Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Hougen-Ogura PUNCH PRO 75002A

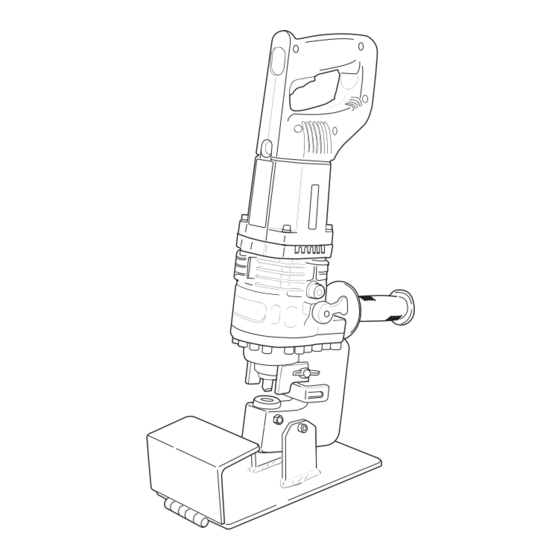

- Page 1 ™ PUNCH PRO ELECTRO-HYDRAULIC HOLE PUNCHER OPERATOR’S MANUAL Model 75002A...

- Page 2 IMPORTANT SAFETY INSTRUCTIONS WARNING: When using electric tools, basic safety precautions should always be followed to reduce the risk of fire, electric shock, and personal injury, including the following. Consider Work Area Environment 1. READ ALL INSTRUCTIONS Do not expose tool to rain Do not use tool in damp or wet 2.

-

Page 3: Safety First

PRINCIPLES OF OPERATION The Hougen-Ogura Electro-hydraulic Hole Puncher is an As a result of this design, the piston will not return to its integrated unit, containing the electric motor, hydraulic home position automatically unless the full stroke has pump, and “C”-frame punching unit. -

Page 4: Operating Procedures

OPERATING PROCEDURES *Position the puncher at the proper location on the Read, understand and follow all safety instructions and workpiece using the hole locator gage or by locating the operating procedures. If you do not understand the point on the end of the punch into a center punch mark on instructions or if conditions are not correct for proper the piece. - Page 5 NEW AND IMPROVED PUNCH RETAINING New Quick Change Punch New Punch w/ cuts to prevent Free Coupling Sleeve Slides Rotation Joint Pin Retaining Ring Old Style Punch and Retaining Nut Punch Pin Spanner Retaining Old Punch PUNCH DESIGNS “O” Ring...

-

Page 6: Maintenance

MAINTENANCE In order to insure smoother operation and longer life of your Unplug the power cord. Wipe any debris from the hole puncher, the following maintenance should be done exposed part of the punch piston. periodically, based on use. 2. Regularly tighten all fasteners and replace any Keep the machine clean. - Page 7 75002A EXPLODED VIEW 85 86...

- Page 8 PARTS LIST - 75002A " "...

- Page 9 ROUND PUNCHES AND DIES FOR MODEL 75002A Round Punch Material Size Part Part Thickness Style Size Nominal Actual Metric 5/64 (.078) to 1/8 (.125) F, A, H Die 1/4 A 75432 14 to 11 GA. 1/4" .256 6.5mm 75421 >1/8 (.125) to 1/4 (.250) F, A, H Die 1/4 B 75433...

- Page 10 OBLONG PUNCHES AND DIES FOR 75002A OBLONG PUNCH MATERIAL Size Part Part Thickness Style Size Nominal Actual Metric 5/64 (.078) to 1/8 (.125) F, A, H Die 1/4 x 1/2 A 75643 14 to 11 GA. 1/4" .256 6.5mm >1/8 (.125) to 1/4 (.250) 75638 F, A, H Die 1/4 x 1/2 B...

-

Page 11: Troubleshooting

Troubleshooting " "... - Page 12 WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE © 2003 Hougen Manufacturing, Inc. Hougen-Ogura Patent Notice Photographs and Specifications shown are accurate in detail at time of printing. Manufacture reserves the right to make improvements and modifications without prior notice.

Need help?

Do you have a question about the PUNCH PRO 75002A and is the answer not in the manual?

Questions and answers