Table of Contents

Advertisement

Quick Links

MODEL 76000PR

™

PUNCH PRO

PUNCH PRO

18V CORDLESS

™

ELECTRO-HYDRAULIC HOLE PUNCHER

ELECTRO-HYDRAULIC HOLE PUNCHER

OPERATOR'S MANUAL

COVERS HOLE PUNCHER PART NUMBERS 0760102 & 0760202

Before operating this machine, read, understand and follow all instructions and

operating procedures. Keep this Operator's Manual with the machine.

OM76000PR0415

Printed in U.S.A.

Advertisement

Table of Contents

Summary of Contents for Hougen-Ogura PUNCH PRO 76000PR

- Page 1 MODEL 76000PR ™ PUNCH PRO PUNCH PRO 18V CORDLESS ™ ELECTRO-HYDRAULIC HOLE PUNCHER ELECTRO-HYDRAULIC HOLE PUNCHER OPERATOR’S MANUAL COVERS HOLE PUNCHER PART NUMBERS 0760102 & 0760202 Before operating this machine, read, understand and follow all instructions and operating procedures. Keep this Operator’s Manual with the machine. OM76000PR0415 Printed in U.S.A.

-

Page 2: Table Of Contents

™ Electro-Hydraulic Hole Puncher Model 76000PR Wecome to Hougen Congratulations on your purchase of the Hougen-Ogura 18V Cordless Electro-Hydraulic Hole Puncher. Your model is designed to produce superior holes quickly and effeciently. Through constant innovation and development, Hougen is committed to provide you with hole-producing tools and products to help you be more productive. -

Page 3: Important Safety Instructions

Important Safety Instructions WARNING 1. Before use, read this Instruction Manual thoroughly. 14. Do not overreach. Do not expose the charger and battery to rain or use Keep proper footing and balance at all times. them in damp or wet locations, as this may cause 15. - Page 4 Important Safety Instructions WARNING 1. Proper selection of the punch and the die is essential. Select the correct punch and die according to the hole shape, size of hole, material thickness and material type. 2. Ensure that any punch with stepped edge to prevent free rotation is installed correctly in the punch piston before tightening the punch retaining nut.

-

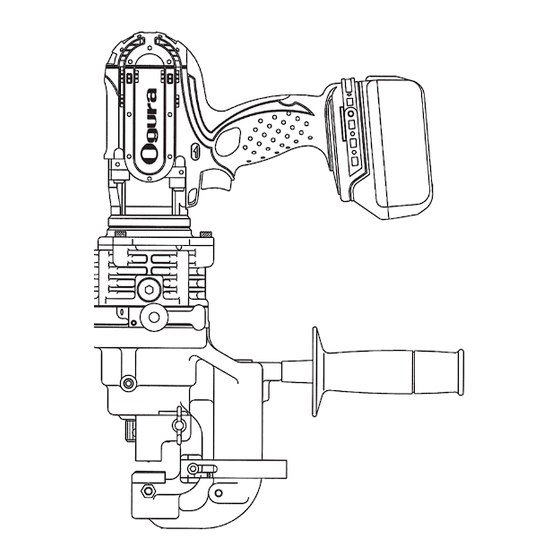

Page 5: Machine Parts, Dimensions And Accessories

76000PR CORDLESS HOLE PUNCHER MODEL 76000 MODEL 76000 Battery Motor Switch Pump Case Oil Port Return Valve Cylinder Handle Punch Slide Stopper C Frame 3 X 1.57" 2 wide X .23 thick 4 X 2 3 X 1.57" 2 wide X .23 thick 4 X 2 1 X 1 X .11 thick 2 X 2 X .23 thick... -

Page 6: Punch And Die Replacing Procedure

Most structural shapes can be punched with the standard die combination. IMPORTANT NOTES: REMOVING THE NEW DIE Your Hougen-Ogura punch unit 1. To make it easier, please remove the strippers 3. Pull the die up to the tip of the punch has been equipped with a new 2. -

Page 7: Battery Charger

7. After charging, remove the battery cartridge from the charger and unplug the charger from the power source. • The battery charger is for charging the Hougen-Ogura battery cartridge. Never use it for other purposes or for other manufacturer’s batteries. -

Page 8: Operating Procedure

OPERATING PROCEDURE WARNING Before the battery is inserted in to the motor, pull and release the Trigger Switch to ensure that the Trigger returns when released. • If the Trigger Switch does not work correctly it may cause an accident. •... - Page 9 ADDING OIL The Cordless Hole Puncher is electro-hydraulic. When shipped from the factory, it was filled with oil. Do not attempt to add oil as long as the tool performs well. When the oil-pressure is not enough for the operation, add the oil as follows.

-

Page 10: 76000Pr Parts Breakdown

76000PR PARTS BREAKDOWN... -

Page 11: 76000Pr Parts & Accessories List

76000PR PARTS LIST Item Part # Description Item Part # Description 76600 Handle 75325 Packing 75361 Bolt HB5 x 12 75052 Spring - Check Valve 75835 Washer WM 5 76066 Check Valve 76601 Slide Stopper 76067 Piston Return Spring 76602 76622 Punch Retaining Nut Piston... - Page 12 76000PR PARTS LIST Item Part # Description Item Part # Description 76638 Position Spring B 76033 Armature with Bearing 76639 Position Spring A 76205 Brush Holder Assembly 76409 Eccentric Shaft 76024 Carbon Brush (Pair) 76407 Spindle 76023 Pin 4 76046 Bearing 76022 Rear Cover...

-

Page 13: Punch & Die List

76000PR ROUND PUNCHES & DIES ROUND PUNCH MATERIAL Size Part Part Thickness Size Nominal Actual Metric 5/32" 76558 76571 .157 5/16 (.078) 14 GA. Die 5/32 SA 5/64 (.078) to .118 3/16" .197 76559 Die 3/16 SA 76572 14 to 12 GA. 5/64 (.078) to .118 7/32"... - Page 14 76000PR OBLONG PUNCHES & DIES OBLONG PUNCH MATERIAL Size Part Part Thickness Size Nominal Actual Metric 1/4" .256 6.5mm >1/8 (.125) to 1/4 (.250) 76594 76236 Die 1/4 x 3/8 10 to 3 GA. 3/8" .394 10mm 1/4" .256 6.5mm >1/8 (.125) to 1/4 (.250) 76595 Die 1/4 x 1/2...

-

Page 15: Troubleshooting

TROUBLE SHOOTING PROBLEM CAUSE SOLUTION Oil is insufficient. Refill Oil. (See pg. 9) Punch piston has not returned completely due to Push back Punch piston. chips, iron powder and dirt present in the sliding Clean Punch piston. portion of the Punch piston and C frame. Punch piston will not come out Punch piston has not returned completely due the... -

Page 16: Warranty & Factory Repair Center

WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE © 2015 Hougen Manufacturing, Inc. Hougen-Ogura Patent Notice Photographs and Specifications shown are accurate in detail at time of printing. Manufacturer reserves the right to make improvements and modifications without prior notice.

Need help?

Do you have a question about the PUNCH PRO 76000PR and is the answer not in the manual?

Questions and answers