Table of Contents

Advertisement

Quick Links

Operator's Manual

Vantage

Register your machine:

www.lincolnelectric.com/register

Authorized Service and Distributor Locator:

www.lincolnelectric.com/locator

Save for future reference

Date Purchased

Code: (ex: 10859)

Serial: (ex: U1060512345)

IM10514

| Issue D ate Oct-18

© Lincoln Global, Inc. All Rights Reserved.

549

®

For use with machines having Code Numbers:

12865

Need Help? Call 1.888.935.3877

to talk to a Service Representative

Hours of Operation:

8:00 AM to 6:00 PM (ET) Mon. thru Fri.

After hours?

Use "Ask the Experts" at lincolnelectric.com

A Lincoln Service Representative will contact you

no later than the following business day.

For Service outside the USA:

Email: globalservice@lincolnelectric.com

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Lincoln Electric 12865

- Page 1 Operator’s Manual Vantage ® For use with machines having Code Numbers: 12865 Need Help? Call 1.888.935.3877 Register your machine: to talk to a Service Representative www.lincolnelectric.com/register Authorized Service and Distributor Locator: Hours of Operation: www.lincolnelectric.com/locator 8:00 AM to 6:00 PM (ET) Mon. thru Fri.

- Page 2 THANK YOU FOR SELECTING A QUALITY PRODUCT BY KEEP YOUR HEAD OUT OF THE FUMES. DON’T get too close to the arc. LINCOLN ELEC TRIC. Use corrective lenses if necessary to stay a reasonable distance away from the arc. READ and obey the Safety Data PLEASE EXAMINE CARTON AND EQUIPMENT FOR Sheet (SDS) and the warning label DAMAGE IMMEDIATELY...

- Page 3 W117.2-1974. A Free copy of “Arc Welding Safety” booklet E205 is available from the Lincoln Electric Company, 2.d. All welders should use the following procedures in order to 22801 St. Clair Avenue, Cleveland, Ohio 44117-1199.

- Page 4 SAFETY ELECTRIC SHOCK ARC RAYS CAN BURN. CAN KILL. 3.a. The electrode and work (or ground) circuits are 4.a. Use a shield with the proper filter and cover plates to protect your electrically “hot” when the welder is on. Do eyes from sparks and the rays of the arc when welding or not touch these “hot”...

- Page 5 SAFETY WELDING AND CUTTING CYLINDER MAY EXPLODE IF SPARKS CAN CAUSE DAMAGED. FIRE OR EXPLOSION. 7.a. Use only compressed gas cylinders containing the correct shielding gas for the process used 6.a. Remove fire hazards from the welding area. If and properly operating regulators designed for this is not possible, cover them to prevent the welding sparks the gas and pressure used.

- Page 6 TABLE OF CONTENTS...

