Subscribe to Our Youtube Channel

Summary of Contents for OTTO MOTORS Lifter MkIV

- Page 1 English OTTO Lifter MkIV - OMM-000108 Operation and maintenance manual OMM-000108 Publication date Jan-23...

- Page 2 Copyright © 2023 CLEARPATH and OTTO Motors are trademarks of Clearpath Robotics Inc. All other product and company names listed are trademarks or trade names of their respective companies. The information provided herein is for general guidance only and is subject to change. For support, please...

-

Page 3: Table Of Contents

OTTO Lifter MkIV - OMM-000108 TABLE OF CONTENTS 1. IMPORTANT SAFETY INFORMATION ..................6 1.1. Hazards ........................6 General hazards ......................7 Robot hazards ......................8 Charger hazards ......................9 1.2. Hazard labels ......................10 1.3. Safety awareness ......................12 Facility conditions ...................... - Page 4 OTTO Lifter MkIV - OMM-000108 7.15. Top door ........................37 7.16. Left side door ......................38 7.17. Safety LiDAR ......................38 7.18. 3D perception cameras ....................38 7.19. Fork impact sensors ....................39 7.20. Dock assist sensors ....................39 7.21. Incremental encoders ....................39 8.

- Page 5 OTTO Lifter MkIV - OMM-000108 12.2. CAN ICES-003(A) / NMB-003(A) ................64 13. Robot forklift pre-op checklist - OMM-000105 ................. 64 13.1. Robot forklift safety and operational checks ..............64 Robot off checks ......................64 Robot on checks ......................65 ©...

-

Page 6: Important Safety Information

OTTO Lifter MkIV - OMM-000108 1. IMPORTANT SAFETY INFORMATION The top priority of OTTO Motors is the safety of its users. OTTO Motors produces high power and fast-moving pieces of machinery that could cause serious injury, including death, if improperly used or maintained. -

Page 7: General Hazards

CAUTION • Never operate the product after faulty parts are identified. • Never expose OTTO Motors products to rain, condensation, or standing water. Store products in a clean and dry location. • Use appropriately rated lift equipment and follow safe lifting procedures as defined by the facility when lifting the product. -

Page 8: Robot Hazards

• IMPACT HAZARD! Never bypass the drive wheels of the robot while on a sloped surface. • Never use OTTO Motors products to transport people or live animals. • CRUSH or IMPACT HAZARD! Robots must be prevented from traveling in areas that do not follow Facility Conditions specifications, such as ramps and stairwells. -

Page 9: Charger Hazards

OTTO Lifter MkIV - OMM-000108 CAUTION • IMPACT HAZARD! Always maintain a safe distance from a robot in operation. A robot being operated in manual mode should only be operated by personnel who have been trained and authorized according to the standards of the facility in which the robot is in use. -

Page 10: Hazard Labels

1.2. Hazard labels Review the following to learn more about the labels that may be used on OTTO Motors products. Hazards can also apply to attachments and accessories used in conjunction with an OTTO Motors product. - Page 11 OTTO Lifter MkIV - OMM-000108 Label Title Description Label Title Description Grounding Improper grounding Pinching risk Keep hands and other electrical of OTTO Motors objects clear of pinch hazard chargers can result in points at all times. a potential shock risk.

-

Page 12: Safety Awareness

Component Overview section of the robot operation and maintenance manual. Personnel present in a facility with OTTO Motors products need to be made aware or be accompanied by personnel who are familiar with the specific risks and hazards associated with automated mobile robots. -

Page 13: Facility Conditions

OTTO Lifter MkIV - OMM-000108 • Personnel should be aware that OTTO Motors LiDAR safety scanners are laser products rated class 1/1M. Personnel must not look directly at the laser beam source. • Personnel should keep all loose clothing and body parts away from robots, accessories, attachments, and payloads, while they are in autonomous operation. -

Page 14: Payload Maximums And Stability

For additional information on the operating environment conditions, refer to the System Specifications in the product operation and maintenance manual. • OTTO Motors robots use LiDAR with a wavelength of 905 nanometers, and are designed to operate indoors free of direct sunlight. Infrared light sources (including sunlight, light curtains, welding) may interfere with the operation of robots when shone directly into the robot's optical sensors. -

