Summary of Contents for Bray KUGELHAHN MULLER KM20

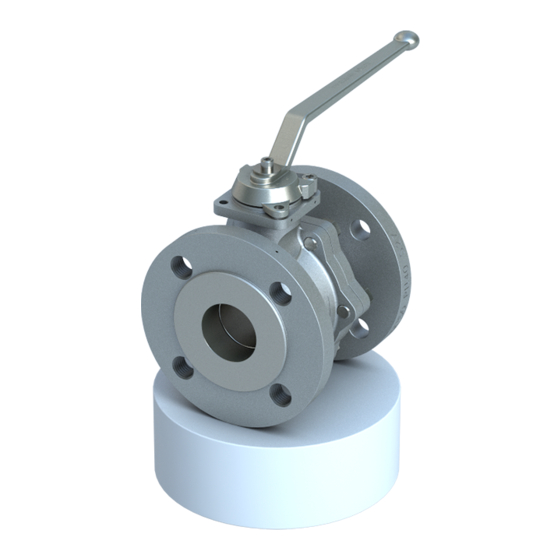

- Page 1 KM20/21 FLANGED BALL VALVES Installation, Operation, and Maintenance Manual KM21-T (KM-TXST/TAST) KM21-O (KM-OXST/OAST) KM20-A (KM-TX-AS/TA-AS) KM20-H (KM-TX-H) KM20-HT (KM-X(A)/HT) KUGELHAHN-MUELLER.DE A BRAY COMPANY...

-

Page 2: Table Of Contents

KM20/21. FLANGED BALL VALVES Installation, Operation and Maintenance Manual CONTENTS Definition of Terms ......... . . 4 Introduction . - Page 3 KM20/21. FLANGED BALL VALVES Installation, Operation and Maintenance Manual 12.0 Operation and Maintenance ........26 12.1 Normal Operation .

-

Page 4: Definition Of Terms

KM20/21. FLANGED BALL VALVES Installation, Operation and Maintenance Manual DEFINITION OF TERMS All information within this manual is relevant to the safe operation and proper care of your Kugelhahn Müller valve. Please understand the following examples of information used throughout this manual. SAFETY STATEMENTS The terms DANGER, WARNING, CAUTION, and NOTICE are used in this document to prevent unwanted consequences. -

Page 5: Introduction

KM20/21. FLANGED BALL VALVES Installation, Operation and Maintenance Manual INTRODUCTION NOTICE Failure to follow these procedures could affect product warranty. Read and follow these instructions carefully and keep this manual in a safe place for future reference. Read and follow these instructions carefully and keep this manual in a safe place for future reference. -

Page 6: Valve Identification

KM20/21. FLANGED BALL VALVES Installation, Operation and Maintenance Manual VALVE IDENTIFICATION NOTICE > Ensure the box is not damaged externally. > Remove the valve from the packaging and check for any damage to the valve and its components during transit. >... -

Page 7: Intended Use

NOTICE Failure to observe this section <Intended Use> constitutes gross negligence and releases the manufacturer, Kugelhahn Müller GmbH or Bray International, from its product liability. In case of any questions, please contact the manufacturer. See back page for contact details. -

Page 8: Hazardous Environments (Atex)

KM20/21. FLANGED BALL VALVES Installation, Operation and Maintenance Manual WARNING When using this product in hazardous environments, the national directives and laws which apply in your country for hazardous areas must be followed. The specifications of the examination certificate valid in country of operation must be also observed. Work may only be done on the valve in an explosion-proof environment without pressure, cooled down and free of fluid. -

Page 9: Qualified Personnel

KM20/21. FLANGED BALL VALVES Installation, Operation and Maintenance Manual QUALIFIED PERSONNEL NOTICE Failure to follow these procedures <Qualified Personnel> could affect product warranty. A qualified person (in terms of this document) is one who is familiar with the installation, commissioning, and operation of the device, and who has appropriate qualifications, such as: >... -

