Subscribe to Our Youtube Channel

Summary of Contents for Landoll 825D Series

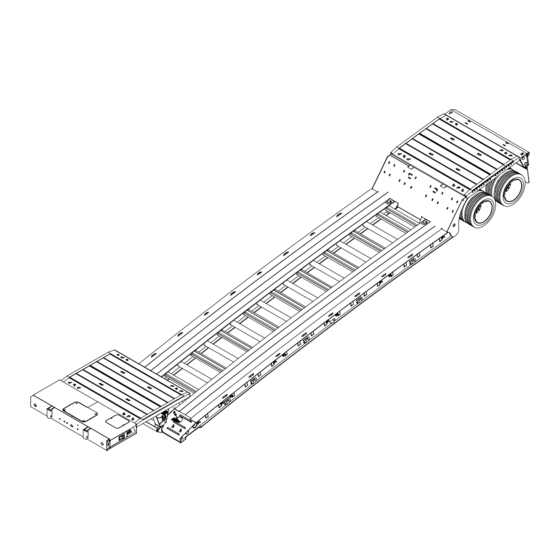

- Page 1 Model 825D/835D Series Detachable Semitrailer Operator’s Manual LANDOLL CORPORATION 1900 North Street Marysville, Kansas 66508 (785) 562-5381 800-428-5655 ~ WWW.LANDOLL.COM F-691-0913 09/2013...

-

Page 3: Table Of Contents

Table of Contents Introduction Understanding Safety Statements ..........1-2 Standard Specifications Operating Instructions General . - Page 4 Lift Axle Operation (Option) (Used on Rigid Three Axle Frame) ..... . . 3-17 Suspension Operation (Axle Down) ......... . . 3-17 Axle Lift Operation (Axle Up) .

- Page 5 Brake System Maintenance ........... . . 4-17 General .

- Page 6 F-691-0913 Edition...

-

Page 7: Introduction

PARTS MANUAL is a separate manual showing the various assemblies, subassemblies, and systems. Refer to that manual when ordering Landoll replacement parts. Order parts from your Landoll dealer. WARRANTY The Warranty Registration form is included with the product documents. -

Page 8: Understanding Safety Statements

INTRODUCTION Understanding Safety Statements You will find various types of safety information on the following pages and on the machine signs (decals) attached to the vehicle. This section explains their meaning. The Safety Alert Symbol means ATTENTION! YOUR SAFETY IS INVOLVED! ... -

Page 9: Standard Specifications

Chapter 2 Standard Specifications MODEL 825D/835D CAPACITY*: 55,000 LB. DISTRIBUTED MODEL 825D 50,000 LB. CONCENTRATED IN 16’ 70,000 LB. DISTRIBUTED MODEL 835D 60,000 LB. CONCENTRATED IN 12’ PULL OUT EXTENSION MAXIMUM CAPACITY IS ONE HALF FRAME CAPACITY LISTED ABOVE. GOOSENECK: 12’-0”... - Page 10 STANDARD SPECIFICATIONS MODEL 825D/835D * CAPACITY RATINGS ARE FRAME CAPACITIES ONLY. ACTUAL LOAD CAPACITIES MAY BE RESTRICTED BY FACTORS SUCH AS GROSS AXLE WEIGHT RATINGS (GAWR) OR STATE AND FEDERAL REGULATIONS. TIRE, BRAKE, AXLE, OR WHEEL SELECTION MAY ALSO LIMIT CAPACITY. ** TRACTOR HYDRAULIC POWER SUPPLY MUST BE CAPABLE OF OPERATING AT THIS PRESSURE AND FLOW RATE AND BE EQUIPPED WITH A PRESSURE RELIEF VALVE SET AT THIS PRESSURE.

- Page 11 STANDARD SPECIFICATIONS SPECIFIC BOLT TORQUES AIR RIDE SUSPENSION: EQUALIZER BEAM PIVOT AND ADAPTER BOLTS 800 FT.-LBS. DESIGNATED W/ NEWAY ON BOLT HEAD 550 FT.-LBS. DESIGNATED W/ HOLLAND NEWAY ON BOLT HEAD 150 FT.-LBS. SHOCK ABSORBER MOUNTING AIR SPRING MOUNTING: 35 FT.-LBS. 1/2”...

