Table of Contents

Advertisement

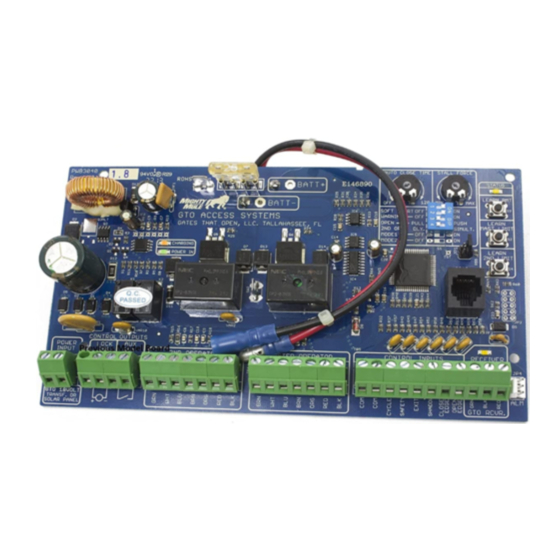

3rd Generation Control Board, (Blue Board)

For Single or Dual Systems

Replaces PRO3040PCB, R4206, R4207, MM500PCB, MM502PCB

Replacement/Upgrade Control Board for

• Better Soft Stop/Start Functions

• Smoother Hookup

• Plug & Play just like 3040

• Easier to set limit for dual application, it has master & slave button and not dip switches

• Increased surge protection on accessory terminals

• Auto Close potentiometer will set 3-120 seconds, not with dip switches as previous version

that only gave 4 options

• Improved Charging circuit will charge all the time; The battery will be charged in stages not

charge to full and then stop

• The circuit board pulls 25 milliamps not 40 like the old board. It is better for solar applica-

tions

• Battery connectors are at the top and soldered on and not plug in like the 3040 board – we

used to have to suggest tightening previously

• Sequencing is automatically set for dual application. The slave will always close first.

GTO's PDF BEGINS ON NEXT PAGE

R4211

(PRO3040-G3)

NOTICE

The Following GTO PDF Manual Pages

Apply to the Below Listed GTO Operators

Where you read the phrase "The GTO PRO® 3000...";

It applies to all the below listed operators.

MM500 • MM502

SW2000XL • SW2002XL

SW2500 • SW2502

SW3000 • SW3000XL

SW4000 • SW4000XL

R4211 ENHANCEMENTS

Advertisement

Table of Contents

Summary of Contents for GTO R4211

- Page 1 Replaces PRO3040PCB, R4206, R4207, MM500PCB, MM502PCB NOTICE The Following GTO PDF Manual Pages Apply to the Below Listed GTO Operators Where you read the phrase “The GTO PRO® 3000...”; It applies to all the below listed operators. Replacement/Upgrade Control Board for MM500 • MM502 SW2000XL •...

- Page 2 Generation-3 Control Board Wiring and Programming Instructions PRO3040-G3 for the GTO/PRO 3000XL/4000XL AUTO CLOSE TIME STALL FORCE FUSE STATUS BATT+ LEARN RMT BATT- SOFT START OFF WARNING LEARN OPEN PULL PUSH MAST LIMIT SLV OPEN DLY. SIMULT. MODE1 MODE2 LEARN...

- Page 3 Connecting Opener Power Cable Step 1 BLACK Make sure the control box power switch is in the OFF position. The ON/OFF Switch is located on the bottom of the control box. Remove the control box cover and slide the battery into position with its terminals to the RIGHT (see illustration).

-

Page 4: Powering The System

• All low voltage wire used with the GTO PRO® Gate Opener must be 16 gauge dual conductor, multi-stranded, direct burial wire (see page 20 and the Accessory Catalog). Do not run more than 1000 feet of wire. - Page 5 IMPORTANT INFORMATION ABOUT LOW VOLTAGE WIRE The only wire acceptable for use with GTO products is 16 gauge multi-stranded, low voltage, PVC sheathed wire. This particular gauge enables the transformer to provide an adequate charge through the control board to the battery at distances up to 1000 ft.

- Page 6 Step 6 Strip " of insulation from the ends of the low voltage wire. Attach these stripped ends to the transformer terminals. A dab of household petroleum jelly on each terminal will help prevent corrosion. Make sure the exposed wires do not touch each other! Step 7 Plug the transformer into the electrical outlet.

