556.doc x @ 9752 @ @ 1 CE Declaration of Conformity... -

Page 7: About This Manual

Pos : 19 /Si ntr atec/Kap./Zu di es er Anleitung/Hers tell er, Kontaktadress e @ 3\mod_1463983657216_6556.doc x @ 9222 @ @ 1 Sintratec AG Badenerstrasse 13 CH-5200 Brugg Switzerland Tel.: +41 (0)56 552 00 22 Internet: www.sintratec.com E-mail: info@sintratec.com Pos : 20 /Si ntr atec/++++++++ Seitenumbr uch ++++++++ @ 3\mod_1463981070991_0.doc x @ 7762 @ @ 1 Sintratec S1 BA_S1_en 1.1... -

Page 8: Support

Sintratec Academy at our website: www.sintratec.com, Support area www.sintratec.info Direct support can be received via our Customer Portal in the Sintratec Academy. Also there, documents that are not generally accessible can be downloaded. In case you did not receive from us the password required for logging in at the time of the order, please request this by e-mail at support@sintratec.com. -

Page 9: Symbols, Abbreviations And Presentation

CE Declaration of Conformity provided – the intended use of the device – improper use of the device Pos : 28 /Si ntr atec/++++++++ Seitenumbr uch ++++++++ @ 3\mod_1463981070991_0.doc x @ 7762 @ @ 1 Sintratec S1 BA_S1_en 1.1... -

Page 10: Other Applicable Documents

Pos : 29 /Si ntr atec/Ü bersc hriften/2. Ebene/M - P/Mitgeltende D okumente @ 3\mod_1463981217445_6556.doc x @ 8341 @ 2 @ 1 Other applicable documents Pos : 30 /Si ntr atec/Kap./Zu di es er Anleitung/Mitgeltende D okumente S1 @ 3\mod_1463981398660_6556.doc x @ 8748 @ @ 1 The following documents are relevant for the use of the device: •... -

Page 11: Safety

In case parts of this operating manual leave questions unanswered or cannot be understood, please contact the manufacturer without delay (see contact details). Pos : 40 /Si ntr atec/++++++++ Seitenumbr uch ++++++++ @ 3\mod_1463981070991_0.doc x @ 7762 @ @ 1 11 / Sintratec S1 BA_S1_en 1.1... -

Page 12: Intended Use

It is not permitted to modify the device in any manner. • It is not permitted to operate the device with safety equipment bypassed. Pos : 45 /Si ntr atec/++++++++ Seitenumbr uch ++++++++ @ 3 \mod_1463981070991_0.doc x @ 7762 @ @ 1 12 / Sintratec S1 BA_S1_en 1.1... -

Page 13: Presentation Of Hazard-Related Information

This signal word indicates the risk of damage to property. Failure to comply can result in the device or surrounding area being damaged. Pos : 48 /Si ntr atec/++++++++ Seitenumbr uch ++++++++ @ 3\mod_1463981070991_0.doc x @ 7762 @ @ 1 13 / Sintratec S1 BA_S1_en 1.1... -

Page 14: Safety And Warning Signs At The Device

Pos : 49 /Si ntr atec/Ü bersc hriften/2. Ebene/Q - T/Sicherheits- und Warnschil der am Ger ät @ 3\mod_1463981241789_6556.doc x @ 8426 @ 2 @ 1 Safety and warning signs at the device Pos : 50 /Si ntr atec/Kap./Sic her hei t/War nsc hilder Anbringungsort S1 @ 3\mod_1469174788654_6556.doc x @ 10368 @ @ 1 Fig. 1: Places for affixing warning labels Pos : 51 /Si ntr atec/Kap./Sic her hei t/Si cherheits- und Warnschil der am Ger ät @ 3\mod_1463986881764_6556.doc x @ 9226 @ @ 1... -

Page 15: Safety Equipment

Pos : 53 /Si ntr atec/Ü bersc hriften/2. Ebene/Q - T/Sicherheits einric htung en @ 3\mod_1463981241836_6556.doc x @ 8431 @ 2 @ 1 Safety equipment Pos : 54 /Si ntr atec/Kap./Sic her hei t/Si cherheits einric htung en S1 @ 3\mod_1463986881826_6556.doc x @ 9230 @ @ 1 Fig. 2: Safety equipment The device is equipped with the following safety equipment: •... -

