Summary of Contents for KUPPET HZB-45

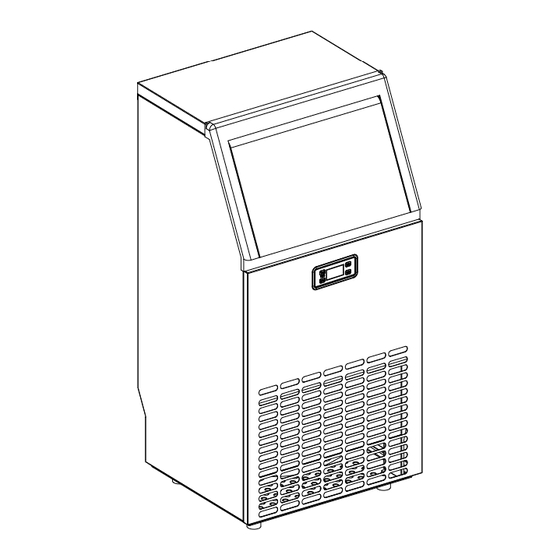

- Page 1 Ice Maker Instruction Manual Model: HZB-45 1020100400 To ensure proper use of this appliance and your safety, please read the following instructions carefully before operating this appliance.

-

Page 2: Table Of Contents

CONTENTS IMPORTANT SAFETY-------------------------------------------------------------------------------------3 SPECIFICATION--------------------------------------------------------------------------------------------5 DIMENSION/CONNECTION---------------------------------------------------------------------5 RATING------------------------------------------------------------------------------------------------5 GENERAL INFORMATION-------------------------------------------------------------------------------6 MAIN UNIT CONSTRUCTION------------------------------------------------------------------------6 ICE-MAKING AND ITS WATER TANK PARTS-----------------------------------------------6 OPERATION PANEL---------------------------------------------------------------------------------7 EXPLOSIVE DRAWING----------------------------------------------------------------------------8 OPERATING PROCEDURE AND MAINTENANCE------------------------------------------------10 UNPACKING YOUR ICE MAKER- ------------------------------------------------------------------------- INSTALLATION LOCATION REQUIREMENT-------------------------------------------------10 ELECTRICAL REQUIREMENT & CONNECTIONS-----------------------------------------11 CLEANING YOUR MAKER BEFROE FIRST USING---------------------------------11... -

Page 3: Important Safety

IMPORTANT SAFETY When using electrical appliances, basic safety precautions should be followed to reduce the risk of fire, electric shock, and injury to persons or property. Read all instructions before using any appliance. Use this appliance only for its intended purpose as described in this owner’s manual. This ice-maker must be properly installed in accordance with the installation instructions before it is used. - Page 4 WARNING: This appliance must be earthed. Use the proper power source according to the nameplate. – WARNING: Keep ventilation openings, in the appliance enclosure or in the built-in structure, clear of obstruction. – WARNING: Do not damage the refrigerant circuit. –...

-

Page 5: Specification

SPECIFICATIONS 1) DIMENSIONS/CONNECTIONS Water Drainage Port Water Inlet Port 2) Rating MODEL HZB-45 POWER SUPPLY VOLTAGE 1Phase, 110-120/60Hz ICE MAKING RATING (Amps) 2.2 Amp ICE HARVEST RATING (Amps) 2.5 Amp ICE MAKING CAPACITY (KG/24H) 45kg/24Hour REFRIGERANT CHARGE R290,3.35Oz/95g VESICANT C5H10... -

Page 6: General Information

GENERAL INFORMATION 1) Main Unit Construction 1. Top cover 2. Door for ice taking 3. Ice-making & its water tank assembly: Including ice-making evaporator, water tank, water pump and some detecting parts 4. Front panel 5. Operation panel 6. Air outlet: Must keep the air circulate smoothly, hot air will blow out when unit running. 7. -

Page 7: Operation Panel

A. Water dividing pipe : with nine little holes, water will flow out from these little holes. And if no water flows out, can be disassembled and cleaned. B. Evaporator (ice-making module) C. Ice full detecting board: Use to detect the inner cabinet is full of ice or not, and to check the the ice-harvest process is over or not. -

Page 8: Explosive Drawing

4) EXPLOSIVE DRAWINGS Parts Name Material Qty. Front panel Stainless steel Bottom plate Zinc-plated steel board Condenser Copper tube and aluminum fin Operation panel paper Operation panel PCB box Operation panel PCB Electrical and Electronic parts Compressor AC110-120V, 60Hz Adjustable foot ABS and bolts Service valve Copper... - Page 9 Water circulation pump AC110-120V,60Hz, Electrical parts Cover of the water tank Water level detecting switch DC5V, Electrical parts Ice-full detecting plate Magnetic control switch DC5V, Electrical parts Cover board on the right side of the evaporator Evaporator and its frame Copper plated with nickle, and ABS frame 1 Water supplying pipe Silicone pipe...

