Subscribe to Our Youtube Channel

Summary of Contents for DITTING 1203

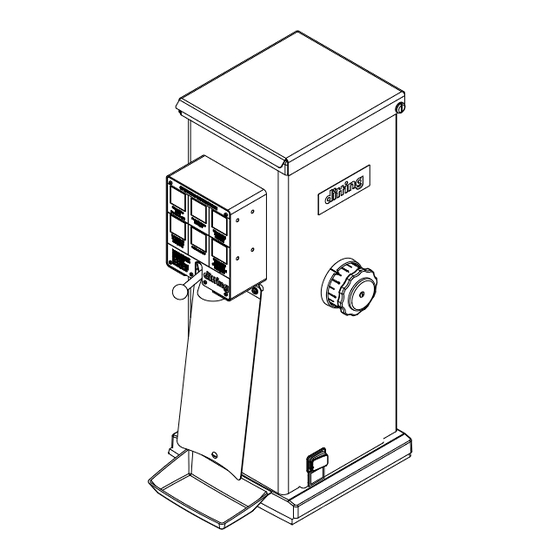

- Page 1 1203 / 1403 ORIGINAL INSTRUCTIONS KFA 1203 / 1403 KR 1203 / 1403 KFA 1403 Industrial www.dittingswiss.ch...

-

Page 2: Overview

SHOP GRINDER Overview KFA 1203 / 1403 KR 1203 / 1403 KFA 1403 Industrial... - Page 3 1203 / 1403 | EN KR 1203 / 1403 KFA 1203 / 1403 | KFA 1403 Industrial KFA 1203 / 1403 KR 1203 / 1403 KFA 1403 Industrial...

- Page 4 SHOP GRINDER KR 1203 / 1403 KFA 1203 / 1403 KFA 1403 Industrial...

-

Page 5: Scope Of Delivery

The bean hopper of model KFA 1403 Industrial has no lid. ** The sliding valve is an optional component for the models KFA 1203, KFA 1403 and KFA 1403 Industrial. The sliding valve enables the bean hopper to be closed off to the grinding mechanism, so that no beans enter the grinding mechanism from the bean hopper. -

Page 6: Table Of Contents

Operation ......12 Setting the grinding degree .....12 Filling with coffee beans ....12 Preparing the receptacle for the ground material and starting the grinding process .......13 KR 1203 / 1403 .......13 KFA 1203 / 1403 and KFA 1403 In- dustrial ..........13 Changing the coffee variety .....14... -

Page 7: General Information

Reading and retaining the original instructions Carefully read these original instructions and the safety information before you put the described shop grinder of the 1203 or 1403 model series into service. This is the only way that you can operate the shop grinder safely and use it without any risk. -

Page 8: Safety

SHOP GRINDER Declaration of Conformity: Products marked with this symbol fulfil all applicable community provisions of the European Economic Area. ETL Listed seal of approval: Products marked with this symbol meet the requirements of electrical product safety in the United States of America. Products marked with this symbol meet the criteria required by the NSF (National Sanitation Foundation) regarding cleanliness and hygiene in the food industry. -

Page 9: Safety Information

1203 / 1403 | EN Safety information WARNING! Danger of electric shock! Improper use, incorrect electrical installation or an excessively high voltage can all lead to electric shock. – Connect the grinder only if the mains voltage of the socket com- plies with the information indicated on the type plate. - Page 10 SHOP GRINDER – Use the grinder in indoor areas only. Never operate the grinder in damp rooms or in the rain. – Keep children away from the grinder. – Ensure that children do not insert any objects into the grinder. –...

-

Page 11: Operating Principle / Differences Between Models

All the grinder models described in these original instructions are shop grinders (see chapter on “Intended use"). The 1203 and 1403 model series differ in their grinding capacity and their type of power supply (see chapter on "Technical data"). Bag clamping and grinding are carried out separately and started manually in models with the prefix KR. -

Page 12: Setting Up The Grinder And Making It Ready For Operation

The maximum filling quantity should be approx. 1 cm below the edge of the bean hopper. 3. Close the lid of the bean hopper. Only the models KFA 1203 / 1403 and KFA 1403 Industrial have an on/off switch. You only need to dis- connect the grinder from the power supply in the models KR 1203 / 1403. -

Page 13: Preparing The Receptacle For The Ground Material And Starting The Grinding Process

1203 / 1403 | EN Preparing the receptacle for the ground material and starting the grinding process Prepare the receptacle to collect the ground material and, with the grinder ready for operation, start grinding as described for your model. KR 1203 / 1403 1. -

Page 14: Changing The Coffee Variety

– Do not use any harsh cleaning products or sharp or metallic cleaning objects such as knives, metal scouring pads or similar. These can scratch the surface. The sliding valve is an optional component for the models KFA 1203, KFA 1403 and KFA 1403 Industrial. -

Page 15: Grinder Installation Surface

3. Use a cloth to clean the inside and outside of the bean hopper and allow to dry. Only the models KFA 1203 / 1403 and KFA 1403 Industrial have an on/off switch. You only need to dis- connect the grinder from the power supply in the models KR 1203 / 1403. -

Page 16: Cleaning The Grinding Mechanism

4. Place a collecting container under the spout (7) to collect the grinder cleaner. 5. Start the grinding of the grinder cleaner as described for your model. KR 1203 / 1403: Press and hold down the start/stop switch (3) to start the grinding of the grinder cleaner. -

Page 17: Troubleshooting

1203 / 1403 | EN Troubleshooting Fault Cause Remedy The grinder is • The spout is clogged. t Set the grinding degree to the making noise but "coarsest grind" and start the not grinding. grinding process. The grinder will clear itself. - Page 18 Switch on the grinder by tilt- ing the on/off switch to the I switched on/ ready for operation. position (only applies to the models KFA 1203 / 1403 and KFA 1403 Industrial) • The thermal overcur- t Check whether the release rent circuit-breaker button of the overcurrent cir- was triggered.

-

Page 19: Technical Data

1203 / 1403 | EN Technical data Models: KR 1203 | KFA 1203 Voltage / frequency: 120 V, 60 Hz 220 V, 60 Hz 220–240 V, 50 Hz Nominal value: 1600 W Protection type: IPX1 Protection class: Fuse: 16 A slow Idle speed:... - Page 20 SHOP GRINDER Model: KFA 1403 Industrial Voltage / frequency: 220/380 V, 60 Hz 230/400 V, 50 Hz Nominal value: 2000 W Protection type: IPX1 Protection class: Fuse: 16 A slow Idle speed: 1400 rpm Sound emission value Idle: 55 dB Grinding: 78 dB Grinding capacity:...

-

Page 21: Disposal

Maintenance and service Contact an authorised service centre for Ditting products for service or main- tenance. Customer Service can answer your questions about repairing and maintaining your product as well as about spare parts. - Page 22 Hemro International AG Länggenstrasse 34 | 8184 Bachenbülach, Switzerland Tel.: +41 44 864 18 00 | Fax: +41 44 864 18 01 info@hemrogroup.com | www.hemrogroup.com...

Need help?

Do you have a question about the 1203 and is the answer not in the manual?

Questions and answers