- Page 12 STANDARD SPECIFICATIONS LANDOLL CORPORATION GENERAL TORQUE SPECIFICATIONS (REV. 4/97) THIS CHART PROVIDES TIGHTENING TORQUES FOR GENERAL PURPOSE APPLICATIONS WHEN SPECIAL TORQUES ARE NOT SPECIFIED ON PROCESS OR DRAWING. ASSEMBLY TORQUES APPLY TO PLATED NUTS AND CAPSCREWS ASSEMBLED WITHOUT SUPPLEMENTAL LUBRICATION (AS RECEIVED CONDITION). THEY DO NOT APPLY IF SPECIAL GRAPHITE MOLY-DISULFIDE OR OTHER EXTREME PRESSURE LUBRICANTS ARE USED.

- Page 13 STANDARD SPECIFICATIONS LANDOLL CORPORATION HYDRAULIC FITTING TORQUE SPECIFICATIONS JIC, ORS, & ORB (REV. 10/97) THIS CHART PROVIDES TIGHTENING TORQUES FOR HYDRAULIC FITTING APPLICATIONS WHEN SPECIAL TORQUES ARE NOT SPECIFIED ON PROCESS OR DRAWING. ASSEMBLY TORQUES APPLY TO PLATED CARBON STEEL AND STAINLESS STEEL FITTINGS ASSEMBLED WITHOUT SUPPLEMENTAL LUBRICATION (AS RECEIVED CONDITION) THEY DO NOT APPLY IF SPECIAL GRAPHITE MOLY-DISULFIDE OR OTHER EXTREME PRESSURE LUBRICANTS ARE USED.

- Page 14 STANDARD SPECIFICATIONS F-691-0913 Edition...

-

Page 15: Operating Instructions

Chapter 3 Operating Instructions General Anti-Lock Brake System (ABS) The Anti-Lock Brake System of the semitrailer is constant This section supplies information for operation of the powered by the auxiliary (blue) circuit of the seven way semitrailer. It describes and locates controls and gives electrical connector, with backup power from the stop general operation procedures. - Page 16 OPERATING INSTRUCTIONS LOAD LIFT ARM BLOCK LIFT CYLINDER REAR FLAG HOLDER ABS BLINK CODE DIAGNOSTIC SCALE-O-MATIC TOOL (OPTION) AIR RAISE/LOWER (825D-835D AG) (OPTION) LOAD CARRIER CARRIER LOCK FEMALE (RETURN) AND MALE (PRESSURE) HYDRAULIC COUPLINGS DETAIL A ABS LIGHT SEE DETAIL A REAR BUMPER INSTALLATION AIR RAISE/LOWER...

-

Page 17: Electrical

OPERATING INSTRUCTIONS Electrical Pre-Coupling of Semitrailer and Tractor The only electrical operation required of the operator is interconnection of the towing vehicle electrical cable plug 1. Slowly back the tractor/truck (towing vehicle) up to with the semitrailer electrical receptacle. the front end of the semitrailer so the kingpin of the It is necessary that the tractor blue wire be connected to semitrailer is centered between the tractor fifth wheel the appropriate electrical source on the tractor. -

Page 18: Coupling Of The Tractor To The Semitrailer

OPERATING INSTRUCTIONS Coupling of the Tractor to the Connecting Tractor Services to Semitrailer the Semitrailer 1. Connect the towing vehicle 7-pole electrical plug to DANGER the electrical receptacle on the front of the semitrailer (See Figure 3-2.) Keep all personnel clear of front, rear, and sides of towing vehicle and semitrailer during coupling, IMPORTANT component operations, and uncoupling. -

Page 19: Tractor And Semitrailer Check-Out

OPERATING INSTRUCTIONS Tractor and Semitrailer 1. Activate the hydraulic power source. 2. Using the TRAILER LIFT lever, lift the trailer up until Check-Out the load blocks can be lowered into position (See Figure 3-1.) WARNING 3. Activate the TRAILER LIFT lever “DOWN” until the semitrailer rests completely on the load blocks (See Failure to properly set and check parking brake, “Trailer Lift Lever”... - Page 20 OPERATING INSTRUCTIONS ENGINE THROTTLE (OPTION) WORK LIGHT SWITCH (OPTION) LOAD BLOCK RELEASE BUTTON CARRIER LOCK RELEASE BUTTON WIRED REMOTE CONTROL RECEPTACLE WINCH HYDRAULIC LEVER (OPTION) TRAILER LIFT LEVER HYDRAULIC FLIP AUXILIARY LEVER (OPTION) 7 WAY ELECTRICAL RECEPTACLE SERVICE GLADHAND W/ SHUTOFF EMERGENCY GLADHAND W/ SHUTOFF 825-835d hyd controls Figure 3-3: Hydraulic Controls...

