Summary of Contents for METROTEC GSM Series

- Page 1 METROTEC S ys te ms f or Meas u ri n g an d Con trol l in g O xygen GSM- touch Oxygen Measuring and Control Device GSM Series *** Version 3.0 ***...

- Page 2 Quality management system DIN EN ISO 9001:2015, No. 12 100 27736 TMS This declaration becomes invalid if changes are made without our consent. Kirchheim/Teck, 04/05/2023 Place, Date Signature METROTEC GmbH Heinkelstrasse 12 • 73230 Kirchheim • Germany Phone +49-(0)7021-953360 • Fax +49-(0)7021-9533613 www.metrotec.eu • info@metrotec.de...

-

Page 3: Table Of Contents

METROTEC Table of Contents Safety Instructions ......................5 Preface ........................... 6 Introduction ........................8 Measuring Principle ....................... 8 Measuring Electronics ....................9 Sensor ..........................9 General Layout ......................10 Description of the Measuring Electronics ..............10 4.1.1 Main Display ............................10 4.1.2... - Page 4 Example with HTERM ........................64 10.2 Modbus UDP ........................ 64 10.2.1 Example using SimplyModbus TCP ....................64 10.2.2 Example using METROTEC Excel-MBAXP ................. 66 10.2.3 Example using Siemens LOGO! (German version) ............... 67 10.3 PLC ..........................71 Messages in the info line .................... 71 Interfaces ........................

-

Page 5: Safety Instructions

METROTEC Safety Instructions Please read these operating instructions carefully before installing and using the device. Improper use of the product will invalidate the warranty! The ambient conditions described in the Specifications chapter must be complied with in order to ensure the device's proper functioning and operational safety. -

Page 6: Preface

METROTEC Preface The measuring device serves for recording oxygen partial pressures in gas atmospheres in connection with an oxygen sensor. Such sensors operate at high temperatures. Therefore, precautions must be taken to keep ignitable gas mixtures from reaching the sensor or the device. - Page 7 METROTEC...

-

Page 8: Introduction

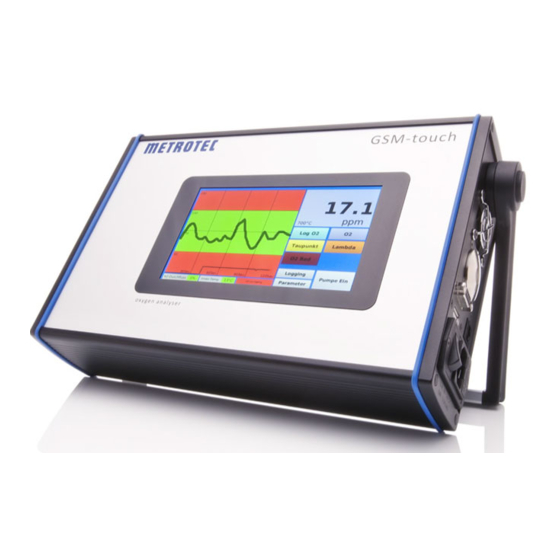

METROTEC Introduction The GSM-touch is a user-friendly measuring instrument for the detection of oxygen partial pressures. The applied measuring principle, with a measuring span of more than 30 decades, allows for the measuring of high concentrations to very small traces. -

Page 9: Measuring Electronics

METROTEC Measuring Electronics The GSM-touch measuring device electronics features the following functions: Measuring the oxygen partial pressure Generating alarms Calculating the dew point Calculating the Lambda air factor Calculating redox potentials The measuring device is operated via a touch screen. -

Page 10: General Layout

METROTEC General Layout Description of the Measuring Electronics 4.1.1 Main Display Touch pad for selecting the Info line unit Measuring Measuring unit Measured value Display of active Axis showing the Measuring outputs Measured values Button Menu selection Button Button Graph... -

Page 11: Keyboard Entry

METROTEC Button opens settings and parameterization menu. Button switches sample gas pump ON/OFF Button starts/stops data logging on internal memory. (In front of "Stop" the number of stored data records is shown) Button starts/stops data logging on USB stick. . -

