Table of Contents

Advertisement

Quick Links

Operating manual

MOBEX F- BIA W3

MOBEX F-28 BIA W3 (Order No.: 09820) Raw gas inlet left

MOBEX F-56 BIA W3 (Order No.: 09821) Raw gas inlet left

MOBEX F-28 BIA W3 (Order No.: 09822) Raw gas inlet right

MOBEX F-56 BIA W3 (Order No.: 09823) Raw gas inlet right

Do not use this device unless you have

read the user manual and understand it.

Translation of the original operating manual

09820-08-00

Advertisement

Table of Contents

Troubleshooting

Subscribe to Our Youtube Channel

Summary of Contents for Esta MOBEX F-BIA W3

- Page 1 Operating manual MOBEX F- BIA W3 MOBEX F-28 BIA W3 (Order No.: 09820) Raw gas inlet left MOBEX F-56 BIA W3 (Order No.: 09821) Raw gas inlet left MOBEX F-28 BIA W3 (Order No.: 09822) Raw gas inlet right MOBEX F-56 BIA W3 (Order No.: 09823) Raw gas inlet right Do not use this device unless you have read the user manual and understand it.

- Page 2 Warnings and safety instructions Electrical current hazard Note Reference to ESTA customer service Reference to legal regulations MOBEX F- BIA W3 09820-52-00...

-

Page 3: Table Of Contents

Contents Contents ..........................3 1. General safety notes ....................... 4 2. Preventing mechanical hazards ..................6 3. Preventing electrical hazards ..................6 4. Preventing dust hazards ....................6 5. Intended use ........................7 6. Technical data and description ..................8 6.1 Technical data ...................... -

Page 4: General Safety Notes

The welding fume exhaust device is intended only for dry cleaning and must not be used or stored outdoors or under wet conditions. Only original ESTA replacement parts must be used; use of other products will void the warranty. During exhaust, the volume flow returned from the welding fume exhaust device into the room must be no more than 50% of incoming air. - Page 5 Installation and operation in dust-explosive or gas-explosive areas is forbidden. Make sure that the power cable does not become damaged by being run over, compressed, pulled, etc. The power cable must be examined regularly for signs of damage or ageing. The device must not be used if damage to the power cable is determined.

-

Page 6: Preventing Mechanical Hazards

In all emergencies, the device must be disconnected from the power supply immediately, the device turned off at the emergency switch, and the plug pulled immediately. If there is a fire, the fire department is to be alerted immediately, and the fire must be contained by appropriate means. 2. -

Page 7: Intended Use

The welding fume exhaust device must not be used or stored outdoors or under wet conditions. Other applications are considered unintended use. ESTA is not liable for damages due to unintended use! The manufacturer sets up the welding fume exhaust device according to the operator’s information. -

Page 8: Technical Data And Description

6. Technical data and description 6.1 Technical data MOBEX BIA W3 model F-28 F-56 Filter type Filter cartridge Number of filter elements [unit] Filter area [m²] Drive output kW [kW] Max. vacuum Pa [Pa] 2,150 3,000 Max. volume flow [m³/h] 2,400 4,400 Min. -

Page 9: Functional Description

6.2 Functional description Depending on the model, the device is driven by a 2.2 kW or 3 kW three-phase motor that drives a radial fan. The main switch supplies or cuts off the necessary power to the device, and the device is turned on and off with the red-green double push button. -

Page 10: Delivery And Commissioning

Upon delivery, please inspect the welding fume exhaust device for transportation damage. Damage determined must be reported and documented immediately. ESTA customer service: +49 (0) 7307 804 - 0 When moving the welding fume exhaust device, make sure the ground can support it and be driven over. - Page 11 200 mm, 250 mm or 160 mm, depending on the model. Onto it is slid and fastened a suitable suction hose or spiral seam duct (original ESTA accessories) that has the necessary safety characteristics.

- Page 12 Pay attention to the direction of rotation. After turning on the device for the first time, check to see that the fan rotor’s direction of rotation is correct. Meanwhile, also look at the red light on the double push button. If this lights up after the device is turned on, the direction of rotation is wrong, and the power supply’s polarity must be reversed.

-

Page 13: Maintenance And Troubleshooting

8. Maintenance and troubleshooting 8.1 Maintenance instructions If the device is not needed in its location of use for a long time, it must be stored in a dry room. The temperature should not be below 5° C or above 40° C. Before storing the MOBEX, it must be emptied and cleaned. -

Page 14: Inspection And Maintenance Intervals

During inspection, the device’s air intake must be closed. If the siren sounds, the equipment is in order. The main annual inspection includes: The last test by ESTA is documented on the device. In collaboration with the ESTA maintenance service • Flow volume measurement •... -

Page 15: Troubleshooting

To empty the compressed air tank, with the compressed air supply shut off, confirm the manual cleaning and wait until it is completed. Get the most from ESTA’s maintenance service! A maintenance contract ensures a long life and top-notch operation for your welding fume exhaust device. - Page 16 Problem Possible cause Possible solution The housing is too hot Suction medium too hot Make sure there is a balanced fresh air supply Suction too weak Main filter dirty Clean filter Suction hose clogged In a vacuumed area, hold the hose vertically and bang it out with a rubber mallet.

