Table of Contents

Advertisement

Quick Links

• TIP – You need solid opening and closing stops. The control board will search for these when

• TIP – You need to fit three small loops of wire to your safety inputs to make anything work. These

can be removed later if you install safety devices to these input terminals. But for now, take three

pieces of light gauge wire (speaker or telephone wire is good) about 50mm long and strip both ends

7mm and insert them as above from 7 to 8, 7 to 9 and 7 to 10.

• TIP – The STOP input will not seal unless you have the manual override handle closed.

• TIP – To program and to run all safety inputs need to be sealed. The LED lights 5,6,7 and 8 should all

• TIP – Start with all dip switches in the off position. You can adjust these to suit later.

• TIP – Do not install any accessories until after you have programmed the unit and have it operating

as you would like. You can then add each accessory one at a time.

• TIP – If using solar power refer to the manual for correct input power connection. Also get hold of a

1. Ensure you have followed the instructions above and that you have the four green LED lights lit.

2. Carefully turn trimmer V-RAL anti clockwise until it comes to a stop. (Do nor force)

3. Release the gate and position it 500mm from the fully open stop.

4. Press the PROG button and hold until DL2 LED starts flashing orange. Release the button.

5. The gate should start to open slowly to find the open stop. If the gate closes instead remove power,

change the polarity of the motor by swapping terminals 23 and 24 and start again from point 3.

6. When the opening stop is found the gate will close slowly searching for the closing stop.

7. When the closing stop is found the gate will complete a full open and close before exiting program

8. If using remote controls press and release quickly CH1. Green LED2 should light to indicate ready.

9. In the next ten seconds press for one second and release one of the buttons on your remote

control. The green LED turns off and on again waiting for further remote controls.

10. When you have programmed all remote controls simply wait ten seconds until DL2 goes out.

12. You can now make adjustments and connect accessories one at a time and test each time.

Q u e s t i o n s – s e r v i c e @ a u t o m a t i c s o l u t i o n s . c o m . a u

TAU 128MA

programming. Make sure they have no movement or flex.

copy of the solar power tips n tricks.

QUICKSTART

mode of working times.

11. Test your install.

be lit green.

Page 1

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for tau K128MA

- Page 1 TAU 128MA • TIP – You need solid opening and closing stops. The control board will search for these when programming. Make sure they have no movement or flex. • TIP – You need to fit three small loops of wire to your safety inputs to make anything work. These can be removed later if you install safety devices to these input terminals.

- Page 2 INSTALLATION GUIDE K128MA IT - Istruzioni originali...

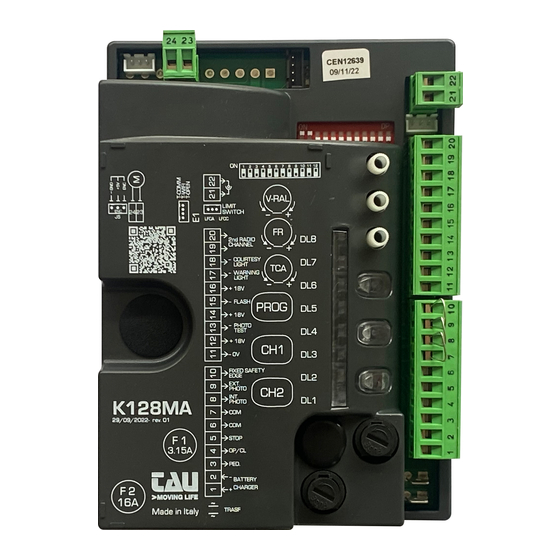

- Page 3 K128MA WIRING DIAGRAM Dip-switches 9 10 11 12 Trimmer: V-RAL 9 10 11 12 LFCA L V-RAL K128MA PROG LEDs: DL8 FIXED SAFETY EDGE EXT. PHOTO INT. PHOTO (SM) STOP OPEN/CLOSE PEDESTRIAN 3.15A ERRORS BATT TRAS...

-

Page 4: Power Supply

Aerial - Terminals 1 – 2: Careful NOT to invert polarity. - If Jumper J6 is plugged in, energy saving mode will be activated and, at the end of each manouvre, outputs 11-12, 12-13, 14-15, 16-17 and 16-18 will be switched off. Gate open Courtesy light Limit... - Page 5 CONNECTION OF BATTERY CHARGER + BATTERY (OPTIONAL) 9 10 11 12 LFCA LFCC V-RAL BATTERY CHARGER K128MA PROG ROSSO VERDE 3.15A BATTERY 12 V 7,2 Ah TRASF To ensure the gate operation during a power failure, the KB4 kit (battery charger + battery 12V 7.2Ah) can be used to connect to the control unit as shown in the diagram above.

