Table of Contents

Advertisement

IM10059-A

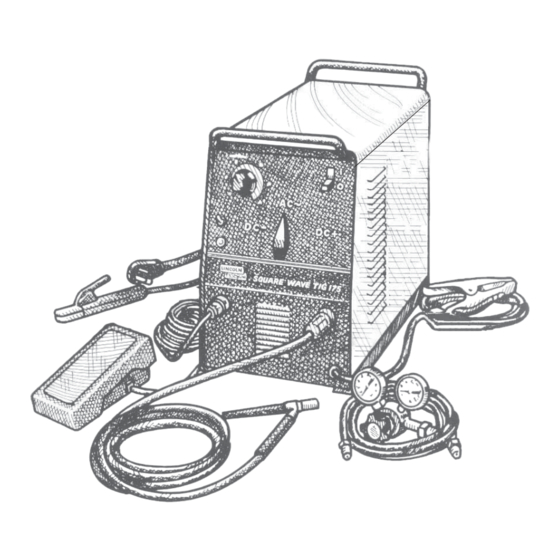

SQUARE WAVE™TIG 175

February, 2012

11691,11826

For use with machines having Code Numbers:

Safety Depends on You

Lincoln arc welding and cutting

equipment is designed and built

with safety in mind. However, your

overall safety can be increased by

proper installation ... and thoughtful

operation on your part. DO NOT

INSTALL, OPERATE OR REPAIR

THIS

EQUIPMENT

WITHOUT

READING THIS MANUAL AND

THE SAFETY PRECAUTIONS

CONTAINED

THROUGHOUT.

And, most importantly, think before

you act and be careful.

OPERATORʼS MANUAL

Copyright © Lincoln Global Inc.

• World's Leader in Welding and Cutting Products •

• Sales and Service through Subsidiaries and Distributors Worldwide •

Cleveland, Ohio 44117-1199 U.S.A. TEL: 216.481.8100 FAX: 216.486.1751 WEB SITE: www.lincolnelectric.com

Advertisement

Table of Contents

Troubleshooting

Subscribe to Our Youtube Channel

Summary of Contents for Lincoln Electric SQUARE WAVE TIG 175

- Page 1 IM10059-A SQUARE WAVE™TIG 175 February, 2012 11691,11826 For use with machines having Code Numbers: Safety Depends on You Lincoln arc welding and cutting equipment is designed and built with safety in mind. However, your overall safety can be increased by proper installation ...

- Page 2 THANK YOU FOR SELECTING A QUALITY PRODUCT BY KEEP YOUR HEAD OUT OF THE FUMES. DON’T get too close to the arc. LINCOLN ELEC TRIC. Use corrective lenses if necessary to stay a reasonable distance away from the arc. READ and obey the Safety Data PLEASE EXAMINE CARTON AND EQUIPMENT FOR Sheet (SDS) and the warning label DAMAGE IMMEDIATELY...

- Page 3 W117.2-1974. A Free copy of “Arc Welding Safety” booklet E205 is available from the Lincoln Electric Company, 2.d. All welders should use the following procedures in order to 22801 St. Clair Avenue, Cleveland, Ohio 44117-1199.

- Page 4 SAFETY ELECTRIC SHOCK ARC RAYS CAN BURN. CAN KILL. 3.a. The electrode and work (or ground) circuits are 4.a. Use a shield with the proper filter and cover plates to protect your electrically “hot” when the welder is on. Do eyes from sparks and the rays of the arc when welding or not touch these “hot”...

- Page 5 SAFETY WELDING AND CUTTING CYLINDER MAY EXPLODE IF SPARKS CAN CAUSE DAMAGED. FIRE OR EXPLOSION. 7.a. Use only compressed gas cylinders containing the correct shielding gas for the process used 6.a. Remove fire hazards from the welding area. If and properly operating regulators designed for this is not possible, cover them to prevent the welding sparks the gas and pressure used.

- Page 6 SAFETY PRÉCAUTIONS DE SÛRETÉ 6. Eloigner les matériaux inflammables ou les recouvrir afin de Pour votre propre protection lire et observer toutes les instructions prévenir tout risque dʼincendie dû aux étincelles. et les précautions de sûreté specifiques qui parraissent dans ce manuel aussi bien que les précautions de sûreté...

