Table of Contents

Advertisement

Quick Links

Operating Instructions

Heating Press for Melting Splices

HPD 450 P 120 and

HPD 500 P 120

Müssel Maschinenbau GmbH

Reichelsweiherstraße 8

95615 Marktredwitz

GERMANY

Tel.: +49 9231 9980-0

Fax: +49 9231 9980-80

E-Mail: kontakt@muessel.com

1

Operating instruction: I001.1

Edition: 01/2016

Subject to alterations.

Advertisement

Table of Contents

Summary of Contents for Mussel HPD 450 P 120

- Page 1 Operating Instructions Heating Press for Melting Splices HPD 450 P 120 and HPD 500 P 120 Müssel Maschinenbau GmbH Reichelsweiherstraße 8 95615 Marktredwitz GERMANY Tel.: +49 9231 9980-0 Fax: +49 9231 9980-80 E-Mail: kontakt@muessel.com Operating instruction: I001.1 Edition: 01/2016 Subject to alterations.

- Page 2 This operating instruction provides you with important information for the proper and safe use of the heating press, HPD 450 P 120 and HPD 500 P 120. Owing to our experience over decades in the development and the fabrication of finishing tools for conveyor...

-

Page 3: Table Of Contents

Contents General information Name and address of the manufacturer Identification of the device CE-Declaration Conformity General safety instructions Usage in accordance with regulations Organisational measures Personnel selection and qualification Safety instructions for specific operating phases Mobile devices Safety instructions Product description Components and proper usage How it works Technical data... - Page 4 Operating instruction: I001.1 Edition: 01/2016 Subject to alterations.

-

Page 5: General Information

Reichelsweiherstraße 8 95615 Marktredwitz GERMANY Identification of the device Product designation: Heating press for melting splices Serial/Type designation: HPD 450 P 120, HPD 500 P Serial number: see type label Year of construction: see type label CE-Declaration see fixed label Operating instruction: I001.1... -

Page 6: Conformity

Conformity Operating instruction: I001.1 Edition: 01/2016 Subject to alterations. -

Page 7: General Safety Instructions

General safety instructions The following document contains important information on serious risks when operating the tool described or important technical information on the tool or processes used. Symbols are used to highlight this important information and indicate as follows: This symbol is always to be found in connection with an endangerment and its respective signal word. -

Page 8: Personnel Selection And Qualification

Never make any modifications, additions or conversions which might affect safety without the supplier´s approval. Additional mountings or modifications have as consequence that the responsibility for the accordance with the EU-directive has to be assured by the person who carries out the mountings and the modifications. -

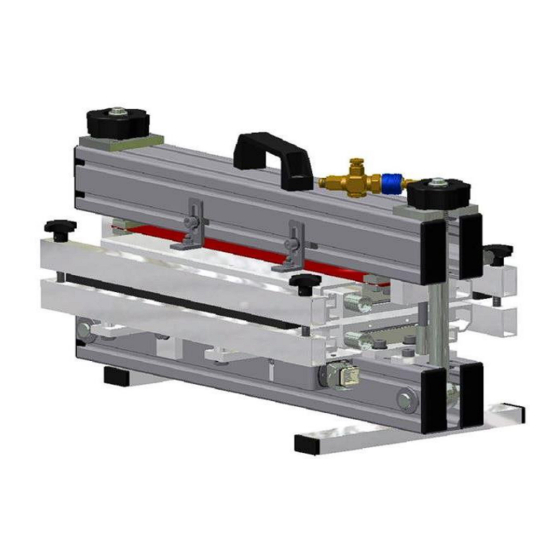

Page 9: Product Description

Product description Components and proper usage Heating presses are electrical heating devices for use in fabricating (splicing) belting material that can withstand maximum temperatures of 200°C. Heating presses are used to splice belting material using pressure and temperature. Depending on the requirement we differentiate between different designs and type. -

Page 10: Technical Data

2 approx. 2 from 180°C up to 40°C Coolant water Air pressure max. Heating temperature max. °C Material number Designation 720029 HPD 450 P 120 (230V) 720350 HPD 500 P 120 (110V) Operating instruction: I001.1 Edition: 01/2016 Subject to alterations. -

Page 11: Wiring Diagram

Wiring diagram Valid for top and bottom part of plug-in connection cables. Voltage: 230V Valid for top and bottom part of fixed connection cables. Voltage: 230V with temperature fuse Operating instruction: I001.1 Edition: 01/2016 Subject to alterations. -

