Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Fiberplex FOI-6012

- Page 1 USER MANUAL Flexible Interface Dual RX/TX SFP/SFP+ Workbox FOI‐6012 / TD‐6012 ...

- Page 2 ...

- Page 3 Installation Site Install the unit in a place where the following conditions are met: The temperature and the relative humidity of the operating environment must be within the specified limits during operation of the unit. Values specified are applicable to the air inlets of the unit. Condensation may not be present during operation. If the unit is installed in a location subject to large variations of ambient temperature (e.g. in an OB‐van), appropriate precautions must be taken. Unobstructed airflow is essential for proper operation. Ventilation openings of the unit are a functional part of the design and must not be obstructed in any way during operation (e.g. ‐ by objects placed upon them, placement of the unit on a soft surface, or improper installation of the unit within a rack or piece of furniture). The unit must not be unduly exposed to external heat sources (direct sunlight, spot lights). Ambient Temperature Units and systems by FiberPlex are generally designed for an ambient temperature range (i.e. temperature of the incoming air) of 5 °C to 40 °C (41 °F to 104 °F). When rack mounting the units, the following facts must be considered: The permissible ambient temperature range for operation of the semiconductor components is 0 °C to +70 °C (32 °F to 158 °F) (commercial temperature range for operation). The airflow through the installation must allow exhaust air to remain cooler than 70 °C (158 °F) at all times. Average temperature increase of the cooling air shall be about 20 °C (68 °F), allowing for an additional maximum 10 °C increase at the hottest components. If the cooling function of the installation must be monitored (e.g. for fan failure or illumination with spot lamps), the exhaust air temperature must be measured directly above the modules at several places within the enclosure. Grounding and Power Supply Grounding of units with mains supply (Class I equipment) is performed via the protective earth (PE) conductor integrated in three‐pin Phoenix™ connector. Units with battery operation (< 60 V, Class III equipment) must be earthed separately. Grounding the unit is one of the measures for protection against electrical shock hazard (dangerous body currents). Hazardous voltage may not only be caused by defective power supply insulation, but may also be introduced by the connected audio or control cables. This equipment may require the use of a different line cord, attachment plug, or both, depending on the available power source at installation. If the attachment plug needs to be changed, refer servicing to qualified personnel. ...

- Page 4 Warranty, Service and Terms and Conditions of Sale For information about Warranty or Service information, please see our published ‘Terms and Conditions of Sale’. This document is available on fiberplex.com or can be obtained by requesting it from clients@fiberplex.com or calling 301.604.0100. Disposal Disposal of Packing Materials The packing materials have been selected with environmental and disposal issues in mind. All packing material can be recycled. Recycling packing saves raw materials and reduces the volume of waste. If you need to dispose of the transport packing materials, recycling is encouraged. Disposal of Used Equipment Used equipment contains valuable raw materials as well as substances that must be disposed of professionally. Please dispose of used equipment via an authorized specialist dealer or via the public waste disposal system, ensuring any material that can be recycled has been. Please take care that your used equipment cannot be abused. After having disconnected your used equipment from the mains supply, make sure that the mains connector and the mains cable are made useless. Disclaimer The information in this document has been carefully checked and is believed to be accurate at the time of publication. However, no liability is assumed by FiberPlex for inaccuracies, errors, or omissions, nor for loss or damage resulting either directly or indirectly from use of the information contained herein. Notice The firmware included in this product utilizes the Atmel Software Framework (ASF), Copyright (c) 2011 ‐ 2012 Atmel Corporation. All rights reserved. Redistribution and use in source and binary forms, with or without modification, are permitted provided that the following conditions are met: 1. Redistributions of source code must retain the above copyright notice, this list of conditions and the following disclaimer. 2. Redistributions in binary form must reproduce the above copyright notice, this list of conditions and the following disclaimer in the documentation and/or other materials provided with the distribution. 3. The name of Atmel may not be used to endorse or promote products derived from this software without specific prior written permission. 4. This software may only be redistributed and used in connection with an Atmel micro‐controller product. THIS SOFTWARE IS PROVIDED BY ATMEL “AS IS” AND ANY EXPRESS OR IMPLIED WARRANTIES, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE AND NON‐INFRINGEMENT ARE EXPRESSLY AND SPECIFICALLY DISCLAIMED. IN NO EVENT SHALL ATMEL BE LIABLE FOR ANY DIRECT, INDIRECT, INCIDENTAL, SPECIAL, EXEMPLARY, OR CONSEQUENTIAL DAMAGES (INCLUDING, BUT NOT LIMITED TO, PROCUREMENT OF SUBSTITUTE GOODS OR SERVICES; LOSS OF USE, DATA, OR PROFITS; OR BUSINESS INTERRUPTION) HOWEVER CAUSED AND ON ANY THEORY OF LIABILITY, WHETHER IN CONTRACT, STRICT LIABILITY, OR TORT (INCLUDING NEGLIGENCE OR OTHERWISE) ARISING IN ANY WAY OUT OF THE USE OF THIS SOFTWARE, EVEN IF ADVISED OF THE POSSIBILITY OF SUCH DAMAGE. ...

