Summary of Contents for Epiroc YT29A

- Page 1 Secoroc YT29A, T29AE, YT29AE(T), 7655D pusher leg rock drills Operator’s instructions Spare parts list...

-

Page 2: Table Of Contents

Trouble shooting ��������������������������������������������������������15 Spare parts list and exploded drawing �������������������16 Foreword Thank you for selecting the Secoroc YT29A, YT29AE,YT29AE(T) or 7655D pusher leg rock drill� These instructions were developed to help you get the best per- formance and productivity from the use of your new rock drill�... -

Page 3: Introduction

Introduction Safety instructions Thank you for choosing a product from Epiroc� We have a strong To reduce the risk of serious injury or death to yourself or global sales and service network, consisting of customer centers others, read and understand the Safety and operating instruction and distributors worldwide�... - Page 4 Drugs, alcohol or medication WARNING WARNING Moving or slipping insertion tool� Drugs, alcohol or medication� An incorrect dimension of the inserted tool’s shank can result in that the inserted tool is lost or is slipping out during operation� Drugs, alcohol or medication may impair your judgment and pow- Risk of severe injury or crushed hands and fingers�...

- Page 5 be sudden and unexpected movement that can cause injuries� WARNING Furthermore, losing your balance or slipping may cause injury� • Make sure that you always keep a stable position with your feet Dust and fume hazard� as far apart as your shoulder width, and keeping a balanced body weight�...

- Page 6 • Work with your employer and trade organization to reduce dust • In case of persistent or recurring symptoms, consult a qualified and fume exposure at the worksite and to reduce the risks� Effec- health professional� tive health and safety programs, policies and procedures for pro- tecting workers and others against harmful exposure to dust and WARNING fumes should be established and implemented based on advice...

- Page 7 Concealed object hazard� • Always use original parts, working tools and accessories ap- proved by Epiroc� During operating, concealed wires and pipes constitute a danger • Change damaged parts immediately� that can result in serious injury�...

-

Page 8: Scope Of Application

The Rock Drill is equipped with lubricator FY250� Secoroc YT29A is intended to be used together with pusher leg FT160A, • Check that the hoses used are of the right quality, and that all FT160B, FT160C for different tunneling and work conditions� It is hose connections are in good condition and properly tightened�... -

Page 9: Operation

Safety label Lubricant recommendation Use a mineral-based air tool oil Ambient temperature ºC Viscosity grade (ISO 3448) -30 to 0 ISO VG 32-68 -10 to +20 ISO VG 68-100 +10 to +50 ISO VG 100-150 4� Air/water pressure and hose dimensions To avoid injury, before using or servicing tool, read and under- stand separately provided safety instructions�... -

Page 10: Fitting And Removing The Tool

Attaching the pusher leg to the rock drill CAUTION • Mount the pusher leg (1), lock sleeve (2), rubber pad (3), washer (4) and locking nut (5) in the order shown in the picture below� Hot insertion tool� • Turn the locking nut clockwise with a wrench until you hear a "click"�... -

Page 11: Oil Regulating Valve

The start-and-stop device of Pusher Leg Rock Drill YT29A can cause a risk of an unimtentional start� To reduce and avoid causing the risk of unintentional start, the control valve og inlet hose must be switched off while the rock drill is put aside for long time�... -

Page 12: Maintenance

Always switch off the main control valve on the air inlet hose to Every day prevent unintentional start of the rock drill� Before undertaking any maintenance or changing the insertion tool on pneumatic machines, always switch off the air supply and Maintenance bleed the machine by depressing the start and stop device then disconnect the air hose from the machine�... -

Page 13: Measures To Prevent Freezing

3026 2586 3310 extracted mm used, as well as upon the exposure time and the physical condi- tion of the user, and the condition of the machine� We, Epiroc Feed length 1338 1098 1490 Drilling Tools AB, cannot be held liable for the consequences of... -

Page 14: Ce Declaration Of Conformity

1000 1300 Piston bore EC Declaration of Conformity (EC Directive 2006/42/EC) We, Epiroc Drilling Tools AB,hereby declare that the machines listed below conform to the provisions of EC Directive 2006/42/EC (MachineryDirective), and the harmonised standards mentioned below� Rock Drills Part number... -