-

Page 7: Table Of Contents

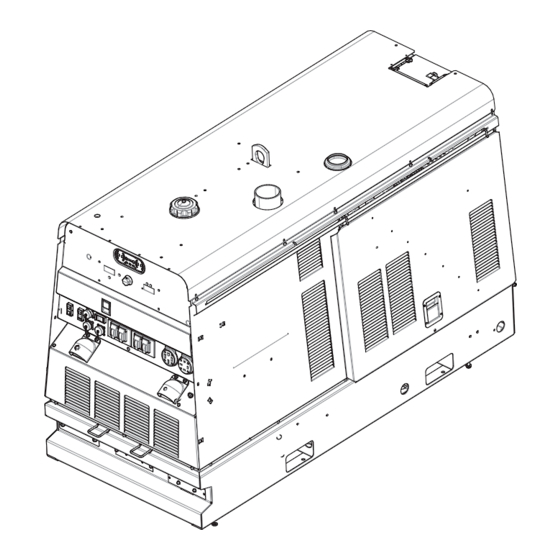

TABLE OF CONTENTS MAINTENANCE .............................SECTION D ROUTINE AND PERIODIC MAINTENANCE ........................D-1 AIR FILTER ................................D-1 FUEL FILTERS................................D-3 COOLING SYSTEM ..............................D-3 BATTERY HANDLING..............................D-3 NAMEPLATES / WARNING DECALS MAINTENANCE ....................D-4 WELDER / GENERATOR MAINTENANCE........................D-4 GFCI TESTING AND RESETTING PROCEDURE ......................D-5 TROUBLESHOOTING .............................SECTION C HOW TO USE TROUBLESHOOTING GUIDE ........................E-1 TROUBLESHOOTING GUIDE ............................E-2 WIRING, CONNECTION DIAGRAMS AND DIMENSION PRINT ................SECTION F... - Page 8 VANTAGE ® INSTALLATION GENERAL DESCRIPTION The VANTAGE® 549 is a diesel engine-driven welding power OUTPUT @ 104°F(40°C) - WELDER AND GENERATOR source. The machine uses a brush type alternating current Welding Range generator for DC multi-purpose welding, for 120/240 VAC single 30 - 575 Amps CC/CV phase and 240V three phase auxiliary standby power.

- Page 9 VANTAGE ® INSTALLATION INSTALLATION FIGURE A.1 ON / OFF VDR SWITCH SAFETY PRECAUTIONS WARNING Do not attempt to use this equipment until you have thoroughly read all operating and maintenance manuals supplied with your machine. They include important safety precautions, detailed engine starting, operating and maintenance instructions and parts lists.

- Page 10 VANTAGE ® INSTALLATION ANGLE OF OPERATION HIGH TEMPERATURE OPERATION To achieve optimum engine performance the VANTAGE® 549 At temperatures above 104°F (40°C), output voltage derating may should be run in a level position. The maximum angle of operation be necessary. For maximum output current ratings, derate welder for the Deutz engine is 30 degrees in all directions.

- Page 11 VANTAGE ® INSTALLATION TOWING Use a recommended trailer for use with this equipment for road, The VANTAGE® 549 is shipped with the engine crankcase filled in-plant and yard towing by a vehicle(1). If the user adapts a non- with high quality SAE 10W-30 Oil that meets (API class CJ-4 or Lincoln trailer, they must assume responsibility that the method of better) for diesel engines.

- Page 12 VANTAGE ® INSTALLATION BATTERY CONNECTION SPARK ARRESTOR Some federal, state or local laws may require that gasoline or CAUTION diesel engines be equipped with exhaust spark arresters when they are operated in certain locations where unarrested sparks Use caution as the electrolyte is a strong acid that can burn may present a fire hazard.

- Page 13 VANTAGE ® INSTALLATION REMOTE CONTROL WELDING OUTPUT CABLES The VANTAGE® 549 is equipped with a 12-pin and a 14-pin With the engine off, route the electrode and work cables through connector. To enable remote control capabilities, the the strain relief bracket provided on the front of the base and LOCAL/REMOTE switch must be in the REMOTE position.

- Page 14 VANTAGE ® INSTALLATION FIGURE A.3 AUXILIARY POWER RECEPTACLES CAUTION • Loose connections will cause the output terminals to 10A 42V/40V ARCLINK BREAKERS overheat. The terminals may eventually melt. 20A 120V AUXILIARY BREAKERS BATTERY 20A BREAKER • Do not cross the welding cables at the output terminal connection.

- Page 15 VANTAGE ® INSTALLATION STANDBY POWER CONNECTIONS 2. Take necessary steps to assure load is limited to the capacity of the VANTAGE® 549 by installing a 50 amp, 240 VAC The VANTAGE® 549 is suitable for temporary, standby or double pole circuit breaker. Maximum rated load for each leg emergency power using the engine manufacturer’s recommended of the 240 VAC auxiliary is 50 amps.

- Page 16 VANTAGE ® INSTALLATION FIGURE A.5 CONNECTION OF WIRE FEEDERS WITH CONTROL Set Mode to Set Weld Terminals to CABLE (14 PIN) Remotely Controlled CV Wire WARNING Set Polarity to Match Electrode Polarity Shut off welder before making any electrical connections. CONNECTION OF LF-72, LF-74, FLEX FEED 74 HT, Set to FLEX FEED 84, LN-25 PRO DUAL POWER TO THE...