Page 15: Battery Handling

Refer to the robot Safety Configuration document for the footprint dimensions. OTTO Motors autonomous mobile robots (AMR) use LiDAR to detect potential obstacles and obstacles located above a robot's LiDAR detection plane may not be perceived by a robot. Existing equipment in the facility could be rendered invisible to a robot due to an "overhang", for example a robot with wheels offset... -

Page 16: Safety System Functionality

OTTO Lifter MkIV - OMM-000108 Robots capable of 3D perception, either integrated or through use of an equipped 3D Perception Attachment, are better able to detect overhanging obstacles without the presence of perception-assist flaps. • Ideally, installed flaps should touch the floor; however, in instances where the flap can't be installed that close to the floor, the distance between the flap's bottom edge and the floor should not exceed 75 mm. -

Page 17: Emergency Stop System

See the applicable safety configuration for the robot and the MicroScan3 LIDAR Operating Instructions document for more details. Credentialed OTTO Motors platform users can learn more on the OTTO Motors Support Center (login required). -

Page 18: Footprint Safety

OTTO Lifter MkIV - OMM-000108 are also disabled while in manual mode. There is a collision risk with objects while driving the OTTO Lifter in manual mode. While controlling the autonomous mobile robot (AMR) using its pendant, there are no speed restrictions and the safety field sets monitored by the LiDAR are disabled. -

Page 19: Disclaimer

OTTO Motors assumes no responsibility for any errors or omissions that may appear in this document. In no event shall OTTO Motors be liable for any costs or damages arising from the use of this document or the hardware and software described within. The reference documents listed in this manual shall be applicable at the latest revision in effect. -

Page 20: Included Items

OTTO Lifter MkIV - OMM-000108 IMPORTANT Information in this document related to software functionality is up-to-date as of OTTO Motors software version 2.26. Hardware functionality outlined in this document pertains both to the base platform and the functionality of any of its versions. - Page 21 OTTO Lifter MkIV - OMM-000108 © Clearpath Robotics Inc. 2023. All rights reserved. CLEARPATH and OTTO are trademarks of Clearpath Robotics Inc. All other product and company names listed are trademarks or trade names of their respective companies.

-

Page 22: Applicable Documents

Take photos or make a drawing. If the robot is connected to OTTO Fleet Manager, create a manual snapshot to capture diagnostic information and robot sensor data to assist OTTO Motors in diagnosing the incident cause. Inspect the robot Shut down the robot. -

Page 23: Otto Lifter Specifications

6.1. Size and weight Component Specification Dimensions (L x W x H) OTTO Lifter MkIV: 2811 x 1201 x 2095 mm (110.7 x 47.3 x 82.3 in) Height (fully-raised forks) 2900 mm (114.2 in) Fork length OTTO Lifter MkIV: 1214 mm (47.8 in) Fork height OTTO Lifter MkIV: 53.5 mm (2.1 in) -

Page 24: Speed And Performance

Maximum autonomous mode OTTO Lifter MkIV: Reference ICD-000113 - Raised pallet pick-up/drop-off raised pick-up/drop-off height interface control document Credentialed OTTO Motors platform users can learn more on the OTTO Motors Support Center (login required). If access is required, contact OTTO Motors Support and they will be happy to answer any questions or provide access. -

Page 25: Battery And Power System

Raised drop-offs with dock target X, Y + / - 10 mm (0.4 in) IMPORTANT Docking accuracy is subject to the deployment. Please speak to an OTTO Motors representative for more information. Pallet positioning tolerance X, Y + / - 200 mm (7.87 in) (pick-up) Yaw + / - 15.0 °... -

Page 26: Operating Environment

IP classification IP20 Operating temperature range 0 °C to 40 °C (32 °F to 104 °F) Please contact OTTO Motors if lower operating temperatures are needed. Non-operating temperature -25 °C to 70 °C (-13 °F to 158 °F) range Operating relative humidity... -

Page 27: Safety System

OTTO Lifter MkIV - OMM-000108 Component Specification Sound pressure emissions 83.7 dB (audible indications) level 102.4 dB (horn) 6.7. Safety system Component Specification Intelligent braking Redundant monitoring with safety-system interlock Adaptive field sets Intelligent PL-d rated switching fieldsets (patent-pending) Standards compliance FCC (RF, for example: WiFi, 5G) ;... -

