Table of Contents

Advertisement

Read the operating instructions prior to

commissioning

Operating instructions

Combisteamer

Unit

SpaceCombi Compact

Classic

SpaceCombi Junior

Classic

Model

Type of energy

6.10

Electric

6.23

10015159-0ABBE-B

Version

HandClean

WaveClean (optional)

1-point core temperature sensor

4-point core temperature sensor

(optional)

en-GB

Advertisement

Table of Contents

Summary of Contents for MKN SpaceCombi Compact Classic 6.10

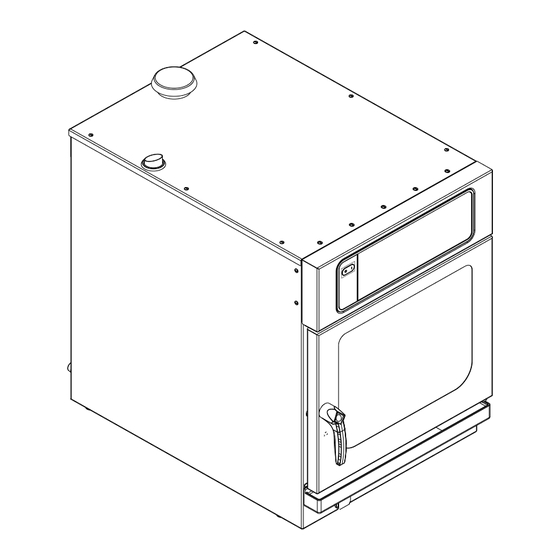

- Page 1 Read the operating instructions prior to commissioning Operating instructions Combisteamer Unit Model Type of energy Version SpaceCombi Compact 6.10 Electric HandClean Classic WaveClean (optional) SpaceCombi Junior 6.23 1-point core temperature sensor Classic 4-point core temperature sensor (optional) 10015159-0ABBE-B en-GB...

- Page 2 Operating and display elements a On Off "I O" button j Ready2Cook button b Selection range k Plus button c Select knob l Minus button d HandClean symbol m Fan speed button e Left display n Left knob f Middle display o "STEP"...

- Page 3 Fax +49 5331 89-280 Internet www.mkn.eu Copyright All rights to text, graphics and pictures in this documentation are held by MKN Maschinenfabrik Kurt Neubauer GmbH & Co. KG. Distribution or duplication is only permitted with the prior written consent of MKN.

-

Page 4: Table Of Contents

Directory of contents 1 Introduction ................. 7 1.1 About this manual ................ 7 1.1.1 Explanation of signs .................. 8 1.2 Intended use .................. 9 1.3 Warranty .................... 9 2 Safety information ............ 10 3 Description of the unit ............. 13 3.1 Overview of the unit ............... 13 3.2 Features .................. 13 3.2.1 Characteristics .................. - Page 5 Directory of contents 4.5.2 Changing the basic setting .............. 24 4.6 Basic functions ................ 25 4.6.1 Select cooking mode ................ 25 4.6.2 Setting the cooking temperature ............. 25 4.6.3 Setting the cooking zone humidity level .......... 25 4.6.4 Setting the cooking time ................ 26 4.6.5 Setting the core temperature ...

- Page 6 Directory of contents 5.5 Cleaning the door seal .............. 39 5.6 Cleaning the cooking zone door ........... 39 5.6.1 Cleaning the door with hygienic glazing .......... 40 5.7 Cleaning the steam outlet .............. 40 5.8 Removing calcium deposits from the unit ........ 40 5.9 Cleaning the cooking zone automatically with WaveClean (optional) ...

-

Page 7: 1 Introduction

Introduction 1 Introduction 1.1 About this manual The operating instructions are part of the unit and contain information: • On safe operation, • On cleaning and care, • On remedies in case of faults. Be aware of the following notes and adhere to them: •... -

Page 8: Explanation Of Signs

Introduction 1.1.1 Explanation of signs DANGER Imminent threat of danger Failure to comply will lead to death or very severe injuries. WARNING Possible threat of danger Failure to comply can lead to death or very severe injuries. CAUTION Dangerous situation Failure to comply can lead to slight or moderately severe injuries. -

Page 9: Intended Use

Introduction 1.2 Intended use This unit is intended to be used solely for commercial purposes, particularly in commercial kitchens. This unit may only be used with suitable accessories and for the cooking of food. It is forbidden to use the unit for purposes, which include the following: •... -

Page 10: 2 Safety Information

Safety information 2 Safety information The unit complies with applicable safety standards. Residual risks associated with operation or risks resulting from incorrect operation cannot be ruled out and are mentioned specifically in the safety instructions and warnings. The operator must be familiar with regional regulations and observe them. - Page 11 Safety information Fire prevention Risk of fire from dirt and grease deposits • Clean the unit when finished using it. • Do not use the unit as a deep fat fryer. Risk of fire from overheating • Do not store any combustible objects or plastic containers in the cooking zone.

