Table of Contents

Advertisement

For use with machines having Code Numbers:

Safety Depends on You

Lincoln arc welding and cutting

equipment is designed and built

with safety in mind. However, your

overall safety can be increased by

proper installation ... and thoughtful

operation on your part. DO NOT

INSTALL, OPERATE OR REPAIR

THIS

EQUIPMENT

WITHOUT

READING THIS MANUAL AND

THE SAFETY PRECAUTIONS

CONTAINED

THROUGHOUT.

And, most importantly, think before

you act and be careful.

Date of Purchase:

Serial Number:

Code Number:

Model:

Where Purchased:

• Sales and Service through Subsidiaries and Distributors Worldwide •

Cleveland, Ohio 44117-1199 U.S.A. TEL: 216.481.8100 FAX: 216.486.1751 WEB SITE: www.lincolnelectric.com

RETURN TO MAIN MENU

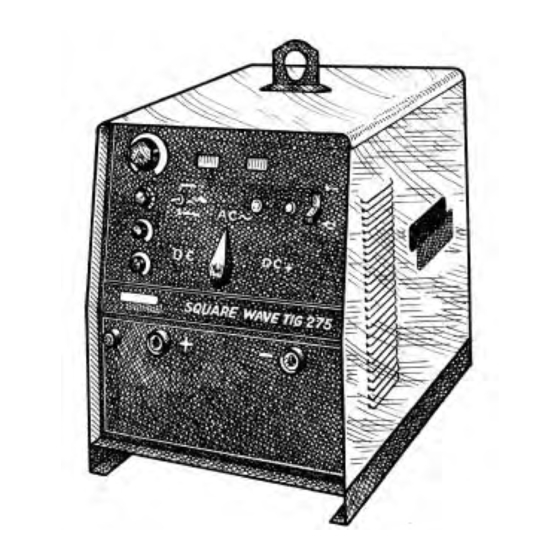

Square Wave TIG 275

10523,

10524,

10525,

10605,

10738

OPERATOR'S MANUAL

• World's Leader in Welding and Cutting Products •

Copyright © 2001 Lincoln Global Inc.

IM609-B

May, 2001

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for Lincoln Electric SQUARE WAVE TIG 275 IM609-B

- Page 1 Square Wave TIG 275 For use with machines having Code Numbers: Safety Depends on You Lincoln arc welding and cutting equipment is designed and built with safety in mind. However, your overall safety can be increased by proper installation ... and thoughtful operation on your part.

-

Page 2: California Proposition 65 Warnings

Miami, Florida 33135 or CSA Standard W117.2-1974. A Free copy of “Arc Welding Safety” booklet E205 is available from the Lincoln Electric Company, 22801 St. Clair Avenue, Cleveland, Ohio 44117-1199. BE SURE THAT ALL INSTALLATION, OPERATION, MAINTENANCE AND REPAIR PROCEDURES ARE PERFORMED ONLY BY QUALIFIED INDIVIDUALS. -

Page 3: Electric Shock Can Kill

ELECTRIC SHOCK can kill. 3.a. The electrode and work (or ground) circuits are electrically “hot” when the welder is on. Do not touch these “hot” parts with your bare skin or wet clothing. Wear dry, hole-free gloves to insulate hands. - Page 4 WELDING SPARKS can cause fire or explosion. 6.a. Remove fire hazards from the welding area. If this is not possible, cover them to prevent the welding sparks from starting a fire. Remember that welding sparks and hot materials from welding can easily go through small cracks and openings to adjacent areas.

- Page 5 PRÉCAUTIONS DE SÛRETÉ Pour votre propre protection lire et observer toutes les instructions et les précautions de sûreté specifiques qui parraissent dans ce manuel aussi bien que les précautions de sûreté générales suiv- antes: Sûreté Pour Soudage A L’Arc 1. Protegez-vous contre la secousse électrique: a.

- Page 6 This statement appears where the information must be followed to avoid minor personal injury or damage to this equipment. for selecting a QUALITY product by Lincoln Electric. We want you to take pride in operating this Lincoln Electric Company product •••...