-

Page 7: Control Board Settings

CONTROL BOARD SETTINGS DIP Switches Main DIP Switch Settings (MODES) DIP Switch #1 - Soft Start/Stop ON - Soft start enabled (factory preset). OFF - Soft start disabled. The Soft Start/Stop feature slowly starts the gate as it begins to open and slows the gate as it comes to the closed position. - Page 8 Pull to Open Applications TURN CONTROL BOX ON Your GTO PRO® has two Limit Settings 1) OPEN Limit setting: (Gate in the OPEN POSITION / the limit is FACTORY SET and NOT ADJUSTABLE) The open limit setting is the fully open position.

- Page 9 Obstruction Sensitivity Potentiometer IMPORTANT: For safety reasons the obstruction setting or Stall Force on the GTO PRO® control AUTO CLOSE TIME AUTO CLOSE TIME STALL FORCE STALL FORCE STALL FORCE board comes from the factory set at MIN (minimum). In many gate in-...

-

Page 10: Setting Your Personal Transmitter Code

Setting Your Personal Transmitter Code All GTO transmitters are set to a standard code at the factory and are ready to operate your GTO PRO® Gate Opener . For ® your safety and security, however, we strongly recommend that you replace the factory setting with your own personal code. -

Page 11: Installing The Receiver

• Standard receiver cable length is 10 feet (receivers with a longer cable are available as special order items; call the GTO Sales Department). NEVER splice receiver cable! • Run the cable through PVC conduit to protect it from damage. -

Page 12: Connecting Additional Safety Devices

PLEASE NOTE: Contact sensors are not included with the GTO PRO® 3000. The GTO PRO® 3000 is equipped with built-in obstruction sensitivity. The opener is designed to stop and reverse the gate within 2 seconds when it comes in contact with an obstruction. However, obstruction sensitivity, although functioning properly, may not be sensitive enough to prevent bodily injury in some circumstances. - Page 13 If not installing a non-contact sensor skip to next section. PLEASE NOTE: Non-contact sensors are not included with the GTO PRO® 3000. The GTO PRO® 3000 can also accept "Safety" input from normally open "dry-contact" output devices such as photo beams connected to the SAFETY input terminal.

-

Page 14: Connecting Accessories

Connecting Accessories If not connecting accessories skip to next section. Cycle Input The GTO PRO® 3000 can accept NORMALLY OPEN "DRY-CONTACT" accessories, such as; Push Button Entry Devices and Key Pads. Refer to the sensor manufacturer’s instructions for information about installing these devices on a vehicular gate. - Page 15 GTO Lock Connection: LOCK SOLAR SLAVE INPUT Connect the red and black leads from the lock to the GTO LOCK terminal on the GTO PRO® 3000 control board. Aux: • These 2 terminals are normally open 'dry-contact' (no voltage) relay ouput.

-

Page 16: Push To Open Installation

Push to Open Installation ON DIP Step 4 1 2 3 4 1 2 3 4 1 2 3 4 Make sure the control box power switch is OFF. Use a small screwdriver to move the Number 3 DIP switch from the factory setting (OFF / Pull-To-Open) to ON for Push-To-Open. - Page 17 Maintenance & Troubleshooting Guide If your gate opener does not function properly after it is installed, use this guide before calling the GTO Service Department. ‘PR03040-G3’ DIAGNOSTIC INDICATORS GUIDE This guide provides detailed explanations of various alarm sound and led indicators for the new PRO3040-G3 board).

- Page 18 Alarm: None ‘RECEIVER’ Led: blinking or OFF. • When the ‘RECEIVER’ led is blinking, the controller is receiving ‘GTO scheme’ 318 MHz signal from the receiver. This indicates that the transmitter and receiver are working properly. However, if the transmitter is not being pressed and the ‘RECEIVER’ led is blinking, this indicates that there is significant interference (i.e.

- Page 19 Alarm: 1 beep then 3 beeps with 2 seconds pause. ‘STATUS’ Led: 1 blink then 3 blinks with 2 seconds pause. • The master motor terminals and/or leads are shorted. The GTO, Inc. Technical Service Department is open Monday – Friday 8:00 – 5:00 (Eastern Time) A.M.

Need help?

Do you have a question about the R4211 and is the answer not in the manual?

Questions and answers