- Page 12 Safety information • Clean the cooking zone carefully. The cooking zone sensor protrudes into the cooking zone. • Do not use any bleaching or chlorine-containing cleaners. • Remove rust spots with an abrasive. • Keep the unit free of calcium deposits. Hygiene Health risk from insufficient hygiene •...

-

Page 13: 3 Description Of The Unit

Description of the unit 3 Description of the unit The unit is a hot air steamer, which is suitable for most cooking methods used in commercial kitchens. It can be used with either hot air or unpressurised live steam, either individually, in sequence, or in conjunction with moist or dry heat. -

Page 14: Usb Port

Description of the unit • AutoShower 3.2.2 USB port The unit is equipped with a USB port (USB 2.0). HACCP logs can be exported to the USB flash drive and archived on an external PC as necessary. 3.2.3 HACCP log All cooking steps are recorded with a log number in the HACCP log. -

Page 15: Expanded Cooking Functions

Description of the unit Hot air Hot air is a cooking mode, in which the food to be cooked is cooked without additional moisture in a temperature range of 30 °C to 300 °C. Regeneration Regeneration is a cooking mode, in which the food being cooked can be kept warm and prepared in a temperature range of 30 °C to 155 °C. -

Page 16: Operating, Control And Display Element Functions

Description of the unit The use of core temperature measurement offers the following benefits: • Reduced energy and water consumption • No overcooking • Less weight lost by the food being cooked • High HACCP safety 3.4 Operating, control and display element functions Symbo Operating and display element Function... -

Page 17: Abbreviations In The Displays

Description of the unit Symbo Operating and display element Function Middle display • Shows the cooking zone hu- midity ClimaSelect symbol • Indicates that settings for the cooking zone humidity can be made here Minus button • Reduces the cooking zone hu- midity Plus button •... -

Page 18: Loading Capacity

Description of the unit Abbreviation Explanation Diagnostic error display Error HACCP Too hot Open Option PASS Password entry Prot Log number Program number Ready Service Software update Trade show mode Software Forced rinse StEP Step Saving completed Step X of Y 3.5 Loading capacity 3.5.1 Plate capacity during regeneration Cooking time and cooking temperature depend on the number of... -

Page 19: Core Temperature Standard-Setting

Description of the unit Cooking mode Standard value Adjustment Alteration (°C) range (°C) increments (°C) Steaming 30 - 130 Combisteaming 30 - 250 Hot air 30 - 300 Regeneration 30 - 150 3.6.2 Core temperature standard-setting The adjustment range for the core temperature depends on the cooking mode. -

Page 20: Basic Settings

Description of the unit 3.6.4 Basic settings The unit is already preset, when it is delivered. The values in the following list can be modified. Basic setting Standard Adjustment Explanation value range Password 0 – 500 Individual passwords can be set in this area. - Page 21 Description of the unit Basic setting Standard Adjustment Explanation value range Ready2Cook preheating 0 – 30 % If the unit is fully loaded with a large mass temperature in percent (roasts, loaves of bread), increase the preheating temperature, so that the cooking zone temperature does not drop too suddenly.

-

Page 22: 4 Operating The Unit

Operating the unit 4 Operating the unit 4.1 Operating the unit in an environmentally responsible manner If used correctly, this Combisteamer achieves very low energy consumption. You can assist low energy consumption by: • Avoiding continuous operation - the Combisteamer heats up very quickly, which means that continuous operation is not necessary. -

Page 23: Close

Operating the unit 4.3.2 Close Image: Closing the single stage door latch Requirement Door handle in initial position Close the cooking zone door with pressure. The cooking zone door is closed. 4.4 Loading and emptying the unit CAUTION Risk of burns from hot liquid •... -

Page 24: Making The Basic Settings

Operating the unit 4. Leave the cooking zone door slightly ajar. This extends the service life of the door seal. No moisture builds up in the cooking zone. 4.5 Making the basic settings The basic settings for operation can be displayed and changed by entering the password "111". -