-

Page 7: Table Of Contents

Installation ...Section A Technical Specifications...A-1, A-2 Select Suitable Location ...A-3 Stacking ...A-3 Lifting and Moving ...A-3 Tilting..A-3 Environmental Rating ...A-3 Machine Grounding and High Frequency Interference Protection ...A-3 Supply Connections...A-4 Input Reconnect Procedures ...A-5 Output Connections...A-7 Work Cable Connections...A-7 TIG Torch Connections ...A-8 Twist-Mate Adapter for LA-9 and LA-17 TIG Torch...A-9 Twist-Mate Adapter for LW-18 and LW-20 TIG Torch ...A-9... -

Page 8: Physical Dimensions

TECHNICAL SPECIFICATIONS - Square Wave TIG 275 (K1617-1, and -2) Input Current at Standard 40% Duty Cycle Voltage DC STICK, DC TIG, UNBALANCED AC TIG DC TIG, BALANCED AC TIG 208/230/460/1/60 (K1617-1) 95/86/43 130/120/61 460/575/1/60 (K1617-2) 43/35 208/230/460/1/60 (K1617-1) 95/86/43 130/120/61 RATED OUTPUT &... - Page 9 TECHNICAL SPECIFICATIONS - Square Wave TIG 275 (K1618-1) Input Current at Standard 40% Duty Cycle Voltage DC STICK, DC TIG, UNBALANCED AC TIG DC TIG, 220/380/415/1/50/60 BALANCED AC TIG 99/57/52 139/79/72 RATED OUTPUT & ADDITIONAL OUTPUT CAPACITY Duty Cycle 40% Duty Cycle AC/DC Stick NEMA Class II (40) AC/DC TIG...

-

Page 10: Select Suitable Location

Dirt, dust or any foreign material that can be drawn into the welder should be kept at a minimum. Failure to observe these precautions can result in excessive operating temperatures and nuisance trips. -

Page 11: Supply Connections

Flexible helically- wrapped metallic conduit is generally not suitable. 8. When the welder is enclosed in a metal building, the metal building should be connected to several good earth driven electrical grounds (as in 5 (b) above) around the periphery of the building. -

Page 12: Input Reconnect Procedures

Failure to follow instructions below can cause immediate failure of components within the welder. 1. Connect the input power leads to the input terminals, L1 (U) and L2 (V), at the right below. - Page 13 Failure to follow instructions below can cause immediate failure of components within the welder. Connect the input power leads to the input terminals, L1 (U) and L2 (V), at the right below.

-

Page 14: Low And High

Designations on the reconnect panel LOW, MID, and HIGH correspond to the nameplated input voltages of a triple voltage welder. Dual voltage welders use only LOW and HIGH. EXAMPLE: On a 208/230/460 volt welder, LOW is 208V, MID is 230V, and HIGH is 460V. -

Page 15: Tig Torch Connections

TIG TORCH CONNECTION The Twist-Mate connection allows fast and reliable TIG torch attachment to the electrode terminal of the Square Wave TIG 275 welding power supply. Twist- Mate TIG adapters are made of brass, combining high electrical conductivity with mechanical strength. They are available in several sizes and styles to accommo- date a wide selection of gas and water-cooled TIG torches. -

Page 16: Twist-Mate Adapter For La-9 And La-17 Tig Torch

TWIST-MATE ADAPTER FOR LA-9 and LA-17 TIG TORCH The Twist-Mate connection allows fast and reliable TIG torch connections to the electrode terminal of the Square Wave TIG 275. The Twist-Mate adapter, strain relief boot and retaining compound needed to connect an LA-9 or LA-17 torch (or any equivalent air-cooled TIG torch with a right-hand male 3/8-24 fitting) are included with the Square Wave TIG 275. -

Page 17: Stick Electrode Cable Connection

A-10 4. Hold the TIG adapter, with cables and hoses installed, firmly in place by securing it into the Twist- Mate receptacle on the power source or into a padded vise. Apply a thin film of lubricant to the boot’s lead in chamfer area. Also apply lubricant to the lead in chamfer and 2"... -

Page 18: Safety Precautions

SAFETY PRECAUTIONS Read and understand this entire section before operat- ing the machine. Observe additional Safety Guidelines detailed in the beginning of this manual. OPERATION WARNING ELECTRIC SHOCK can kill. • Do not touch electrically live parts or electrode with skin or wet clothing. •... -