-

Page 21: Towing The Semitrailer

OPERATING INSTRUCTIONS Towing the Semitrailer CAUTION Driving the towing vehicle with the semitrailer coupled If a fault exists in the semitrailer ABS, normal behind requires constant attention to the overall length of braking will occur, but wheels may lock. Service the combination. -

Page 22: Parking The Trailer

OPERATING INSTRUCTIONS Parking the Trailer Trailer Lift Lever 1. Position truck/semitrailer rig on a level, solid surface. The TRAILER LIFT lever (See Figures 3-1 and 3-3) is located on the driver’s side of the gooseneck assembly. It 2. Set the PARKING BRAKE, not the semitrailer is the middle lever and has three positions: hand brake, and check for proper brake holding. -

Page 23: Pull Out Extensions

OPERATING INSTRUCTIONS Pull Out Extensions 1. Pull out extensions are adjustable in six inch increments. Extension lock pin can be held in released position when pulled back and rotated one DANGER quarter turn into catch. 2. Adjust pull out to desired extended position and trip Do not operate if any extension is not locked in lock pin to secure. - Page 24 OPERATING INSTRUCTIONS MAXIMUM WIDTH NOT TO EXCEED TRAILER WIDTH CENTERLINE OF CENTERLINE OF TRACKS OR TIRES TRACKS OR TIRES OUTRIGGER FLAG HOLDER WELDMENT 835-or2a Figure 3-5: Swingout Outrigger Platform Extension 3-10 F-691-0913 Edition...

-

Page 25: Swingout Outrigger Platform Extension Set-Up

OPERATING INSTRUCTIONS Swingout Outrigger Platform WARNING Extension Set-Up 1. Top of extension planks must be flush with main deck boards. DANGER 2. Centerline of tracks or tires must be loaded on the main deck, not on extension brackets. Do not operate if any extension is not locked in place. - Page 26 OPERATING INSTRUCTIONS GOOSENECK FRAME hookup Figure 3-6: Gooseneck Attachment to Frame 3-12 F-691-0913 Edition...

-

Page 27: Preparation For Loading And Unloading

OPERATING INSTRUCTIONS Preparation for Loading and 1. Practice all standard industrial safety standards. Do not load any payload that will overload any Unloading component of the trailer or cause an unsafe condition. CAUTION 2. Park the tractor/semitrailer in a straight line on level even surface. -

Page 28: Loading The Semitrailer

OPERATING INSTRUCTIONS Loading the Semitrailer Securing the Load 1. Set the semitrailer up for loading as outlined in WARNING “ Preparation for Loading and Unloading” on page 3-13. Do not allow slack in tiedowns. A shifting load 2. Drive or winch the load onto the semitrailer. Insure may create enough momentum to break hi-test that the load is steering straight up onto the chains or strap ties. -

Page 29: Preparation For Transport

OPERATING INSTRUCTIONS Preparation for Transport Unloading the Semitrailer 1. After securing the load, following the steps as 1. Prepare to unload the semitrailer by following the outlined in “Securing the Load” on page 3-14, back steps outlined in “ Preparation for Loading and the tractor until the gooseneck is within a few inches Unloading”... -

Page 30: Air Ride Operation

OPERATING INSTRUCTIONS Air Ride Operation Manual Height Control Operating Instructions (825 and 835 Ag (Tail 1. Trailer air pressure must be maintained above 90 PSI Plate) before operating. PROTECTION VALVES are used to maintain 65 PSI air brake pressure during suspension or remote system air loss. -

Page 31: Normal Highway Operation

OPERATING INSTRUCTIONS Operating Instructions (835 SEE DETAIL A Construction) (Curbside Bolster) Normal Highway Operation 1. Position control handle at normal ride (See Figure 3-8.) Loaded trailer may be operated 1” above or below normal ride position. 2. Empty trailer with lifted 3rd axle may be operated at CURBSIDE OF TRAILER 2”... - Page 32 OPERATING INSTRUCTIONS FLIP AXLE AIR BAG SWITCH FLIP RETAINING PIN PIN STORAGE WHEN AXLE FLIPPED D-RING FOR MANUAL FLIP OPERATION AC-77-M-1 AND AC-77-S-1 OPERATING INSTRUCTIONS FLIP AXLE AIR BAGS NORMAL HIGHWAY OPERATION When vehicle is in motion, switch must be in “off” position for nor- mal height control valve automatic operation.