Page 12: Special Buttons

METROTEC 4.1.4 Special Buttons Currently entered value is deleted Last entry is deleted One or more menu pages back without saving Leave Save and Menu page Description of Sensor After switching on the device, the sensor will be heated up to measuring temperature within the following 15 minutes. -

Page 13: Draft Of Flow Run

METROTEC Draft of Flow run... -

Page 14: Commissioning The Device

METROTEC Commissioning the Device Switching on the Measuring device After connecting the power cable to the mains, the power switch can be activated. The display lights up briefly. After ca. 30 seconds, system start information and, after the boot procedure, the standard screen or the measuring instrument screen last activated will be displayed, depending on the default setting. - Page 15 METROTEC After the heating up phase, the measuring unit will display the measured oxygen value. In this case the info area shows: "Ready" while the background colour is green. A stable measured value is reached 15 minutes after the heating up process has been completed.

- Page 16 METROTEC The start screen may display an alarm message in the info line on a red background. The alarm message can be removed by entering suitable alarm limits (see section "Alarms") and if the measured value lies within these limits.

-

Page 17: Measurement

METROTEC In case the beeper is activated and an alarm pending, the diagram area will display "Beeper Off" The button will acknowledge the beeper and the button fades out. Measurement 5.2.1 Sample gas connection After the starting routine the device is ready for use and can determine the oxygen content in gases. - Page 18 METROTEC The flow is shown in the touch screen. The parameterization is described separately (see Pump parameters: Flow) In case, the pressure of the sample gas source is too low to feed the sample gases through the measuring instrument, the integrated sample gas pump must be switched on by pressing the "Pump"...

-

Page 19: Pump Capacity

METROTEC 5.2.3 Pump capacity There are two possible modes for operating the sample gas pump: Automatic mode In automatic mode, the capacity of the sample gas pump is controlled. For this purpose, the current indication of the flow meter, which is scaled to 0-100 %, will be compared with the target value. - Page 20 METROTEC "Automatic" has been chosen. The current flow as well as the target value are displayed. Pressing the button A new target value can be entered here. opens: For this example, the operation mode "Manual" has been chosen. The current flow as well as the target value are displayed.

-

Page 21: Cylinder Gases

METROTEC Cylinder Gases When measuring synthetic gases, such as nitrogen, argon, helium etc., no further preparations are required for processing the gas. However, pressure must be reduced and the amount fine- tuned. Process Gases 5.4.1 General There is no exact procedure the adherence of which would ensure that all process gases used for technical purposes are correctly prepared and will not harm the measuring device. -

Page 22: Specific Instructions

METROTEC 5.4.4 Specific instructions When deploying condensate separators, especially for water, make sure that the collecting tank is located at the lowest point in the entire pipe system. Due to the dead volume of condensate containers and filters, delay times must be expected. - Page 23 METROTEC Confirmation with The sample gas pump and the fan are switched to run at maximum speed and the sensor is heating turned off. opens: Pull the power plug.

-

Page 24: Selecting The Measured Value

METROTEC Selecting the Measured value By selecting a measured value, several different ways of displaying the measured oxygen partial pressure are available. Measured value display and touchpad for selecting the measured value After activating the touchpad, the following table displays the available options. -

Page 25: Log O2

METROTEC Example of the display showing a 0-240 ppm O trend with band alarm Log O2 The display can assume values between 0.0 und –30.0. The value shown is the logarithm of the oxygen partial pressure. Example of the display showing a 10... -

Page 26: Dew Point

METROTEC Conversation table log (x) 1000000 0.00 100000 -1.00 0.01 10000 -2.00 0.001 1000 -3.00 0.01 0.0001 -4.00 0.001 0.00001 -5.00 0.0001 0.000001 -6.00 0.00001 0.0000001 -7.00 0.000001 0.00000001 0.01 -8.00 The measuring instrument can display values down to 10 Dew point Some measurement tasks require an evaluation of the dew point in degrees. -