Page 19: Operation

GRAPHIC SYMBOLS THAT APPEAR ON THIS MACHINE OR IN THIS MANUAL POWER SWITCH SYMBOL MEANING INPUT POWER TEMPERATURE OUTPUT CONTROL SYMBOL MEANING CURRENT CONTROL (OUTPUT) AC WAVE BALANCE CONTROL SYMBOL MEANING AC WAVE BALANCE CLEAN (INCREASING & POSITIVE POLARITY) PENETRATE (INCREASING &... - Page 20 GRAPHIC SYMBOLS THAT APPEAR ON THIS MACHINE OR IN THIS MANUAL OPTIONAL WATER SOLENOID CONNECTIONS SYMBOL MEANING WATER (COOLANT) WATER (COOLANT) OUTPUT OUTPUT CONNECTIONS SYMBOL MEANING CONNECTION ELECTRODE CONNECTION OPERATION ADDITIONAL SYMBOLS SYMBOL INPUT WORK SQUARE WAVE TIG 275 MEANING REMOTE CONTROL DO NOT SWITCH WHILE WELDING...

-

Page 21: General Description

GENERAL DESCRIPTION The Square Wave TIG 275 is a constant current, single range square wave AC/DC TIG (GTAW) arc welding power source with built-in high frequency stabilization. It also has stick (SMAW) capability. A TIG Pulser Kit, Power Factor Capacitor Kit, and a Water Solenoid Kit are available as field installed options. -

Page 22: Limitations

• DC+/AC/DC- Polarity Switch allows the welder to change polarity without reconnecting leads. • Provides excellent arc starting and stability through- out the machines wide current range (5 to 315 Amps) to handle the vast majority of TIG welding applica- tions. -

Page 23: Controls And Settings

CONTROLS AND SETTINGS All operator controls and adjustments are located on the case front of the Square Wave TIG 275. Refer to Figure B.1 and corresponding explanations following. 1. Current Control - This knob is used to set the welding current from 5 to 315 amps. Read the complete Operating Instructions section for more information on Local and Remote setting of current. -

Page 24: Welding Operation

See the Maintenance Section for more information on thermostatic protection. 10. Power Switch - Turns power “ON” “OFF” to the welder. When switched “ON” the digital meters will illuminate, indicating that the power is on. 11. Polarity Switch - Selects DC+,... -

Page 25: Tig Welding Sequence Of Operation

(5) TIG torch nozzles are typically made from alumina ceramic. Special applications may require lava nozzles, which are less prone to breakage, but cannot withstand high temperatures and high duty cycles. 3. Turn the welder, gas supply and water supply (if equipped), on. The digital ammeter/voltmeter dis- plays will illuminate when the power is on. - Page 26 2. Connect an Arc Start Switch to the Remote Amphenol. 3. Turn the welder, gas supply and water supply (if so equipped), on. The digital ammeter/voltmeter dis- play will illuminate when the power is on. NOTE: Cooling fan may not be “ON” when not welding.

-

Page 27: Advanced Tig Welding Features

10. With the torch held safely away from everything, press the Arc Start Switch and set the gas flow meter. Release the switch. The welder is now ready for welding. 11. Position the tungsten electrode at the start of the weld at a 65˚... -

Page 28: Stick Welding

B-11 STICK WELDING 1. Turn the welder “ON”. The digital ammeter/voltmeter will illuminate when the power is on. 2. Set the Mode Switch to “STICK”. Set the output cur- rent displayed on the digital ammeter with the Output Control Knob. No other functions or adjust- ments operate in the Stick Mode. -

Page 29: Accessories

ACCESSORIES INCLUDED WITH MACHINE K852-50 - Twist Mate Cable Plug for #2 to #1 Work Lead. K1622-1 - Twist Mate Adapter Kit for LA9 and LA17 Torches. K1622-2 - Twist Mate Adapter Kit for LW18 and LW20 Torches. ACCESSORIES OPTIONAL ACCESSORIES K963-1, -2 - Hand Amptrol K870 - Foot Amptrol K814 - Arc Start Switch... -

Page 30: Maintenance

1. Periodically blow out dust and dirt which may accu- mulate within the welder using an air stream. 2. Inspect welder output and control cables for fraying, cuts, and bare spots. 3. Inspect the spark gap at regular intervals to main- tain the recommended spacing. -

Page 31: Component Location And Access

COMPONENT LOCATION AND ACCESS Control PC Board: Remove the left case side. Use a 3/8" Nut Driver or other suitable tool. Note: The Case side can be removed while roof is in place, as long as the three screws which secure the roof to the case side are removed. -

Page 32: Troubleshooting

HOW TO USE TROUBLESHOOTING GUIDE Service and Repair should only be performed by Lincoln Electric Factory Trained Personnel. Unauthorized repairs performed on this equipment may result in danger to the technician and machine operator and will invalidate your factory warranty. For your safety and to avoid Electrical Shock, please observe all safety notes and precautions detailed throughout this manual. -

