Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Hyundai 30EPCR

- Page 1 30EPCR Electric Pallet Truck Operation Manual Service Manual...

- Page 2 Welcome to choose “HYUNDAI” electric pallet truck! We hope our electric trucks will bring great convenience to your work ! Please read the manual carefully before operation. This manual is a common manual. We reserve the right to modify technology of the electric pallet truck.

-

Page 3: Table Of Contents

......................1 Ⅱ.Forklift introduction ....................1 1. applications ......................1 2. service environment ....................1 3. technical parameters ....................1 3.1 structure ...................... 2 3.2 main technical parameters (30EPCR Electric Pallet Truck) ........ 2 Operation ........................7 Ⅲ. 1Safety norms………………………………………………………………………………………………………..9 safety instructions .................. -

Page 4: Ⅰ.specified Use

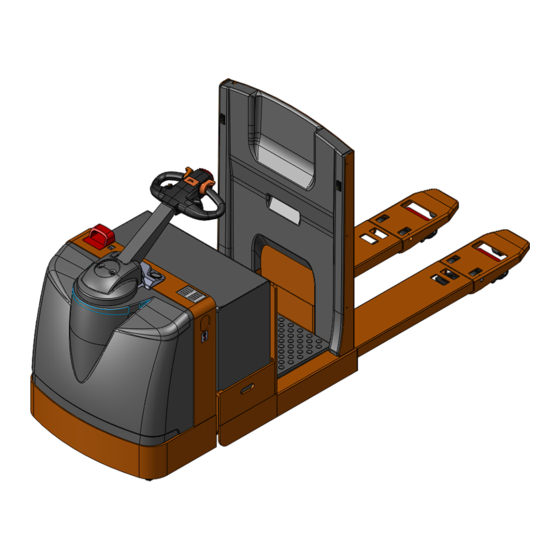

Ⅱ.Forklift introduction 1. Applications 30EPCR series electric pallet truck is powered by storage battery, and driven by motor. This kind of truck travels by means of gear transmission. The fork is lifted by means of DC motor and hydraulic actuation, which motivate hydraulic cylinder up and down to lift fork and goods together. -

Page 5: Technical Parameters

3. Technical parameters 3.1 Structure Number CBD30Q Name ● Handle ● Emergency Power disconnect SW ● Instrument ● Electrical control assembly ● Drive unit ● Electric lock ● Lift button ● Storage box ● Battery Hydraulic power unit ● ● Steering power unit ●... - Page 6 (1)Instrument: Electricity Quantity Indicator This instrument is a combination of battery capacity indicator and LCD hour meter, with the battery indicator of ten segments of colorful LED display (5 red segments, 3 yellow segments and 2 red LED).When battery discharges by 70% capacity, one red flicker lamp shows “energy storage”...

- Page 7 ②Accelerator knob: It is used to control the travel direction and speed of the electric truck. Before operation of the truck, firstly turn the operation handle to area B shown as above. When the handle is placed in area A or C, the truck will be powered-off and braked.

-

Page 8: Main Technical Parameters (30Epcr Electric Pallet Truck)

3.2 Main technical parameters (30EPCR Electric Pallet Truck) - Page 9 Manufacturer(abbreviated) HYUNDAI Model 30EPCR Driving type Electric Operating type ( Manual, Walking, Stand Standing driving, Seat driving ,Order picking) Rated load Q(kg) 3000 Load center distance (mm) Front overhang (mm) 1036/933 Tread (mm) 2115 Service weight(with battery) 1150 Axle load, front/rear, laden...

-

Page 10: Ⅲ. Operation

780X335X625(490/550/595) Battery dimension(L X W X H) Noise level at operator’s ear, according to dB(A) DIN12053 Ⅲ. Operation Warning 1. Safety Norms Please pay attention to the following items first before operation of the truck: 1. This electric truck is only limited to utilization indoor with a hard flat floor. Operation in inflammable, explosive environment or corrosive environment such as acid or alkaline condition shall be strictly forbidden. -

Page 11: Safety Instructions

15. It is strictly to use the truck under stipulated voltage of 20.4V. 16. It is strictly forbidden to conduct charge by connecting the plug to AC power directly. 1.1 Safety instructions ⑴Training of driver: Notice Even though each electric pallet truck may have the same technical parameters, there may be differences on features of braking and acceleration as well. - Page 12 maintenance of the truck. B No modification or addition shall be made to the truck without written permission by our company. A modification of the truck may have a negative effect on its safe operation. (6)Prepare safety operation procedure: Safety operation procedure shall be formulated with consideration of practical situations before operation of the truck.