Page 27: Lambda

METROTEC Lambda With some processes, knowing the Lambda value of a combustion or a gas mixture is important. Lambda is defined as: Lambda = (combustion air supply)/(theoretically required combustion air) The calculation requires entering a password in menu line No. 27. -

Page 28: Redox Graph

METROTEC Example of the display showing a 0 - 1000 ppm range trend without band alarm Redox Redox potential is a mathematical function scaled on a 0-1 range. It is calculated from the oxygen partial pressure and the temperature entered in the redox graph or measured externally. - Page 29 METROTEC the respective entered or externally measured temperature. The redox potential display above the temperature shows the oxidation or oxygen reduction of a metal. The example uses a fixed value of 950 °C. Pressing the button A new value within the...

-

Page 30: Parameterization

METROTEC If "Cr" has been chosen In this example, the "Cr" line appears bold. The green point indicates: "No Oxidation" In this example showing a rising oxygen partial pressure, the potential falls below the "Cr" line at 950° C, with the red point indicating possible oxidation. - Page 31 METROTEC Pressing the button In this example, only level "0" is accessible opens: Pressing the button Language is German changes the language setting Pressing the button Language is English changes the language Pressing the button Here a new brightness value can be entered within the given range.

- Page 32 METROTEC Pressing the button Entering the correct CODE (initial state = 1234) opens: Level 1 enabled is displayed. The factory CODE for LEVEL "2" is "5678". Enabling level 2 follows the same procedure. Note: Level 3 can only be cleared by the factory...

-

Page 33: Level "0

METROTEC Level "0" This level may be accessed by each user without entering a CODE. -

Page 34: General Settings

METROTEC From this page all parameters and settings displayed can be changed. 7.2.1 General settings The respective description is explained in the previous chapter. 7.2.2 Pump Parameters The respective description can be found in the "Pump Capacity" chapter. 7.2.3 Alarm History... -

Page 35: Level "1

METROTEC Lists all alarms stating date and time of each alarm. Level "1" This level can be accessed by the user, if the correct CODE is entered. The transparent buttons can only be activated on the next level up. From this page all parameters and settings displayed can be changed. -

Page 36: Alarms

METROTEC 7.3.2 Alarms The alarms refer to the diagram in which they are indicated in red, as well as to the sound alarms, the relay output and the message in the info line. Pressing the button opens the following overview:... - Page 37 METROTEC Pressing the right field Here a break can be programmed between the beeps within the indicated range. Note: == Continuous tone opens: In the following example an alarm has been set for Lambda but the beeper remains off. The green text "Lambda" indicates that there is currently no alarm pending referring to the Lambda value display.

- Page 38 METROTEC An alarm will be given No alarm will be given Pressing the button results in: Pressing the button results in: If an alarm is given, there is a 3 second delay Here a time can be preset within the given range...

-

Page 39: Analog Outputs

METROTEC 7.3.3 Analog outputs 2 analog outputs 0/4 to 20 mA available which can be configured independently of There are each other. Pressing the button opens the following overview: This overview shows all key settings of both analog outputs, including the currently delivered mA values. - Page 40 METROTEC Pressing the button opens: Here a measurand can be selected from the available options. Leaving the menu page (if no changes are required) For example Pressing the Here the measurement button opens: range can be defined. Pressing the button...

-

Page 41: Data Logging

METROTEC Pressing the button Switch from 0-20 mA to 4- 20 mA defines: Leaving the menu page (if no changes are required) 7.3.4 Data logging The measured and calculated measured values can be stored as data records. The data carrier can be an external USB stick or the internal SD memory card. - Page 42 METROTEC Pressing the button A new value within the range shown can be entered here for the time interval between 2 measured values. opens: If the button The file name created at the start can be seen in the "File name"...

- Page 43 METROTEC Pressing the button A new value within the range shown can be entered here for the time interval between 2 measured values. opens: If the button The file name can be seen in the "File name" line. Access to the file takes...

