Summary of Contents for Softmaster MMP 1

- Page 1 ® Softmaster MMP 1 Microprocessor controller for softening plants Operating instructions...

-

Page 2: Table Of Contents

Table of Contents General notes ..............3 Hardness unit ............. 16 Introduction ..............3 Exchanger capacity ........... 16 Handling notes ............. 3 Regeneration ............. 16 Safety instructions ............3 Regeneration delay ............ 17 Installation and commissioning ........3 Early regeneration triggering ........17 General description ............ -

Page 3: General Notes

General notes Introduction These operating instructions describe the installation, operation and programming of the Softmaster MMP 1 controller. We recommend that, while familiarising yourself with the operation of the instrument aided by these operating instructions, you have immediate access to the operable controller in order to perform the described functions and combinations. -

Page 4: General Description

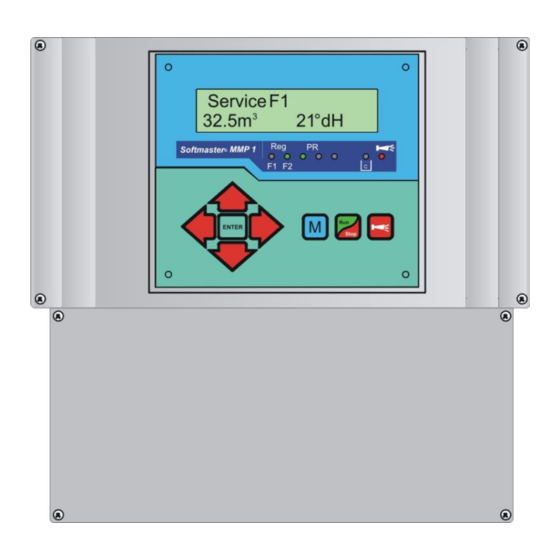

General description Views of the instrument Wall-mounted variant Panel-mounted variant Terminal box Terminal box Drilling-scheme for wall-mounted varant Panel cut-out for panel-mounted variant 4/28... -

Page 5: Description Of Display And Operating Features

Description of display and operating features G "Run/Stop" key (“Regeneration-Start/Stop”) A On/Off switch Only the wall-mounted variant is equipped with an If the key is pressed for 5 seconds, manual triggering On/Off switch on the side. Use this switch to switch the of regeneration occurs (the filter in operation is instrument on or off. -

Page 6: Led Displays

LED displays Filter 1 Filter 2 Add. Warning Error „Chemicals low“ prog. in Regeneration The displays signal operating statuses, plant functions and current error messages: Reg. F1 and Reg. F2 (green) LED lights up: Filter 1 or Filter 2 in regeneration. LED flashes: Today, a regeneration of the respective filter is triggered at the set time (also see Regeneration delay). -

Page 7: Error Messages

Error messages In addition to the displayed error messages, the red LED ”Alarm” lights up or flashes. Alternate display of all error messages and operating displays. Each occurred error is stored in the error history. Error message ”Power failure” Message after each switching on, ”power failure”. Check the time and, if Power failure necessary, set the time. - Page 8 Error message ”Maximum number of regenerations achieved” The entered maximum number of possible regenerations has been achieved. Min. reg. nums. The current status of the regeneration meter can be viewed in the SERVICE menu under ”Reg. meter”. In addition to the error message, the yellow warning light ”Low chemicals” lights up. Confirm the fault display via the ”Horn”...

-

Page 9: Terminal Block Identification

Terminal block identification Functions (IN = input, OUT = output) Terminal Type Function Note 4x mains protective earth Mains, N = Neutral Mains input Mains, L = Live 230 - 240 V AC 5x live, switched Mains voltage, max. 6 A 5x Neutral, switched Filter 1 - normally open Volt-free relay output... - Page 10 Terminal blocks for mains supply and relay outputs Terminal block for inputs and interface 10/28...

-

Page 11: Description Of The Relay Outputs

Description of the relay outputs Filter 1 / Filter 2 Pilot distributor or central control valves 1 and 2 Connect the regeneration valves (central control valves) or pilot distributors which are controlled via an electrical change-over switch or impulse switch control at these relay outputs. Change-over contact: For versions with a change-over switch the output changes after each regeneration stage. -

Page 12: Description Of The Signal Inputs

Description of the signal inputs Note Only connect the signal inputs "WM", "LL", "Prog", "Start" and "Stop" to volt-free contacts! Start External regeneration start Connection for hardness monitoring instrument (e.g. Testomat) Function Type of Contact Test time Action – Filter change (only for double- Start programmable filter operation) - Page 13 Low chemicals For extended control of the plant it is possible to use the "LL" input for connecting a level transmitter (monitoring of the chemical tank). Function Type of Contact Test time Action programmable: – Chemical fill valve open programmable Level transmitter input: programmable –...