Page 10: Handling Requirements

KM20/21. FLANGED BALL VALVES Installation, Operation and Maintenance Manual HANDLING REQUIREMENTS WARNING A potential hazard exists with handling valves. Failure to handle valves properly may cause a valve to shift, slip or fall causing serious injury or death and/or equipment damage. Caution must be taken during handling to avoid this equipment passing over workers, or over any other place where a possible fall could cause injury or damage. -

Page 11: Storage

KM20/21. FLANGED BALL VALVES Installation, Operation and Maintenance Manual STORAGE NOTICE The packaging is designed to protect the valve only during shipping. If you are not installing the valve immediately after delivery, then you must store it according to these requirements. Failure to follow these procedures <Storage>... - Page 12 KM20/21. FLANGED BALL VALVES Installation, Operation and Maintenance Manual 7.2.3 End protectors shall remain on the valve ends to prevent the entrance of dirt, debris, or insects/wildlife and should only be removed at the time of valve installation. 7.2.4 Product shall remain in the original shipping container with the original packaging materials.

-

Page 13: Lifting

KM20/21. FLANGED BALL VALVES Installation, Operation and Maintenance Manual LIFTING WARNING A potential hazard exists with handling valves. Failure to handle valves properly may cause a valve to shift, slip or fall causing serious injury or death and/or equipment damage. CAUTION Under no circumstances should the hand lever be used during this operation. -

Page 14: Material Of Construction (Cont.)

KM20/21. FLANGED BALL VALVES Installation, Operation and Maintenance Manual MATERIAL OF CONSTRUCTION (cont.) KM21-T (PTFE PACKING) ITEM DESCRIPTION MATERIAL Body Stainless Steel (EN 1.4408) Carbon Steel (EN 1.0619) End Cap Stainless Steel (EN 1.4408) Carbon Steel (EN 1.0619) Ball Stainless Steel (EN 1.4404, EN 1.4408) Seat PTFE / 25% glass, PTFE / 50%, Virgin PTFE Stem... -

Page 15: Km21-O (O-Ring Sealing System)

KM20/21. FLANGED BALL VALVES Installation, Operation and Maintenance Manual MATERIAL OF CONSTRUCTION (cont.) KM21-O (O-RING SEALING SYSTEM) ITEM DESCRIPTION MATERIAL Body Stainless Steel (EN 1.4408) Carbon Steel (EN 1.0619) End Cap Stainless Steel (EN 1.4408) Carbon Steel (EN 1.0619) Ball Stainless Steel (EN 1.4404, EN 1.4408) Seat PTFE / 25% glass, PTFE / 50%, Virgin PTFE... -

Page 16: Km20-A (Asme Design)

KM20/21. FLANGED BALL VALVES Installation, Operation and Maintenance Manual MATERIAL OF CONSTRUCTION (cont.) KM20-A (ASME DESIGN) ITEM DESCRIPTION MATERIAL Body Stainless Steel (ASTM A351 Gr. CF8M) Carbon Steel (ASTM A216 Gr. WCB) End Cap Stainless Steel (ASTM A351 Gr. CF8M) Carbon Steel (ASTM A216 Gr. -

Page 17: Km20-H (Heat Jacket)

KM20/21. FLANGED BALL VALVES Installation, Operation and Maintenance Manual MATERIAL OF CONSTRUCTION (cont.) KM20-H (HEAT JACKET) ITEM DESCRIPTION MATERIAL Body Stainless Steel (EN 1.4408) Carbon Steel (EN 1.0619) End Cap Stainless Steel (EN 1.4408) Carbon Steel (EN 1.0619) Ball Stainless Steel (EN 1.4404, EN 1.4408) Seat PTFE / 25% glass, PTFE / 50%, Virgin PTFE Stem... -

Page 18: Km20-Ht (High Temperature)

