Table of Contents

Summary of Contents for Quincy Compressor QPNC1600

- Page 1 ENGLISH Code 2200780133 Edit. 10/2014 INSTRUCTION AND MAINTENANCE MANUAL DRYERS QPNC1600 - QPNC1800 - QPNC2500 - QPNC3000 READ THIS MANUAL CAREFULLY BEFORE CARRYING OUT ANY OPERATIONS ON THE DRYER. Cod. 2200780133 00 - Edition 10/2014 - 1...

-

Page 2: Table Of Contents

ENGLISH CONTENTS PART A: INFORMATION FOR THE USER GENERAL CHARACTERISTICS INTENDED USE OPERATION GENERAL SAFETY STANDARDS DESCRIPTION OF DANGER SIGNALS DANGER ZONES SAFETY DEVICES POSITION OF PLATES DRYERS ROOM 10.0 TRANSPORT AND HANDLING 11.0 UNPACKING 12.0 INSTALLATION 13.0 DIMENSIONS AND TECHNICAL DATA 14.0 MACHINE ILLUSTRATION 15.0... -

Page 3: General Characteristics

ENGLISH 1.0 GENERAL CHARACTERISTICS The dryer is a chilling machine with direct expansion and dry evaporator. The air to be dried is sent to the heat exchanger in which the water vapour present is condensed: the condensate gathers in the separator and is discharged outside through a steam trap. 2.0 INTENDED USE The dryer has been built to dry the compressed air for industrial use. -

Page 4: Description Of Danger Signals

ENGLISH 5.0 DESCRIPTION OF DANGER SIGNALS 1) Dangerous 2) Air not fit for 3) High pressure 4) Fan rotating 5) Hot parts electricvoltage breathing 6.0 DANGER ZONES 6.1 DANGER ZONES Risks present on the whole machine FIG. 2 4 - Edition 10/2014 Cod. 2200780133 00 -... -

Page 5: Safety Devices

ENGLISH 7.0 SAFETY DEVICES 7.1 SAFETY DEVICES 1) Cooling fan shield 3) Earth 2) Shield FIG. 3 Cod. 2200780133 00 - Edition 10/2014 - 5... -

Page 6: Position Of Plates

55 °C (131 °F) 13 bar (188 °F) 10.0 TRANSPORT AND HANDLING The machine must be transported as shown in the following figures. FIG. 5 MODD. WEIGHT Kg. (lb) QPNC1600 380 (837) QPNC1800 550 (1212) QPNC2500 600 (1323) QPNC3000 650 (1433) 11.0 UNPACKING... -

Page 7: Installation

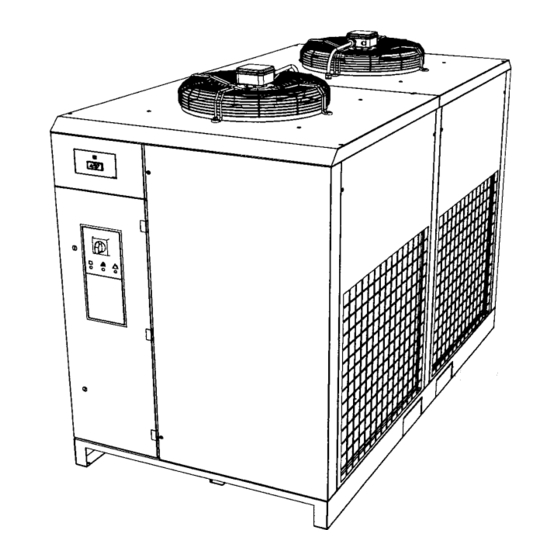

ENGLISH 12.0 INSTALLATION 12.1 POSITIONING After unpacking the equipment and preparing the dryers room, put the machine into position, checking the following items: ensure that there is sufficient space around the machine to allow maintenance (see Fig. 6). ENSURE THAT THE OPERATOR CAN SEE THE WHOLE MACHINE FROM THE CONTROL PANEL AND CHECK THE PRESENCE OF ANY UNAUTHORIZED PERSONS IN THE VICINITY OF THE MACHINE. - Page 8 Max. inlet air temperature 4 °C (39 °F) 13 bar (188 psi) Dew point in pressure Max. working pressure 14.0 MACHINE ILLUSTRATION 14.1 GENERAL LAY-OUT (QPNC0750 - QPNC1000 - QPNC1250 - QPNC1600) Refrigerant compressor Freon filter Condenser Capillary Motor fan...

