Table of Contents

Advertisement

Quick Links

DISPENSING VALVE

MODEL BV-300T

INSTRUCTION MANUAL

◀

BanSeok Precision Ind. Co., Ltd.

Tel. 82.2.469.1239

Fax. 82.2.469.6955

▶

CONTENTS

1 Introductions -----------------------------------

2 Specifications ----------------------------------

3 Explanation of parts --------------------------

4 Principal of operations -----------------------

5-1 Setup --------------------------------------

5-2-1 Washing --------------------------

5-2-2 Dissembly ------------------------

Diaphragm assembly --------

①

6 Sectional Drawing & Dimension ------------

7 Exploded View & Parts List -----------------

page 1

page 1

page 1

page 1

page 1

page 1

page 1

page 1

page 1

page 1

Advertisement

Table of Contents

Summary of Contents for Ban Seok BV-300T

-

Page 1: Table Of Contents

DISPENSING VALVE CONTENTS MODEL BV-300T 1 Introductions ----------------------------------- page 1 INSTRUCTION MANUAL ◀ ▶ 2 Specifications ---------------------------------- page 1 3 Explanation of parts -------------------------- page 1 4 Principal of operations ----------------------- page 1 5 Direction for Use 5-1 Setup --------------------------------------... -

Page 2: Introductions

1. INTRODUCTIONS 3. EXPLANATION OF PARTS Diaphragm Needle Valve of BV-300T series is a kind of pneumatic valve. This valve dispenses material which has viscosity of 10,000cps or less. The dispensing amount can be controlled by the delivery pressure of material, opening period of valve and the stroke size of valve. -

Page 3: Direction For Use

4. OPERATION PRINCIPLES 5. DIRECTIONS FOR USE 5-1. Setup Dispensing OFF Dispensing ON example for general installation ▶ short Stroke long little Flux much In case of "Normal", In case of "Air", diaphragm is opened to dispense. diaphragm is closed not to dispense. - Page 4 5-1-6) 5-1-1) At the time of delivery, the scale of flux control knob is being initiated Fasten firmly using mount hole. to point 3(½ of full stroke). Increase or decrease the number as needed. (M5*P0.8*D98) Maximum length of stroke is 0.6mm. (This is corresponding to the amount when flux control knob makes 1 5-1-2)

-

Page 5: Maintenance

▶ 4 options In case of washing valve head with ② By increasing or sharp pin or others, try not to scratch Pressure increase Dispensing amount increase → decreasing pressure needle or seat part. If damaged you to container need replace parts because... -

Page 6: Sectional Drawing & Dimension

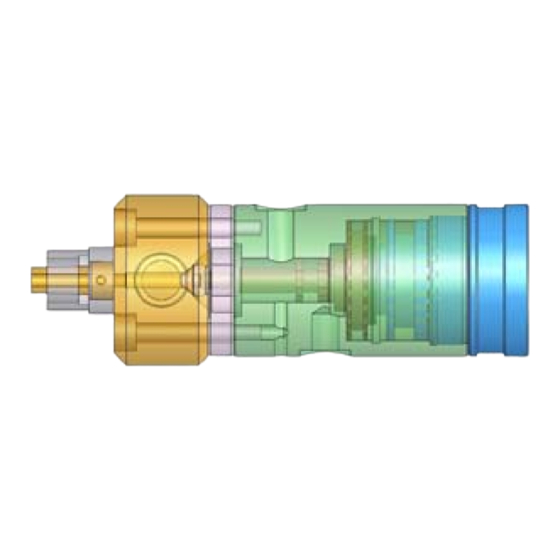

6. SECTIONAL DRAWING & DIMENSION Cross-sectional View ▶ To reinstall valve head fasten L-wrench bolt firmly. ⓕ Fasten stroke control knob until it is closed. Then open it again until ⓖ stroke is appropriate. Dimension ▶ Notice Scale may not indicate to ‘0’ of reference mark. In this case refer to relative scale.(There is no problem to use.) -

Page 7: Exploded View & Parts List

7. EXPLODED VIEW & PARTS LIST Part Name Spec Part Name Spec BOLT M3*18 O-RING AS016 ADAPTER PISTON ∙ ∙ CHAMBER WASHER ∙ ∙ DIAPHRAGM 10 SPRING ∙ ∙ BODY 11 O-RING ∙ O-RING 12 CAP ∙...

Need help?

Do you have a question about the BV-300T and is the answer not in the manual?

Questions and answers