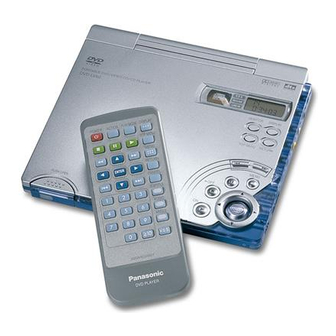

Panasonic DVD-LV60 Service Manual

Portable dvd audio/video player

Hide thumbs

Also See for DVD-LV60:

- Operating (92 pages) ,

- Operating instructions manual (92 pages) ,

- Service manual (7 pages)

Summary of Contents for Panasonic DVD-LV60

- Page 1 ORDER NO.ODSD010847C3 Portable DVD AUDIO/VIDEO PLAYER DVD-LV60 Colour (S)....Silver Type Areas GK....China. SPECIFICATIONS Specifications...

- Page 2 Power supply: DC 9V (DC IN terminal) / DC 7.2V (Exclusive battery terminal) Power consumption: 14W (8W: Unit only) AC adaptor Power source: AC 100-240V, 50/60Hz Power consumption: DC output: 9V, 2A Dimensions: 159(W) x 140(D) x 27(H) mm (when the LCD screen is closed, excluding protrusions) Mass: 510g...

-

Page 3: Safety Precautions

Wave length: 660nm/ 780nm Laser power: CLASS 2/ CLASS 1 Note Specifications are subject to change without notice. Mass and dimensions are approximate. Power consumption in standby mode:1.5W (when using the included AC adaptor) 2001 Matsushita Electric Industrial Co., Ltd. All rights reserved. Unauthorized copying and distribution is a violation of law. -

Page 4: Prevention Of Electro Static Discharge

Figure 1 1.1.2. LEAKAGE CURRENT HOT CHECK (See Figure 1 1. Plug the AC cord directly into the AC outlet. Do not use an isolation transformer for this check. 2. Connect a 1.5k , 10 watts resistor, in parallel with a 0.15 capacitors, between each exposed metallic part on the set and a good earth ground such as a water pipe, as shown in Figure 1... - Page 5 body by touching a known earth ground. Alternatively, obtain and wear a commercially available dischargingESD wrist strap, which should be removed for potential shock reasons prior to applying power to the unit under test. 2. After removing an electrical assembly equipped with ES devices, place the assembly on a conductive surface such as alminum foil, to prevent electrostatic charge buildup or exposure of the assembly.

-

Page 6: Precaution Of Laser Diode

3. PRECAUTION OF LASER DIODE 4. HANDLING PRECAUTIONS FOR TRAVERSE DECK The laser diode in the optical pickup may break down due to potential difference caused by static electricity of clothes or human body. So be careful of electrostatic break down during repair of the optical pickup. 4.1. -

Page 7: Grounding For Electrostatic Breakdown Prevention

Board). 4. Do not turn the variable resistor (Laser power adjustment). / It has already been adjusted. 4.2. Grounding for electrostatic breakdown prevention 1. Human body grounding / Use the antistatic wrist strap to discharge the static electricity from your body. 2. -

Page 8: Self-Diagnosis Function And Service Mode

5.2. The ON/OFF, HOLD switch 6. Self-diagnosis function and service mode 6.1. Service Precautions 6.1.1. Recovery after the dvd player is repaired... - Page 9 6.1.2. Firmware version-up of the DVD player 6.2. Handling After Completing Repairs Use the following procedure after completing repairs. 6.2.1. Precautions Do not disconnect the power plug from the outlet with the tray still open, then close the tray manually. 6.3.

-

Page 10: Service Mode Table

6.6. Service mode table Pressing various button combinations on the player and remote control unit can activate the service modes. -

Page 12: Servo Process Flow

6.7. Servo Process Flow... - Page 13 6.8. Servo Process Display Mode 6.9. ADSC Internal Ram Data Display...

-

Page 14: Self-Diagnosis

7. Diagnosing problems with the optical pick-up and repair procedure 7.1. Self-diagnosis As a new feature, this unit has an “optical pick-up problem diagnosis function” and “a tilt adjustment confirmation function” built in. Use the following procedure to efficiently determine the problem and adjusttilt.If "NO DISC"... -

Page 15: Cautions To Be Used Before Replacing The Optical Pickup Unit And Spindle Motor Assembly

Note: Carry out diagnosis within 3 minutes of turning the unit on. (The player’s current can increase as it warms up, so turn the unit off and allow it to cool down before diagnosis.) 7.2. Cautions to Be Used Before Replacing the Optical Pickup Unit and Spindle Motor Assembly Before replacing the optical pickup unit and spindle motor assembly, check the total using hours for each of them. - Page 16 Cautions to be taken when replacing the optical pickup The optical pickup may break down due to the static electricity of human body. Take proper protection measures against static electricity before repairing the parts around the optical pickup. (See the page describing the PREVENTION OF STATIC ELECTRICITYDISCHARGE.) 1.

-

Page 17: General Description

8. General Description 8.1. Operating Instructions 9. DISASSEMBLING AND REASSEMBLING THE CASING AND CHECKING P.C.B.s <Caution> Pull the DC power plug out of the outlet before disassembling and reassembling the unit or replacing the parts. Not doing so may cause an electric shock or injury. The laser won't come on while the inner cover is open. - Page 18 9.2. P.C.B. Positions...

- Page 19 9.3. Main Cabinet 1. Unscrew the screws from the bottom of the body...

