Advertisement

Quick Links

Ref. 3.205B_UK - 06/2007. www.axel-larsson.se

MANUAL

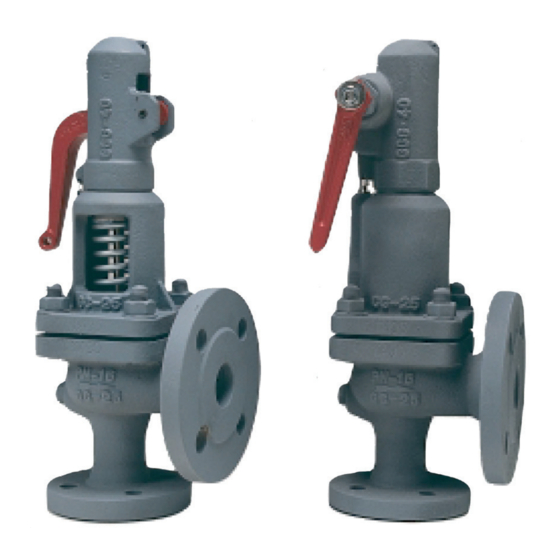

Safety valve AL 61-496

1.1. Preliminary advice

1.1.1. General instructions

Safety valves are high-responsibility accessories, which are manufactured

with extreme precision. Incorrect handling can affect the hermetic

properties of the seal.

1.1.2. Cleaning

Ensure that the valve is free from foreign bodies. Clean the tubes and

connections thoroughly before assembly.

1.1.3. Paint

Keep all moving parts, connections and/or discharge areas free of paint.

1.1.4. Transportation

Remove protective covers and anchoring clamps from the lever when

assembling.

1.1.5 Storage conditions

Temperature should be between 5 and 25ºC, and relative humidity less

than 75%. After 6 months, check these values before installing.

1.2 Installation

Installation must be carried out by a qualified technician.

1.2.1 General advice

Install as close as possible to the system to be protected.

The vertical connection tube must be straight and short, and the flow

section must have at least the same diameter as the valve inlet.

Avoid transmitting inadmissible static, dynamic or thermal forces from

the inlets and outlets to the valve. Avoid tension.

Transport must be in the direction of the arrow on the body.

Do not install any sealing devices prior to the valve.

In the case of steam, install a detour before the valve inlet in order to

remove the air from the installation when it is turned on. If the fluid is

harmful, inflammable, toxic, etc., install discharge tubes that lead to a

secure place.

1.2.2. Removal of condensed matter

Steam and gases

1.2.3. Insulation

The valve is left uncovered, so that the spring does not heat up.

1.2.4. Ducts

1.2.4.1. Inlet ducts:

These should be as short as possible, with pressure drops of less than

3% of release pressure.

1.2.4.2. Outlet ducts:

The tube must not rest on the valve. It must be self-draining and the

reaction force to discharge should be taken into consideration.

The tube should be as short as possible, with sufficient diameter to

limit a pressure drop through said tube to a maximum level of 10% of

the release pressure.

The diameter must never be less than the diameter of the valve.

Discharge tubes should be of a sufficient size to ensure that inherent

or generated counter-pressure is no greater than 15% of the release

pressure.

A silencer should be installed where discharge is noisy.

Liquids

Advertisement

Summary of Contents for Axel Larsson AL 61-496

- Page 1 Ref. 3.205B_UK - 06/2007. www.axel-larsson.se MANUAL Safety valve AL 61-496 1.1. Preliminary advice 1.1.1. General instructions Safety valves are high-responsibility accessories, which are manufactured with extreme precision. Incorrect handling can affect the hermetic properties of the seal. 1.1.2. Cleaning Ensure that the valve is free from foreign bodies. Clean the tubes and connections thoroughly before assembly.

- Page 2 Ref. 3.205B_UK - 06/2007. www.axel-larsson.se MANUAL Safety valve AL 61-496 1.2.6. Examples of assembly combinations 1.3.2. Characterisation Every safety valve is assembled and checked in our workshop. They are methodically adjusted in line with release pressure, sealed and then certified before being despatched, all in accordance with the conditions set out in our ISO-9001 quality control manual.

Need help?

Do you have a question about the AL 61-496 and is the answer not in the manual?

Questions and answers