- Page 17 VANTAGE ® INSTALLATION FIGURE A.7 CONNECTION OF ACROSS THE ARC WIRE FEEDERS TO THE VANTAGE® 549 These connections instructions apply to both the LN-25 Pro and Activ8 models. The feeders have an internal contactor and the Weld electrode is not energized until the gun trigger is closed. When the Terminals On gun trigger is closed the wire will begin to feed and the welding process is started.

- Page 18 VANTAGE ® INSTALLATION FIGURE A.5 CONNECTION OF WIRE FEEDERS WITH CONTROL Set Mode to Set Weld Terminals to CABLE (14 PIN) Remotely Controlled CV Wire WARNING Set Polarity to Match Electrode Polarity Shut off welder before making any electrical connections. CONNECTION OF LF-72, LF-74, FLEX FEED 74 HT, Set to FLEX FEED 84, LN-25 PRO DUAL POWER TO THE...

- Page 19 The use of an arc welder for pipe thawing is not • Insulate yourself from the work and approved by the CSA, nor is it recommended or supported ground. by Lincoln Electric. • Always wear dry insulating gloves. GENERATOR ENGINE EXHAUST can kill.

- Page 20 VANTAGE ® OPERATION CONTROLS AND SETTINGS All welder and engine controls are located on the case front panel. Refer to Figure B.1 and the explanations that follow. ENGINE CONTROLS 1. STOP / (LOW IDLE/RUN) / (HIGH IDLE/RUN) a. When switched from “High” to “Auto” or after starting the engine, the engine will operate at full speed for approximately SWITCH 12 seconds and then go to low idle speed.

- Page 21 VANTAGE ® OPERATION Idler Operational exceptions 5. VRD (Voltage Reduction Device) INDICATOR LIGHTS- On the front panel of the VANTAGE® 549 are two When the WELDING TERMINALS switch is in the “Remotely indicator lights. A red light when lit indicates OCV(Open Circuit Controlled”...

- Page 22 VANTAGE ® OPERATION FIGURE B.2 Alternate CV mode selection. Default CV mode will be non- synergic FCAW-SS (mode 6). Alternate settings will be non- synergic GMAW (mode 5) and non-synergic FCAW-GS (mode 7). The left display will show “CV” and “type” alternately at 0.5 second intervals.

- Page 23 VANTAGE ® OPERATION Selection of the remote connector for stick (SMAW) modes. The FIGURE B.10 customer can select between the 12-pin or the 14-pin connector for the remote potentiometer input when in the “remote” switch position for stick (SMAW) modes. The default from the factory will be the 12-pin connector.

- Page 24 VANTAGE ® OPERATION 7. WELD TERMINALS ON SWITCH- Output is enabled 15. WELD OUTPUT TERMINALS “+” POSITIVE AND when in the ON position. Output is remotely controlled when in “-” NEGATIVE - These 1/2” - 13 studs with flange nuts the REMOTE position.

- Page 25 VANTAGE ® OPERATION 28. DIAGNOSTIC PLUG - This is used by Field Service TABLE B.1 shops to connect and troubleshoot engine error codes and is DEFINITION found on the firewall inside the machine on the service side. CONDITION (Figure B.12) Steady green System is communicating normally.

- Page 26 Many variables beyond the control of The In constant current modes, this control adjusts the welding Lincoln Electric Company affect the results obtained in amperage. applying these programs. These variables include, but are...

- Page 27 VANTAGE ® OPERATION Most pulse welding programs are synergic. As the wire feed speed is adjusted, the VANTAGE® 549 will automatically recalculate the waveform parameters to maintain similar arc properties. The VANTAGE® 549 utilizes “adaptive control” to compensate for changes in the electrical stick-out while welding. (Electrical stick-out is the distance from the contact tip to the work piece.) The VANTAGE®...