- Page 20 2. Release tabs. (Release the tab A. Press the tab B backward to release. Release the tabs C & D with the left side of the main cabinet raised.) 3. Remove the flexible cable. <The way of FPC holder and Membrane SW>...

- Page 21 1. It bends FPC connection part from the place of the reinforcement board to the L form. 2. It installs FPC connection part in FPC holder. - It hangs both edges on FPC holder locking tabs. - It is careful of the bend of Membrane SW. 3.

- Page 22 Note: The attention item of the bend of Membrane SW - Don’t do except for the bend which is indicated about the manufacturing standard. (Because a pattern is broken if bending the others in the shown bend part) - Don’t bend as shown in the following example.

- Page 24 9.4. Main P.C.B. 1. Remove the flexible cable. 9.5. Recharge battery P.C.B. 1. Remove the screws. 2. Remove the cable.

-

Page 25: Traverse Unit

9.6. Traverse Unit <Caution> Electrostatic breakdown prevention is required when servicing is performed in the area around the traverse unit. Proceed servicing works under the working environment where grounding works is completed. 9.6.1. Removing the traverse unit Before removing the traverse unit, remove the casing parts. 1. - Page 26 4. Solder the laser short land on the flexible cable in the optical pickup unit at the bottom of the traverse unit. 9.6.2. Installing the traverse unit The traverse unit has been adjusted. Do not touch the adjusting screws. 1. Install the flexible cable on the optical pickup unit and lock the cable securely.

- Page 27 3. Remove the spring that locks the main shaft. 4. Slide the main shaft in the direction indicated by the arrow, and remove the optical pickup unit. 9.6.4. Installing the optical pickup unit The optical pickup unit is an adjusted and finished product. Never touch the adjusting screw. 1.

- Page 28 2. Disengage the tabs. (Press the tab A of the Hinge A backward to remove.) 3. Remove the flexible cable. 9.7.2. Assembling procedure After the hinge part is put into the close all states of the monitor unit is installed.(Afterwards,hinge B is set on the right side.) Note When the monitor cover is disassembled...

-

Page 29: Monitor Cover

1. Assemble the monitor cover and install the flexible cable. After that, assemble hinges A and B in this order. Note When the monitor cover isn't disassembled 1. Install the flexible cable. 2. Install the tab B of the hinge A and assemble the hinge A with the tab B pressed. - Page 30 9.8.1. Disassembling and reassembling the flexible unit 1. Remove the hinge B. 2. Disengage the hook sections A and B in this order and remove the flexible cable.

- Page 31 9.9. Speaker Unit 1. Remove the screws. 2. Remove the angle. 3. Remove the connectors. 4. Disengage the tabs. 9.10. Inverter unit 1. Remove the screws. 2. Disengage the tabs. 3. Remove the connectors. 4. Remove the flexible cable. 9.11. LCD Drive P.C.B.

- Page 32 1. Remove the screws. 2. Remove the flexible cable. 3. Disengage the tabs. 9.12. LCD panel 1. Remove the screws. 2. Remove the panel securing metal fittings. 9.13. Service Position <Caution> If the laser should be lit up for playback check, never look at the light of the laser.

-

Page 33: Adjustment Procedures

To prevent the disc from getting damaged, take appropriate measures not to raise the FFC from the upper surface of the traverse unit. 2. Disassemble the liquid crystal drive P.C.B. and the inverter unit as shown in the figure below. 3. -

Page 34: Service Tools And Equipment

10.1. Service Tools and Equipment Application Name Number Tilt adjustment DVD test disc DVDT-S15 or DVDT-S20 Hex. wrench JGS0100 Bottom cabinet jig VUC8039 Inspection Extension cable JGS0096 (Traverse unit to main P.C.B.) Extension cable VUC8029 (Traverse unit to main P.C.B.) Others Screw lock RZZ0L01... -

Page 35: Optical Adjustment

Surface precision is vital for DVD test discs. Be sure to store and handle them carefully. 1. Do not place discs directly onto the workbench, etc., after use. 2. Handle discs carefully in order to maintain their flatness. Place them into their case after use and store them vertically. Store discs in a cool place where they are not exposed to direct sunlight or air from air conditioners. - Page 36 10.4.1.2. Adjustment procedure 1. Play test disc T01 (inner periphery). 2. Set the unit to the tilt adjustment service mode. (Press PAUSE and PLAY buttons on the player, and “5” button on the remote control unit.) 3. Make sure that "XX-YYYZZ" appears on the display of the disc cover.

- Page 37 9. Adjust tangential adjustment screw A (at inner periphery side of the jack shaft) so that the jitter value is minimized. (See Fig. 1 10. After adjustment is finished, lock the adjustment screws A, B and C in position using screw lock. Note: For the adjustment screw A, lock the tilt cam and traverse base in position securely using screw lock.

- Page 38 (Way of CANCEL) Power supply OFF, ( It pulls out DC power supply). Once again, make a power supply “ON” condition. By pushing the "STOP" button, it makes a stop condition. Push the "CANCEL" button of remote control. ( If not making a stop condition, there is not an effect.) 10.5.1.

- Page 39 Standard for carrying Check point out the adjustment Any noise such as TP8401 striping on the screen is observed Adjustment procedure Adjusting Adjusting to higher to lower value value Press "3" on the main Press Press body / remote control on the main on the main unit /...

- Page 40 Standard for carrying Check point out the adjustment White balance gap is TP8602 remarkable TP8603 Adjustment procedure Adjusting Adjusting to higher to lower value value Press "6" on the main Press Press body / remote control the main the main unit / unit / remote...