Page 16: Conversions And Unauthorised Modifications

Comply with generally-applicable work safety rules and regulations. Pos : 61 /Si ntr atec/Kap./Sic her hei t/Pers önlic he Schutz ausrüs tung S1 @ 3\mod_1463981421047_6556.doc x @ 8884 @ 3 @ 1 3.9.1 Personal protective equipment Failure to use personal protective equipment can lead to damage to health or injuries. -

Page 17: Information On Certain Hazards And Residual Risks

Pos : 66 /Si ntr atec/Kap./Sic her hei t/Gefahren durc h Laserstr ahlung S1 @ 3\mod_1463987588803_6556.doc x @ 9295 @ 3 @ 1 3.10.2 Hazards due to laser radiation The device works with a high-energy Class 4 laser beam. -

Page 18: Hazards Due To Hot Places

Perform maintenance work or similar activities at the device only when this is in a cold state. Pos : 68 /Si ntr atec/Kap./Sic her hei t/Gefahren durc h bewegte T eile S1 @ 3\mod_1463981420336_6556.doc x @ 8827 @ 3 @ 1 3.10.4 Hazards due to moving parts During operation, there are moving parts inside the device. -

Page 19: Hazards To The Environment

Pos : 74 /Allgemein/++++++++++++ Neues Kapitel ++++++++++++ @ 0\mod_1414754200269_0.doc x @ 6973 @ @ 1 19 / Sintratec S1 BA_S1_en 1.1... -

Page 20: Technical Data

Pos : 76 /doc uglobe CE- Expert/Ü berschriften/1. Ebene/T ec hnisc he D aten @ 0\mod_1414506774559_6556.doc x @ 6573 @ 1 @ 1 Technical data Pos : 77 /Si ntr atec/Kap./Tec hnisc he Daten/T ec hnisc he D aten S1 @ 3 \mod_1463981440662_6556.doc x @ 8912 @ @ 1 Dimensions (height x width x depth) -

Page 21: Specifications For Computer Using "Sintratec Central" Print Software

Pos : 81 /Si ntr atec/Kap./Tec hnisc he Daten/Spezifi kati on Rec hner für Steuer ungss oftwar e @ 3 \mod_1466168407746_6556.doc x @ 9610 @ 2 @ 1 Specifications for computer using "Sintratec Central" print software A computer with the following specifications is required for the "Sintratec Central" print software: •... -

Page 22: Nameplate

Pos : 83 /doc uglobe CE- Expert/Ü berschriften/2. Ebene/Q - T/T ypenschil d @ 0\mod_1414752921241_6556.doc x @ 6613 @ 2 @ 1 Nameplate Pos : 84 /Si ntr atec/Kap./Sic her hei t/T ypensc hild S1 @ 3\mod_1468829986657_6556.doc x @ 10090 @ @ 1 Fig. 3: Place for affixing the nameplate Fig. -

Page 23: Product Description

Pos : 88 /Si ntr atec/Ü bersc hriften/2. Ebene/A - D/Aufbau und Ansic hten @ 3\mod_1463981166491_6556.doc x @ 8026 @ 2 @ 1 Structure and views Pos : 89 /Si ntr atec/Kap./Pr oduktbesc hreibung/Aufbau und Ansic hten S1 @ 3\mod_1463981456848_6556.doc x @ 8920 @ @ 1 The Sintratec S1 comprises the following components: Fig. - Page 24 Fig. 7: Working section (door open) 11 Excess powder container 15 Collecting tray 12 Print container 16 Door-monitoring switch 13 Powder container 17 Glass cover of laser 14 Coater 18 IR heating elements (4 in total) 24 / Sintratec S1 BA_S1_en 1.1...

- Page 25 20 IR heating elements (3 in total) 25 Laser unit 21 Drive units for platforms 26 Voltage transformer, 18 VDC 22 Safety relay 27 Control electronics 23 Voltage transformer, 12 VDC 28 Fans (3 in total) 25 / Sintratec S1 BA_S1_en 1.1...

- Page 26 Used to switch the power supply on and off. • Also serves as EMERGENCY STOP switch. Pos : 90 /Si ntr atec/++++++++ Seitenumbr uch ++++++++ @ 3 \mod_1463981070991_0.doc x @ 7762 @ @ 1 26 / Sintratec S1 BA_S1_en 1.1...