-

Page 33: Third Axle Flip Operation (Option)

OPERATING INSTRUCTIONS Third Axle Flip Operation Flip Axle Down (Option) 1. Reconnect flip axle electrical harness to trailer frame and turn on air supply to brake chambers (red and white couplers). Flip Axle Up 2. To flip to road position, use the manual height control 1. -

Page 34: Winch Controls

OPERATING INSTRUCTIONS Winch Controls Free Spool Clutch Operation (Warn Winch) DANGER Warn Series XL winches are equipped with either a manual or air operated freespool clutch depending on the 1. The winch is not designed or intended to be model. -

Page 35: Free Spool Clutch Operation (Dp Winch)

OPERATING INSTRUCTIONS Free Spool Clutch Operation (DP Free Spool Clutch Operation (Braden) Winch) 1. The WINCH CLUTCH HANDLE (See Figures 3-12 DP winches are equipped with either a manual or air and 3-13) is located on the right or curb-side end of operated freespool clutch depending on the model. - Page 36 OPERATING INSTRUCTIONS NOTCHED PLATE, LOCKING LOCK PLATE CHANNEL COVER CHAIN HANGER HEX HEAD CAP SCREW SIDE BAR BUSHING SPACER EXTENSION HEX NUT HEX HEAD CAP SCREW BULKHEAD WELDMENT SPACER HEX HEAD CAP SCREW HAIR PIN SNAP LOCK PIN BULKHEAD WELDMENT/ FRONT EXTENSION MOUNT WELDMENT SUPPORT PIN...

-

Page 37: Front Extension/Bulkhead (Option)

OPERATING INSTRUCTIONS Front Extension/Bulkhead Anti-Lock Brake System (ABS) (Option) Vehicle standards FMVSS No. 121, anti-lock brake system requires all trailers manufactured after March 1, 1. Optional bulkheads may come with or without chain 1998 with air brake systems to have ABS. Each trailer racks. -

Page 38: Cold Weather Operation

OPERATING INSTRUCTIONS Cold Weather Operation CAUTION 1. Cold weather causes lubricants to congeal, insulation The auxiliary (blue) circuit is for powering the and rubber parts to become hard, which may lead to semitrailer ABS. This circuit must be hot when problems found in bearings, electrical systems, and the tractor key switch is on. -

Page 39: Hot Weather Operation

OPERATING INSTRUCTIONS Hot Weather Operation 1. Hot weather operation can create certain problems which must be checked. Expansion of parts result in tightening of bearings, fasteners, and moving parts. Failure of gaskets or seals can occur. 2. The semitrailer should be parked in the shade if possible. - Page 40 OPERATING INSTRUCTIONS Page Intentionally Blank 3-26 F-691-0913 Edition...

-

Page 41: Maintenance And Lubrication

Chapter 4 Maintenance and Lubrication Inspection This section contains instructions necessary for proper maintenance of the semitrailer. The 825D/835D 1. Inspect the tractor, the trailer, and trailer parts semitrailer is designed for years of service with minimal periodically for damage or signs of pending failure. maintenance. - Page 42 MAINTENANCE AND LUBRICATION CYLINDER END BUSHINGS (3) (FOUR PLACES) LOAD BLOCK PIVOTS (3) (TWO PLACES) HUB OIL (5) (BOTH SIDES) CARRIER PIVOT (3) (TWO PLACES) KINGPIN PLATE (3) 825c lube assy Figure 4-1: Lubrication Points (1 of 2) F-691-0913 Edition...