- Page 41 Standard for carrying Check point out the adjustment White balance gap is TP8603 remarkable TP8604 Adjustment procedure Adjusting Adjusting to higher to lower value value Press "7" on the main Press Press body / remote control the main the main unit / unit / remote...

- Page 42 Standard for carrying Check point out the adjustment ---------- TP8401 Adjustment procedure Adjusting Adjusting to higher to lower value value Press "2" on the main Press Press body / remote control on the main on the main unit / unit / remote remote control...

- Page 43 10.5.7. Adjusting contrast Standard for carrying Check point out the adjustment ---------- TP8603 Adjustment procedure Adjusting Adjusting to higher to lower value value Press "4" on the main body / remote control Press Press on the main on the main unit / unit / remote...

- Page 44 Standard for carrying Check point out the adjustment ---------- TP8604 Adjustment procedure Adjusting Adjusting to higher to lower value value Press "5" on the main Press Press body / remote control on the main on the main unit / unit / remote remote control...

- Page 45 10.6. Electrical confirmation (Confirming video output) 10.6.1. Confirming video output (luminance signal) Check point Mode Disc Measurement point Video S video Color bar DVDT-S15 output output play 75% or DVDT- terminal terminal Measuring equipment Confirmation value Oscilloscope 100 Vp-p ± 50 mV Purpose: To maintain video signal output compatibility 1.

- Page 46 Check point Mode Disc Measurement point Video S video Color bar DVDT-S15 output output play 75% or DVDT- terminal terminal Measuring equipment Confirmation value Oscilloscope 670 Vp-p ± 100 mV Purpose: To maintain video signal output compatibility 1. Connect the monitor TV to the chrominance signal (C) of the S video output terminal and terminate at 75 ohms.

- Page 47 INITIAL/LOGO ABBREVIATIONS A0~UP ADDRESS ACLK AUDIO CLOCK AD0~UP ADDRESS BUS ADATA AUDIO PES PACKET DATA ADDRESS LATCH ENABLE AMUTE AUDIO MUTE AREQ AUDIO PES PACKET REQUEST AUDIO RF SERVO AMP INVERTED INPUT SERVO AMPOUTPUT ASYNC AUDIO WORD DISTINCTION SYNC BIT CLOCK (PCM) BCKIN BIT CLOCK INPUT BLACK DROP OUT...

- Page 48 INITIAL/LOGO ABBREVIATIONS CONSTANT ANGULAR VELOCITY CBDO CAP. BLACK DROP OUT COMPACT DISC CDSCK CD SERIAL DATA CLOCK CDSRDATA CD SERIAL DATA CD RF (EFM) SIGNAL CDRF COMPACT DISC-VIDEO CHANNEL DATA CHNDATA SYSTEM CLOCKSELECT CKSL CONSTANT LINEAR VELOCITY CAP. OFF TRACK COFTR CPU ADDRESS CPU CHIP SELECT...

- Page 49 INITIAL/LOGO ABBREVIATIONS ERROR TORQUE CONTROL ERROR TORQUE CONTROL REFERENCE ENCODER SELECT ENCSEL EXTERNAL M CLOCK (81MHz/ ETMCLK 40.5MHz) ETSCLK EXTERNAL S CLOCK (54MHz) FBAL FOCUS BALANCE FCLK FRAME CLOCK FOCUS ERROR FOCUS ERROR AMP INVERTED INPUT FOCUS ERROR AMP OUTPUT FREQUENCY GENERATOR FREQUENCY SUB CARRIER FSCK...

- Page 50 INITIAL/LOGO ABBREVIATIONS MA0~UP MEMORY ADDRESS MEMORY CLOCK MCKI MEMORY CLOCK INPUT MCLK MEMORY SERIAL COMMAND CLOCK MDATA MEMORY SERIAL COMMAND MDQ0~UP DATA MDQM MEMORY DATA INPUT/OUTPUT MPEG MEMORY DATA I/O MASK MEMORYSERIAL COMMAND LOAD MOVING PICTURE EXPERTS GROUP OPTICAL DISC CONTROLLER SOURCE DRIVER OUTPUT ENABLE OEV 1, 2...

- Page 51 INITIAL/LOGO ABBREVIATIONS READ ENABLE RFENV RF ENVELOPE RF PHASE DIFFERENCE OUTPUT (CD-ROM) REGISTER SELECT RSEL RF POLARITY SELECT RESET RESERVE...

- Page 52 INITIAL/LOGO ABBREVIATIONS SBI0, 1 SERIAL DATA INPUT SBO0 SERIAL DATA OUTPUT SBT0, 1 SERIAL CLOCK SERIAL DATA CLOCK SCKR AUDIO SERIAL CLOCK RECEIVER SERIAL CLOCK SCLK SERIAL CLOCK SERIAL DATA SEG0~UP FL SEGMENT OUTPUT SELCLK SELECTCLOCK SERIAL PORT ENABLE SIN1, 2 SERIAL DATA IN SOUT1, 2 SERIAL DATA OUT...

- Page 53 INITIAL/LOGO ABBREVIATIONS TRACKING ERROR TIBAL BALANCE CONTROL BALANCE OUTPUT 1 BALANCE INPUT BALANCE INPUT BALANCE OUTPUT 2 TPSN OP AMP INPUT TPSO OP AMP OUTPUT TPSP OP AMP INVERTED INPUT TRCRS TRACK CROSSSIGNAL TRON TRACKING ON TRSON TRAVERSE SERVO ON INITIAL/LOGO ABBREVIATIONS VBLANK...