Page 25: Basic Functions

Operating the unit 6. Press and hold the "STEP" button for 3 seconds. Changes are saved. "OPt" flashes on the left display. The centre display shows "Stor". 7. Press the "STEP" button to leave the Settings menu. 8. Fill out the commissioning report. 4.6 Basic functions 4.6.1 Select cooking mode Requirement The unit is on... -

Page 26: Setting The Cooking Time

Operating the unit 00:45 ° Image: Cooking zone humidity set 4.6.4 Setting the cooking time The cooking time can be set for up to 23 hours and 59 minutes in 1-minute increments. Continuous operation is stopped automatically after 23 hours and 59 minutes. -

Page 27: Setting The Fan Speed

Operating the unit 4.6.6 Setting the fan speed The fan speed can be set only on Model 6.10. The fan speed is adjusted in up to five steps. Each step is displayed by an indicator light. The number of steps depends on the type of cooking. Press the Fan speed button several times until the desired speed is reached. -

Page 28: Displaying The Haacp Log Number

Operating the unit 4.6.9 Displaying the HAACP log number Requirement The cooking process is running 1. Press the Minus button. The current log number is displayed. 2. Record the log number. 4.6.10 Exporting the HACCP log Requirement USB flash drive inserted Registered with password under Settings 1. -

Page 29: Measuring With A 4-Point Core Temperature Sensor

Operating the unit 4.7.1 Measuring with a 4-point core temperature sensor Image: Core temperature sensor with one and four measuring points Insert the core temperature sensor completely into the food being cooked. Insert the core temperature sensor into the thickest point of the food being cooked. -

Page 30: Manual Cooking

Operating the unit 4.8 Manual cooking 4.8.1 Starting the type of cooking Requirement The unit is on 1. Use the Select knob to select the type of cooking desired. The indicator light above the selected type of cooking illuminates. The left display flashes the preset cooking time. The centre display flashes the preset cooking zone humidity. -

Page 31: Changing The Cooking Mode

Operating the unit 4.8.3 Changing the cooking mode 1. Press the "STEP" button. The indicator light for the type of cooking illuminates. The left display flashes the set cooking temperature. The centre display flashes the set cooking zone humidity. The right display flashes the set cooking time. On Model 6.10: The number of indicator lights above the Fan speed button shows the speed level. -

Page 32: Saving User's Own Cooking Program

Operating the unit 4.9.2 Saving user's own cooking program Requirement Cooking program entered 1. Press the "Programs" button for 3 seconds. "Pro" appears on the left display. The indicator light flashes. The centre display is off. The right display shows the first free program position. 2. -

Page 33: Automatic Cooking

Operating the unit Press and hold the Plus button and Minus button at the same time for 3 seconds. All the cooking programs are deleted. All the program space is free again. Deleting individual cooking programs Turn the Select knob to the Programs symbol. "Pro"... -

Page 34: Cancelling The Cooking Program

Operating the unit 4.10.3 Cancelling the cooking program 1. Press the "START STOP" button. The cooking program is cancelled. The indicator light for the selected cooking mode illuminates. The left display shows the preset cooking temperature. The right display shows the preset cooking time. 2. -

Page 35: Expanded Cooking Functions

Operating the unit 3. Press the "Programs" button for 3 seconds. A signal sounds. The centre display shows "===". The cooking program is saved. 4.11 Expanded cooking functions 4.11.1 Manual humidification This function is not programmable. Requirement Cooking program selected and started Press and hold the Plus button. -

Page 36: Starting Ready2Cook

Operating the unit 4.11.4 Starting Ready2Cook The unit is brought to the correct starting temperature with Ready2Cook. Preselected temperature Requirement Cooking program selected or a manual cooking program set 1. Briefly press the Ready2Cook button. Temperature of the cooking chamber is set at 15% via set-up start temperature. -

Page 37: Cancelling Ready2Cook

Operating the unit 4. Close the cooking zone door. The set cooking program starts automatically. 4.11.5 Cancelling Ready2Cook Briefly press the Ready2Cook button. Ready2Cook stops. The indicator light for the Ready2Cook button goes out. The set cooking program starts automatically. 4.12 Pausing and finishing use Switch off the unit during pauses and at end of use. -

Page 38: 5 Cleaning And Caring For The Unit

Cleaning and caring for the unit 5 Cleaning and caring for the unit CAUTION Risk of burns from hot surfaces • Allow surfaces to cool prior to cleaning. CAUTION Risk of chemical burns from cleaning agent • Follow the instructions of the cleaning agent manufacturer. •... -

