Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for ROJEK RFT 630

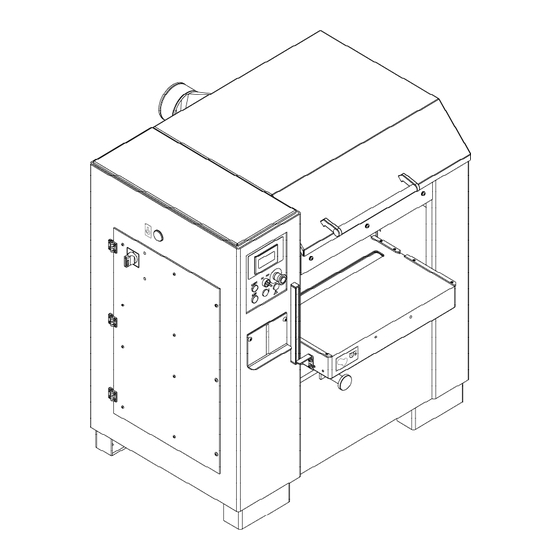

- Page 1 RFT 630~RFT 520~RFT 410 original translation of Service instructions handbook up dated 9 / 2018 WOODWORKING MACHINES Masarykova 16 cz- 517 50 Častolovice ROJEK the Czech Republic - Europe www.rojek.cz export@rojek.cz + 420 494 339137- up to - 41 fax - 322701, -323341...

-

Page 3: Table Of Contents

1 Machine using 1.1 Workers´ qualification 1.2 Work surroundings 2 Machine signification 3 Technical data 3.1 Technical data RFT 630 3.2 Machine dimensions 3.3 Possible machine variants 3.4 Values of removal thickness, feeding and power 3.5 Machine nois values 3.6 List of used documents 4 Safety directions 4.1 General... - Page 4 11 Maintenance and repairs 11.1 Tensioning the chain of the table setting drive 11.1.1 Nastavování stolu ručním kolem (RFT 520, RFT 410) 11.1.2 elektromotoric table setting (RFT 630) 11.2 Tensioning the V-belts of the cutter block drive 11.3 Feeding drive chain tensioning 11.3.1...

-

Page 5: Introduction

Notice The text and pictures of this manual is a know how of the ROJEK Co. No part of it can be copied and third persons are not allowed to learn it or its part without the company´s approval. -

Page 6: Machine Using

2 Machine signification Machine type can be identified at the production shield on machine frame. RFT 630 - single-side thicknesser, drawn width 630 mm. RFT 520 - single-side thicknesser, drawn width 520 mm RFT 410 - single-side thicknesser, drawn width 410 mm ROJEK a.s. - Page 7 8. Binding points for crane ropes 9. Switch for unbraking the working block. 9a) Operating condition of the motor brake 9b) Unbraked. 10. tightening 11. lifting up of thicknessing table 12. descent of thicknessing table ROJEK a.s. RFT 630, 520, 410...

-

Page 8: Technical Data

8/12 (5 ÷ 21) Extraction diameter Voltage / frequency 3f + PE + N ; 400 (230) V / 50 (60) Hz Line securing Dimensions with packaging mm 1200x1600x 1600 1200x1400x1600 1200x1400x1600 Gross weight Net weight ROJEK a.s. RFT 630, 520, 410... -

Page 9: Machine Dimensions

3.2 Machine Dimensions ROJEK a.s. RFT 630, 520, 410... -

Page 10: Possible Machine Variants

- display - touch panel - display Cutter block with cutting diameter 120 mm four-cutter structure ROJEK four-cutter monoblock TERSA Pull-in roller solid with gearing in a spiral divided with sprung segments and gearing... - Page 11 (m/min) machined splinter removed volume width (mm) thickness (mm) 1064 5.33 1066 3.55 1065 2.66 1064 2.13 1065 1071 66.5 5.33 2.66 1.77 1.33 0.85 3.55 1.78 0.56 2.66 1.33 0.88 0.66 0.53 0.42 ROJEK a.s. RFT 630, 520, 410...