-

Page 54: Voltage Chart

INITIAL/LOGO ABBREVIATIONS X' TAL XALE X ADDRESS LATCH ENABLE XAREQ X AUDIO DATA REQUEST XCDROM X CD ROM CHIP SELECT X CHIP SELECT XCSYNC X COMPOSITE SYNC X DATA STROBE XHSYNCO X HORIZONTAL SYNC OUTPUT XHINT XH INTERRUPT REQUEST X' TALOSCILLATOR INPUT XINT X INTERRUPT X MEMORY WRITE ENABLE... -

Page 55: Circuit Board Assembly

14.2. RECHARGE BATTERY SCHEMATIC DIAGRAM 14.3. POWER SUPPLY SECTION (MAIN P.C.B. (1/10)) SCHEMATIC DIAGRAM 14.4. SERVO SECTION (MAIN P.C.B. (2/10)) SCHEMATIC DIAGRAM 14.5. FEP SECTION (MAIN P.C.B. (3/10)) SCHEMATIC DIAGRAM 14.6. ADSC SECTION (MAIN P.C.B. (4/10)) SCHEMATIC DIAGRAM 14.7. ODC SECTION (MAIN P.C.B. (5/10)) SCHEMATIC DIAGRAM 14.8. -

Page 56: Mechanism Section Exploded View

16.2. Mechanism Section Exploded View... -

Page 57: Packing & Accessories Section Exploded View

16.3. Packing & Accessories Section Exploded View... -

Page 58: Replacement Parts List

17. REPLACEMENT PARTS LIST Notes: *Important safety notice: Components identified by mark have special characteristics important for safety. Furthermore, special parts which have purposes of fire-retardant (resistors), high-quality sound (capacitors), low-noise (resistors), etc. are used. When replacing any of components, be sure to use only manufactures specified parts shown in the parts list. - Page 59 *Warning: This product uses a laser diode. Refer to caution statements. *ACHTUNG: Die lasereinheit nicht zerlegen. Die lasereinheit darf nur gegen enic vom hersteller spezifizierte einheit ausgetauscht werden. *Capacity values are in microfarads ( F) unless specified otherwise, P=Pico-farads (pF), F= Farads (F).

- Page 60 Ref. No. Part No. Part Name & Description Remarks EDTCA39QKF LCD ASS'Y RGK1395-K ORNAMENT SHEET RGP0868-S MONITOR CABINET RGQ0299-S MONITOR COVER RGQ0300-Q CUSHION RJB2414A MONITOR FPC RKC0017 HINGE RKQ0243-S HINGE COVER(A) RSC0587 SHIELD PLATE XQN17+BG6FN SCREW VWJ20D0038AA FFC(20P) RMR1401-W MEMBRANE FIX PIECE RMG0566-K SPACER BKL2E01KA...

- Page 61 Ref. No. Part No. Part Name & Description Remarks C1017 RCST1CY106RG 16V 10U F3F1C1060002 C1018 ECUV1H101JCV 50V 100P F1H1H101A004 C1019,20 RCST1CY106RG 16V 10U F3F1C1060002 C1021 ECUV1H151KBV 50V 150P C1022 ECUV1H271KBV 50V 270P F1H1H271A009 C1023 ECUVNC105KBN 16V 1U F1J1C105A091 C1024 ECUX1H102KBV 50V 1000P C1025 ECUX1H682KBV...

- Page 62 Ref. No. Part No. Part Name & Description Remarks C2008 ECUZNC104ZFV 16V 0.1U F1H1C1040008 C2009 ECUVNH102JCV 50V 1000P F1H1H102A737 C2010 ECUZNC104ZFV 16V 0.1U F1H1C1040008 C2011,12 ECUX1H681JCV 50V 680P C2013 ECUX1H682KBV 50V 6800P C2014 ECUX1H681JCV 50V 680P C2015,16 ECUVNC104KBV 16V 0.1U C2017 ECUZNC104ZFV 16V 0.1U...

- Page 63 Ref. No. Part No. Part Name & Description Remarks C3065 ECUV1A105ZFV 10V 1U F1H1A105A030 C3066 ECUZNC104ZFV 16V 0.1U F1H1C1040008 C3071-74 ECUZNC104ZFV 16V 0.1U F1H1C1040008 C3075 ECUV1A105ZFV 10V 1U F1H1A105A030 C3076 ECUZNC104ZFV 16V 0.1U F1H1C1040008 C3080 RCST1AX476RG 10V 47U F3G1A4760002 C3081,82 ECUZNC104ZFV 16V 0.1U F1H1C1040008...

- Page 64 Ref. No. Part No. Part Name & Description Remarks C5016 RCST1CY106RG 16V 10U F3F1C1060002 C5018 ECUVNC473KBV 16V 0.047U F1H1C473A071 C5019 ECUVNC104KBV 16V 0.1U C5020 ECUVNH102JCV 50V 1000P F1H1H102A737 C5021 RCST1CY106RG 16V 10U F3F1C1060002 C5022 ECUVNC104KBV 16V 0.1U C5023 ECUX1H561JCV 50V 560P ECJ1XC1H561J C5024 ECUX1H472KBV...

- Page 65 Ref. No. Part No. Part Name & Description Remarks C8032 ECUVNA225KBN 10V 2.2U F1J1A225A003 C8040 ECUZNC104ZFV 16V 0.1U F1H1C1040008 C8041 ECUX1H270JCV 50V 27P C8042 ECUX1H560JCV 50V 56P C8048 ECUZNC104ZFV 16V 0.1U F1H1C1040008 C8049,50 ECUVNA105KBV 10V 1U F1H1A105A028 C8201 ECUVNJ105KBV 63V 1U F1H0J105A002 C8202-11 ECUV1H470JCV...