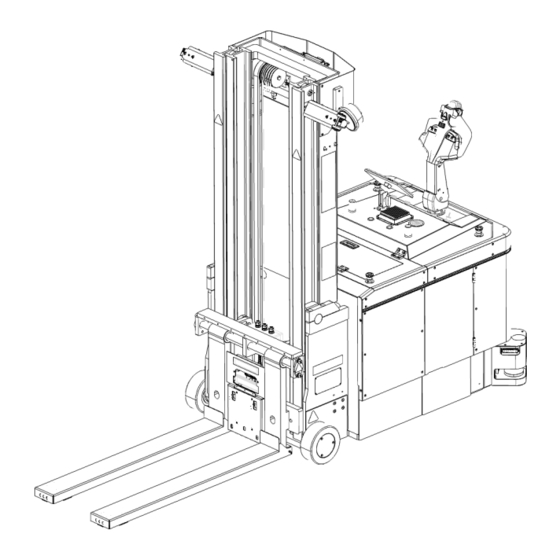

Page 28: Components

OTTO Lifter MkIV - OMM-000108 7.1. Components © Clearpath Robotics Inc. 2023. All rights reserved. CLEARPATH and OTTO are trademarks of Clearpath Robotics Inc. All other product and company names listed are trademarks or trade names of their respective companies. - Page 29 OTTO Lifter MkIV - OMM-000108 Power button Robot battery state indicator Safety Reset button Digital interface Auto button Dome light Direction lights Emergency Stop buttons Light pipe 3D perception cameras Safety LiDAR © Clearpath Robotics Inc. 2023. All rights reserved. CLEARPATH and OTTO are trademarks of Clearpath Robotics Inc.

-

Page 30: Power Button

OTTO Lifter MkIV - OMM-000108 Left side door Forks Top door Tiller WiFi antenna Dock assist sensors Fork impact sensors Key switch Rear door Top rear door 7.2. Power button The OTTO Lifter autonomous mobile robot (AMR) is started up and shut down using the Power button. -

Page 31: Auto Button

OTTO Lifter MkIV - OMM-000108 Reset button will be illuminated if the robot entered an emergency stop state and the conditions have been cleared to indicate that the safety system is now ready for reset. 7.5. Auto button The Auto button is used to control the operation mode of the OTTO Lifter. This button, when pressed, toggles the robot between autonomous and manual mode. -

Page 32: Robot Battery State Indicator

OTTO Lifter MkIV - OMM-000108 Movement controls Fork controls Fine control mode button Horn button Safety belly switch CAUTION PINCH HAZARD! Keep objects and body parts away from pinch points. 7.8. Robot battery state indicator The robot battery state indicator displays the current charge state of the robot battery. -

Page 33: Light Pipe And Visual Indications

OTTO Motors robots rely on audiovisual indications to warn nearby personnel of their presence, intent, and mode of motion. Ensure that the robot audio volume is at least loud enough that nearby personnel can detect the presence of the robot. - Page 34 OTTO Lifter MkIV - OMM-000108 Name Description Visual indication Docking The robot is docking. Front solid dull white Rear solid red Alternating yellow stripes WARNING CRUSH HAZARD! Pedestrians should be aware of hazard mode or docking mode audio-visual indications. When robots are in docking mode, the front of the robot is no longer safeguarded—...

-

Page 35: Safety Reset Button States

OTTO Lifter MkIV - OMM-000108 Name Description Visual indication Attachment The robot has activated activated its attachment or Full pulsing yellow its integrated lift. Working in The robot's place movement is locked as it Full solid green waits for further input from a user or attachment. -

Page 36: Speakers

The robot is on but has not completed the boot cycle. OTTO Lifter MkIV: Off Normal travel The robot is traveling normally. OTTO Lifter MkIV: Full solid green Parked The robot has entered a parked state. OTTO Lifter MkIV: Off Docking The robot is docking. -

Page 37: Direction Lights

OTTO Lifter MkIV - OMM-000108 Robot status Description Dome light state Blocked The robot is blocked from proceeding on its planned path. OTTO Lifter MkIV: Blinking yellow : Blinking yellow Safety stop The robot has entered a safety stop state. -

Page 38: Left Side Door

OTTO Lifter MkIV - OMM-000108 CAUTION PINCH HAZARD! Keep objects and body parts away from pinch points. 7.16. Left side door The left side door enables access to the OTTO Lifter autonomous mobile robot (AMR) battery compartment. 7.17. Safety LiDAR WARNING •... -

Page 39: Fork Impact Sensors

This section describes the operation of the product. Prior to using the robot, the surrounding area must be approved for autonomous navigation by an OTTO Motors representative. Never use the robot in an area without prior consultation by an OTTO Motors representative. -

