Table of Contents

Advertisement

Quick Links

Installation, Operation and Maintenance

INSTRUCTIONS MANUAL

REFRIGERANT: R410A

IMPORTANT:

READ

AND UNDERSTAND

INSTRUCTION

MANUAL

USING THIS AIR CONDITIONER.

KEEP THIS MANUAL FOR FUTURE

REFERENCE.

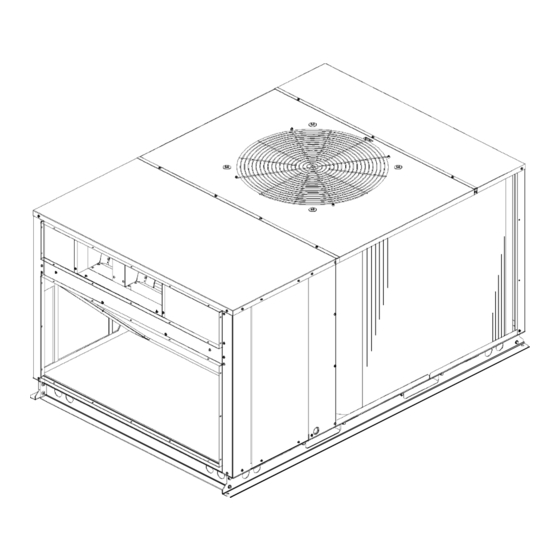

SELF-CONTAINED

AIR CONDITIONERS

Models:

RUA-NP5ATS

RUA-NP8ATS

RUA-NP10ATS

RUA-NP15ATS

THIS

BEFORE

65MP3212

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Hitachi RUA-NP5ATS

- Page 1 SELF-CONTAINED AIR CONDITIONERS Models: RUA-NP5ATS RUA-NP8ATS RUA-NP10ATS Installation, Operation and Maintenance RUA-NP15ATS INSTRUCTIONS MANUAL REFRIGERANT: R410A IMPORTANT: READ AND UNDERSTAND THIS INSTRUCTION MANUAL BEFORE USING THIS AIR CONDITIONER. KEEP THIS MANUAL FOR FUTURE REFERENCE. 65MP3212...

- Page 2 The types of charging refrigerants are indicated in the Installation and Maintenance Manuals, Technical Catalogs, Service Manuals and the specification label in the each unit. Be aware that Hitachi does not take any responsibility for unit failure, troubles of malfunction, and any accidents caused by charging the...

-

Page 3: Table Of Contents

— CONTENTS — No. Item ....................Page Operation Instructions................Ⅰ PREPARATION ................... 1 1.1 Initial Check......................1.2 Transportation ....................... 1.3 Placing the Unit ..................... INSTALLATION .................. 3 2.1 Ducting Arrangement .................... 2.2 Condensate Drain Piping ..................ELECTRICAL WIRING ............... 4 3.1 Main Power W iring Procedures ................ - Page 4 Ⅰ...

-

Page 5: Preparation

2,140 1,070 1,000 1,000 1,000 1,000 1,200 1,070 Fig. 1. Operation Space NOTE: When the unit is installed at a location, which is encircled with walls and obstruction to free air circulation is suspected, consult HITACHI regarding the operation space. -

Page 6: Placing The Unit

PREPARATION Dimensions Model deg. deg. RUA-NP5ATS RUA-NP8ATS RUA-NP10ATS RUA-NP15ATS Fig. 2. Foundation Gradient Dimension (mm) Model RUA-NP5ATS 1,435 RUA-NP8ATS 1,435 RUA-NP10ATS 1,300 1,709 RUA-NP15ATS 1,370 2,102 Fig. 3. Recommended Concrete Curbs 1.3 Placing the Unit Lifting by Forklift – Insert the forks under the Tools and Instruments –... -

Page 7: Installation

INSTALLATION Dimensions (mm) Weight Model (kg) RUA-NP5ATS RUA-NP8ATS RUA-NP10ATS 1000 RUA-NP15ATS 1300 Fig. 4. Center of Gravity 2. INSTALLATION 2.1 Ducting Arrangement 2.2 Condensate Drain Piping Tools and Instruments – General tools for ducting. Tools and Instruments – General piping tools. -

Page 8: Electrical Wiring

Fig. 6 or the wiring label attached to the magnetic switch box. A scroll compressor is equipped. Because that the rotation direction of the orbiting scroll of the HITACHI scroll type compressor is fixed, therefore a reverse & single phase sequence protection relay is equipped in this unit. -