- Page 43 MAINTENANCE AND LUBRICATION CENTRALIZED GREASE SYSTEM LOCATION SHAFT BUSHINGS SLACK ADJUSTERS (3) CENTRALIZED GREASE SYSTEM CENTRALIZED GREASE SYSTEM TANDEM AXLE (825C-49, 825C-51, TRIPLE AXLE (835C-R-53AG 835C-48AG, 835C-51AG, 835C-53AG, 835C-S60-53AG) 835C-S-53AG) 825-835B lube points p2-2012 Figure 4-2: Lubrication Points (2 of 2)

- Page 44 MAINTENANCE AND LUBRICATION BRAND AND PRODUCT (WEIGHT AND/OR TYPE) LUBE SEASON AMOCO EXXON PHILLIPS TEXACO ALL YEAR Rycon MV HDX Plus 10W Mangus Oil Rando HD-AZ A KV 5W-20 SUMMER Permagear EP Spartan 460 Phil Gear Lube 460 Meropa 460 SAE 140 SAE 140 SAE 140...

-

Page 45: Maintenance Procedures

MAINTENANCE AND LUBRICATION Maintenance Procedures Cleaning 1. Wash semitrailer to remove all accumulated dirt and Repair Parts grime. 2. Use any mineral spirits paint thinner (or its Repair parts are illustrated and listed in a separate parts equivalent) to remove grease and oil from all parts of manual. - Page 46 MAINTENANCE AND LUBRICATION NORMAL OPERATING SERVICE INTERVALS SERVICE INTERVAL: 1ST 5 ITEM TIMES HOURS WEEKLY MONTHLY MONTHS YEARLY LUBE # NOTES MILES 2,000 12,000 25,000 LIGHTS WIRING AND CONNECTIONS FASTENERS KING PIN AND PLATE C,I,L BRAKE AIR SYSTEM RELAY VALVES BRAKE ADJ &...

-

Page 47: Gooseneck, Frame, And Deck

If any cracks or breaks are found, cylinders in the retracted position and the hydraulic contact the Landoll factory for repairs. Inspect the deck pump disengaged. Enough volume in tank daily for broken or missing planks or missing (approximately 15 gallons) above hydraulic oil level attachments. - Page 48 MAINTENANCE AND LUBRICATION 7-WAY RECEPTACLE FRONT OF CLEARANCE CLEARANCE TRAILER FRONT FRONT LEFT RIGHT MARKER MARKER FRONT FRONT LEFT RIGHT COURTESY LIGHT LIGHT SWITCH WORK LIGHTS JUNCTION MAIN MARKER MARKER FRONT BED FRONT BED LEFT RIGHT MARKER MARKER LEFT TURN RIGHT TURN CENTER CENTER...

- Page 49 MAINTENANCE AND LUBRICATION MODEL 825D/835D WIRING PARTS LIST REF. REF. DES. FUNCTION DES. FUNCTION FRONT LEFT CLEARANCE, YELLOW DS26 LEFT STOP/TAIL, OUTER FRONT RIGHT CLEARANCE, YELLOW DS27 RIGHT STOP/TAIL, OUTER FRONT LEFT MARKER, YELLOW DS28 LEFT STOP/TAIL, INNER FRONT RIGHT MARKER, YELLOW DS29 RIGHT STOP/TAIL, INNER LEFT FRONT BED MARKER, YELLOW...

-

Page 50: Electrical System

MAINTENANCE AND LUBRICATION CONNECTS TO BUMPER CONNECTS TO MAIN WIRING HARNESS ON TRAILER HARNESS ON TRAILER DS24 DS25 DS26 DS27 MARKER MARKER DS28 DS29 STOP STOP LEFT RIGHT STOP STOP DS35 TAIL TAIL DS30 DS34 REAR REAR TAIL TAIL TURN LEFT RIGHT TURN... - Page 51 MAINTENANCE AND LUBRICATION EXHAUST PORT IN: FROM AIR SUPPLY OUT: TO AIR BAGS AIR TANK LOCATED ON BUMPER m105141bop Figure 4-5: Tandem Axle Air Ride Suspension System 4-11...

- Page 52 MAINTENANCE AND LUBRICATION EXHAUST PORT IN: FROM AIR SUPPLY OUT: TO AIR BAGS CONNECT TO BUSHING IN REAR BUMPER FLIP AXLE EXTENSION m120789aop Figure 4-6: Tandem Axle w/ Flip Air Ride Suspension System 4-12 F-691-0913 Edition...