Page 40: Locking-Out/Tagging-Out The Otto Lifter

OTTO Lifter MkIV - OMM-000108 8.1. Locking-out/tagging-out the OTTO Lifter WARNING SHOCK HAZARD! Always perform the lock-out/tag-out procedure at the facility or on the product before inspecting, servicing, cleaning, removing components, or opening any enclosure. To complete maintenance or inspection on the robot, ensure that the correct lock-out/tag-out procedure has been followed to remove energy from the system. -

Page 41: Starting Up The Otto Lifter

Electrical—inspect wiring/connections/terminals/contactors for damage—confirm screw terminals are secure Tiller handle—secure, free of debris, returns to neutral position after use LiDAR safety scanners—clean with an OTTO Motors-approved product 3D perception cameras—clean with an OTTO Motors-supported product Dock assist sensors—clean with an OTTO Motors-supported product Buttons—secure—check visually... -

Page 42: Shutting Down The Otto Lifter

OTTO Lifter MkIV - OMM-000108 Wait until the light pipe pattern has changed to the emergency stop state pattern. When ready, check that the Emergency Stop buttons are released, then press the Safety Reset button to enable the system. The light pipe should now switch to the neutral state pattern. - Page 43 OTTO Lifter MkIV - OMM-000108 Lock-out/tag-out the robot [40]. Open the top rear door. Open the left side door. Position the battery transfer cart in front of the open battery compartment. Use the pump truck to lower the battery transfer cart to the floor.

- Page 44 OTTO Lifter MkIV - OMM-000108 Pull the robot side of the battery connection up and out of the way of the battery compartment. © Clearpath Robotics Inc. 2023. All rights reserved. CLEARPATH and OTTO are trademarks of Clearpath Robotics Inc.

- Page 45 OTTO Lifter MkIV - OMM-000108 Using the handle on the battery, pull the battery out of the battery compartment and onto the battery transfer cart. CAUTION PINCH HAZARD! Keep objects and body parts away from pinch points. WARNING CRUSH HAZARD! OTTO Lifter batteries are extremely heavy and can tip easily.

-

Page 46: Manually Charging The Otto Lifter

OTTO Lifter MkIV - OMM-000108 11. Return the robot to operation. 8.5. Manually charging the OTTO Lifter The OTTO Lifter autonomous mobile robot (AMR) relies on a manual charger to charge the battery. Always attempt to charge the OTTO Lifter before the robot automatically shuts down at 25% charge level. A low battery exception will be displayed at 30% charge level. -

Page 47: Storing The Otto Lifter

8.7. Connecting to a robot using an Ethernet cable OTTO Motors robots can be interfaced with using a computer with an Ethernet port and an Ethernet cable. The Ethernet port on the OTTO Lifter autonomous mobile robot (AMR) is located under the right side door of the robot. -

Page 48: Connecting A Robot To A Network

8.9. Adding a robot to a fleet To add a robot to the fleet, a computer must be connected to the OTTO Motors autonomous mobile robot (AMR) and the robot must be connected to the network. It is also assumed that OTTO Fleet Manager has been fully deployed. -

Page 49: Autonomous Operation

OTTO Lifter MkIV - OMM-000108 Connect a computer to the robot using an Ethernet cable [47]. Using a supported browser, navigate to http://10.255.255.1:8090. OTTO Network Setup will be displayed. Under VPN Settings, enter the OTTO Fleet Manager Hostname (or IP). -

Page 50: Dispatching Jobs

OTTO Lifter MkIV - OMM-000108 WARNING • CRUSH or IMPACT HAZARD! Robots must be prevented from traveling in areas that do not follow Facility Conditions specifications, such as ramps and stairwells. • CRUSH HAZARD! Payloads, attachments, or a combination thereof, should always remain within the stability envelope relevant to the specific robot model. -

Page 51: Manual Mode Operation

OTTO Lifter MkIV - OMM-000108 Enable manual mode on the robot. Using the tiller, manually pick up the pallet. Ensure that the fork impact and dock assist sensors are not triggered. Confirm the robot is clear of obstacles on all sides by at least 1 m, if so, remove them. -

Page 52: Raising And Lowering Forks

OTTO Lifter MkIV - OMM-000108 CAUTION IMPACT HAZARD! Always maintain a safe distance from a robot in operation. A robot being operated in manual mode should only be operated by personnel who have been trained and authorized according to the standards of the facility in which the robot is in use. -

