Snapper 1 Series Operator's Manual

Hide thumbs

Also See for 1 Series:

- Safety instructions and operator's manual (13 pages) ,

- Parts manual (68 pages) ,

- Operator's manual (36 pages)

Table of Contents

Advertisement

Quick Links

DRIVE SYSTEM TYPE

MOWER ORIENTATION

Z – Zero Turning – Hydro Drive

M – Mid Mount Mower

Z – Zero Turning – Hydro Drive

M – Mid Mount Mower

Thank you for buying a SNAPPER Product! Before operating your machine, read this manual carefully and pay

particular attention to the "IMPORTANT SAFETY INSTRUCTIONS" on Pages 2 & 3. Remember that all power

equipment can be dangerous if used improperly. Also keep in mind that SAFETY requires careful use in

accordance with the operating instructions and common sense!

COPYRIGHT © 1999

SNAPPER INC.

ALL RIGHTS RESERVED

Safety Instructions & Operator's Manual for

MODEL NUMBER EXPLANATION

Z

M

25 – Engine Horse Power

52 – Mower Cutting Width

61 – Mower Cutting Width

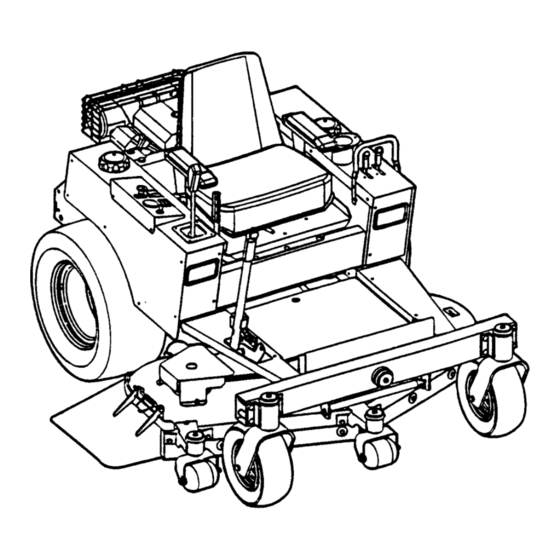

MID MOUNT Z-RIDER

ZERO TURNING

HYDRO DRIVE

25

01

KH

POWER UNIT

01 – Series Designation

MOWER UNIT

00 – Series Designation

SERIES 1

POWER UNIT MODELS

ZM2501KH

MOWER UNIT MODELS

ZM5200M

SERIES DESIGNATION

KH – Kohler Engine

M – Mower Deck

MANUAL No. 7-2902 (REV. 1, 8/20/99)

ZM6100M

ENGINE TYPE

ENGINE HP

Advertisement

Table of Contents

Need help?

Do you have a question about the 1 Series and is the answer not in the manual?

Questions and answers