- Page 12 Output (kW) Feed (m/min) Mach. width (mm) Splinter (mm) Removed volume (mm 1440 1460 1470 1480 1450 1450 0.75 0.55 ROJEK a.s. RFT 630, 520, 410...

- Page 13 Output (kW) Feed (m/min) Mach. width (mm) Splinter (mm) Removed volume (mm 2000 2010 2000 2000 3.17 1997 1000 1000 3.33 1000 1000 1000 1008 6.66 3.33 1.66 1.33 62.5 1.66 1.25 machined width ROJEK a.s. RFT 630, 520, 410...

- Page 14 The most permissible exposition levels can differ according to country in questi- on, too. This information will serve for machine user to a better astimation of risks. ROJEK a.s. RFT 630, 520, 410...

-

Page 15: List Of Used Documents

Basic rules for graphical symbols for use on objects - Part 1: Making of graphical symbols for registration EN 80416-2 : 2002 (EN 80416-2 : 2001) Basic rules for grafical symbols for use on objects - Part 2: Shape and using of arrows. ROJEK a.s. RFT 630, 520, 410... -

Page 16: General

- Pay attention so as not to touch any switch by chance during machine run. - Never touch rotating cutterblock by hands or with whatever else. ROJEK a.s. RFT 630, 520, 410... -

Page 17: Dress And Personal Safety

- Replace blunt tools as soon as possible, for blunt tools often cause injuries or damages . - Never use tools at higher speed than recommended by its producer. - Stop all machine functions before replacing of tools. ROJEK a.s. RFT 630, 520, 410... - Page 18 - Ensure sufficient lighting in working space that will not throw shadows or cause a stroboscopic effect. Hygienic norms indicate 500 lx for minimal lighting for a safe and quality work. - Never lay tools or other subjects onto working tables or coverings. ROJEK a.s. RFT 630, 520, 410...

-

Page 19: Transport And Storage

- Lift the machine carefully and slowly and then relocate it without sudden changes of movement to chosen place. The weight of the machine RFT 630 is 830 kg RFT 520 - 780 kg RFT 410 - 720 kg. ROJEK a.s. -

Page 20: Working Space

0.5 mm / 1000 mm and do screw them to the bottom (anchor them). Attached drawing shows a lay-out of anchoring openings on the machine. ROJEK a.s. RFT 630, 520, 410... - Page 21 Wooden waste must be liquidated eco-friendly - not to worsen the environment. ROJEK a.s. RFT 630, 520, 410...

-

Page 22: Operating Safety

Always switch off the machine main switch and lock it before the tools adjusting and replace and all adjusting, treatment and maintenance works. Herewith you avoid eventual machine starting by chance by an else person. ROJEK a.s. RFT 630, 520, 410... -

Page 23: Rotation Direction

If you stand on the left side of the machine near the stand cover (see Chap. 9.1 pos. 11), the cutter block must rotate counter clockwise, i.e. to the left. In order to ascertain the rotation direction, remove the stand cover and turn on the machine for a short moment. ROJEK a.s. RFT 630, 520, 410... -

Page 24: Rotation Direction Change

! The protection against dangerous contact of inanimate parts is assured with a self acting disconnecting from the mains according to the norm EN 60 204-1 and IEC 60 364-4-41. ROJEK a.s. RFT 630, 520, 410... -

Page 25: Machine Control

Failure light indication (F) (e.g. open the tipping lid, failure at the circuit breakers etc.), the failure cause is displayed in an error message on the display. The control board viewport (G) is filled according to machine making in following cha- pters. ROJEK a.s. RFT 630, 520, 410... - Page 26 The lid (A)[for battery (B) exchange] is si- tuated at control box (C) lower side. The lid is accessible after removing or opening of the side cover of machine stand. Batte- ry instalation is desribed in Enclosure E chapter 3. ROJEK a.s. RFT 630, 520, 410...