-

Page 9: Dimensions And Technical Data

ENGLISH 13.1 DIMENSIONS AND TECHNICAL DATA ( QPNC1800 - QPNC2500 - QPNC3000 ELECTRICAL CABLE AIR INLET INGRESSO ARIA AIR OUTLET ARIA CONDENSATE DRAINING MODD. MODD. Refrigerant gas 100 (2) (mm / in) (mm / in) (mm / in) FLANGED “DN 125” FLANGED “DN 125”... - Page 10 ENGLISH 14.2 COMMAND AND CONTROL PANEL BEFORE CARRYING OUT THE OPERATION TEST, READ CAREFULLY AND ACQUIRE A GOOD KNOWLEDGE OF THE COMMAND FUNCTIONS. FIG. 9 Ref. 1) Digital controller Ref. 8) Stop - Running button - Door block Ref. 9) Green indicator of voltage - Running Ref.

-

Page 11: Partial Routine Maintenance

ENGLISH 15.0 PARTIAL ROUTINE MAINTENANCE BEFORE CARRYING OUT ANY MAINTENANCE JOBS IT IS OBLIGATORY TO STOP THE MACHINE AND DISCONNECT IT FROM THE POWER MAINS AND FROM THE COMPRESSED AIR DISTRIBUTION NETWORK. 15.1 MAINTENANCE SCHEDULE These maintenance intervals are recommended for work environments that are not dusty and are will ventilated. For particularly dusty environments, double the frequency of controls. -

Page 12: Trouble-Shooting And Emergency Remedies

ENGLISH 16.0 SCRAPPING THE UNIT If the machine is to be scrapped, it must be dismantled into parts of the same material, to be disposed of according to the local regulations in force. ALWAYS RESPECT THE REGULATIONS IN FORCE FOR DISPOSING OF OLD OIL AND OTHER POLLUTING MATERIALS SUCH AS INSULATING FOAM, ETC. - Page 13 ENGLISH 17.1 TROUBLE-SHOOTING AND EMERGENCY REMEDIES N.B. OPERATIONS MARKED MUST BE CARRIED OUT BY PROFESSIONALLY SKILLED PERSONNEL APPROVED THE MANUFACTURER DISPLAY FLASHING WARNING NOTES Possible root causes Observations Dryer is working OK Warning icon NOT Fan control probe failed ...

- Page 14 ENGLISH SE ALARM After 4000Hrs, the controller will issue a “SE” warning. This is the maintenance due warning. How to reset the maintenance warning: follow steps 1 to 6 14 - Edition 10/2014 Cod. 2200780133 00 -...

-

Page 15: Starting Up

ENGLISH PART “B” THIS PART “B” OF THE INSTRUCTIONS MANUAL IS RESERVED FOR PROFESSIONALLY SKILLED PERSONNEL APPROVED THE MANUFACTURER. 18.0 STARTING UP BEFORE CARRYING OUT ANYOPERATION ON THE MACHINE, ENSURE THAT THE ELECTRIC POWER SUPPLY HAS BEEN DISCONNECTED WAIT AT LEAST TWO HOURS BEFORE STARTING UP, AFTER ANY MACHINE MOVEMENT (TRANSPORT OR HANDLING). - Page 16 ENGLISH CALIBRATIONS BYPASS VALVE FOR HOT GAS N.B.These valves have already been calibrated and they do not require any adjistment. A dew point different from the rated one generally depends on causes which are not attributable to their operation. Ref. 1) Closing cap Ref.

Need help?

Do you have a question about the QPNC1600 and is the answer not in the manual?

Questions and answers