-

Page 44: Bus Parameters

METROTEC Sample file inserted via Excel Date Time LogO2 O2 in Lambda O2Red Dew Redox Alarm Alarm point Code 2022,3,16 -4.63 23.6 9999 A000 10:28:20 Ready 2022,3,16 -0.68 209400 9999 A000 10:28:25 Ready 2022,3,16 -0.68 209400 9999 A000 10:28:30 Ready 2022,3,16 -18.97... - Page 45 METROTEC Pressing the button Network (LAN) is activated The current IP address is displayed. In this example: activates (Designation of socket M12 is " " Pressing the button Network (LAN) is deactivated deactivates: Pressing the button Here the remote maintenance program "AnyDesk"...

-

Page 46: Password

METROTEC from the mains. Here the field bus is displayed, the hardware of which has been factory- setting. The user cannot modify the bus. (Connector lable is "bus") The data transfer is continuously "9600,8,1,e" without request. (9600 Baud, 8 data bits, 1 stop bit, parity even) 7.3.6 Password... -

Page 47: Diagram

METROTEC 7.3.7 Diagram Note: All entries referring to "O " are given in ppm Pressing the button opens the following overview of all available diagrams. The following table shows the parameterization of the "Log O2" diagram as an example. All other diagram settings follow this pattern. - Page 48 METROTEC easier to read. In this example, -20 bar are saved. This means that the oxygen partial pressure was programmed to be 10 bar. Pressing the button A new target value can be entered here. opens: In this example, -20 bar are saved.

-

Page 49: Date & Time

METROTEC 7.3.8 Date & Time Pressing the button opens the following overview: The following table shows the parameterization of date and time: The current date is 14 March, 2022 Exit the menu page without saving Pressing the button A new target value can be entered here. -

Page 50: Level "2

METROTEC Pressing the button A new target value can be entered here. opens: Level "2" If level 2 has been enabled, the button opens the following menu. -

Page 51: Settings Described On Level 1

METROTEC 7.4.1 Settings described on Level 1 7.4.2 Correction of a measured value If necessary, the current measured value can be corrected. In this case it is advisable to make the adjustment after a stable measurement has been achieved and possible errors in measurement can be ruled out. - Page 52 METROTEC Pressing the button Here the value displayed in the header can be changed by pressing the "+" or "-" button. The change is shown opens: immediately. Pressing the button Here a numeric correction value can be entered, if the increments used for the "+“...

-

Page 53: Gas Constants

METROTEC 7.4.3 Gas Constants The calculation of the dew point is made based on the measured oxygen partial pressure and the known hydrogen proportion in the gas mixture. The hydrogen proportion must be entered as a percentage. The calculation of the Lambda value is made based on the measured oxygen partial pressure and the gas used for combustion. - Page 54 METROTEC In the example, the external input for measuring the H2 proportion currently displayed has been activated. Pressing the button This menu must be used to configure the required measured. In case an external measuring device has been opens: connected up, the current value is shown, otherwise "--- ".

-

Page 55: Password (Code)

METROTEC Pressing the button Here a new value can be entered within the given range. This value is the maximum percentage of the external measuring opens: device. In the example a fixed value of 0.25 has been used. Pressing the button... -

Page 56: Redox Temperature

METROTEC Attention! In case the CODE is lost or forgotten, the original state can only be re-established by resetting the device to factory settings. The following table uses access level 1 as an example for all available settings. These are also valid for access level 2. - Page 57 METROTEC In this example, the external input for measuring the temperature currently displayed has been activated. Pressing the button This menu must be used to configure the required measured. In case an external temperature measuring device has opens: been connected up, the current value is shown.