- Page 28 VANTAGE ® OPERATION WELDER OPERATION TOUCH START TIG MODE DUTY CYCLE The VANTAGE® 549 can be used in a wide variety of DC TIG Duty cycle is the percentage of time the load is being applied in a welding applications. 10 minute period.

- Page 29 VANTAGE ® OPERATION SETTINGS WHEN USING THE K930-2 TIG MODULE • Set the WELD MODE switch to the “Touch Start TIG Setting”. • Set the Stop/Auto Idle/High Idle switch to the “AUTO/RUN” position. • Set the WELDING TERMINALS switch to the “Remotely Controlled”...

- Page 30 VANTAGE ® OPERATION CV-WIRE MODE ARC LINK Connect a wire feeder to the VANTAGE® 549 and set welder This weld mode is intended to unlock basic non-synergic and controls according to the instructions listed earlier in this section. synergic modes intended for use with compatible ArcLink wire feeders.

- Page 31 VANTAGE ® OPERATION PARALLELING When paralleling machines in order to combine their outputs, all units must be operated in the CC-STICK mode at the same output settings. To achieve this, turn the WELD MODE switch to the CC- STICK position. Operation in other modes may produce erratic outputs, and large output imbalances between the units.

- Page 32 VANTAGE ® OPERATION AUXILIARY POWER OPERATION SIMULTANEOUS WELDING AND AUXILIARY POWER LOADS Start the engine and set the IDLER control switch to the desired operating mode. Full power is available regardless of the welding It must be noted that the above auxiliary power ratings are with no control settings, if no welding current is being drawn.

- Page 33 VANTAGE ® OPERATION TYPICAL FUEL CONSUMPTION Refer to Table B.2 for typical fuel consumption of the VANTAGE® 549 Engine for various operating scenarios. Table B.2 (Deutz TD 2.9 L4) Fuel Consumption HRS @ 25 GAL(94.6L) GAL/HR Liters/Hr 30.30 High Idle 0.83 3.12 39.40...

- Page 34 6 and 14-pin remote connections TIG welding with square wave performance, use the AC generator can be made to this unit. For all Lincoln Electric Chopper of the engine-driven welder to supply the power. Easy setup.

- Page 35 VANTAGE ® ACCESSORIES WIRE FEEDER OPTIONS LN-25 Ironworker™ Wire Feeder - Portable CV unit for flux-cored and mig welding with maxtrac® wire drive system. includes digital meters for wire feed speed/amperage and voltage, gas solenoid, internal contactor and 5/64 in. (2.0 mm) drive roll kit for cored wire.

-

Page 36: Maintenance

VANTAGE ® MAINTENANCE MAINTENANCE AIR FILTER WARNING SAFETY PRECAUTIONS READ AND UNDERSTAND ENTIRE SECTION BEFORE • Excessive air filter restriction will result in reduced OPERATING MACHINE. engine life. • Never use gasoline or low flash point solvents for cleaning the air cleaner element. A fire or explosion WARNING could result. - Page 37 VANTAGE ® MAINTENANCE Service Instructions Service Instructions Single- and Two-Stage Engine Air Cleaners Single- and Two-Stage Engine Air Cleaners Inspect the New Filter for Damage Inspect the New Filter for Damage Remove the Filter Remove the Filter Inspect the new filter carefully, paying attention to Unfasten or unlatch the the inside of the open end, which is the service cover.

-

Page 38: Fuel Filters

VANTAGE ® MAINTENANCE FUEL FILTERS BATTERY HANDLING WARNING WARNING GASES FROM BATTERY can When working on the fuel system explode. • Keep naked lights away, do not smoke! • Keep sparks, flame and cigarettes away from • Do not spill fuel! battery. -

Page 39: Nameplates / Warning Decals Maintenance

VANTAGE ® MAINTENANCE WARNING NAMEPLATES / WARNING DECALS MAINTENANCE Do not attempt to polish slip rings while the engine is Whenever routine maintenance is performed on this machine - or running. at least yearly - inspect all nameplates and labels for legibility. Replace those which are no longer clear. -