-

Page 14: Programming

Programming Menu start “M“ Use the "M" key to open the menu. Menu selection / Selection The current line position is displayed as a header in CAPITAL LETTERS. Use the "ENTER" key to activate the selected/displayed menu item, i.e. you ”jump” into a submenu. -

Page 15: Switching On And Power Failure

After switching on the instrument and after each power failure, the plant automatically returns to the last active position. Operating modes (plant type) The Softmaster MMP1 controller can control the following softening plants: Single-filter plant Only one filter is in operation. Soft water is not available during regeneration. -

Page 16: Hardness Unit

Hardness unit The raw water hardness can be entered and displayed in various units: HARDNESS UNIT German hardness = dH °dH ✓ French hardness = f (1.79 = 1° dH) ppm as CaCO3 = ppmCaCO3 (17.9 ppmCaCO3, 1° dH) °f The exchanger capacity has to be entered (in the next menu item) according to ppmCaCO3 the unit. -

Page 17: Regeneration Delay

Quality-controlled regeneration With the internal control function combined with a water hardness measuring instrument (e.g. Testomat 2000 / ECO) it is possible to install a convenient and reliable plant. The water hardness measuring instrument monitors the soft water hardness and sends a start signal to the controller to trigger regeneration once the set limit value has been reached. By combining the various control possibilities you can ensure the largest possible operational reliability. -

Page 18: Regeneration Interval

Regeneration interval To prevent improper bacterial contamination of the resin bed during longer downtimes, REG. INTERVAL regeneration can be carried out at fixed daily intervals. The regeneration interval (0 - 99 days) complies to the operational conditions and Days national regulations for the drinking water supply (e.g. DVGW, DIN, etc.). If regeneration should be carried out at a certain time, please additionally program ”Regeneration delay”... -

Page 19: Fct.out Al/Pr

Fct. Out AL/PR FCT.OUT AL/PR The output ”AL/PR” can either be used as alarm output or as output for the additional Aux. prog. PR program PR. ✓ Alarm AL Additional program PR AUX PROG. With the additional program it is possible to switch on a valve or pump prior to, during or after regeneration only once for a programmed time. -

Page 20: Function Prog Input

Function prog input FUNCT. PROG The additional program can be externally started with this input. norm. closed - Basic program Funct. Prog "M" ➔ ➔ ✓ norm. open Delay Chemical tank monitoring (LL input) FUNCT. LL The input ”LL" has been designed as level transmitter input for the "Low chemicals" alarm or ”EMPTY”... -

Page 21: Service" Menu

”SERVICE” menu Request and change current settings and statuses of the instrument in the service menu. Regeneration of the reserve filter REG. RES.FILTER If the reserve/standby filter should be regenerated, press the ”ENTER” key in the START (Enter) menu. No filter change occurs. This function is only possible with double-filter operation! ONLY FILT.CHANGE Filter change without regeneration start... -

Page 22: Water Meter

Water meter WATER METER The water meter records the removed soft water quantity for the quantity-dependent regeneration triggering and the total quantity counted since the last reset. Soft water0.0m Reset (ENTER): Resets of the currently stored total soft water quantity. Total 0.0m Fast mode... -

Page 23: Status History

Status history STATUS HISTORY Open the status history via ”show”. The status history is a list of statuses which have occurred during current operation. display The occurred status is recorded with time and date, e.g.: A. Reg F1: 23.7m delete 21:28 30.09.03 A maximum of 20 statuses is logged in a ring buffer. -

Page 24: Menu Structure

Menu structure Call the basic factory default setting by simultaneously pressing and holding down the „Arrow down“ key while switching on the instrument. The most recent programming will be lost! 24/28... -

Page 25: Technical Appendix

Technical Appendix Example for a 2-filter softening plant 25/28... -

Page 26: Connection Example

Connection example 26/28... -

Page 27: Conformity Declaration

Conformity Declaration 27/28... -

Page 28: Technical Data

Technical data Power supply: 230 - 240 V or 24 V or 115V+/-10% / 50 -60 Hz, fuse T6,3A Power consumption without exterior load: max. 9 VA Degree of protection: IP65 Protection class: Conformity: EN 61000-6-2, EN 61000-6-4, EN 61010-1 BS EN 61000-6-4+A1, BS EN 61000-6-2, BS EN 61010-1+A 0 –...

Need help?

Do you have a question about the MMP 1 and is the answer not in the manual?

Questions and answers