-

Page 27: Function

The heating duration is 1 to 2 hours. Pos : 93 /Si ntr atec/Kap./Pr oduktbesc hreibung/Funkti on - R estpul ver S1 @ 3\mod_1470654362179_6556.doc x @ 10503 @ @ 1 The non-consolidated powder around the print object, in the excess powder container and in the collecting tray, which remains after the printing process has finished, can be re-used after appropriate treatment. -

Page 28: Installation And Start-Up

Pos : 99 /Si ntr atec/Ü bersc hriften/2. Ebene/X - Z/Z wisc henl agerung @ 3\mod_1463981272287_6556.doc x @ 8611 @ 2 @ 1 Interim storage Pos : 100 /Si ntratec /Kap./Lag erung/Z wisc henlag erung S1 @ 3\mod_1463981496292_6556.doc x @ 8960 @ @ 1 In case the device is not installed immediately and therefore has to be stored... -

Page 29: Unpacking

– Protect against further damage. 2. Check that all of the required items have been delivered. Pos : 109 /Si ntratec /++++++++ Seitenumbruc h ++++++++ @ 3\mod_1463981070991_0.doc x @ 7762 @ @ 1 29 / Sintratec S1 BA_S1_en 1.1... -

Page 30: Scope Of Delivery

Place of installation, positioning Pos : 113 /Si ntratec /Kap./M ontag e und Anschl üss e/Posi tionier ung S1 @ 3\mod_1471434125005_6556.doc x @ 10812 @ @ 1 The place of installation must be stable, flat and have a sufficient load-bearing capacity. -

Page 31: Installing The "Sintratec Central" Print Software

Pos : 116 /Si ntratec /Kap./M ontag e und Anschl üss e/Softwareinstallati on @ 3\mod_1466149854720_6556.doc x @ 9528 @ @ 1 Note The "Sintratec Central" print software is used on a computer which is connected to the device via a USB cable. -

Page 32: Electrical Connection

Pos : 117 /Si ntratec /Übersc hriften/2. Ebene/E - H /El ektr oansc hlus s @ 3\mod_1463981182444_6556.doc x @ 8131 @ 2 @ 1 Electrical connection Pos : 118 /Si ntratec /Kap./M ontag e und Anschl üss e/Elektroans chl uss S1 Bil d @ 3\mod_1463981507342_6556.doc x @ 8972 @ @ 1 Fig. 13: Connection point for mains plug of device Pos : 119 /Si ntratec /Kap./M ontag e und Anschl üss e/Elektroans chl uss T ext @ 3 \mod_1469019240138_6556.doc x @ 10336 @ @ 1... -

Page 33: Data Connection

Pos : 121 /Si ntratec /Übersc hriften/2. Ebene/A - D /Datenansc hl uss @ 3\mod_1464101388073_6556.doc x @ 9422 @ 2 @ 1 Data connection Pos : 122 /Si ntratec /Kap./M ontag e und Anschl üss e/D atenansc hluss S1 Bild @ 3\mod_1464100986897_6556.doc x @ 9418 @ @ 1 Fig. 14: Data connection point, SD card slot Pos : 123 /Si ntratec /Kap./M ontag e und Anschl üss e/D atenansc hluss Text @ 3\mod_1469019967407_6556.doc x @ 10356 @ @ 1... -

Page 34: Initial Start-Up

Pos : 125 /Si ntratec /Übersc hriften/2. Ebene/E - H /Erste Inbetriebnahme @ 3\mod_1466493554903_6556.doc x @ 9650 @ 2 @ 1 6.10 Initial start-up Pos : 126 /Si ntratec /Kap./M ontag e und Anschl üss e/Inbetriebnahme, ers te Ei nschalten S1 @ 3\mod_1470654907747_6556.doc x @ 10515 @ @ 1 Following the installation procedure, the device can be put into operation. -

Page 35: Operation

Pos : 131 /Si ntratec /Übersc hriften/2. Ebene/Q - T /Sic her hei t @ 3\mod_1463981241743_6556.doc x @ 8421 @ 2 @ 1 Safety Pos : 132 /Si ntratec /Kap./Betrieb/Pers önlic he Sc hutz ausrüs tung S1 @ 3\mod_1466160153844_6556.doc x @ 9591 @ 3 @ 1 7.1.1... -

