Table of Contents

Advertisement

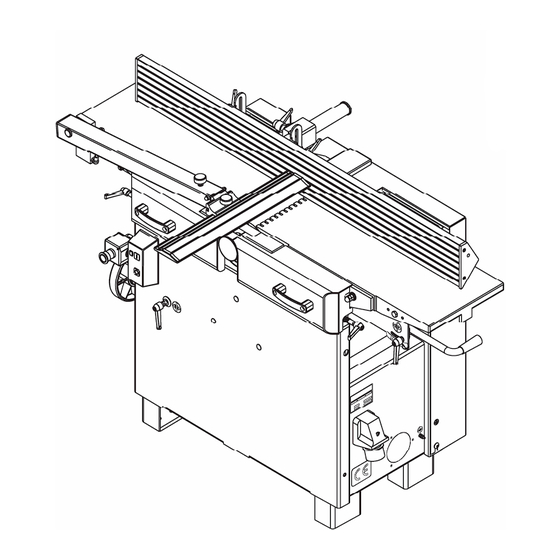

COMBINED PLANING

AND THICKNESSING MACHINE

MSP 315 - MSP 415 - SP 410

MP 415

ONE-SIDED THICKNESSING MACHINE

translation of the original Service instructions handbook

updated 11/ 2017

WOODWORKING MACHINERY , Masarykova 16, 517 50 astolovice

ROJEK

the Czech Republic - Europe www.rojek.cz export @ rojek.cz

+420 494 339137 up to - 41, fax +420 494 323341, - 322701

Advertisement

Table of Contents

Need help?

Do you have a question about the MSP 315 and is the answer not in the manual?

Questions and answers