-

Page 7: Table Of Contents

TABLE OF CONTENTS Page _______________________________________________________________________________________ Installation ......................Section A Technical Specifications ....................A-1 Safety Precautions ..............................Select Suitable Location ..................A-2 Grinding .........................A-2 Stacking .........................A-2 Lifting ........................A-2 Tilting ........................A-2 Environmental Rating ....................A-2 Machine Grounding and High F ....A-2,A-3 REQUENCY NTERFERENCE ROTECTION Input Connections ......................A-3 Input Reconnect Procedure ..................A-3 Output Connections .....................A-4... -

Page 8: Installation

INSTALLATION TECHNICAL SPECIFICATIONS - SQUARE WAVE™ TIG 175 (K1478-5) INPUT - SINGLE PHASE ONLY Standard Input Current at Code Voltage Rated Output Number 208/230/1/60 58/52 AC/DC Stick & DC TIG - 64/57 AC TIG 11691 11826 RATED OUTPUT Duty Cycle Amps Volts at Rated Amperes GTAW 25% Duty Cycle 15.0 V AC/DC... -

Page 9: Safety Precautions

INSTALLATION SAFETY PRECAUTIONS MACHINE GROUNDING AND HIGH FRE- QUENCY INTERFERENCE PROTECTION Read entire installation section before starting installation. The welder must be grounded. See your local and national WARNING electrical codes for proper grounding methods. The high frequency generator, being similar to a radio ELECTRIC SHOCK can kill. -

Page 10: Input Connections

INSTALLATION a) A metal underground water pipe in direct contact INPUT RECONNECT PROCEDURE with the earth for ten feet or more. On multiple input voltage welders, be sure the machine is connected per the following instructions for the volt- b) A 3/4” (19mm) galvanized pipe or a 5/8” (16mm) age being supplied to the welder. -

Page 11: Output Connections

INSTALLATION A TIG welding torch with cable and connector is sup- plied with the welder. Turn the Power Switch “OFF”. Connect the torch cable quick connect plug into the FOR LOWEST RATED VOLTAGE Electrode/Gas Output Receptacle on the front of the : H2 CONNECTED welder and turn it clockwise until it is tight. -

Page 12: Remote Control Connection

INSTALLATION REMOTE CONTROL CONNECTION A remote control receptacle is provided on the case front of the welder for connecting a remote control to to the machine. A Foot Amptrol , foot activated remote control, is included with the SQUARE WAVE™ TIG 175. -

Page 13: Peration

OPERATION SAFETY PRECAUTIONS PRODUCT DESCRIPTION Read and understand this entire section before operat- The SQUARE WAVE™ TIG 175 is a constant current, ing the machine. single range AC/DC TIG (GTAW) arc welding power source with built-in arc starter / stabilizer. It also has WARNING stick welding (SMAW) capability. -

Page 14: Controls And Settings

OPERATION CONTROLS AND SETTINGS All operator controls and adjustments are located on the front of the SQUARE WAVE™ TIG 175. Refer to Figure B.1 and corresponding explanations. FIGURE B.1 - CONTROL PANEL 1. POWER SWITCH 2. TIG/STICK SWITCH 3. POLARITY SWITCH 4. -

Page 15: Operating Steps

OPERATION 6. REMOTE CONTROL CONNECTOR - This connector REMOTE CONTROL OPERATION provides connection for a remote control. See Remote Control Operation in this section of the manual. A Foot Amptrol™ is included with the SQUARE WAVE™ TIG 175 for remote current control while TIG welding. 7. -

Page 16: Welding In Stick Mode

OPERATION The AC waveform of the SQUARE WAVE™ TIG 175 WARNING optimizes cleaning and heating of the work. The result is the capability to weld through the complete range of In Stick Mode the output terminal and 10 to 175 amperes in AC TIG or DC- TIG requiring only electrode will be electrically hot one electrode, a 3/32”... -

Page 17: Accessories

ACCESSORIES OPTIONAL EQUIPMENT K964-1 Undercarriage with Pivoting Single Gas TIG Torch Parts Kits - Parts kits are available for the Cylinder Platform - This undercarriage features a piv- PTA-9 and PTA-17 TIG torches. These kits include oting platform to easily load and unload the gas cylin- back cap, collets, collet bodies, nozzles and tungstens. -