Page 36: Printing Process

More detailed information and user tips can be found in the Sintratec Academy. Pos : 137 /Si ntratec /Kap./Betrieb/Gerät eins chalten S1 @ 3 \mod_1466156076266_6556.doc x @ 9556 @ 3 @ 1 7.3.1 Switching on the device 1. -

Page 37: Filling Device With Powder

Operation Pos : 139 /Si ntratec /Kap./Betrieb/Pul ver ei nfüllen S1 @ 3\mod_1466156208954_6556.doc x @ 9561 @ 3 @ 1 7.3.2 Filling device with powder 1. In "Sintratec Central", select the "3. Powder" tab. Fig. 17: "3. Powder" tab. Note In order to be able to move the platforms or the coater for the steps below, the door must be closed. - Page 38 If there is a high degree of unevenness or holes, possibly add some powder at the places concerned. Fig. 20: Top surfaces after being smoothed out with coater Pos : 140 /Si ntratec /++++++++ Seitenumbruc h ++++++++ @ 3\mod_1463981070991_0.doc x @ 7762 @ @ 1 38 / Sintratec S1 BA_S1_en 1.1...

-

Page 39: Loading Of 3D Model Data For Print Object

Note 3D model data The "Sintratec Central" print software supports STL files of 3D model data. Each common CAD application has a function that exports to the STL format. STL files for all types of objects can be found on the internet and can be used for testing purposes. - Page 40 Note Placement of the print object is important for ensuring a good result. In this regard, please read the corresponding information in the Sintratec Academy, in the "Software" area under the ‘Tab "1. Place"’ section, in particular in the "Best Position Practice"...

-

Page 41: Setting Parameters

"Sintratec PA12" parameter settings (for the "Sintratec PA 12 Black" powder) or individual parameter settings. Note Details on parameter settings can be found in the Sintratec Academy, in the "Software" area under the ‘Tab "2. Parameters"’ section. 1. In "Sintratec Central", select the "2. Parameters" tab. - Page 42 If you spot such a problem and correct the file before the printing process is started, time and money can be saved. Pos : 144 /Si ntratec /++++++++ Seitenumbruc h ++++++++ @ 3\mod_1463981070991_0.doc x @ 7762 @ @ 1 42 / Sintratec S1 BA_S1_en 1.1...

-

Page 43: Starting The Printing Process

2. Click on the "Start Print" button. 3. Set the "Enable laser" key switch to ON (white lamp lights up). "Sintratec Central" starts loading data to the device. This action lasts a few seconds. Afterwards, the whole printing process is executed automatically and no intervention by the operator is necessary. -

Page 44: Removing The Print Object And Performing Finishing Work

Pos : 146 /Si ntratec /Kap./Betrieb/Pri ntobj ekt entl aden und nachbear beiten S1 @ 3\mod_1466157812532_6556.doc x @ 9576 @ 3 @ 1 7.3.6... -

Page 45: Cleaning The Device

Operation Pos : 148 /Si ntratec /Kap./Betrieb/R einigung S1 @ 3\mod_1466158322255_6556.doc x @ 9581 @ 3 @ 1 7.3.7 Cleaning the device The following cleaning tasks are to be performed after each printing process: • empty excess powder container •... - Page 46 7. To calculate the correction factors, press the "Calculate new scaling factors" button. The correction factors are displayed. Here also correction factors which were previously effective are taken into account in the calculations. Fig. 28: Calculated correction factors (example) 46 / Sintratec S1 BA_S1_en 1.1...

-

Page 47: Treating The Residual Powder

Operation 8. To accept the correction factors, press the "Send scaling to S1" button. 9. If required, produce another sample print object, check it and repeat the calibration procedure. Note If the optimum digital re-calibration settings have been found, it is recommended to make a note of these, to be on the safe side. -

Page 48: Cleaning And Servicing

There is a risk of being cut at sharp edges. • Wear protective gloves. • Work with care. Pos : 160 /Si ntratec /++++++++ Seitenumbruc h ++++++++ @ 3\mod_1463981070991_0.doc x @ 7762 @ @ 1 48 / Sintratec S1 BA_S1_en 1.1... -