Page 39: Cleaning The Housing

Cleaning and caring for the unit 5.3 Cleaning the housing Requirement Unit switched off and cooled down Clean the housing with warm water and commercially available washing-up liquid. 5.4 Cleaning the door handle, operating elements and control panel ATTENTION Risk of physical damage from improper cleaning •... -

Page 40: Cleaning The Door With Hygienic Glazing

Cleaning and caring for the unit ATTENTION Risk of physical damage from improper cleaning of the surface • Do not use abrasive cleaners or cloths. • Do not use grill cleaners. 5.6.1 Cleaning the door with hygienic glazing Remove residual calcium deposits from the glass window with vinegar or citric acid. -

Page 41: Cleaning The Cooking Zone Automatically With Waveclean (Optional)

The use of unsuitable cleaning agents often causes damage to units. MKN makes great efforts to be able to offer a cleaning agent, which on the one hand achieves an outstanding cleaning performance, but which on the other hand does not attack and damage the hot air steamer. -

Page 42: Preparing For Cleaning

Cleaning and caring for the unit 5.9.1 Preparing for cleaning ATTENTION Risk of physical damage from improper cleaning • Do not clean the unit with a high-pressure cleaner or water jet. Requirement GN containers, baking trays and grates removed from the cooking zone 1. -

Page 43: Inserting The Cleaning Cartridge

Cleaning and caring for the unit 5.9.3 Inserting the cleaning cartridge Use only cleaning cartridges with an undamaged wax seal. If the wax seal is damaged, the cleaner can enter the cleaning circuit prematurely or not dissolve completely, so that complete cleaning is no longer assured. -

Page 44: Cancelling Automatic Cleaning

Cleaning and caring for the unit 5.9.5 Cancelling automatic cleaning Press the "START STOP" button. The cleaning program is cancelled. "End" appears on the left display. The centre display shows the selected cleaning level. "CAr" flashes on the right display. Automatic cleaning is cancelled. -

Page 45: Starting The Cleaning Program

Cleaning and caring for the unit Requirement GN containers, baking sheets and grates removed from the cooking zone 1. Remove any food remains from the cooking zone. The drain screen is not obstructed. 2. Leave only the support rack in the cooking zone. 3. -

Page 46: Drying The Cooking Zone

Cleaning and caring for the unit 11.The acting time starts automatically. The right display shows the remaining acting time of the cleaner. The indicator light for the "START STOP" button flashes. 12.The acting time of the cleaner has elapsed. 13.The cleaning time starts automatically. The right display shows the remaining cleaning time. -

Page 47: Stopping Autoshower

Cleaning and caring for the unit 3. Press the "START STOP" button. "ON" appears on the right display. AutoShower starts. 5.11.2 Stopping AutoShower 1. Press the "START STOP" button. AutoShower stops. 2. Press the "STEP" button. 5.12 Removing and installing the air diverter CAUTION Pinch hazard from rotating fan •... -

Page 48: Inspecting The Unit

Cleaning and caring for the unit 5.13 Inspecting the unit 5.13.1 Performing a visual inspection ATTENTION Risk of physical damage from improper inspection • Inspect in accordance with the inspection intervals. • Have inspections performed by a capable user. • In the event of damage or signs of wear, contact customer service immediately and stop using the unit. -

Page 49: 6 Troubleshooting

Troubleshooting 6 Troubleshooting Image: Left, centre and right displays If an error occurs during operation, the error group and the error number within the group are displayed. • The left display shows the error group. • The right display flashes the error number. For a remedy, give customer service the error group and error number displayed. -

Page 50: Nameplate

Troubleshooting Fault Fault no. Failure Possible causes Remedy group • 07 Excess temperature in the • • Contact Customer service cooking zone • 07 Core temperature sensor is • Sensor failure • Contact Customer service defective • 07 Electronics too hot •... -

Page 51: 7 Dispose Of Unit In An Environmentally Responsible

Dispose of unit in an environmentally responsible manner 7 Dispose of unit in an environmentally responsible manner The unit has been designed to provide a lifetime of 10 years with average use. Do not dispose of unit or the unit's components together with non- recyclable waste. -

Page 52: 8 Manufacturer's Declaration

Manufacturer's declaration 8 Manufacturer's declaration EC Declaration of Conformity Manufacturer MKN Maschinenfabrik Kurt Neubauer GmbH & Co. KG • Halberstädter Straße 2a • 38300 Wolfenbüttel, Germany We hereby declare, that the following product: Description of the unit Unit for cooking food in commercial applications... - Page 56 www.mkn.eu...

Need help?

Do you have a question about the SpaceCombi Compact Classic 6.10 and is the answer not in the manual?

Questions and answers