Page 40: Gfci Testing And Resetting Procedure

VANTAGE ® MAINTENANCE FIGURE D.2 Green Light GFCI TESTING AND RESETTING PROCEDURE The GFCI should be properly tested at least once every month or whenever it is tripped. To properly test and reset the GFCI: • If the GFCI has tripped, first carefully remove any load and check it for damage. -

Page 41: Troubleshooting

VANTAGE ® TROUBLESHOOTING TROUBLESHOOTING HOW TO USE TROUBLESHOOTING GUIDE WARNING Service and Repair should only be performed by Lincoln Electric Factory Trained Personnel. Unauthorized repairs performed on this equipment may result in danger to the technician and machine operator and will invalidate your factory warranty. - Page 42 VANTAGE ® TROUBLESHOOTING Observe all Safety Guidelines detailed throughout this manual PROBLEMS POSSIBLE RECOMMENDED (SYMPTOMS) CAUSE COURSE OF ACTION ENGINE PROBLEMS Major Physical or Electrical Damage . Contact your Local Lincoln is Evident. Authorized Field Service Facility. 1. Battery low. Engine will not crank 2.

- Page 43 VANTAGE ® TROUBLESHOOTING Observe all Safety Guidelines detailed throughout this manual PROBLEMS POSSIBLE RECOMMENDED (SYMPTOMS) CAUSE COURSE OF ACTION FUNCTION PROBLEMS Battery does not stay charged. 1. Faulty battery. 2. Faulty engine alternator. 3. Loose or broken lead in charging circuit.

- Page 44 VANTAGE ® TROUBLESHOOTING Observe all Safety Guidelines detailed throughout this manual PROBLEMS POSSIBLE RECOMMENDED (SYMPTOMS) CAUSE COURSE OF ACTION FUNCTION PROBLEMS Engine goes to low idle but does 1. Faulty Weld Control PCB or Idler not stay at low idle. relay.

- Page 45 VANTAGE ® WIRING DIAGRAMS...

- Page 46 VANTAGE ® CONNECTION DIAGRAMS...

- Page 47 VANTAGE ® CONNECTION DIAGRAMS...

- Page 48 VANTAGE ® CONNECTION DIAGRAMS...

- Page 49 VANTAGE ® CONNECTION DIAGRAMS...

- Page 50 VANTAGE ® CONNECTION DIAGRAMS...

- Page 51 VANTAGE ® CONNECTION DIAGRAMS...

- Page 52 VANTAGE ® CONNECTION DIAGRAMS...

- Page 53 VANTAGE ® CONNECTION DIAGRAMS...

- Page 54 VANTAGE ® CONNECTION DIAGRAMS F-10...

- Page 55 VANTAGE ® CONNECTION DIAGRAMS F-11...

- Page 56 VANTAGE ® CONNECTION DIAGRAMS F-12...

- Page 57 VANTAGE ® CONNECTION DIAGRAMS F-13...

- Page 58 VANTAGE ® DIMENSION PRINT F-14...

- Page 59 VANTAGE ® NOTES F-15...

- Page 60 VANTAGE ® NOTES F-16...

- Page 62 WARNING Do not touch electrically live parts or Keep flammable materials away. Wear eye, ear and body protection. electrode with skin or wet clothing. Insulate yourself from work and AVISO DE ground. Spanish PRECAuCION No toque las partes o los electrodos Mantenga el material combustible Protéjase los ojos, los oídos y el bajo carga con la piel o ropa moja-...

- Page 63 WARNING Keep your head out of fumes. Turn power off before servicing. Do not operate with panel open or Use ventilation or exhaust to guards off. remove fumes from breathing zone. AVISO DE Spanish PRECAuCION Los humos fuera de la zona de res- Desconectar el cable de ali- No operar con panel abierto o piración.

- Page 64 We respond to our customers based on the best information in our possession at that time. Lincoln Electric is not in a position to warrant or guarantee such advice, and assumes no liability, with respect to such information or advice.

Need help?

Do you have a question about the 12865 and is the answer not in the manual?

Questions and answers