- Page 13 goods.Abrupt turning during traveling may cause the tilting of truck and result in serious accident. Do decelerate and take care to turn.. B Observe all items of safety rules on working place. Decelerate and sound horn when travel by other truck or vehicles.

-

Page 14: Inspection Before Operation

2. Drive and operation 2.1 Inspection before operation For the sake of safety operation and good situation of the electric truck, it is compulsory to check the truck completely before operation. Contact the sales department of our company when founding problems. -

Page 15: Driving

2.2 Driving: ⑴ Start-up Get on the standing pedal and open the guardrail to turn the switch of electric lock to ON position. When the operation handle is turned to area B and accelerator knob is rotated slowly, the truck will start gradually. -

Page 16: Important Notice After Operation

2.3 Important notice after operation (1) Parking: Park the truck at appointed place. Never park the truck on slope. Ensure the following points to be achieved before leaving away the truck: Lay down the fork to the lowest position naturally. Turn the steering wheel to the middle position. -

Page 17: Initial Charge

Ⅳ.Maintenance, charge and replacement of storage battery Standard configuration is external charger. Charging operation method as follow: External charger Charging ways for external charger: Open the cover,the first step,pull out the charging socket from main circuit;step two,connect with charging plug of battery and charger; step three, put the battery socket into two-phase AC power supply;step four, open the power switch, it starts to charger in a few senconds. -

Page 18: Use And Maintenance

1.3 When the charging equipment is able to operate normally, pour the sulfuric acid electrolyte with a density of 1.260± 0.005 (25℃) and a temperature of lower than 30℃ into the batteries. The electrolyte level should be 15-25mm higher than the protective board. In order to reduce the temperature rise caused by chemical reaction of the electrolyte and let the electrolyte fully penetrates into the pores of the polar plates and the baffles, the batteries should be placed still for 3-4 hours, not exceeding 8 hours. -

Page 19: Storage

for the batteries in following situation, i.e. balance charge. a. a. The “lag-behind” batteries--- batteries with a voltage lower than that of the other batteries in the discharging process and the batteries having been repaired for failure. (When balance charge is conducted, the positive and negative poles of the “lag-behind” battery should be respectively connected with the positive and negative ends of the charger, the DC power supply, and the charge should be conducted independently.) b. - Page 20 ⑵The electrolyte spills into eyes: wash with large amount of water, and then seek help from specialized doctor. ⑶ The electrolyte spills on clothes: take off clothes right away, wash with water, and then flush with week basic soap solution. The electrolyte leakage: in case of electrolyte leakage outside, neutralize it with lime, strong carbonic acid ⑷...

-

Page 21: Ⅴ. Maintenance And Repair

Ⅴ. Maintenance and repair 1. Maintenance Comprehensive check for truck can avoid malfunction and ensure the service life. The hours listed in maintenance procedures is based on the cases that the truck works for 8 hours per day and 200 hours per month. -

Page 22: Precautions During Maintenance

Please contact the sales department of our company if you need to adjust or replace the components. 1.1 Precautions during maintenance: Notice The components for replacement shall be produced completely by our company. When replacing components of the truck, the components with the same safety requirement with the original design shall be used. The lubricating oil and hydraulic oil in use shall be recommended by our company. - Page 23 1.5 The inspection and maintenance after 50 hours (Weekly) When the operation handle is turned, with the steering handle switching between area A and B, there is a noise from the brake. Braking system The oil dirt and dust on the turning gearwheel should be cleaned. The clearance between brakes should be kept between 0.2mm and 0.8mm Capability Inspect the liquid level of electrolyte, pure water can be used for...