-

Page 6: Solar Panel

CONNECTION OF SOLAR PANEL + ADJUSTMENT BOARD + BATTERY (OPTIONAL) SOLAR PANEL 9 10 11 12 LFCA LFCC V-RAL K128MA PROG ROSSO VERDE 3.15A BATTERY TRASF 12 V If you do not have the mains voltage to power the gate automation and you want to use renewable energy, you can connect a photovoltaic panel + adjustment board + 12V battery to the automation control unit as shown in the diagram above. -

Page 7: Installation

This product may only be installed and serviced by qualified personnel in compliance with current, laws, regulations and directives. When designing its products, TAU observes all applicable standards (please see the attached declaration of conformity) but it is of paramount importance that installers strictly observe the same standards when installing the system. -

Page 8: Technical Characteristics

STRIAN, etc.), in order to avoid gate malfunctions, it will be necessary to uncouple the various controls using RELAYS or using our 750T-RELE device. 2. INTRODUCTION The K128MA board has two working modes, selectable through the J6 jumper (see wiring diagram). J6 Not jumped: standard mode, i.e. the control unit is powered all the time;... - Page 9 STOP button N.C. input – Stops the automation in any position, temporarily pre- venting the automatic closure, if programmed. (5= STOP - 6= COM ) NOTE: A safety micro-switch is connected to the STOP push-button. In case 5 - 6 the STOP input remains open for more than 5 seconds, the operator will per- STOP form a cycle at a slow speed to reset the operating parameters to the values...

- Page 10 Quick coupling for connection for limit switches. Notice: connect/disconnect the limit switches with the control unit OPTIONAL J2 (FC) LIMIT SWITCHES disconnected. It is advisable to wait 10 seconds before powering up the control unit again. J3 (SM) MEMORY CARD Quick plug-in for MEMORY CARD connection for transmitters codes.

- Page 11 the automation ignores the closure command during opening and auto-close time NO REVERSE Off the automation responds as established by dip switch No. 2. On the pre-flashing function is enabled. PRE- FLASHING Off the pre-flashing function is disabled. On the “photocell test” function is enabled. FOTOTEST the “photocell test”...

- Page 12 If the automation closes instead of opening, stop the run of the gate (by cutting the photocells or closing the STOP contact), invert the polarity of the motor, take the gate at approx 0,5 m from the mechanical stop) and restart the procedure from the beginning.

-

Page 13: Obstacle Detection

7. K128MA CHARACTERISTICS TIMER-OPERATED OPENING AND CLOSING CYCLES The opening/closing of the automation can be controlled by means of a timer that has a free N.O. output contact (relay). The timer must be connected to terminals 4 - 6 (OPEN/CLOSE button) and can be programmed so that, at the desired opening time, the relay contact closes until the desired closing time (when the timer’s relay contact opens, enabling the automatic closing of the gate). - Page 14 no motor encoder signal; 3 (red) flashes : Check wiring, check encoder by TEST-ENCODER (optional); Check the correct flashing of led E1 * no motor signal; 4 (red) flashes: Check wiring, check the motor rotates freely and is powered directly by the battery; max current limit for motor exceeded; 5 (red) flashes : Excessive absorption peaks of the gearmotor, check there are no obstacles on the automation path, check the current absorption of the motor when in a no-load condition and when applied to the gate, master/slave communication error; 6 flashes (orange): Check wiring between the controllers, efficiency of slave controller (fuses), efficiency of interface boards;...

- Page 15 DL7 - Green EXTERNAL PHOTOCELLS LED signal DL8 - Green SENSITIVE EDGE LED signal Multiple errors are signalled by a 2-second pause between signals. Should the encoder (obstacle detection) activates while closing, the controller will reverse the direction and slowly open until the laef reaches its fully opened position. Auto Close function will be deactivated until a further command pulse is given.

-

Page 16: Memory Capacity

REMOTE PROGRAMMING BY MEANS OF T-4RP / K-SLIM-RP / S-2RP / S-4RP (V 4.X) With the new version of software V 4.X it is possible to carry out the remote self-learning of the new version of transmitters T-4RP / K-SLIM-RP / S-2RP / S-4RP (V 4.X), that is without pressing the receiver’s programming buttons. - Page 17 Check that the new and old remote control use the same technology. 13. GUARANTEE: GENERAL CONDITIONS TAU guarantees this product for a period of 24 months from the date of purchase (as proved by the sales document, receipt or invoice).

- Page 18 Declares under its sole responsibility, that the product: Electronic control unit designed for automatic movement of: Sliding gates for use in a: Residential/Apartment building use complete with: Radioreceiver Model: K128MA Type: K128MA Serial number: see silver label Commercial name: Control panel for one 18V motor with encoder Has been produced for incorporation on an access point (sliding gate) of for assembly with other devices used to move such an access point, to constitute a machine in accordance with the Machinery Directive 2006/42/EC.

- Page 19 Via Enrico Fermi, 43 - 36066 Sandrigo (VI) - Italy Tel +39 0444 750190 - Fax +39 0444 750376 info@tauitalia.com - www.tauitalia.com Foglietto illustrativo CARTA - Raccolta differenziata. Segui le indicazioni del tuo comune. (N.B.: togliere i punti metallici) Instruction leaflet PAPER - Waste separation. Follow the instructions of your city hall. (Note: remove the staples)

Need help?

Do you have a question about the K128MA and is the answer not in the manual?

Questions and answers