-

Page 5: Theory Of Operation

Introduction The true “Swiss Army Knife” of fiber optic transport, the FOI‐6012 in conjunction with any combination of a myriad of FiberPlex or third party SFP/SFP+ (Small Form‐Factor Pluggable) optical & electrical modules, allows you to transport what you want, when you want it, how you want it, wherever you want it; all over one product solution... The FiberPlex FOI‐6012 and SFP/ SFP+ module should be in everyone’s toolbox. Key Features Ultra flexible SFP+ to SFP+ Dual TX/RX interface Supports Data Rates up to 12.5 Gbps USB interface for full access to all SFP standard and custom registers Limitless Conversion applications including but not limited to: Video distribution Analog Video to Fiber Conversion SD‐SDI (composite) to HD video conversion MADI to Fiber Conversion OM1/OM2 to OM3 Multi‐mode Conversion Optical Repeater Multimode to Singlemode Fiber Conversion Theory of Operation Many sorts of interfaces, not just fiber, are now available in the SFP/SFP+ format, including Full HD video and networking. On the user, connector side, they support the signals appropriate to those protocols, but then convert them internally to a standard stream of high‐speed serial data. The FOI/TD‐6012 connects those standard streams together, so that the different interface protocols can talk the same language. Since the fiber‐based SFPs are the most generic, it is usually possible to connect, not only two different copper interfaces together in the same FOI/TD‐6012, but also to interpose a fiber link between them. Since the range of signals over fiber is so much greater than that of copper, this allows significant expansion of the range of those protocols. SFPs also have an additional, low‐speed serial interface that provides identification, monitoring and also control of the devices through the processor in the FOI/TD‐6012. The FOI‐6012 and TD‐6012 support dual transmit and dual receive SFP and SFP+ ONLY. For standard MSA and non‐MSA transceivers use the FOI‐6010 or TD‐6010. Differences between FOI‐6012 and TD‐6012 Functionally, the FOI‐6012 and TD‐6012 are identical. The only differences are the packaging and power supply. The FOI‐6012 is part of the FOI line of products designed for ruggedized mil applications. It is housed in the familiar FOI shielded can enclosure. For standalone applications it can be powered by adding a PSQ‐4909 AC supply or a PSQ‐4920 DC power supply (not included). Optionally, up to 8 FOI units can be mounted on ... -

Page 6: Getting Started

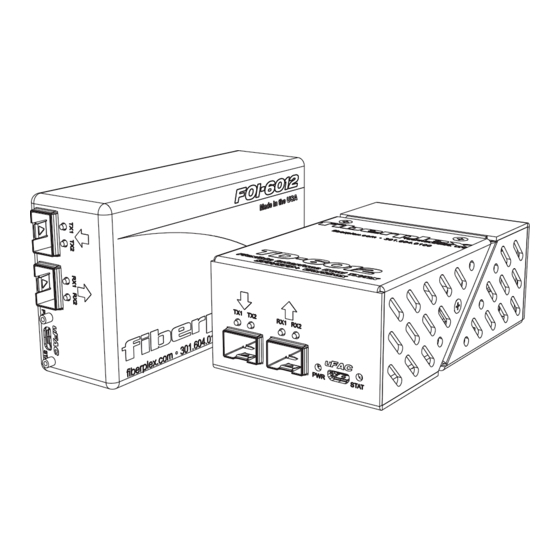

Getting Started Initial Inspection Immediately upon receipt, inspect the shipping container for damage. The container should be retained until the shipment has been checked for completeness and the equipment has been checked mechanically and electrically. If the shipment is incomplete, if there is mechanical damage, or if the unit fails to operate notify FiberPlex and make the shipping materials available for the carrier's inspection. ... - Page 7 Front Indicators/Connections Figure 1 TD‐6012 (left) and FOI‐6012 (right) Front Face SFP Port A – Install SFPs in this slot. These slots support dual TX or dual RX SFPs ONLY. Any non‐MSA complaint dual transmit or dual receive SFP can be used in these slots including but not limited to optical modules with data rates in the range of 155Mbps to 12.5 Gbps, video copper modules, copper quadrax SFP to SFP cables, etc. Each channel is independent and will accept any format and any user supplied SFP module that is appropriate for the user’s equipment. Above 500 Mbps, ultra‐low jitter SFP’s are recommended (40 psec.) as well as ITU‐T G.652.D/IEC 60793‐2‐50.B1.3 compliant fiber optic cable. SFP Port B – A second SFP slot functionally equivalent to SFP Port A. Any SFP installed in this slot will be directly electrically connected to the SFP in Port A. Any signals presented in the Receive of Port B will exit on the Transmit of Port A. TX Fault RX Detect – There is one pair of these LED indicators associated with each SFP slot on the unit. They correspond to the slot directly below. Color indications can be interpreted using the following table: TX Fault RX Detect SFP Installed Transmitter Functioning* Receive Signal Present* Off Off No n/a n/a Red Red Yes No No Red Green Yes No Yes Green Red Yes Yes No ...