-

Page 24: Recommended Working Medium

system Contactor Contact performance and function Inching switch Function Controller Function Wearing status of carbon brush and selenium Driving motor rectifier. Wearing status of carbon brush and selenium Lifting motor rectifier. Wearing status of carbon brush and selenium Steering motor rectifier. -

Page 25: Structure Of Lifting Cylinder And Wearing Parts

All the working conditions mentioned above can use the hydraulic oil LHPISOVG46 in accordance with standard DIN51524T.2 for replacement. The viscidity of this lubricant is very high (mostly used hydraulic oil). If it is difficult to buy hydraulic oil, SAE20W/20 engine oil can be used to substitute HLP68 hydraulic oil. ⑵... -

Page 26: Common Faults And Trouble Shooting

Check for carbon brushes and Steering motor 1000 hours bearings Check for carbon brushes and Oil pump motor 1000 hours bearings 2. Common faults and trouble shooting: 1.Mechanical faults Faults Possible cause Trouble shooting The oil-absorptive filter is blocked Clean or replace the oil-absorptive filter The oil-absorptive tube leaks and Fasten the tie-in, check the oil level, or the oil are foaming. - Page 27 The electromagnetic brake is out of Check the circuit. release electricity. after braked clearance Adjust the brake clearance to 0.2mm. electromagnetic brake is too large. (2)Adjustment methods of safety valve pressure The pressure of safety valves has already been adjusted when the truck is ex-factory.

- Page 28 Hydraulic principle diagram...

- Page 29 2. Electrical faults...

- Page 30 1234 controller faults code and diagnostic display There has two luminous on the controller housing red and yellow LED lights, flashing different situations represent different fault conditions, see the table below: Display case Representatives meaning Two lights are not bright The controller has no power, no electricity because the battery or line failure Yellow light flashes...

- Page 31 Severe low battery voltage 1. Battery voltage parameter setting error. (Drive torque decreases) 1,7 2. The battery is exhausted. 3. Battery internal resistance is too high. 4. the battery is not connected when driving 5. View capacitor voltage under monitor menu. 6.

- Page 32 Overvoltage cut (drive torque and displays the fault, the controller’s overvoltage limit decreases) parameters takes effect 2.Battery voltage parameter setting error. 3.when the battery resistance is too high when generates Regenerative braking current 4.battery connection open when generates Regenerative braking 5.View capacitor voltage under programming unit menu.

- Page 33 ) Main Open / Short 1. Main contactor coil open or shorted. Main contactor coil open 2. The connection terminals are pollution. short (driving a motor 3. Harness is damaged or connection error. electromagnetic brake does not work) Coil2 Driver Open / Short 1.

- Page 34 (Governor does not work) Throttle Wiper Low Slide the end of the accelerator input is Slide the end of the accelerator voltage is too low. too low 2 View Monitor menu accelerator input. (Governor does not work) Brake Wiper High Brake potentiometer wiper input is too Brake potentiometer wiper voltage is too high.

- Page 35 (Main contactors, motors, electromagnetic brake, governor, interlock, driven proportional valves do not work 1-4, full braking input) PDO Timeout 1. CAN PDO PDO newsletter receive time is in excess of the CAN PDO timeout accepted PDO overtime period Stall Detect 1 motor stops.

-

Page 36: Ⅵ. Loading And Unloading, Transportation And Storage Of Truck

VI. Loading and unloading, transportation and storage of truck 1. Loading and unloading: Before loading the truck, check out the nameplate for the total weight of truck to choose appropriate hoisting handling equipment. The hoisting of truck shall be kept level, and landing shall be kept slow and stable. - Page 37 Electric Pallet Truck Technical documents, Accessory bag accessories spare parts Note:1.The following documents are in the file bag ① 30EPCR Electric Pallet Truck operating instruction 1 volume ② Packing list 1 copy ③ Certificate of quality 1 copy 2. Accessory and spare parts Q’ty...

- Page 38 Appendix II Maintenance and repairing recording card: Maintenance Maintenance Maintenance Items Material used Remarks time part personnel...

- Page 39 Appendix III Customer advisement feedback Time Items Trouble location Fault cause Trouble-shooting Remarks occurred...

Need help?

Do you have a question about the 30EPCR and is the answer not in the manual?

Questions and answers