-

Page 27: Touchable Control Panel (See Annex D)

8.6.2.3 ELGO control panel with programmer (K)- see enclosure C. 8.6.2.4 Touchable control panel (L) - see enclosure D. ROJEK a.s. RFT 630, 520, 410... -

Page 28: Machine Operation And Adjustment

18 return throw catchers 19 splinter limiter at housings 20 pusher behind the cutter block 21 pulling out rollers 22 cutter block drive 23 feed drive 24 table lifting drive (according to the design). ROJEK a.s. RFT 630, 520, 410... - Page 29 22 cutter block drive 23 feed drive 24 table lifting drive (according to the design). 25 table pole 26 table pole body 27 table adjusting chain 28 chain wheels holder 29 table lifting drive (according to making) ROJEK a.s. RFT 630, 520, 410...

- Page 30 (D). Wheel (C) is (by chain) con- nected with chain wheel of motion screw. The screw is in body (F) with adjustable pole. 9.2.1.2 Electromotive RFT 630 Table position change (height setting) by electric gearbox (control described - chapter 8.6.2.)

- Page 31 0 to 1 mm according to the nature of accuracy requirements of the machined area and the machined material. The larger the roller exposure, the larger the breach of the table planarity and thus the possibility of worsening the quality of the machined area. ROJEK a.s. RFT 630, 520, 410...

- Page 32 6 mm, which means that turning the screw by 6 results in a change of 0,1 mm. We recommend leaving this to an expert service. ROJEK a.s. RFT 630, 520, 410...

- Page 33 WARNING: Do adjust always both screws at the same side of the table from the standpoint of material passing. Tighten all wel. ║ We recommend to let the (table cutter block) parallelity adjusted in a special service. ROJEK a.s. RFT 630, 520, 410...

- Page 34 – and the value of 2 mm - return throw catcher overlap under the cutter block. The lower end position is implemented using a couple of screws (F) with positioning nuts (G) at both sides of the table width that are located in the stand (H). ROJEK a.s. RFT 630, 520, 410...

-

Page 35: Adjustment Of The End Switches Of End Positions Of The Table And The Table Position Admeasuring Sensor

(D and E) can be adjusted in height and thus the upper and lower turning off position can be adjusted. The bar of the stoppers (D and E) also bears the impulse sensor (F) that must be adjusted to a gap of 1 to 2 mm from the magnetic tape (H). ROJEK a.s. RFT 630, 520, 410... -

Page 36: Frequency Controlled Motor

The belting chain wheel (E) is floating on its block and self-adjusting. ROJEK a.s. RFT 630, 520, 410... -

Page 37: Two-Speed Motor

(A) around the pivot using the screw (B) with the locking nut (3) b) Pushing Force Adjustment Performed by changing the spring rigidi- ty (D) by its pressing using screw (E) and nuts (6 and 7). ROJEK a.s. RFT 630, 520, 410... -

Page 38: Pulling Out Roller

2 mm under the “body” of the cutter block. The rear edge is solid of hardened sheet metal and it is adjusted to 0.1 through 0.5 mm under the cutting cylinder. ROJEK a.s. RFT 630, 520, 410... -

Page 39: Front Pushing Edge

(A) around the pivots of the housing (G). Set the edge (A) so that its lower area is in the range of 0.1 to 0.5 mm below the cutting cylinder. ROJEK a.s. RFT 630, 520, 410... -

Page 40: Working Places

20 mm. ROJEK a.s. RFT 630, 520, 410... -

Page 41: Tools

EN 847 - 1: 1997. RFT 630 - Suitable cutters for use in this machine in the cutter block are planing cutters 635x30x3 mm (length x height x thickness) from the HSS or HSS18 material (HLS 1.2379). -

Page 42: Adjustment Using A Setting Jig (Setter)

(D), best from the cutter centre to the edges. Repeat the procedure with all cutters and try to adjust them to the same value that must range with- in 0.8 to 1 mm. ROJEK a.s. RFT 630, 520, 410... - Page 43 The knife is reversible. As soon as both cutting edges of a knife are blunt - do not sharpen them, but replace them with new ones ! Aways do replace the three knives all at once ! ROJEK a.s. RFT 630, 520, 410...