- Page 66 Ref. No. Part No. Part Name & Description Remarks D6003 MA728-TX DIODE MA2J72800L D6004 MA111-TX DIODE MA2J11100L D6010 MA111-TX DIODE MA2J11100L D6011 MA8047M DIODE MAZ80470M D6012-14 MA728-TX DIODE MA2J72800L D6301 MA728-TX DIODE MA2J72800L D8001 MA77-TX DIODE MA2Z07700L D8201 MA745WAGTX DIODE D8202 MA77-TX DIODE...

- Page 67 Ref. No. Part No. Part Name & Description Remarks IC6301 PST596JNR C0EBE0000070 IC6302 RFKFPV450080 IC6303 C3EBEC000024 IC6501 C1DB00000582 IC7001 MN103S13BGA IC8001 AN2546FH-A IC8002 C1AB00001458 IC8201 MN5814 IC8202 TC7W14FU IC8401 C3EBDC000024 IC8403 TA75W558FU IC8602 NJM2904V C0ABBA000084 IC8801 AN78L05M IC8802 TK71533SCL C0DBCGB00001 J1401 VJJ0605 DC INLET...

- Page 68 Ref. No. Part No. Part Name & Description Remarks L8201 VLQ0910K100T COIL G1C100KA0019 L8205 VLQ0910K100T COIL G1C100KA0019 L8602 VLQ0426J2R2 COIL G1C2R2J00008 L8603 VLQ0910K100T COIL G1C100KA0019 L8801-04 VLQ0910K100T COIL G1C100KA0019 LB1102-11 EXC3BB601H COIL LB1112 VLP0155-T CHIPBEAD J0JCC0000119 LB3001 ERJ3GEYJ101 1/16W 100 D0GB101JA002 LB3201,02 EXC3BB102H...

- Page 69 Q3203 2SD1328QRS TRANSISTOR...

- Page 70 Ref. No. Part No. Part Name & Description Remarks Q3204 2SD1819A TRANSISTOR 2SD1819AW Q4001-04 2SD1328QRS TRANSISTOR Q5001,02 CPH3106 TRANSISTOR Q6003 2SB710AQRS TRANSISTOR Q8001 2SD2216STX TRANSISTOR 2SD22160SL Q8201,02 2SD2216STX TRANSISTOR 2SD22160SL Q8401 2SB1462STX TRANSISTOR 2SB14620SL Q8402 2SD2216STX TRANSISTOR 2SD22160SL Q8406 XP4601-TX TRANSISTOR XP0460100L QR1007...

- Page 71 Ref. No. Part No. Part Name & Description Remarks R1027 ERJ3RBD182 1/16W 1.8K R1028 ERJ3RBD561 1/16W 560 R1029 ERJ3RBD123 1/16W 12K R1030 ERJ3GEY0R00 1/16W 0 R1032 ERJ3RBD392 1/16W 3.9K R1033 ERJ3RBD471 1/16W 470 R1034 ERJ3RBD332 1/16W 3.3K R1035 ERJ3RBD391 1/16W 390 ERJ3RBD391V R1037 ERJ3RBD392...

- Page 72 Ref. No. Part No. Part Name & Description Remarks R1432 ERJ3GEY0R00 1/16W 0 R1433 ERJ3GEYJ103 1/16W 10K R1435 ERJ3GEYJ103 1/16W 10K R1436 ERJ3RBD562 1/16W 5.6K R1437 ERJ3GEY0R00 1/16W 0 R1438 ERJ3GEYJ103 1/16W 10K R1439 ERJ3RBD152 1/16W 1.5K R1440 ERJ3RBD103 1/16W 10K R1441 ERJ3RBD562 1/16W 5.6K...

- Page 73 Ref. No. Part No. Part Name & Description Remarks R3086 ERJ3GEYJ561 1/16W 560 R3089,90 ERJ3GEYF750 1/16W 75 R3201,02 ERJ3GEYD680V 1/16W 68 R3203 ERJ3GEYF750 1/16W 75 R3206 ERJ3GEYJ104 1/16W 100K R3207,08 ERJ3GEYJ102V 1/16W 1K ERJ3GEYJ102Z R3209 ERJ3GEYJ222 1/16W 2.2K R3210 ERJ3GEYJ332 1/16W 3.3K R3211 ERJ3GEYJ682...

- Page 74 Ref. No. Part No. Part Name & Description Remarks R5018 ERJ3GEYJ333V 1/16W 33K D0GB333JA002 R6003 ERJ3GEYJ394 1/16W 390K R6004 ERJ3GEYJ470 1/16W 47 R6005 ERJ3GEYJ563 1/16W 56K R6007 ERJ3GEYJ473 1/16W 47K R6008 ERJ3RBD103 1/16W 10K R6009 JAR0816P333D 1/16W 33K D0HB333ZA002 R6010 JAR0816P561D 1/16W 560 D0HB561ZA002...

- Page 75 Ref. No. Part No. Part Name & Description Remarks R8040 ERJ3RBD102 1/16W 1K R8042 ERJ3GEYJ561 1/16W 560 R8044 ERJ3GEYJ154 1/16W 150K R8045 ERJ3GEYJ561 1/16W 560 R8057-59 ERJ3GEY0R00 1/16W 0 R8205 ERJ3GEYJ102V 1/16W 1K ERJ3GEYJ102Z R8209,10 ERJ3GEYJ102V 1/16W 1K ERJ3GEYJ102Z R8211 ERJ3GEY0R00 1/16W 0 R8212-14...