Page 49: Personal Protective Equipment

Always comply with the regulations concerning accident prevention as well as any internal work, operating and safety regulations. Pos : 166 /Si ntratec /++++++++ Seitenumbruc h ++++++++ @ 3\mod_1463981070991_0.doc x @ 7762 @ @ 1 49 / Sintratec S1 BA_S1_en 1.1... -

Page 50: Cleaning

Vacuum cleaner for powder (recommended) (small bag-free vacuum cleaner suitable for removing powder) Pos : 170 /Si ntratec /Kap./R einigung & Instandhaltung/R estpul verbehälter l eer en S1 @ 3\mod_1466057299994_6556.doc x @ 9433 @ 3 @ 1 8.2.3 Emptying the excess powder container Fig. -

Page 51: Emptying Of Collecting Tray

Residual powder can be re-used after treatment (see "Treating the residual powder" section). For information on disposal of residual powder: see "Disposal" section. Pos : 173 /Si ntratec /++++++++ Seitenumbruc h ++++++++ @ 3\mod_1463981070991_0.doc x @ 7762 @ @ 1 51 / Sintratec S1 BA_S1_en 1.1... -

Page 52: Cleaning Of Glass Cover Of Laser

The performance of the laser can be impaired if the glass is not cleaned regularly. Pos : 175 /Si ntratec /Kap./R einigung & Instandhaltung/Las er-Abdec kglas rei nigen - Bild S1 @ 3\mod_1470660873794_6556.doc x @ 10593 @ @ 1 Fig. 31: Cleaning of glass cover of laser Pos : 176 /Si ntratec /Kap./R einigung &... -

Page 53: Cleaning The Working Section

1. Clean the glass on both sides using a soft cloth and a glass cleaner. 2. Wipe the glass dry. Pos : 180 /Si ntratec /++++++++ Seitenumbruc h ++++++++ @ 3\mod_1463981070991_0.doc x @ 7762 @ @ 1 53 / Sintratec S1 BA_S1_en 1.1... -

Page 54: Cleaning The Rear Section

Remove any dirt at the drive units and heating elements using small brushes/cloths. 5. Refit the cover by applying the same procedure but in reverse. Pos : 182 /Si ntratec /++++++++ Seitenumbruc h ++++++++ @ 3\mod_1463981070991_0.doc x @ 7762 @ @ 1 54 / Sintratec S1 BA_S1_en 1.1... -

Page 55: Maintenance

• Replace rear container wall container or powder container Pos : 185 /Si ntratec /Kap./Wartung/Plattform ers etz en S1 @ 3\mod_1466063979741_6556.doc x @ 9463 @ 3 @ 1 8.3.2 Replacement of a platform Note If powder falls into the collecting tray from the powder container or the print container, the seal of the respective platform may be worn. -

Page 56: Replacing A Rear Container Wall

Cleaning and servicing Pos : 187 /Si ntratec /Kap./Wartung/Schac htr üc kwand ersetzen S1 @ 3 \mod_1466065844157_6556.doc x @ 9468 @ 3 @ 1 8.3.3 Replacing a rear container wall Note If powder falls into the rear section from the powder container or the print container, the seal of the respective rear container wall may be worn. - Page 57 7. Fit the new rear container wall by applying the preceding two steps but in reverse. 8. Refit the rear cover by applying the first four steps but in reverse. Pos : 188 /Si ntratec /++++++++ Seitenumbruc h ++++++++ @ 3\mod_1463981070991_0.doc x @ 7762 @ @ 1 57 / Sintratec S1 BA_S1_en 1.1...

-

Page 58: Replacement Of Fan Filters

6. Insert new filter mats and then snap the outlet grids back onto the respective housings. 7. Refit the cover by applying the same procedure but in reverse. Pos : 190 /Allgemein/++++++++++++ Neues Kapi tel ++++++++++++ @ 0 \mod_1414754200269_0.doc x @ 6973 @ @ 1 58 / Sintratec S1 BA_S1_en 1.1... -

Page 59: Faults And Problems

There is a risk of being cut at sharp edges. • Wear protective gloves. • Work with care. Pos : 198 /Si ntratec /++++++++ Seitenumbruc h ++++++++ @ 3\mod_1463981070991_0.doc x @ 7762 @ @ 1 59 / Sintratec S1 BA_S1_en 1.1... -