KM20/21. FLANGED BALL VALVES Installation, Operation and Maintenance Manual MATERIAL OF CONSTRUCTION (CONT.) KM20-HT (HIGH TEMPERATURE) ITEM DESCRIPTION MATERIAL Body Stainless Steel (EN 1.4408) Carbon Steel (EN 1.0619) End Cap Stainless Steel (EN 1.4408) Carbon Steel (EN 1.0619) Ball Stainless Steel (EN 1.4404, EN 1.4408) Seat Stainless Steel (1.4571), Antimony Impregnated Graphite Stem... -

Page 19: Installation Considerations / Safety Instructions

KM20/21. FLANGED BALL VALVES Installation, Operation and Maintenance Manual 10.0 INSTALLATION CONSIDERATIONS / SAFETY INSTRUCTIONS WARNING > Only qualified personnel, refer to section <Qualified Personnel> is allowed to install the valve. > Failure to follow this section <Installation Consideration/ Safety Instructions> could affect product warranty. >... -

Page 20: Valves With Spring Return Actuators

KM20/21. FLANGED BALL VALVES Installation, Operation and Maintenance Manual 10.2 VALVES WITH SPRING RETURN ACTUATORS 10.2.1 Fail Closed Assemblies 10.2.1.1 If the valve is supplied with an actuator, the ball valve is shipped in the full closed position (as no air pressure is present to compress the springs and open the ball). -

Page 21: Installation & Commissioning

KM20/21. FLANGED BALL VALVES Installation, Operation and Maintenance Manual 11.0 INSTALLATION & COMMISSIONING WARNING > Ensure to follow the section <Installation Consideration / Safety Instructions> as well as section <Installation & Commissioning>. > Ensure that the selected materials of the wetted parts of the ball valve are suitable for the line media. - Page 22 KM20/21. FLANGED BALL VALVES Installation, Operation and Maintenance Manual 11.1.8 Use water or compressed air to clean the valves. Place the opening of the valve perpendicular to the floor and clean it. Make sure that the dust is completely removed from the opening.

- Page 23 KM20/21. FLANGED BALL VALVES Installation, Operation and Maintenance Manual CAUTION > If retrofitting an actuator it must be confirmed that the torque, direction of rotation, angle of actuation and the “OPEN” and CLOSED” travel stop settings are adjusted to suit the ball valve position.

-

Page 24: Valve-Actuator-Assembly

KM20/21. FLANGED BALL VALVES Installation, Operation and Maintenance Manual 11.2 VALVE-ACTUATOR-ASSEMBLY CAUTION > Actuators supplied together with ball valves are adjusted to the operating data specified in the order. The “OPEN” and “CLOSED” travel stop settings shall not be changed without the permission of the manufacturer. -

Page 25: Valve Removal

KM20/21. FLANGED BALL VALVES Installation, Operation and Maintenance Manual 11.3.6 > If the valve is marked with “Class” only, limit the test pressure [bar] to 0.077 x Class. (PS = maximum permissible operating pressure) 11.3.7 > If a leakage occurs at a valve, observe the section <Troubleshooting>. -

Page 26: Operation And Maintenance

KM20/21. FLANGED BALL VALVES Installation, Operation and Maintenance Manual 12.0 OPERATION AND MAINTENANCE WARNING > Verify line is depressurized before installing, removing, or repairing a valve or operator. > Do not pressurize the line without an operator on the valve. >... -

Page 27: Maintenance

KM20/21. FLANGED BALL VALVES Installation, Operation and Maintenance Manual 12.1.6 Valves with actuators should be checked for actuator-valve alignment. Misalignment will result in high operational torque and damage to valve stem and seals. 12.2 MAINTENANCE 12.2.1 Ball valves do not require regular maintenance. However, when checking the pipeline section at suitable intervals make sure that there is no leakage at the flange and screw connections of the valve body and at the stem seal. -

Page 28: Disassembly/Assembly Instructions

KM20/21. FLANGED BALL VALVES Installation, Operation and Maintenance Manual 13.0 DISASSEMBLY/ASSEMBLY INSTRUCTIONS NOTICE > Failure to follow this section <Disassembly/Assembly> could affect product warranty. WARNING > Verify line is depressurized before disassembly. > Valve should be cycled to assure there is no pressure trapped in valve cavity. -