Page 53: Moving Forward And Backward

OTTO Lifter MkIV - OMM-000108 The tiller must be moved to the middle position (A) to operate the robot in manual mode using its tiller. The robot can't operate in autonomous mode when the tiller is in the middle position (A). Autonomous mode requires the tiller to be in a neutral position (B). -

Page 54: Using The Horn

OTTO Lifter MkIV - OMM-000108 Using the horn To activate an audible horn to warn others that the robot is being operated in manual mode, press the Horn button. IMPORTANT The horn can reach a sound pressure level of 102.4 dB. In such conditions, proper hearing protection may be necessary. -

Page 55: Navigating Exceptions

Select an individual exception to obtain more detail. If desired, select Show Attributes to display additional detail. Typically the detail shown through clicking Show Attributes will only be useful to advanced users or OTTO Motors Support staff. Filtering exceptions Exceptions can be filtered by their severity (error or warning), state (active or resolved), or source using the filter field. -

Page 56: Maintenance Schedule

OTTO Lifter MkIV - OMM-000108 CAUTION • PINCH HAZARD! Keep objects and body parts away from pinch points. • Only qualified personnel should perform installations, maintenance, and inspections. Take special care while maintaining and inspecting electrical equipment and devices. All personnel working on or around the system are to be aware of, and adhere to, all CAUTION, DANGER, and WARNING labels. -

Page 57: Robot Off Checks

Electrical—inspect wiring/connections/terminals/contactors for damage—confirm screw terminals are secure Tiller handle—secure, free of debris, returns to neutral position after use LiDAR safety scanners—clean with an OTTO Motors-approved product 3D perception cameras—clean with an OTTO Motors-supported product Dock assist sensors—clean with an OTTO Motors-supported product Buttons—secure—check visually... -

Page 58: Checking The Battery Water Level

• Always use level rigging when lifting or lowering the product. • BURN HAZARD! Do not overfill the battery. CAUTION Proper PPE must be worn, including safety footwear (ie. steel toe) around OTTO Motors products. Open the left side door. -

Page 59: Monthly Preventative Maintenance

OTTO Lifter MkIV - OMM-000108 The water level under each cap should reach the midpoint of the water fill basket (B). If required, add distilled water until the water level reaches the required level. 9.3. Monthly preventative maintenance Perform the following tasks at least once each month. -

Page 60: Inspecting String Pots

OTTO Lifter MkIV - OMM-000108 Inspecting string pots Inspect the string pots to ensure the cables do not have any debris on the wires or where they enter/leave the unit. If there is some debris, carefully remove it from the cable. Having a clean cable will ensure your lift system is running accurately. -

Page 61: Disposal

OTTO Lifter MkIV - OMM-000108 Fully lower the forks to their lowest position. Follow the lock-out/tag-out procedure. Inspect the hydraulic fluid level. The oil level height shall be in the not lifted position, minimum 8.4 L to 8.6 L. If necessary, add oil at the filling point. - Page 62 Remove any dust or debris using OTTO Motors-supported cleaning products. Start up the robot [41]. If all of the above checks fail, contact OTTO Motors Support. Red blinking lights and Robot in emergency stop Confirm that all Emergency Stop buttons are released.

-

Page 63: Declarations

Swipe up from the bottom of the display and tap < repeatedly until blank gray screen the loading screen appears. 12. Declarations This OTTO Motors product adheres to the standards summarized in this section and the following declarations apply: 12.1. SUPPLIER'S DECLARATION OF CONFORMITY 47 CFR § 2.1077 Compliance Information... - Page 64 OTTO Lifter MkIV - OMM-000108 Chief Financial Officer 1-844-733-6886 legal@clearpath.ai (legal@clearpath.ai) This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions: This device may not cause harmful interference, and This device must accept any interference received, including interference that may cause undesired operation.

- Page 65 Electrical—inspect wiring/connections/terminals/contactors for damage—confirm screw terminals are secure Tiller handle—secure, free of debris, returns to neutral position after use LiDAR safety scanners—clean with an OTTO Motors-approved product 3D perception cameras—clean with an OTTO Motors-supported product Dock assist sensors—clean with an OTTO Motors-supported product Buttons—secure—check visually...

Need help?

Do you have a question about the Lifter MkIV and is the answer not in the manual?

Questions and answers