-

Page 17: Monitoring The Minimum Airflow Volume

The pressure controller must be adjusted only by an appropriately trained person in consultation with ESTA. The adjustment is made with a size 6 Allen wrench. After the pressure controller has been set, the device is ready for operation again. -

Page 18: Replacing The Filter

If the warning signal still immediately sounds again after the device has been cleaned and started, check the amount of material in the dust collection equipment. If necessary, empty the container. If the warning signal still sounds, replace the filter elements. 10.2 Replacing the filter After an extended operation period, the filter pores can be clogged by extremely fine dust. - Page 19 First disconnect the compressed air supply and manually clean the vessel to empty it. The door cover is separated by pushing it up from the housing. Remove the screws from the inspection doors that now become visible. Remove the door to allow access to the filter unit.

-

Page 20: Cleaning The Demisting Mat

Running the welding fume exhaust device without the demisting mat is not permitted. The new demisting mat bears item No. 01000107. ESTA maintenance service: +49 (0) 7307 804 - 832 ESTA replacement part service: +49 (0) 7307 804 - 831 MOBEX F- BIA W3 09820-52-00... -

Page 21: Disposal

Pack the device in a suitable manner and dispose of it in compliance with local regulations. Due to contamination of the device with toxic dust, ESTA cannot take the device back. 09820-52-00 MOBEX F- BIA W3... -

Page 22: Optional Equipment

PIN 1 and 2 of the external potential-free contact are connected to the plug (packaged with the device). PIN 3 is reserved for the neutral wire. This is needed only when using special ESTA accessories. Connect potential equalization to the PIN with the earthing (ground) indicator. -

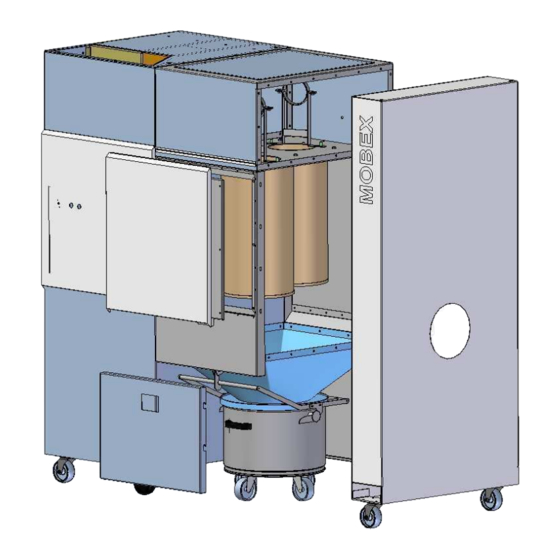

Page 23: Device Diagram

Door cover with inspection door Intake port Filter cartridge Cover plate Dust collection container With the model information, request the replacement parts you need from the ESTA maintenance service: +49 (0) 7307 804 - 831 09820-52-00 MOBEX F- BIA W3... -

Page 24: Declaration Of Conformity

14. Declaration of conformity Name of manufacturer: ESTA Apparatebau GmbH & Co. KG Address of manufacturer: Gotenstraße 2 - 6 89250 Senden Authorized person for Michael Mertins documentation: Gotenstr. 2 - 6 89250 Senden Here we explain that the design of the machine... -

Page 25: Notes

Notes ESTA Apparatebau GmbH & Co. KG Gotenstraße 2 - 6 89250 Senden / Ay Tel.: +49 (0) 7307 804 - 0 Fax: +49 (0) 7307 804 - 500 E-Mail: info@esta.com www.esta.com 09820-52-00 MOBEX F- BIA W3... -

Page 26: Notes

Notes ESTA Apparatebau GmbH & Co. KG Gotenstraße 2 - 6 89250 Senden / Ay Tel.: +49 (0) 7307 804 - 0 Fax: +49 (0) 7307 804 - 500 E-Mail: info@esta.com www.esta.com MOBEX F- BIA W3 09820-52-00... -

Page 27: Notes

Notes ESTA Apparatebau GmbH & Co. KG Gotenstraße 2 - 6 89250 Senden / Ay Tel.: +49 (0) 7307 804 - 0 Fax: +49 (0) 7307 804 - 500 E-Mail: info@esta.com www.esta.com 09820-52-00 MOBEX F- BIA W3... - Page 28 ESTA Apparatebau GmbH & Co. KG Gotenstraße 2 - 6 89250 Senden / Ay Tel.: +49 (0) 7307 804 - 0 Fax: +49 (0) 7307 804 - 500 E-Mail: info@esta.com www.esta.com...

Need help?

Do you have a question about the MOBEX F-BIA W3 and is the answer not in the manual?

Questions and answers