-

Page 53: Air Ride Height Adjustment

MAINTENANCE AND LUBRICATION Air Ride Height Adjustment 5. Check the ride height to make sure it is correct. Consult Landoll Service Center if correct height (See Figure 4-7 for parts identification.) cannot be obtained. 1. Before adjusting, the vehicle must be empty with the 6. -

Page 54: Alignment

MAINTENANCE AND LUBRICATION Figure 4-8: Checking Axle for Bend Alignment 1. Remove wheel, hub and bearing assemblies. 2. Place a 3-point axle gauge against the front side of the axle, and adjust each axle gauge point to the Wheel Alignment axle. - Page 55 MAINTENANCE AND LUBRICATION Figure 4-9: Examples of Camber check Figure 4-10: Checking Axle Alignment 4-15...

-

Page 56: Axle Alignment

MAINTENANCE AND LUBRICATION Axle Alignment Air Ride Suspension Axles The air ride suspension is aligned and adjusted at the Proper axle to king pin alignment is necessary to obtain factory and it should not be necessary to align the axles. straight tracking. -

Page 57: Brake System Maintenance

MAINTENANCE AND LUBRICATION Brake System Maintenance Spring Air Brake Chambers Check for faulty units. Check the condensation holes on the underside of the brake chambers to make sure they WARNING are open. The spring brake has two brake chambers, a 1. -

Page 58: Caging The Power Spring

WARNING Repair or replacement of the relay/emergency valve is a complex operation and should be performed by trained service personnel. Contact a landoll authorized service center or the landoll factory for servicing. 4-18 F-691-0913 Edition... -

Page 59: Brake Assembly Maintenance

MAINTENANCE AND LUBRICATION Figure 4-12: Brake Lining Wear Brake Assembly Maintenance 7. Swing the lower shoe back approximately 180 relieve the tension on the shoe keeper springs. The brake assemblies should be inspected and adjusted Remove the springs and slip the shoes off the anchor every 2,000 miles or monthly. - Page 60 MAINTENANCE AND LUBRICATION Figure 4-13: Axle and Brake Assembly 4-20 F-691-0913 Edition...

-

Page 61: Automatic Slack Adjuster

MAINTENANCE AND LUBRICATION Automatic Slack Adjuster WARNING The semitrailer automatic slack adjusters provide the means for routine brake adjustment to compensate for If the adjuster appears not to be operating, check lining wear. Inspect slack adjusters every 2,000 miles to the other brake components for proper function assure correct operation. -

Page 62: Adjusting Slack Adjuster

MAINTENANCE AND LUBRICATION PUSHROD COTTER PIN 1/2” CLEVIS PIN JAM NUT COTTER PIN 1/4” CLEVIS PIN CLEVIS INSTALLATION GUIDE CAMSHAFT SLACK ADJUSTER ADJUSTMENT HEX slack Figure 4-14: Slack Adjuster Fit the installation guide over the cam splines so the Adjusting Slack Adjuster 1/2"... -

Page 63: Hub And Drum Maintenance

MAINTENANCE AND LUBRICATION Hub and Drum Maintenance 3. Replacement of the brake drum is required if any of the following conditions exist: 1. Clean and inspect the brake drums whenever relining a. The brake drum is cracked. the brakes. To be suitable for further service, the b. - Page 64 MAINTENANCE AND LUBRICATION Figure 4-15: Outboard Hub and Drum IMPORTANT n. Remove the filler plug and fill the hub cavity to Do not mix new cups with old cones or new cones the recommended level with a gear type oil. with old cups.

-

Page 65: Wheel Bearing Lubrication And Adjustment

MAINTENANCE AND LUBRICATION Wheel Bearing Lubrication and Adjustment Adjustment 1. With a drain pan under the hub cap, remove the hub cap assembly allowing oil to drain. With semitrailer sitting level, the oil level must be checked 2. Lift the wheel off of the ground. daily and maintained between the “ADD”... -

Page 66: Tire Maintenance

MAINTENANCE AND LUBRICATION Figure 4-16: Tire Inflation Examples Tire Maintenance Tire Inflation Tire inflation will cause tire to ground contact characteristics as shown in Figure 4-16. Tire inflation should be checked daily while the tire is cold, and during road stops. Checking the tire pressures while tires are hot will give a faulty increased pressure reading. - Page 67 MAINTENANCE AND LUBRICATION Figure 4-19: Mounting Tires and Wheels 10 BOLT stud tight 10 Figure 4-20: Stud Tightening Sequence 4-27...