-

Page 44: Maintenance And Repairs

When the chain is tightened, it is necessary to shift the digital position indicator to machine base and to arrest it. 11.1.2 Electromotoric adjusting of table (RFT 630) The table adjusting drive chain (A) gets tightened by help of tensioner (B). - Page 45 20 N (about 2 kg), it should bend by about 10 11.3 Tensioning of feeding drive chain 11.3.1 Tensioning of feeding drive chain RFT 630 Tensioning of feeding drive chain (A) is automatic by help of idler (B) controled by spring (C).

-

Page 46: Setting Mechanic Digital Indication Of Thicknessing Table Position

[in place (E)] (course indicator fixing against turning) would be pushed into machine stand positioning opening. 11.5 Setting thrust of pulling in and pulling out rolls Adjusting is described in chapter 9.2.3.2 Adjusting of feeding rolls. ROJEK a.s. RFT 630, 520, 410... -

Page 47: Cleaning And Lubricating

Lubrication point necessary action (hours) Permanent grea- upon repla- se fill cement Lubricate ba 1000 spreading Grease gun Lubricate by oiler Plastic lubricant LV-2-3 LV-2-3 OL-B5 OL-B5 OL-B5OL-B5 or oil equivalent ISO-L-XCBEA 3 ISO-LAN 68 ROJEK a.s. RFT 630, 520, 410... -

Page 48: Faults Remedy

The thicknessing table is not clean. Fitting on the front or rear part of the machined piece: Poorly pushed or led material. Necessary to adjust the pushing forces of the pulling in and pulling out roller. ROJEK a.s. RFT 630, 520, 410... -

Page 49: Delivery Scope

PE bag with a for enclosed 250 x 350 mm zipper + manual 13 Special Accessories Cutter setter with a dial indicator. ROJEK a.s. RFT 630, 520, 410... -

Page 50: Spare Parts

15 Guarantee Works and operations, not mentioned here, involve a written agreement of the ROJEK Co., Masarykova 16, 5170 50 Castolovice, the Czech Republic, Europe. Every machine and equipment is provided with a guarantee certificate. It is important to fill the warranty certifica- te just during purchasing it with a respect of possibility to set up an eventual guarantee claim and for sake of product´s safety. - Page 51 Electric connection diagram Enclosure A 5,5 / 7,5 kW, 3 x 400 V, motoric table lifting, feed frequency drive ROJEK a.s. RFT 630, 520, 410...

- Page 52 ROJEK a.s. RFT 630, 520, 410...

- Page 53 ROJEK a.s. RFT 630, 520, 410...

- Page 54 (5,5 / 7,5 kW, 3 x 400 V, motoric lifting, 2-speed feeding) ROJEK a.s. RFT 630, 520, 410...

- Page 55 ROJEK a.s. RFT 630, 520, 410...

- Page 56 Power cir- H05VV-K4G1,5 CYSY 4Bx1,5mm W31-40 cuits H05VV-K5G1,5 CYSY 4Bx1,5mm H05VV-K7G1,5 CYSY 5Bx1,5mm Protection W21-30 H05V-K1G1,5 CYA 1,5 mm circuits Note : The producer reserves himself the right for changing component(s) and its supplier. ROJEK a.s. RFT 630, 520, 410...

- Page 59 RFT 530 RFT 630 thicknessing machine list of parts updated 12 / 2012 WOODWORKING MACHINES Co. Masarykova 16, 517 50 Častolovice ROJEK the Czech Republic - Europe export@rojek.cz www.rojek.cz +420 494 339137, to - 41 fax 323 341, 322 701...

- Page 63 P - 3...

Need help?

Do you have a question about the RFT 630 and is the answer not in the manual?

Questions and answers