Page 9: Fan Speed Adjustment

PD:Pitch Diameter of Motor Pulley (mm) Models RPM/Turn** RPM PD* RUA-NP5ATS RPM 1,120 1,090 1,060 1,025 21.5 RPM: Fan Speed (rpm) PD*: Pitch Diameter of Motor Pulley (mm) RPM/Turn**: Fan Speed Change per One Turn of Movable Motor Pulley Flange (RPM per Turn) -

Page 10: Removing Shipping Washers

REMOVING SHIPPING WASHERS 5. REMOVING SHIPPING WASHERS Compressor is mounted on rubber isolators, and is held rigidly during shipment by two sets of shipping washers. Before starting the compressor, remove the yellow-painted shipping washers, the compressor should float freely on the rubber isolators. Fig. -

Page 11: Test Running

TEST RUNNING 6. TEST RUNNING 6.1 Final Installation Check Inspect the installation work according to all documents and drawings. Table 2 shows the minimum checkpoints. Table 2. Installation W ork Check List INSTALLATION W ORK CHECK LIST 1. Is the unit solidly mounted and leveled? 2. -

Page 12: Test Running Record

TEST RUNNING 6.4 Test Running Record Compile test running records according to Table 4. Utilize these records for periodic operation checks, as well as for troubleshooting. Operational Sequence Chart Standard Ventilation and Cooling Operation Fig. 9. Standard Operation Sequence * : Thermostat ON denotes that it is calling for the cooling operation ** : ORIF is a manual resetting device, and the other are automatic resetting safety devices. -

Page 13: Safety And Control Device Setting

TEST RUNNING 6.5 Safety and Control Device Setting Table 3. Safety and Control Device Setting Model RUA-NP5ATS RUA-NP8ATS RUA-NP10ATS RUA-NP15ATS For Compressor E505DH E855DH E505DH E855DH High Pressure Switch Automatic Reset, Non-Adjustable Cut-Out 4.15 4.15 4.15 4.15 kg/cm 42.3 42.3 42.3... -

Page 14: Maintenance

MAINTENANCE Refrigerant Cycle 7. MAINTENANCE Strainer – Check for clogging after the time when The unit should be periodically inspected according the cycle is opened. to the same items as those described in the Refrigerant Re-Charge – This unit has been paragraph entitled "Test Running". -

Page 15: Winter Shutdown

7. Tighten all wiring connections and access panels. 9. REPLACEMENT OF PARTS Replacement of parts should be performed by ordering from the HITACHI Parts List. The Form A HITACHI Recommended Spare Parts List is advisable. When replacement of parts becomes necessary,... - Page 16 MAINTENANCE Table 4. Test Running and Maintenance Record MODEL: RUA- MFG. NO. COMPRESSOR MFG. NO.: CUSTOMER'S N AME AND ADDRESS: DATE: Is the rotation direction of the evaporator fan correct? Is the rotation direction of the condenser fan correct? Are there any abnormal sounds? Has the unit been operated at least twenty (20) minutes? Check Room Temperatures: ℃,W B...

-

Page 17: Troubleshooting

TROUBLESHOOTING 10. TROUBLESHOOTING Troubleshooting Charts The following charts show efficient checking procedures for trouble. :Fault :Check :Cause No Brackets:Remedy No Cooling No Cooling (Compressor Does Not Start) Stopped Evaporator Fan Motor ------------------------------- Obtain the Correct Voltage No Voltage or Low Voltage Operating Faulty Unit Power Supply... - Page 18 TROUBLESHOOTING Insufficient Cooling Insufficient Cooling Cycling ON Compressor Cycling High Discharge Pressure or --------------------- See ”High Discharge Pressure” or Operating Low Suction Pressure ”Low Suction Pressure” Tripped High or Low Clogged Capillary of Pressure Switch --------------------- Repair the Clogging and Pressure Switch Replace the Switch if Required Faulty Switch...

- Page 19 TROUBLESHOOTING High Suction Pressure High Suction Pressure ----------------------------- Reduce the Fresh Air Intake Excessive Fresh Air Intake High Evaporator Air Inlet Temperature ----------------------------- Reinforce the Duct Insulation Insufficient Duct Insulation ----------------------------- Replace or Repair the Compressor Defective Compressor Valve ----------------------------- Charge Correct Refrigerant Quantity Overcharged Refrigerant ----------------------------- See ”High Discharge Pressure”...

- Page 20 65MP3212 Printed in the Philippines...

Need help?

Do you have a question about the RUA-NP5ATS and is the answer not in the manual?

Questions and answers