-

Page 68: Mounting Tire And Wheel (Hub Type)

MAINTENANCE AND LUBRICATION Mounting Tire and Wheel (Hub Type) Hydraulic Engine Package (Option) 1. Make sure that all mounting surfaces are clean and free of rust, dirt or paint. A wire brush may be used to The hydraulic engine package should be inspected clean these surfaces (See Figure 4-19.) weekly to insure continued proper operation. -

Page 69: Troubleshooting Guide

Most electrical system problems show up as a burned out responsible for equipment that is improperly maintained. light or fuse, or inoperative electrical component. Wiring, Contact an authorized Landoll Service center for grounds, or components may be at fault. Locate the servicing. -

Page 70: Tires - Wheels - Suspension

TROUBLESHOOTING GUIDE Tires - Wheels - Suspension • “Hydraulic System” on page 4-7 • “Alignment” on page 4-14 Most tire, wheel, and suspension related problems are • “Hub and Drum Maintenance” on page 4-23 due to excessive loads, extreme conditions, and improper maintenance. - Page 71 TROUBLESHOOTING GUIDE PROBLEM PROBABLE CAUSE SOLUTION BENDING OR WARPING Curb-hopping or potholes Adjust turning practices and adjust speed accordingly with road conditions. Improper tightening sequence Follow proper tightening sequence (See Figure 4-20.) BROKEN STUDS* Over tightening Use correct torque when mounting (See Table 2-1) *REPLACE BROKEN STUDS BEFORE USING THE SEMITRAILER! SEMITRAILER TRACKING PROBLEMS:...

-

Page 72: Brakes

TROUBLESHOOTING GUIDE Brakes For maintenance procedures, see “Brake System Maintenance” on page 4-17. PROBLEM PROBABLE CAUSE SOLUTION NO BRAKES OR BRAKES ARE Brake air system improperly connected Reconnect hand valves properly. INTERMITTENT Relay/Emergency valve plugged Clean valve. Defective tractor protection valve Repair or replace. - Page 73 TROUBLESHOOTING GUIDE PROBLEM PROBABLE CAUSE SOLUTION ALL BRAKES DO NOT RELEASE Air system improperly connected to tractor Tighten or adjust connections. Brake valve on tractor is applied Release brake Relay emergency valve in emergency Check line pressure and check valve position Restricted tubing or line Locate restriction and remove...

-

Page 74: Brake Drums

TROUBLESHOOTING GUIDE Brake Drums • “Suspension Maintenance” on page 4-10 • “Alignment” on page 4-14 For maintenance procedures, refer the following • “Brake System Maintenance” on page 4-17 sections: • “Hub and Drum Maintenance” on page 4-23 • “Wheel Bearing Lubrication and Adjustment” on page 4-25 PROBLEM PROBABLE CAUSE... -

Page 75: Hydraulic System

TROUBLESHOOTING GUIDE Hydraulic System Most hydraulic system failures follow the same pattern: a gradual or sudden loss of pressure or flow with a resulting loss of cylinder or motor power. Any one of the system’s components may be at fault. By following step-by-step procedures, the trouble can be located in a short time. - Page 76 TROUBLESHOOTING GUIDE PROBLEM PROBABLE CAUSE SOLUTION OVER HEATING OF OIL IN SYSTEM Oil passing through relief valve for Return control valve to neutral when not in excessive time Incorrect, low, dirty oil Use recommended oil (See Table 4-1). Fill reservoir with clean oil. Replace filter.

- Page 77 TROUBLESHOOTING GUIDE Notes:...

- Page 78 TROUBLESHOOTING GUIDE 5-10 F-691-0913 Edition...

- Page 80 Equipment from Landoll Corporation is built to exacting standards ensured by ISO 9001 registration at all Landoll manufacturing facilities. Model 825D/835D Series Detachable Trailer Operator’s Manual Re-Order Part Number F-691-0913 LANDOLL CORPORATION 1900 North Street Marysville, Kansas 66508 (785) 562-5381 800-428-5655 ~ WWW.LANDOLL.COM...

Need help?

Do you have a question about the 825D Series and is the answer not in the manual?

Questions and answers