Page 33: Troubleshooting E

Observe all Safety Guidelines detailed throughout this manual PROBLEMS (SYMPTOMS) Machine will not turn on. No machine output. Control panel display does not func- tion, but the output is normal. The Voltmeter always reads "000", but the output is normal. If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed. - Page 34 Observe all Safety Guidelines detailed throughout this manual PROBLEMS (SYMPTOMS) The Ammeter displays “000", but the machine has output with no control. One of the meters is blank. Accessories plugged into the 115 volt receptacle do not work. (220 volt receptacle on European model only) Machine regularly overheats;...

- Page 35 Observe all Safety Guidelines detailed throughout this manual PROBLEMS (SYMPTOMS) The machine makes a very loud buzzing noise in DC stick, or in DC TIG when the Arc Start Switch or Amptrol is pressed. The machine has output and the meters are “ON”...

- Page 36 Observe all Safety Guidelines detailed throughout this manual PROBLEMS (SYMPTOMS) Machine does not respond (no gas flow, no high frequency, no open cir- cuit voltage) when Arc Start Switch or Amptrol is pressed. Thermal light is not lit. No gas or water flow (with optional water solenoid) when Arc Start Switch or Amptrol is pressed in the TIG Weld Mode.

- Page 37 Observe all Safety Guidelines detailed throughout this manual PROBLEMS (SYMPTOMS) Weak High Frequency. Output quits momentarily; gas flow and high frequency are also inter- rupted. If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed.

-

Page 38: Pc Board Troubleshooting

PC BOARD TROUBLESHOOTING PROCEDURE Before replacing a PC Board which is suspected of being defective, visually inspect the PC Board in question for any electrical or mechanical damage to any of the components or conductors on the board, partially insulated molex pins or connectors. -

Page 39: Wiring Diagram

WIRING DIAGRAM 275C 277A SQUARE WAVE TIG 275 232A 211A 220A... - Page 40 WIRING DIAGRAM 275C 277A SQUARE WAVE TIG 275 232A 211A 220A...

- Page 41 WIRING DIAGRAM 275C 277A SQUARE WAVE TIG 275 232A 211A 220A...

-

Page 42: Dimension Print

DIMENSION PRINT SQUARE WAVE TIG 275... -

Page 43: Basic Course

|_|_|_|_|_|_|_|_|_|_|_|_|_|_|_|_|_|_|_|_|_| Account No. AMERICAN EXPRESS MasterCard AMERICAN EXPRESS USE THIS FORM TO ORDER: Order from: BOOK DIVISION, The Lincoln Electric Company, 22801 St. Clair Avenue, Cleveland, Ohio 44117-1199 BOOKS OR FREE INFORMATIVE CATALOGS Lincoln Welding School (ED-80) Seminar Information (ED-45) - Page 44 ● WARNING ● Spanish ● AVISO DE PRECAUCION ● French ● ATTENTION ● ● German WARNUNG ● Portuguese ● ATENÇÃO ● Japanese Chinese Korean Arabic READ AND UNDERSTAND THE MANUFACTURER’S INSTRUCTION FOR THIS EQUIPMENT AND THE CONSUMABLES TO BE USED AND FOLLOW YOUR EMPLOYER’S SAFETY PRACTICES. SE RECOMIENDA LEER Y ENTENDER LAS INSTRUCCIONES DEL FABRICANTE PARA EL USO DE ESTE EQUIPO Y LOS CONSUMIBLES QUE VA A UTILIZAR, SIGA LAS MEDIDAS DE SEGURIDAD DE SU SUPERVISOR.

- Page 45 ● ● Keep your head out of fumes. Turn power off before servicing. ● Use ventilation or exhaust to remove fumes from breathing zone. ● Los humos fuera de la zona de res- ● Desconectar el cable de ali- piración. mentación de poder de la máquina ●...

- Page 46 • World's Leader in Welding and Cutting Products • • Sales and Service through Subsidiaries and Distributors Worldwide • Cleveland, Ohio 44117-1199 U.S.A. TEL: 216.481.8100 FAX: 216.486.1751 WEB SITE: www.lincolnelectric.com...

Need help?

Do you have a question about the SQUARE WAVE TIG 275 IM609-B and is the answer not in the manual?

Questions and answers