Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Newport MS-1315TT-12

- Page 1 MEMS MS1X2 Optical Switch Operation Manual...

- Page 2 This Product is ESD sensitive Please take all necessary precautions when handling the MEMS switch...

-

Page 3: Table Of Contents

Contents PRODUCT OVERVIEW ......................... 4 MEMS 1x2 Optical Switch ....................4 SWITCH OPERATION ........................5 Pin Assignments ......................... 5 Electrical Specifications ...................... 6 Environmental Specification ....................6 MECHANICAL DIMENSIONS ....................... 7 TTL INTERFACE ........................... 8 Parallel Digital I/O Control ....................8 Parallel Digital I/O Timing .................... -

Page 4: Product Overview

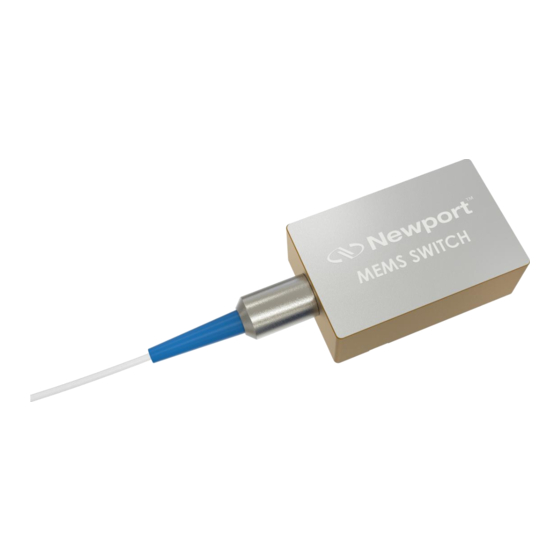

MS-1315TT-12-APC MEMS 1x2 Optical Switch Newport’s MEMS 1x2 Switch is based on a micro-electro-mechanical system (MEMS) chip. The MEMS chip consists of an electrically movable mirror with two axes of rotation. Voltages applied to the MEMS chip cause the mirror to tilt along one or both axes, which changes the coupling of light between a common fiber and N input/output fibers. -

Page 5: Switch Operation

Switch Operation Pin Assignments The MEMS 1x2 Switch operates through a 14-pin interface. Pin assignments are listed in the following table. The relative position of each pin is presented in Figure 2. The 1xN built-in driver is based on an 8051 Microcontroller with external 16-bit D/A converter (DAC) and amplifier. -

Page 6: Electrical Specifications

2.1.1 VCC (Pin 2) VCC (pin 2) is the power supply pin to the MEMS 1x2 Switch. The value of the supply voltage can vary within the specified range without affecting the switch output. If VCC is absent, the switch will revert to the default position (parking state for standard products). -

Page 7: Mechanical Dimensions

Mechanical Dimensions Figure 3. MS1 with Bare Fiber Mechanical Specifications... -

Page 8: Ttl Interface

TTL Interface Parallel Digital I/O Control TTL control is only available for switches having up to 16 channels since there are four TTL control pins (D0, D1, D2, D3). With TTL control, switches with <16 channels may be set to a parking state (<-50dB Crosstalk on all channels) by selecting the “N+1”... -

Page 9: Handling Fiberoptic Components And Cables

Table 5. Parallel Digital I/O Timing Parameters Parameter Description Units μs Setup time. The channel address <D0:D3> and RESET inputs must remain stable preceding the falling edge of STROBE μs Hold time. The channel address <D0:D3> and RESET inputs must remain stable following the falling edge of STROBE STROBE pulse width... -

Page 10: Storing Optical Connectors

• Avoid bending the optical cable over a sharp edge. • Avoid using cable tie wraps to hold optical cable. Tie wraps when tightened can create micro- bends or break an optical cable. Microbends can cause a dramatic reduction in optical performance. - Page 11 • Smoothly insert the appropriate connector ferrule into the adapter. Do not allow the fiber tip to contact any surface. If the tip accidentally contacts a surface before mating, stop. Re-clean the connector and try again. • Tighten the connector until it is finger tight or to the torque specified by the connector manufacturer.

Need help?

Do you have a question about the MS-1315TT-12 and is the answer not in the manual?

Questions and answers