Advertisement

Quick Links

Advertisement

Summary of Contents for ZUBI 200

- Page 1 MODEL 200 KNIFE GATE VALVES INSTALLATION & MAINTENANCE MANUAL...

- Page 2 Installation & maintenance manual Index 1. List of components / General arrangement 2. Description 3. Handling 4. Installation 5. Actuators / Operation 6. Maintenance a. Changing the packing b. Replacing the seat c. Maintenance of the pneumatic cylinders 7. Recommendations 8.

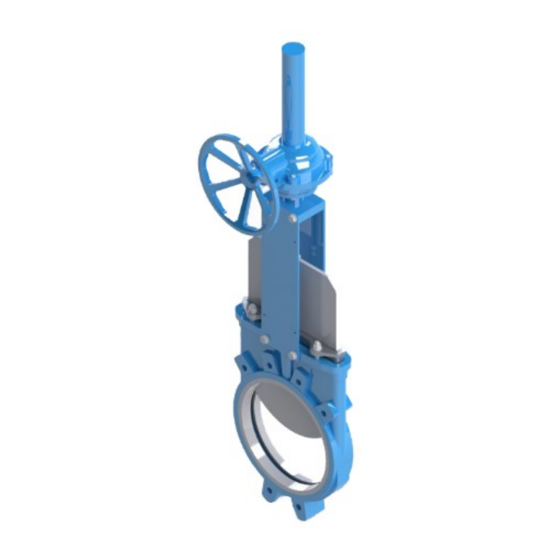

- Page 3 Installation & maintenance manual 1. List of components / General arrangement Knife gate valves Page 3 Rev. 1 – 03/2019...

- Page 4 Installation & maintenance manual 2. Description The model 200 knife gate valve is unidirectional or bidirectional depending on the type of closure that has been chosen commonly used for fluids with suspended solids. The Model 200 complies with the following European directives: ...

-

Page 5: Installation

Installation & maintenance manual 4. Installation For proper installation of the Model 200 valves it is important to consider the following: Personnel handling and installing the valves must be trained and must comply with all necessary safety regulations. Prior to installation of the valve is important to inspect and verify that it has not suffered any damage or harm during shipping and/or storage. - Page 6 Where valves are in storage it is recommended to operate every 4 months. Electric Recommended electric actuator rpm for Zubi T200 valve is 45rpm, higher speed rpm under end user responsibility. Knife gate valves Page 6 Rev.

-

Page 7: Maintenance

Installation & maintenance manual 6. Maintenance In general the valves only require maintenance for changing the packing and changing the seats on both the unidirectional and bidirectional valves when leakage is detected across the valve when fully closed. To maintain easy operation it is recommended that the threaded valve stem be cleaned and greased through the bronze drive bush housed in the bridge. - Page 8 Installation & maintenance manual 4. Remove old packing, clean out packing box and replace with new gland. 5. Replace the gland follower tightening the nuts in a crosswise pattern. Do not overtighten. 6. Replaced the stem connecting bolts and the support plate bolts. 7.

- Page 9 Installation & maintenance manual 5. With care replace the seat retaining ring, tapping with a drift all round the edge until ring is back in place 6. Close the valve tightly against the seat, checking contact between gate and seat. 7.

- Page 10 Installation & maintenance manual When replacing the cylinder components, you must follow the guidelines above as 1-2-3 then as follows: To renew the o-rings on the covers, undo the tie rod nuts; carefully remove cover tapping gently upwards trying not to damage the barrel or cap. Remove old o-ring clean cap, insert new o-ring and replace cap.

- Page 11 Installation & maintenance manual 7. Recommendations For proper maintenance of the valves, we recommend periodic changes as mentioned the valve components. Its duration will depend on the working conditions, temperature and chemical corrosion to which they are subjected to. 8. Storage ...

Need help?

Do you have a question about the 200 and is the answer not in the manual?

Questions and answers