- Page 76 Ref. No. Part No. Part Name & Description Remarks RA6204 EXBV4V103J RESISTOR-RESISTOR EXBV4V103JV RA6205 EXBV8V473J RESISTOR-RESISTOR EXBV8V473JV RA6206 EXBV4V473J RESISTOR-RESISTOR EXBV4V473JV RA6207 EXBV4V103J RESISTOR-RESISTOR EXBV4V103JV RA7001-03 EXBV8V473J RESISTOR-RESISTOR EXBV8V473JV S6001 EVQPUL02K SWITCH,AV IN/OUT SW5001,02 ESE11MV9T SWITCH SW6001 VSS0534 SWITCH,HOLD K0D112B00071 SW6002 K0C115A00002 SWITCH,SELECT...

- Page 77 IC3001 IC4001 AUDIO L AUDIO CONVERTER AUDIO R IC6501 16.9M DECODER SYNTHESIZER (AV DEC) 33.8M IC6302 FLASH IC6201 IC3201 IC3061 16M- SDRAM VIDEO VIDEO IN/OUT DRIVE S-VIDEO OUT IC3071 16M- SDRAM DVD-LV60GK OVERALL BLOCK DIAGRAM...

- Page 78 IC1001 (REG CONTROLLER) DC IN IC1405 PVCC1 OUT4 PVCC2 INV4 IC6004 (REG/SW) OUT1 VOUT CONT INV1 V-REF 47 STB23 OUT3 INV3 45 STB5 OUT5 QR6001 STB1 STB4 OUT2 Q6003 QR6002 INV2 IC6001 (OPERATION MPU) DVD-ON(H) P-ON(H) LCD-ON(H) IC6006 IC6002 (REG 3.3V) (RESET) VOUT NRST...

- Page 79 UNREG(LCD) D+1.8V D+3.3V Q1001 A+3.3V SP+5.5V IC1003 (REG 2.5V) M+5.5V VOUT D+2.5V T1101 Q1002 -13V(LCD) +7.5V(LCD) Q1003 +17V(LCD) A+5V Q1004 Q1006 SWA+5V QR1007 Q1101 QR1102 LCD+5V(LCD) IC6201 (CPU) < CMD > SBI3 < STATUS > SBO3 < DSPCLK > SBT3 PANEL 3.3V SW6003...

- Page 80 IC5001 IC2001 PICK-UP UNIT (FEP) (DSC) IC001 VIN2 VIN4 TRACKING PIN DIODE VIN1 VIN3 FOCUS PIN DIODE VIN7 NARF VIN8 DVD MODULE VIN6 CD MODULE VIN5 FOCUS PIN DIODE VIN9 TRACKING VIN10 PIN DIODE DVD MODULE CD MODULE Q5002 RFENV DRIVE Q5001 DRIVE...

- Page 81 :RF SIGNAL :SPINDLE MOTOR DRIVE SIGNAL :STEPPING MOTOR DRIVE SIGNAL :TRACKING ERROR SIGNAL :FOCUS ERROR SIGNAL STEPPING MOTOR UNIT IC2501 STEPPING MOTOR (MOTOR DRIVE) TRSDRV LOGIC BRIDGE DRIVER FODRV PICK-UP UNIT LOGIC IC2501-2,3,30,31 7.2Vp-p(20usec./div.) ACTUATOR FOCUS COIL DRIVER BRIDGE TRDRV TRACKING COIL LOGIC...

- Page 82 IC1401 Ref No. MODE STOP PLAY Ref No. IC1402 IC1405 MODE STOP PLAY Q1401 Q1402 QR1401 QR1404 Ref No. MODE STOP PLAY...

- Page 83 IC8001 Ref No. MODE STOP PLAY IC8001 Ref No. MODE STOP PLAY IC8001 Ref No. MODE STOP PLAY IC8001 Ref No. MODE STOP PLAY IC8201 Ref No. MODE STOP PLAY IC8201 Ref No. MODE STOP PLAY IC8201 Ref No. MODE STOP PLAY Ref No.

- Page 84 LCD DRIVE P.C.B. C8403 R8615 R8613 C8606 C8601 C8236 R8234 R8403 C8235 IC8602 R8405 R8607 K8005 C8402 R8608 C8604 R8605 R8406 R8609 L8201 C8602 IC8205 C8218 C8217 IC8403 R8227 C8409 L8603 C8201 D8202 R8225 R8410 R8409 C8407 C8225 IC8201 R8037 C8028 C8029 C8215...

- Page 85 LCD DRIVE P.C.B. Transistors Q8001 Q8011 Q8012 TL8020 Q8013 Q8201 FP8004 Q8202 TL8014 TL8021 Q8401 FP8002 Q8402 TP8401 Q8406 CP8804 Q8406 Transistor & Resistor FP8003 QR8401 TL8018 Q8402 QR8901 TL8022 Integrated Circuit TL8202 TL8019 TL8002 IC8001 JP8001 Q8401 L8205 IC8002 R8429 IC8201 R8236...

- Page 86 C1151 FP1002 TL1008 TL1004 TL1007 TL1001 Q1151 TL1009 R1101 C1001 R1153 R1019 QR1151 TL1002 4 5 6 C1027 3 2 1 5 4 3 R1021 QR1102 QR1101 C1028 R1040 R1039 R1038 R1037 C1070 C1106 R1060 C1071 L1009 C1007 C1022 R1063 Q1101 R1061 C1046...