-

Page 10: Operating Procedure And Maintenance

OPERATING PROCEDURES & MAINTENANCE UNPACKING YOUR ICE MAKER 1. Remove the exterior and interior packaging. Check if all the accessories, including instruction manual, ice scoop, white water inlet pipe, 4 ways to 2 ways water quick connector and the water draining pipe, etc., are inside or not. -

Page 11: Electrical Requirement & Connections

Choose a well-ventilated area with temperatures above 10℃ and below 32℃. This unit MUST be installed in an area protected from the elements, such as wind, rain, water spray or drips. The ice maker requires a continuous water supply with pressure 1-8 Bar as required in above specification table. -

Page 12: Water Connections For Your Ice-Maker

otherwise, the unit will not make the ice normally. And suggest that you should discard the ice-cube made by the first ice making cycle after cleaning. 4. The outside of the ice maker should be cleaned regularly with a mild detergent solution and warm water. -

Page 13: Operation Your Unit

OPERATION YOUR UNIT Operation button and display area diagram OPERATION DISPLAY OPERATION AREA AREA AREA TIMER CLEAN ON/OFF Operation the ice-making process Starting up: Plug in the power plug,the symbol will flash in the display window,press the ON/OFF button on the control panel,the machine will start to make ice when the external pipe add water to reach the standard level on the water tank through the electromagnetic water valve,then symbol will change to light on always in display window and symbo rotate;The... -

Page 14: Automatic Self-Cleaning Program

4. When the symbol lights up,the machine stop working,it will work again after you take out the ice. Shut down the unit: During the unit making ice,press the“ON/OFF”button on the control panel,the unit shut down and into standby mode.If you press "ON/OFF" longer than 5S during ice making, then the unit enters the deicing process directly, this function can help remove the ice on the ice plate. -

Page 15: Wiring Diagram

WIRING DIAGRAM Start Relay ELECTRICAL DIAGRAM C O M PR ESSO R Overload Protector Power VALVE PUMP AC - L C O M P Supply AC - N AC Water Pump Relay DC Fan Motor Solenoid Vale for Ice-harvest DC Water Inlet Valve W ATER Main Control PCB WATER LEVEL... -

Page 16: Preparing Ice Maker For Long Storage

Preparing the Ice Maker for Long Storage If the ice maker will not be used for a long time, or is to be moved to another place, it will be necessary to drain out all of the water in the system. 1. -

Page 17: Exterior Cleaning

What shouldn't be done Never keep anything in the ice storage bin that is not ice: objects like wine and beer bottles are not only unsanitary, but also it’s labels may slip off and obstruct the drain pipe. Exterior Cleaning The door and cabinet may be cleaned with a mild detergent and warm water solution such as 28g of dish washing liquid mixed with 7.5L of warm water. - Page 18 3、 When there are ice cubes on the surface of the evaporator, but can’t fall down easily, do not use the mechanical substance to remove it by force; Only press the “ON/FF” button for more than 5 seconds, the unit will enter the ice melting process, after some while, the big ice-cubes will fall down, then turn off the unit and unplug the power cord to clean the surface of the evaporator.

-

Page 19: Ice-Machine Cleaner

Ice Making Assembly System Cleaning by Using Nu-Calgon Nickle Safe Ice-machine Cleaner Minerals that are removed from water during the freezing cycle will eventually form a hard scaly deposit in the water system. Cleaning the system regularly helps remove the mineral scale buildup. -

Page 20: Cleaning Suggestion

The ice machine cleaner contains acids. DO NOT use or mix with any other solvent-based cleaner products. Use rubber gloves to protect hands. Carefully read the material safety instructions on the container of the ice machine cleaner. DISCARD the first batch of ice troduced after cleaning. 8. -

Page 21: Normal Trouble Shooting

NORMAL TROUBLE SHOOTING Problem Possible Cause Solution Check the main water supply pressure or check the water supply hose is blocked or No water supply not, adding the water pressure or cleaning the hose necessary. Floating ball of the water level “... -

Page 22: Correct Disposal Of This Product

ERROR INDICATOR Ambient temp sensor breakdown----- Display E1 in digital window. The machine not make ice or the gas leak ----Display E2 in digital window Magnetic control switch cutoff----”Full” light will be on when plugging on or just turning on the unit.

Need help?

Do you have a question about the HZB-45 and is the answer not in the manual?

Questions and answers

My machine is showing an E2 error, meaning ice making is abnormal. So what do I need to do to fix this issue

The E2 error on the KUPPET HZB-45 ice maker indicates that the machine is not making ice or there is a gas leak. To fix this issue, follow these steps:

1. Check for Ice Production – Ensure that the ice-making process is functioning correctly.

2. Inspect Refrigerant Levels – A refrigerant leak may cause this error. If you suspect a refrigerant issue, contact a qualified technician for maintenance.

3. Examine Cooling System Tubes – If the cooling system tubes are clogged, they need to be cleaned or repaired by a technical service professional.

If the issue persists, professional maintenance is required.

This answer is automatically generated