Page 29: Assembly

KM20/21. FLANGED BALL VALVES Installation, Operation and Maintenance Manual 13.3 ASSEMBLY CAUTION Extreme care must be exercised during the adjustment of body screw to make sure that body screws are fully engaged. There should be at least one stud thread exposed beyond the flange on the body side and beyond the nut on the cap side. -

Page 30: Testing

KM20/21. FLANGED BALL VALVES Installation, Operation and Maintenance Manual 13.4 TESTING WARNING If not properly secured, the valve can become separated from the pressure source, resulting in possible injury. Always join the valve to flanges of the same pressure rating and secure with a full set of flange bolts. -

Page 31: Troubleshooting

KM20/21. FLANGED BALL VALVES Installation, Operation and Maintenance Manual 14.0 TROUBLESHOOTING NOTICE > Only original parts from Kugelhahn Müller GmbH may be installed. > If, after disassembly, it is found that the body and/or internal parts are not sufficiently resistant to the media, appropriate components made of suitable materials should be selected in consultation with Kugelhahn Müller GmbH. - Page 32 KM20/21. FLANGED BALL VALVES Installation, Operation and Maintenance Manual Malfunction > Check actuator unit and control commands. > If actuator and control system are OK, remove valve. > Observe section <Installation considerations/Safety instructions> and check the valve. > Repair is required if ball valve is damaged – see above. >...

-

Page 33: Return Merchandise Authorization

Product information is provided on identification tag attached to device. 16.1 All products that are returned require a Return Merchandise Authorization (RMA). Contact a Bray representative to obtain authorization and shipping instructions. 16.2 The following information must be provided when submitting RMA. -

Page 34: Appendix A: Tables

KM20/21. FLANGED BALL VALVES Installation, Operation and Maintenance Manual APPENDIX A: Tables Table 1: KM20 Assembly Dimensions DIMENSIONS (mm) Stem Ø 13.5 13.5 13.5 13.5 13.5 13.5 13.5 13.5 1 1/2 19.5 19.5 19.5 19.5 19.5 19.5 37.5 Table 2: KM21 Assembly Dimensions DIMENSIONS (mm) Stem Ø... - Page 35 KM20/21. FLANGED BALL VALVES Installation, Operation and Maintenance Manual APPENDIX A: Tables Table 3: Pressure/Temperature Carbon Steel DN 15 to 50 DN 65 to 200 Temperature PTFE 25% PTFE 50% Temperature PTFE 25% PTFE 50% °C °C 14.8 14.8 14.5 14.5 13.5 12.8...

-

Page 36: Appendix B: Conformity Of Eu Directives

KM20/21. FLANGED BALL VALVES Installation, Operation and Maintenance Manual APPENDIX B: CONFORMITY OF EU DIRECTIVES The current version of the Declaration of Conformity according to the applicable EC/EU Directives can be downloaded from the website. REQUIREMENT ACCORDING TO DIRECTIVE 2006/42/EC (FOR MACHINERY) 1.1.1 g) Intended use See Installation, Operation and Maintenance Manual. - Page 37 KM20/21. FLANGED BALL VALVES Installation, Operation and Maintenance Manual 1.7.4. Operating instructions The Installation, Operation and Maintenance Manual contains instructions on the operation of the valve during regular industrial use in accordance with the section <Intended Use> of this manual. Any necessary additional aspects to be considered for special use are the responsibility of the operator.

- Page 38 The right to change or modify product design or product without prior notice is reserved. Patents issued and applied for worldwide. © 2022 KUGELHAHN MÜLLER GMBH. ALL RIGHTS RESERVED EN_KM_IOM_20-21_2023_09_22 A BRAY COMPANY YOUR SPECIALIST FOR BALL VALVES KUGELHAHN-MUELLER.DE...

Need help?

Do you have a question about the KUGELHAHN MULLER KM20 and is the answer not in the manual?

Questions and answers