Page 12: Accessories

Accessories Accessories are not included in the scope of delivery and must be ordered separately! HPD 450 P 120 HPD 500 P 120 Designation Optional with control unit: 7875134 HPS2 control unit (single phase) 7875122 CWD 55 E cooling device for HPS2... -

Page 13: Preparing The Product For Usage

Preparing the product for usage Before starting the operation of the tool, the following steps must be carried out each time to ensure that the tool works properly. Check the following points: Transport The transport / the relocation / the use of the device should be carried out by an appropriate lifting appliance (regarding the minimum lifting force, please look at chapter “3.3 Technical data“). -

Page 14: Electric Installations

Electric installations The existing mains voltage must be suitable for the tools' operating voltage. The heating plates must have their own electricity supply according to the information on the type plate. The connection cables are delivered partial in plug-in form. Utilities ... -

Page 15: Connection Points For The Compressed Air

Connection points for the compressed air The pressing power does not depend on the width of the inserted belt. The required pressing power should not be exceed or below this value. The Press is carefully to be closed. Fill presses equipped with pressure hose only with cleaned and dry compressed air. Fill pressure hose only, when the press is firmly closed and the hose is properly fitting. -

Page 16: Control And Limitation Of Temperature

Control and limitation of temperature Several parts of the heating device get extremely hot during operation; therefore touch the press only at the points intended for. The temperature must be measured always at the bore of the heating plate. Other measuring points would falsify the reading. Only gauged and operative measuring devices may be used! Attention The temperature of the heating plates may not exceed 200°C! -

Page 17: Handling

Handling General Heating presses are electrical heating devices for use in fabricating (splicing) belting material that can withstand maximum temperatures of 200°C. There are two basic methods of controlling the heating procedure, a.) An automatic one using a control unit that carries out the heating and cooling phases on special heating presses automatically after the operator has programmed in and b.) A manual one where the operator supervises and carries out independently all the cycles. -

Page 18: Closing The Heating Press

If necessary etc., cover the splice with additional material (PVC-Z-foil, PU-Z-foil) (Fig. 3). 10. Depending on the belt type, place the prescribed cover material (silicone embossing mat, separating paper, textured fabric fine etc.) (Fig. 4). 11. Cover the splice with the top pressure equalizing metal sheet. 12. -

Page 19: Connecting The Water Cooling System

Connecting the water cooling system Warning Risk of injury! Connect the cooling hoses carefully to the tool. Leaking water or steam can be leading to burns. Make sure no more water is in the cooling system. Before heating connect the cooling hoses as shown in the following figure to the rapid couplings on the heating plates. -

Page 20: Connecting The Heating Press To The Mains And Heating The Splice

Connecting the heating press to the mains and heating the splice Connect the heating press to the mains. Attention Risk of fire or damage because of overload to the electricity supply. The electricity supply for the heating plate must be separated from the mains according to the indications mentioned on the type plate! If necessary, make sure the heating press has a separate electricity supply. -

Page 21: Controlling And Cooling The Heating Press

Controlling and cooling the heating press Without control unit The heating device can be operated without using a control unit. The temperature can be supervised by watching the insert thermometer. When the necessary tem- perature is reached, the heating press is separated from the mains. The supply in cooling water can be done by means of a hose and is hand-operated. -

Page 22: Maintenance Work

Maintenance work Before operating the tool, the following maintenance work must be carried out each time to ensure that the tool works properly. If damage is detected during maintenance that cannot be eliminated on site, the tool must no longer be used and has to be sent for repair to the manufacturer. Check the following each time before use: ... -

Page 23: Spare Parts

Spare parts … 450 P 120 … 500 P 120 Designation on request on request Heating plate top complete 230V on request on request Heating plate bottom complete 230V 7871422 7871422 Temperature fuse 7870511 7870511 Jack 3/8 inch RPL 08.1152 7870512 7870512 Hose coupling... -

Page 24: Disassembling And Disposal

Disassembling and disposal The disassembling in individual components can only be effected by competent staff with a good knowledge of machine building. Please sort out the device according to the respective materials (metal, plastics, electronic) and recycle them. Operating instruction: I001.1 Edition: 01/2016 Subject to alterations.

Need help?

Do you have a question about the HPD 450 P 120 and is the answer not in the manual?

Questions and answers