Page 60: Personal Protective Equipment

The FAQ area of the Sintratec Academy provides solutions for various types of problems. Make use of the support of Sintratec for faults and problems which you cannot rectify yourself. Support can be received via our Customer Portal in the Sintratec Academy. -

Page 61: Spare Parts

Pos : 207 /Si ntratec /Übersc hriften/2. Ebene/E - H /Ers atz teilliste @ 3\mod_1463981183304_6556.doc x @ 8166 @ 2 @ 1 10.2 Spare parts list Pos : 208 /Si ntratec /Kap./Ersatzteile/Ers atzteilliste S1 @ 3\mod_1463981631599_6556.doc x @ 9158 @ @ 1 Description •... - Page 62 Spare parts Rear container wall • ‒ Fan filter • ‒ Glass cover of laser • ‒ Pos : 209 /Allgemein/++++++++++++ Neues Kapi tel ++++++++++++ @ 0 \mod_1414754200269_0.doc x @ 6973 @ @ 1 62 / Sintratec S1 BA_S1_en 1.1...

-

Page 63: Shutdown And Disposal

There is a risk of being cut at sharp edges. • Wear protective gloves. • Work with care. Pos : 217 /Si ntratec /++++++++ Seitenumbruc h ++++++++ @ 3\mod_1463981070991_0.doc x @ 7762 @ @ 1 63 / Sintratec S1 BA_S1_en 1.1... - Page 64 Arrange for the re-use of parts: • Have the device scrapped for its metal. • Have plastic elements recycled. • Dispose of the remaining components according to their material properties. 64 / Sintratec S1 BA_S1_en 1.1...

- Page 65 Shutdown and disposal As with plastic elements, powder can be handed over for recycling. Pos : 225 /Allgemein/++++++++++++ Neues Kapi tel ++++++++++++ @ 0\mod_1414754200269_0.doc x @ 6973 @ @ 1 65 / Sintratec S1 BA_S1_en 1.1...

- Page 66 Pos : 227 /Si ntratec /Übersc hriften/1. Ebene/Anhang @ 3\mod_1466497494097_6556.doc x @ 9655 @ 1 @ 1 12 Appendix Pos : 228 /Si ntratec /++++++++ Seitenumbruc h ++++++++ @ 3\mod_1463981070991_0.doc x @ 7762 @ @ 1 66 / Sintratec S1 BA_S1_en 1.1...

- Page 67 Appendix Pos : 229 /Si ntratec /Kap./Anhang/M aterial mer kbl att PA 12 @ 3\mod_1467723964047_6556.doc x @ 10042 @ @ 1 67 / Sintratec S1 BA_S1_en 1.1...

- Page 68 Appendix 68 / Sintratec S1 BA_S1_en 1.1...

- Page 69 Appendix 69 / Sintratec S1 BA_S1_en 1.1...

- Page 70 Appendix 70 / Sintratec S1 BA_S1_en 1.1...

- Page 71 Appendix 71 / Sintratec S1 BA_S1_en 1.1...

- Page 72 Appendix === Ende der Liste für T extmar ke Inhalt === 72 / Sintratec S1 BA_S1_en 1.1...

- Page 73 Removing the print object and performing General information on safety 11 finishing work 44 General safety information 16 Replacement of a platform 56 Replacement of fan filters 59 Replacing a rear container wall 57 Residual risks 17 73 / Sintratec S1 BA_S1_en 1.1...

- Page 74 Specifications for powder 20 Starting the printing process 43 Vapours 18 Start-up 28 Start-up initial 34 Warning signs 14 Structure and views 23 Warranty and guarantee 10 === Ende der Liste für T extmar ke Index === 74 / Sintratec S1 BA_S1_en 1.1...

- Page 76 Pos : 234 /Si ntratec /Rüc ks eite/Rüc ksei te @ 3\mod_1463981710311_6556.doc x @ 9218 @ @ 1 Sintratec AG Badenerstrasse 13 CH-5200 Brugg Switzerland Tel.: +41 (0)56 552 00 22 Internet: www.sintratec.com E-mail: info@sintratec.com === Ende der Liste für T extmar ke Rüc ksei te ===...

Need help?

Do you have a question about the S1 and is the answer not in the manual?

Questions and answers