- Page 87 MAIN P.C.B. (1/2) TL6025 FP1101 TL6026 TL6024 TL6023 TL6021 TL6022 C4054 TP4012 TL6043 TL6020 TP4011 QR4051 TL6051 CP5001 TL6044 C4053 FP6001 5 4 3 TL6034 TL6030 TL6040 TL6028 TL6037 TL6038 IC4051 TP6201 TL6036 PS6201 SW5001 SW5002 R4053 C4051 TP6202 TP4009 TP6205 R4051 K5001...

- Page 88 MAIN P.C.B. (2/2) TC1016 TC1017 TC1009 TC1024 TC1022 TC1021 TC1018 TC1019 D4004 TC6015 TC6010 R4030 R3206 CP5023 TC6014 IC3202 QR3203 R6028 CP5030 TC6003 Q5002 CP5029 CP5027 TC6001 R5006 TC6007 R5004 Q5001 C5027 C5010 C5028 R5013 C5011 IC5001 C5012 CP5031 C5013 TC5015 L5002 C5014...

- Page 89 MAIN P.C.B. IC1003 TC1020 TC6017 Transistors TL6022 TP6501 IC2001 TC1021 TC6018 TL6023 TP6503 Q1001 IC2501 TC1022 TC6201 TL6024 TP6504 Q1002 IC2502 TC1023 TC6311 TL6025 TP6505 Q1003 IC3001 TC1024 TC6312 TL6026 TP6508 Q1004 IC3061 TC1025 TL1001 TL6027 TP6509 Q1006 IC3071 TC1026 TL1002 TL6028 TP6510...

- Page 90 IC1001 Ref No. MODE STOP PLAY IC1001 Ref No. MODE STOP PLAY IC1001 Ref No. MODE STOP PLAY IC1002 IC1003 Ref No. MODE STOP PLAY IC2001 Ref No. MODE STOP PLAY IC2001 Ref No. MODE STOP PLAY IC2001 Ref No. MODE STOP PLAY...

- Page 91 IC3001 Ref No. MODE STOP PLAY IC3001 Ref No. MODE STOP PLAY IC3001 Ref No. MODE STOP PLAY IC3001 Ref No. MODE STOP PLAY IC3001 Ref No. MODE STOP PLAY IC3001 Ref No. MODE STOP PLAY IC3001 Ref No. MODE STOP PLAY IC3061...

- Page 92 IC6201 Ref No. MODE STOP PLAY IC6201 Ref No. MODE STOP PLAY IC6201 Ref No. MODE STOP PLAY IC6301 Ref No. MODE STOP PLAY IC6302 Ref No. MODE STOP PLAY IC6302 Ref No. MODE STOP PLAY IC6302 Ref No. MODE STOP PLAY IC6303...

- Page 93 Q1001 Q1002 Q1003 Q1004 Q1006 Ref No. MODE STOP PLAY Ref No. Q1008 Q1009 Q1010 Q1011 Q1101 MODE STOP PLAY Q1151 Q3202 Q3203 Q3204 Q4001 Ref No. MODE STOP PLAY Q4002 Q4003 Q4004 Q5001 Q5002 Ref No. MODE STOP PLAY Q6003 Q6004 QR1007...

- Page 94 RECHARGE BATTERY P.C.B. PR1402 D1408 C1405 R1402 PR1404 R1401 TL1417 IC1403 D1407 L1402 FR1403 CP1406 PR1401 C1412 C1410 L1401 C1409 (COMPONENT SIDE) TC1406 C1402 TC1414 TC1401 R1416 C1401 R1411 R1414 R1430 C1420 QR1401 R1415 R1417 R1410 C1404 TC1410 IC1401 R1425 C1418 C1414 R1431...

- Page 96 POWER SECTION: Page 52 SRV SECTION: Page 54 FEP SECTION: Page 56 ADSC SECTION: Page 58 ODC SECTION: Page 60 AVDEC SECTION: Page 62 AOUT SECTION: Page 64 VOUT SECTION: Page 66 CPU SECTION: Page 67 OPR SECTION: Page 69 DVD-LV60GK ADSC SECTION (MAIN P.C.B.

- Page 98 POWER SECTION: Page 52 SRV SECTION: Page 54 FEP SECTION: Page 56 ADSC SECTION: Page 58 ODC SECTION: Page 60 AVDEC SECTION: Page 62 AOUT SECTION: Page 64 VOUT SECTION: Page 66 CPU SECTION: Page 67 OPR SECTION: Page 69 DVD-LV60GK AUDIO OUT SECTION (MAIN P.C.B.

- Page 100 POWER SECTION: Page 52 SRV SECTION: Page 54 FEP SECTION: Page 56 ADSC SECTION: Page 58 ODC SECTION: Page 60 AVDEC SECTION: Page 62 AOUT SECTION: Page 64 VOUT SECTION: Page 66 CPU SECTION: Page 67 OPR SECTION: Page 69 DVD-LV60GK AV DECORDER SECTION (MAIN P.C.B.

- Page 102 POWER SECTION: Page 52 SRV SECTION: Page 54 FEP SECTION: Page 56 ADSC SECTION: Page 58 ODC SECTION: Page 60 AVDEC SECTION: Page 62 AOUT SECTION: Page 64 VOUT SECTION: Page 66 CPU SECTION: Page 67 OPR SECTION: Page 69 DVD-LV60GK CPU SECTION (MAIN P.C.B.

- Page 104 POWER SECTION: Page 52 SRV SECTION: Page 54 FEP SECTION: Page 56 ADSC SECTION: Page 58 ODC SECTION: Page 60 AVDEC SECTION: Page 62 AOUT SECTION: Page 64 VOUT SECTION: Page 66 CPU SECTION: Page 67 OPR SECTION: Page 69 DVD-LV60GK FEP SECTION (MAIN P.C.B.