Page 15: Trouble Shooting

Trouble shooting Problem Cause Solution Decreased Air leakage in hoses, couplings Change packings, and where required, change parts in penetration rate the throttle valve� Shank sleeve Check the shank sleeve for excessive wear� Replace if necessary� Air leakage due to worn piston/cylinder Replace the piston and/or cylinder Air leakage due to worn guide sleeve/pilot guide Change the worn part... -

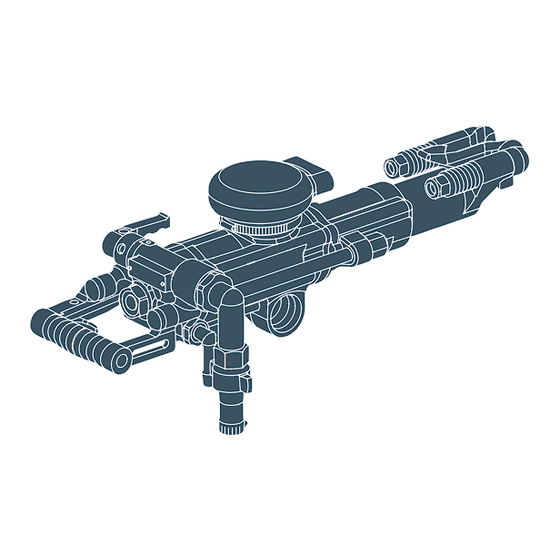

Page 16: Spare Parts List And Exploded Drawing

Spare parts list and exploded drawing YT29A... - Page 17 No� Description Quantity Product no� Product code No� Description Quantity Product no� Product code Spring 96000179 9605-1-3312310169 Trigger 96000162 9603-1-3312310151 96000180 9605-1-3312310170 Elastic pin 96000527 9605-1-3312310708 Conical pipe Spring 96000186 9605-1-3312310176 96000169 9605-1-3312310159 connector cover Hoop 96000540 9605-1-3312310723 Steel retaining 96000183 9605-1-3312310173 Wing nut...

- Page 18 Spare parts list and exploded drawing YT29AE 34 21 75 32 76 18 33 19 35 37 20 75 56 36 38 42 14 43 72 24 45 73 41 25 57 63 2 74 22 48 40 1 31 44...

- Page 19 No� Description Quantity Product no� Product code No� Description Quantity Product no� Product code Spring 96000179 9605-1-3312310169 96000184 9605-1-3312310174 96000180 9605-1-3312310170 Water valve 96000171 9605-1-3312310161 body Conical pipe 96000186 9605-1-3312310176 connector Water valve 96000173 9605-1-3312310163 Hoop 96000540 9605-1-3312310723 O-ring 96000489 9605-1-3312310642 Wing nut 96000185...

- Page 20 Spare parts list and exploded drawing YT29AE(T)

- Page 21 No� Description Quantity Product no� Product code No� Description Quantity Product no� Product code Spring 96000179 9605-1-3312310169 Rotation nut 96000146 9603-1-3312310135 96000180 9605-1-3312310170 96000184 9605-1-3312310174 Conical pipe Water valve 96000186 9605-1-3312310176 96000171 9605-1-3312310161 connector body Hoop 96000540 9605-1-3312310723 Water valve 96000173 9605-1-3312310163 Wing nut...

- Page 22 Spare parts list and exploded drawing 7655D Spare parts list and exploded drawing...

- Page 23 No� Description Quantity Product no� Product code No� Description Quantity Product no� Product code 7655 7655D 7655 7655D Handle 96000819 9600-1-3312310016 Pressure regulating 96000828 9600-1-3312310025 Roll pin 96000527 9605-1-3312310708 valve Trigger 96000820 9600-1-3312310017 O-ring 96000486 9605-1-3312310633 Circlip 96000183 9605-1-3312310173 Control valve 96000090 9601-1-3312310048 Spring cap...

- Page 24 Inspired by innovation. Performance unites us, innovation inspires us, and commitment drives us to keep moving forward. Count on Epiroc to deliver the solutions you need to succeed today and the technology to lead tomorrow. epiroc.com Epiroc Drilling Tools AB...

Need help?

Do you have a question about the YT29A and is the answer not in the manual?

Questions and answers