Table of Contents

Advertisement

Quick Links

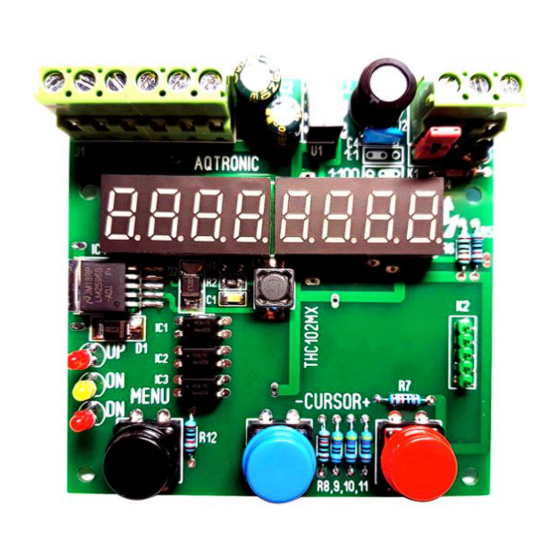

THC102MX

CNC PLASMA Torch Height Controller

Safety P-recautions

Enviroment cannot contain any explosive gas.

It must be wired by professional wiring staff. Otherwise, it may cause electronic

shock.

Cut off the power supply before wiring. Otherwise, it may cause electronic shock.

Do not touch any control port, internal boards and their electronic componets

while the electricity is turned on. Otherwise, it may cause electronic shock.

Device information

The unit is a modern analogue - microprocessor plasma torch height

controller that operates by analyzing voltage changes in the plasma source due

to variations in height between the torch tip and the material being cut. The mi-

croprocessor makes determinations to raise or lower the torch based off of the

strength of the voltage signal being read. It is equipped with an easy to read LED

display and two user friendly keys making operation simple and does not require

any additional measuring instruments. The device has patented solutions made

with the highest quality components to ensure a safe, durable, and reliable long-

term operation.

Top layer view:

Characteristics:

Supply voltage (V)

Plasma volatge input

Plasma voltage threshold

Plasma interface

I/O interface

Supported plasma ratio

Display

Weight

Dimensions L*W*H (mm)

AQTRONIC

THC102MX Operation manual

Typical

9-36VDC

0-350V

40V

Optical Isolated

Active Low Optical Isolated

1:1 / 1:100

8 bit 7 Segments

10 0g

8 0 * 80 * 23

1

http://www.aqtronic.com

Bottom layer view:

Max

48VDC

450V

2 50V

-

-

-

-

-

-

Advertisement

Table of Contents

Summary of Contents for AQTRONIC THC102MX

- Page 1 THC102MX http://www.aqtronic.com CNC PLASMA Torch Height Controller AQTRONIC THC102MX Operation manual Safety P-recautions Enviroment cannot contain any explosive gas. It must be wired by professional wiring staff. Otherwise, it may cause electronic shock. Cut off the power supply before wiring. Otherwise, it may cause electronic shock.

- Page 2 THC102MX http://www.aqtronic.com CNC PLASMA Torch Height Controller ATTENTION:When connecting directly, use the shortest possible cables for connecting the plasma source with THC controller - it is recommended the THC controller to be lo- Example 1:50 Ratio wiring. cated directly at the plasma source.

- Page 3 TH102MX http://www.aqtronic.com CNC PLASMA Torch Height Controller COM terminal is a common input terminal connected to the ARC, UP and DOWN optocoupler contacts inside the device, according to the diagram located on the cover. Suggested route is to “GND” at driver/pc end. Do not jumper this connection to the “7-35V”...

- Page 4 THC102MX http://www.aqtronic.com CNC PLASMA Torch Height Controller “HYS” (Hysteresis see image 15 page 5) - The hystere- sis voltage - a range in which the voltage is measured, in which there are signals controlling UP/DOWN is deactive.1-15V.Factory setting “1” “dLy” (delay) - delay time of output OK when the sys- tem detects the main (cutting) arc 1 - 15 seconds.

- Page 5 THC102MX http://www.aqtronic.com CNC PLASMA Torch Height Controller Image15 Image16...

Need help?

Do you have a question about the THC102MX and is the answer not in the manual?

Questions and answers