Advertisement

Quick Links

Advertisement

Summary of Contents for ZUBI 700

- Page 1 MODEL 700 KNIFE GATE VALVES INSTALLATION & MAINTENANCE MANUAL...

- Page 2 Installation & maintenance manual Index 1. List of components / General arrangement 2. Description 3. Handling 4. Installation 5. Actuators / Operation 6. Maintenance a. Changing the packing b. Replacing the seat c. Maintenance of the pneumatic cylinders 7. Recommendations 8.

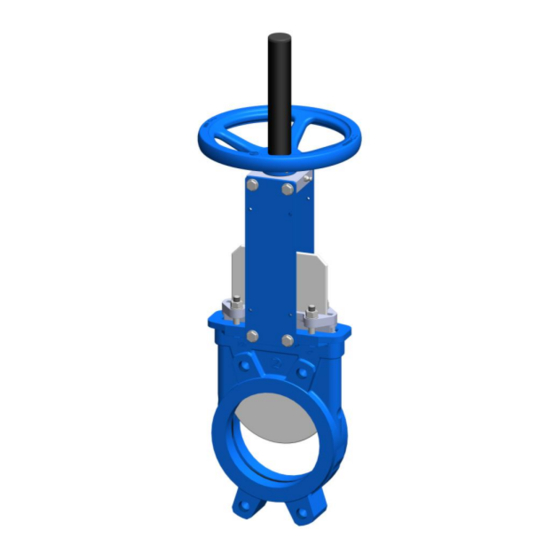

- Page 3 Installation & maintenance manual 1. List of componentes / general arrangement Knife gate valves Page 3 Rev. 0 – 12/2019 T700...

- Page 4 Installation & maintenance manual 2. Description The model 700 knife gate valve is bidirectional so it can be installed in either of his two directions. The valve is commonly used for clean fluids with few suspended solids. The Model 700 complies with the following European directives: ...

-

Page 5: Installation

Installation & maintenance manual 4. Installation For proper installation of the Model 700 valves it is important to consider the following: Personnel handling and installing the valves must be trained and must comply with all necessary safety regulations. Prior to installation of the valve is important to inspect and verify that it has not suffered any damage or harm during shipping and/or storage. -

Page 6: Maintenance

6. Maintenance VALVULAS ZUBI is not responsible for any damage that may occur due to the use of non- original components or spare parts. For any modification, consult ZUBI VALVES for advice. The valves require a periodical minimum maintenance of the packing set and body seal. Knife sliders need to be checked and replaced if they are in poor condition. - Page 7 Installation & maintenance manual Procedure: It is important to replace the seat and packing set. The life of these elements will depend on the working conditions of the valve such as: pressure, temperature, abrasion, chemical action, number of operations, etc. Maintenance should be carried out as follows Bear in mind that in this process we will remove the valve drive so it would be advisable to use lifting gear if you consider it necessary.

- Page 8 Installation & maintenance manual 7. Once all is removed, clean the seat cavity and stuffing box area. Lubricate new U- profile seat with synthetic lubricating grease, silicone based and install by pushing it in from both sides. 8. Fit both HD1000 sliders (This maybe made easier using a dab of Vaseline (non pretroleum based) on the back of the slider to keep them in place in the body cavity).

- Page 9 Installation & maintenance manual c) Maintenance of pneumatic cylinders The actuators seals must be replaced if leaking is detected between the two cylinder chambers. This leak is due to the deterioration of the seals or cylinder liner. Complete replacement of the cylinder must be made as follows: 1.

- Page 10 Installation & maintenance manual 7. Recommendations For proper maintenance of the valves, we recommend periodic changes as mentioned in the valve components. Its duration will depend on the working conditions, temperature and chemical corrosion to which they are subjected. 8. Storage ...

- Page 11 Installation & maintenance manual www.valvulaszubi.com ZUBI FACTORY Auzolan 2b Bajo 20303 Irun Guipuzcoa (Spain) ZUBI OFFICES Hilanderas 5 20303 Irun Guipuzcoa (Spain) Knife gate valves Page 11 Rev. 0 – 12/2019 T700...

Need help?

Do you have a question about the 700 and is the answer not in the manual?

Questions and answers