- Page 8 uFAC – USB 2.0 Micro‐B connector for configuration and monitoring of SFP registers. This function is not currently implemented. Status – LED which indicates the health status of the unit. The LED can be interpreted according to the following table. Status Indicator Off If Power LED is on, there is an internal failure inside the FOI. Replace Green Power supply is operating properly Amber At limit of normal range of temperature, apply more cooling to the unit Red Exceeding temperature limits or internal failure Rear Indicators/Connections Figure 2 TD‐6012 (left) and FOI‐6012 (right) Rear Face Circular DC Power Connection – DC power entry for the unit. On the FOI‐6012 this is a Lemo connector designed to interface with either a PSQ power module or RMC chassis. On the TD‐6012 this is a standard DC connection for use with the included DC wall power supply. Phoenix CD Power Connection – Secondary power option for the TD‐6012. This is wired in direct parallel with the Circular connector and has the addition of a positive earth chassis ground connection. This can be used to power the unit on a client supplied power buss. Figure 3 FOI Module Installed in an RMC‐3101 Chassis ...

- Page 9 Power Requirements and Mounting Flexible mounting allows the FOI‐6012 to be chassis mounted or standalone configuration. Any combination of 8 FiberPlex FOI units can be mounted in a RMC‐3101 using CMA‐2001 chassis mount adapters. The RMC‐3101 can accommodate hot swapped redundant power. Alternately, the FOI‐6012 can be used in a standalone application when paired with a PSQ‐4909 for full range AC operation or the PSQ‐4920 for 12‐48VDC operation. Figure 4 FOI Module with PSQ‐4909 (left) and with CMA‐3002 (right) Lower TD Unit Over Screw Heads, Figure 5 Installing a TD Module Using Mounting Slots #2 Wood Screw, 1/2" Long, #1 Phillips Drive Figure 6 TD Module installation on a TDR‐01 tray...

-

Page 10: Handling Warnings

Inserting and Removing SFP Modules Handling Warnings SFP Modules are static sensitive. To prevent damage from electrostatic discharge (ESD), it is recommended to attach an ESD preventative wrist strap to your wrist and to a bare metal surface when you install or remove an SFP Module. Disconnect all optical or copper cables from SFP Modules prior to installing or removing the SFP Module. Failure to do so could result in damage to the cable, cable connector or the SFP Module itself. Removing and inserting an SFP Module can shorten its useful life, so you should not remove and insert SFP Modules any more often than is absolutely necessary. Protect optical SFP modules by inserting clean dust covers into them after the cables are removed. Be sure to clean the optic surfaces of the fiber cables before you plug them back into the optical ports of another SFP module. Avoid getting dust and other contaminants into the optical ports of your SFP modules, because the optics will not work correctly when obstructed with dust. Identify the Latch Type of the SFP Module SFP Modules have various latching mechanisms to secure them into the SFP Cage of a device. The FiberPlex WDM can support a host of manufacturers and brands of SFP Modules so the user may encounter any number of different latches. Some of these are described below. Bail Clasp Actuator Button The bail clasp SFP module has a clasp The actuator button SFP module includes a button that you that you use to remove or install the SFP push in order to remove the SFP module from a port. This module. button can either lift ‘Up’ or press ‘In’ to release the SFP Module depending on the manufacturer. Mylar Tab Slide Tab The Mylar tab SFP module has a tab that The slide tab SFP module has a tab underneath the front of the you pull to remove the module from a SFP module that you use to disengage the module from a port. port. ... - Page 11 Inserting a Module Attach an ESD‐preventative wrist or ankle strap, following its instructions for use. Disconnect and remove all interface cables from SFP Module. If the SFP Module has a Bail Clasp , close the Bail Clasp before inserting the SFP Module. With the gold finger connector on the bottom and the label on the top, line up the SFP Module with the empty cage and slide it in making sure that it is completely inserted and seated in the cage. Removing a Module Attach an ESD‐ preventative wrist or ankle strap, following its instructions for use. Disconnect and remove all interface cables from SFP Module. Release the latching mechanism. Bail Clasp – Open the bail clasp on the SFP Module with your finger in a downward direction. Actuator Button – Gently press the actuator up (or in) while pulling the body of the SFP Module to release the SFP Module from the cage. Mylar Tab – Pull the tab gently in a straight outward motion until it Actuator Button disengages from the port. Make sure the tab is not twisted when pulling as it may become disconnected from the SFP Module. Slide Tab ‐ With your thumb, push the slide tab on the ...