- Page 106 DVD-LV60GK INTERCONNECTION SCHEMATIC DIAGRAM...

- Page 108 DVD-LV60GK LCD DRIVE SCHEMATIC DIAGRAM...

- Page 110 POWER SECTION: Page 52 SRV SECTION: Page 54 FEP SECTION: Page 56 ADSC SECTION: Page 58 ODC SECTION: Page 60 AVDEC SECTION: Page 62 AOUT SECTION: Page 64 VOUT SECTION: Page 66 CPU SECTION: Page 67 OPR SECTION: Page 69 DVD-LV60GK ODC SECTION (MAIN P.C.B.

- Page 112 POWER SECTION: Page 52 SRV SECTION: Page 54 FEP SECTION: Page 56 ADSC SECTION: Page 58 ODC SECTION: Page 60 AVDEC SECTION: Page 62 AOUT SECTION: Page 64 VOUT SECTION: Page 66 CPU SECTION: Page 67 OPR SECTION: Page 69 DVD-LV60GK OPERATION SECTION (MAIN P.C.B.

- Page 114 POWER SECTION: Page 52 SRV SECTION: Page 54 FEP SECTION: Page 56 ADSC SECTION: Page 58 ODC SECTION: Page 60 AVDEC SECTION: Page 62 AOUT SECTION: Page 64 VOUT SECTION: Page 66 CPU SECTION: Page 67 OPR SECTION: Page 69 DVD-LV60GK POWER SUPPLY SECTION (MAIN P.C.B.

- Page 116 DVD-LV60GK RECHARGE BATTERY SCHEMATIC DIAGRAM...

- Page 118 POWER SECTION: Page 52 SRV SECTION: Page 54 FEP SECTION: Page 56 ADSC SECTION: Page 58 ODC SECTION: Page 60 AVDEC SECTION: Page 62 AOUT SECTION: Page 64 VOUT SECTION: Page 66 CPU SECTION: Page 67 OPR SECTION: Page 69 DVD-LV60GK SERVO SECTION (MAIN P.C.B.

- Page 119 POWER SECTION: Page 52 SRV SECTION: Page 54 FEP SECTION: Page 56 ADSC SECTION: Page 58 ODC SECTION: Page 60 AVDEC SECTION: Page 62 AOUT SECTION: Page 64 VOUT SECTION: Page 66 CPU SECTION: Page 67 OPR SECTION: Page 69 DVD-LV60GK VIDEO OUT SECTION (MAIN P.C.B.

- Page 121 IC3001 (AV DEC) IC3201-11 IC3201-12 IC3201-6 2.2Vp-p 1.2Vp-p 2.2Vp-p IC3001-92 (20usec./div.) (20usec./div.) (20usec./div.) 7.3Vp-p(10usec./div.) IC4001 IC4052 (A-D/A) IC4002 (1/2) ADOUT0 SERIAL SRCK LRCK Hi-Z STANDBY LOGIC CONTROLLER MODULATOR IC4001-7,8 3.1Vp-p(0.5msec./div.) IC4002 (1/2) IEC OUT 85 IC3201 (VIDEO DRIVE) IC3001-129 0.8Vp-p(20usec/div) C-IN VCOUT 129 C-OUT...

- Page 122 :VIDEO SIGNAL :AUDIO SIGNAL IC4051 (AUDIO AMP) TP4010 Q4003 SP-L TP4012 Q4004 SP-R HEADPHONES VR4001 IC4003 Q4001 (1/2) QR4003 QR4005 CPU A-MUTE FROM CPU IC4003 QR4004 (1/2) POW A-MUTE FROM OPERATION AUDIO LINE IN/OUT Q4002 +3.3V DOUT-ON IC6001-39 QR4001 QR4002 IC3202 Q3202 Q3204...

- Page 123 IC8001-52 IC8001-57 0.8Vp-p 2.8Vp-p (20usec./div.) (20usec./div.) IC8001 (CHROMA DECODER) Y IN PICTURE IC3201-7 TRAP CONTROL C IN IC3202-1 DEMOD KILLER TINT GENE NTSC Xtal X8001 3.58MHz Q8201 VD FILTER INV.

- Page 124 :VIDEO SIGNAL IC8001-26 IC8001-21 IC8001-19 4.2Vp-p 4.2Vp-p 4.2Vp-p (20usec/div.) (20usec/div.) (20usec/div.) LCD PANEL R-OUT G-OUT INT/EXT MATRIX INVERT SOURCE DRIVER B-OUT SYNC SEP VCOM SYNC CSYNC VCOM IC8403 Q8406,8401 BUFFER IC8201 (CONTROLLER) IC8202 SYNC STH1 HD IN CPH1 IC8202 IC8202 CPH2 CPH3 GATE...

- Page 125 MAIN P.C.B. TRAVERSE MECHANISM UNIT IC5001 IC2001 IC7001 FRONT-END PICK-UP PROCESSOR UNIT (FEP) IC2502 OPTICAL DIGITAL SPINDLE DISC SPINDLE SERVO MOTOR CONTROLLER MOTOR CONTROLLER DRIVE (ODC) (DSC) IC2501 STEPPING MOTOR MOTOR DRIVE FOCUS COIL TRACKING COIL IC6001 REMOTE OPERATION CONTROL...

Need help?

Do you have a question about the DVD-LV60 and is the answer not in the manual?

Questions and answers