Page 18: Maintenance

MAINTENANCE SAFETY PRECAUTIONS WARNING Use extreme caution when working with circuit of the high WARNING frequency. The high voltages developed can be lethal. Turn the input power off using the disconnect switch or fuse box ELECTRIC SHOCK can kill. before working inside machine. This is particularly impor- tant when working on the secondary circuit of the high volt- •... -

Page 19: Troubleshooting

HOW TO USE TROUBLESHOOTING GUIDE WARNING Service and Repair should only be performed by Lincoln Electric Factory Trained Personnel. Unauthorized repairs performed on this equipment may result in danger to the technician and machine operator and will invalidate your factory warranty. For your safety and to avoid Electrical Shock, please observe all safety notes and precautions detailed throughout this manual. -

Page 20: Troubleshooting

TROUBLESHOOTING Observe all Safety Guidelines detailed throughout this manual PROBLEMS POSSIBLE RECOMMENDED (SYMPTOMS) CAUSE COURSE OF ACTION OUTPUT PROBLEMS Machine is Dead - 1. Make certain that the input No Output - No Fan power switch is in the “ON” position and machine is plugged in. - Page 21 TROUBLESHOOTING Observe all Safety Guidelines detailed throughout this manual PROBLEMS POSSIBLE RECOMMENDED (SYMPTOMS) CAUSE COURSE OF ACTION OUTPUT PROBLEMS Machine regularly over heats - ther- 1. Welding application may mostat opens, Yellow light on front exceed recommended duty panel glows. The fan runs but cycle.

- Page 22 TROUBLESHOOTING Observe all Safety Guidelines detailed throughout this manual PROBLEMS POSSIBLE RECOMMENDED (SYMPTOMS) CAUSE COURSE OF ACTION TIG MODE PROBLEMS Machine output is intermittently lost. 1. Problem may be caused by high Gas flow and high frequency are frequency interference. Make also interrupted.

- Page 23 TROUBLESHOOTING Observe all Safety Guidelines detailed throughout this manual PROBLEMS POSSIBLE RECOMMENDED (SYMPTOMS) CAUSE COURSE OF ACTION TIG WELDING PROBLEMS Black areas along weld bead. 1. Clean any oily or organic conta- mination from the work piece. 2. Tungsten electrode may be cont- aminated.

- Page 24 TROUBLESHOOTING Observe all Safety Guidelines detailed throughout this manual PROBLEMS POSSIBLE RECOMMENDED (SYMPTOMS) CAUSE COURSE OF ACTION TIG WELDING PROBLEMS No high frequency. Machine is in 1. If the machine location is in a the TIG Mode and has normal out- highly dirty environment with put.

- Page 25 TROUBLESHOOTING Observe all Safety Guidelines detailed throughout this manual PROBLEMS POSSIBLE RECOMMENDED (SYMPTOMS) CAUSE COURSE OF ACTION STICK WELDING PROBLEMS Stick electrode “Blasts Off” when arc 1. Weld current may be set too is struck. high for electrode size. Reduce current control setting, or use a larger diameter electrode.

- Page 26 WIRING DIAGRAM Enhanced Diagram SQUARE WAVE™ TIG 175...

- Page 27 WIRING DIAGRAM ENHANCED DIAGRAM SQUARE WAVE™ TIG 175...

- Page 28 Keep your head out of fumes. Turn power off before servicing. Do not operate with panel open or Use ventilation or exhaust to guards off. WARNING remove fumes from breathing zone. Spanish Los humos fuera de la zona de res- Desconectar el cable de ali- No operar con panel abierto o AVISO DE...

- Page 29 Do not touch electrically live parts or Keep flammable materials away. Wear eye, ear and body protection. WARNING electrode with skin or wet clothing. Insulate yourself from work and ground. Spanish No toque las partes o los electrodos Mantenga el material combustible Protéjase los ojos, los oídos y el AVISO DE bajo carga con la piel o ropa moja-...

- Page 30 • World's Leader in Welding and Cutting Products • • Sales and Service through Subsidiaries and Distributors Worldwide • Cleveland, Ohio 44117-1199 U.S.A. TEL: 216.481.8100 FAX: 216.486.1751 WEB SITE: www.lincolnelectric.com...

Need help?

Do you have a question about the SQUARE WAVE TIG 175 and is the answer not in the manual?

Questions and answers