-

Page 58: Level "3

METROTEC Level "3" Note: Only available for factory settings. Connections The right side panel of the GSM-touch accommodates all available sockets for connecting cables. Photo of the right side panel of the GSM-touch Analog inputs Input 0/4 – 20 mA from... -

Page 59: Analog Outputs

METROTEC Analog outputs View of built-in M12 CODE Output 0/4-20 mA A jack Type Output 1 Output 2 Alarm outputs View of built-in M12 CODE A Relay output socket Semiconductor relay 24VAC/DC, max 2 A) Type Collective alarm Maximum alarm... -

Page 60: Data Bus

METROTEC Data bus Field depending configuration. Factory setting RS422/485 Function TX+ (+TX1) RX+ (+RX1) TX- (-TX1) RX- (-RX1) View of built-in M12 CODE D socket Network LAN connection e. g. with standard cable M12-Ethernet View of built-in M12 CODE D socket... -

Page 61: Network

METROTEC Network Connection to an Ethernet network Attention! Operating on the WINDOWS platform requires special skills and may only be performed by authorized personnel. In other countries and languages, the headings and texts may differ from the examples shown. A connection will be established within the network by means of an Ethernet cable between router GSM-touch. - Page 62 METROTEC (User name: gsmtouch; Password: gsmtouch) The file "GSM_Touch_log.txt" is listed on the right side of the file manager. The file "GSM_Touch_log.txt" (for file contents see example further up) is now available.

-

Page 63: Data File Examples

METROTEC Data File Examples 10.1 Field bus RS485 Field bus RS422/485 (9600,8,N,1) Log O ppm O Lambda Redox Status CR/LF point The data flow can be displayed and recorded with PUTTY or HTERM. 10.1.1 Example with Putty... -

Page 64: Example With Hterm

METROTEC 10.1.2 Example with HTERM Enlarged view of HTERM example 10.2 Modbus UDP 10.2.1 Example using SimplyModbus TCP The following examples have been performed using the SimplyModbus TCP tool. The bus is a read only tool. Write commands are not supported. - Page 65 METROTEC In the example, the reading was 3680 ppm In the example, the reading included all analog measured values...

-

Page 66: Example Using Metrotec Excel-Mbaxp

METROTEC In the example, the reading included all analog and digital values 10.2.2 Example using METROTEC Excel-MBAXP Excel was adjusted in order to ensure a simple connection with GSM-touch and display measured values on the PC. -

Page 67: Example Using Siemens Logo! (German Version)

METROTEC 10.2.3 Example using Siemens LOGO! (German version) Connection is prepared with Siemens Tools, as shown in the following example: Create new network project LOGO! by Add new device LOGO! Select version Configure network settings (PI…) GSM-touch by Add new device, Select Modbus compatible device Configure network settings (IP…) - Page 68 METROTEC Insert analog network input module in diagram editor Select parameter remote device Select GSMtouch device Port to 502 Device ID to 1 Modbus Type to HR Modbus address to 2, Register 1 (Log=2 LowWord) + Offset 1 repeat above steps for each module...

- Page 69 METROTEC In order to display values on LOGO Display Insert two analog threshold switches and connect with one analog network input module each Insert a message text module Pull parameter Ax from both analog threshold switch modules into message text Insert three open terminal modules and connect with open module outputs.

- Page 70 METROTEC Load program in LOGO and start it Display line 1 shows Register 1 (Log=2 LowWord) Display line 2 shows Register 12 (Status) Result: As described in chapter "Modbus UDP", the values are transferred with 32 bit in the form of 2 "Word".

-

Page 71: Plc

METROTEC 10.3 PLC Connecting the device with a PLC requires knowledge about the PLC used. The principle of the data flow can be derived from the examples given. Usually, the administration of numerical formats is already implemented in the PLC, especially for float numbers. -

Page 72: Technical Data

METROTEC Technical data Measuring range 100 % to 10 bar O Environment temperature 0 to 45 degrees Celsius Measurement accuracy +/- 0.3 mV of the sensor e.m.f. +/- 2 degrees Celsius +/- 2% of the mA output +/- 2% of the log oxygen partial pressure...

Need help?

Do you have a question about the GSM Series and is the answer not in the manual?

Questions and answers