-

Page 12: Other Considerations

Other Considerations USB FiberPlex Auxilary Control (uFAC) Interface The FOI‐6012 includes a uFAC (FiberPlex Auxiliary Control over USB) interface which allows read write access to status and parameter registers in both installed SFP/ SFP+ modules if supported by Fiberplex. This port communicates over a USB 2.0‐compliant, full speed connection, via a USB Micro‐B connector. It enumerates as a custom Fiberplex device, requiring its own driver. Please contact Fiberplex Technologies for details and availability of the applications built around this interface. Although power can be supplied across the port, it is recommended that the appropriate external supply for the TD/FOI‐6012 be used. Power supplied through the USB port itself is not sufficient to power the device with SFPs installed. Video Optimization The Society of Motion Picture and Television Engineers, or SMPTE, is a leader in the development of standards for film, television, and other video. The Serial Digital Interface or SDI, was standardized by SMPTE for broadcast quality digital video transmission. Other standards evolved from this original standard, defining Enhanced, High‐definition (HD), 3G‐SDI (1080p) and Ultra High‐definition (UHD), or 4K video (2160p). To help ensure error‐free transmission, the standards include a data scrambler / descrambler to create a high density of transitions in the serial data, making it easier for the receiver to maintain timing. Where an encoding method such as 8B‐10B ensures a minimal sequential run of all ones or zeros, it does so at the cost of a 25% increase in bandwidth requirements. The scrambler / descrambler method does not require this, but as a result there are certain combinations of scrambler state and the next data bits to be scrambled that result in a sequence of up to twenty consecutive ones or zeros. These sequences are referred to as pathological conditions, and are present in specific shades of pink or grey. These pathological conditions may create errors in transmission through typical AC coupled optics, or any other AC coupled interface. Video Enhanced or SMPTE Compliant optics are designed to accept these pathological conditions, allowing the longer sequences of ones or zeros to pass without error. ... - Page 13 SFP MSA Compliance The SFP Multi‐Source Agreement (MSA) is an agreement that was drafted among competing manufacturers of SFP optical modules. The SFF Committee was formed to oversee the creation and maintenance of these agreements including the SFP MSA designated as INF‐8074i. This agreement describes a mutually agreed upon standard for the form and function of SFP modules. However, not all SFPs produced are MSA compliant. The MSA provides for a transceiver (TX/RX) pinout. Other industries such as broadcast had the need for dual TX and dual RX SFP for unidirectional applications such as video. Naturally, a non‐MSA standard was introduced allocating pinout assignments for dual output and dual input I/O configurations. In addition, the some of the internal serial communication pins were reassigned. The FOI/TD‐6012 will only accept non‐MSA Dual TX and Dual RX pinout schemes. The following table shows the differences in these pinouts. Pinout Comparison Chart PIN Transceiver (MSA) Transceiver (Non‐MSA) Dual TX (Non‐MSA) Dual RX (Non‐MSA) 1 VEE VEE VEE VEE 2 TX_FAULT [VEE] VEE NC Rx2‐ 3 TX_DIS NC NC Rx2+ 4 MOD_DEF(2) ‐ SDA VEE VEE VEE 5 MOD_DEF(1) ‐ SCL SCL ...

-

Page 14: Specifications

Specifications Figure 7 FOI‐6012 Dimensions ... - Page 15 Figure 8 TD‐6012 Dimensions ELECTRICAL SPECIFICATIONS Min Typ Max unit Power Requirement Voltage Range 5 9 40 VDC Supply Current, no SFPs 21 23 30 mA Supply Current, max 2 SFP+ ‐ 500 600 mA Environmental Storage Temperature ‐40 ‐ 85 °C OperatingTemperature 0 ‐ 50 °C Interface ...

- Page 16 18040-412 Guilford Rd. • Annapolis Junction, MD 20701 fiberplex.com • clients@fiberplex.com • 301.604.0100 6012UM‐1607 ...

Need help?

Do you have a question about the FOI-6012 and is the answer not in the manual?

Questions and answers